I Table of contents

Table of Contents

1Characteristics........................................................................................................ 1

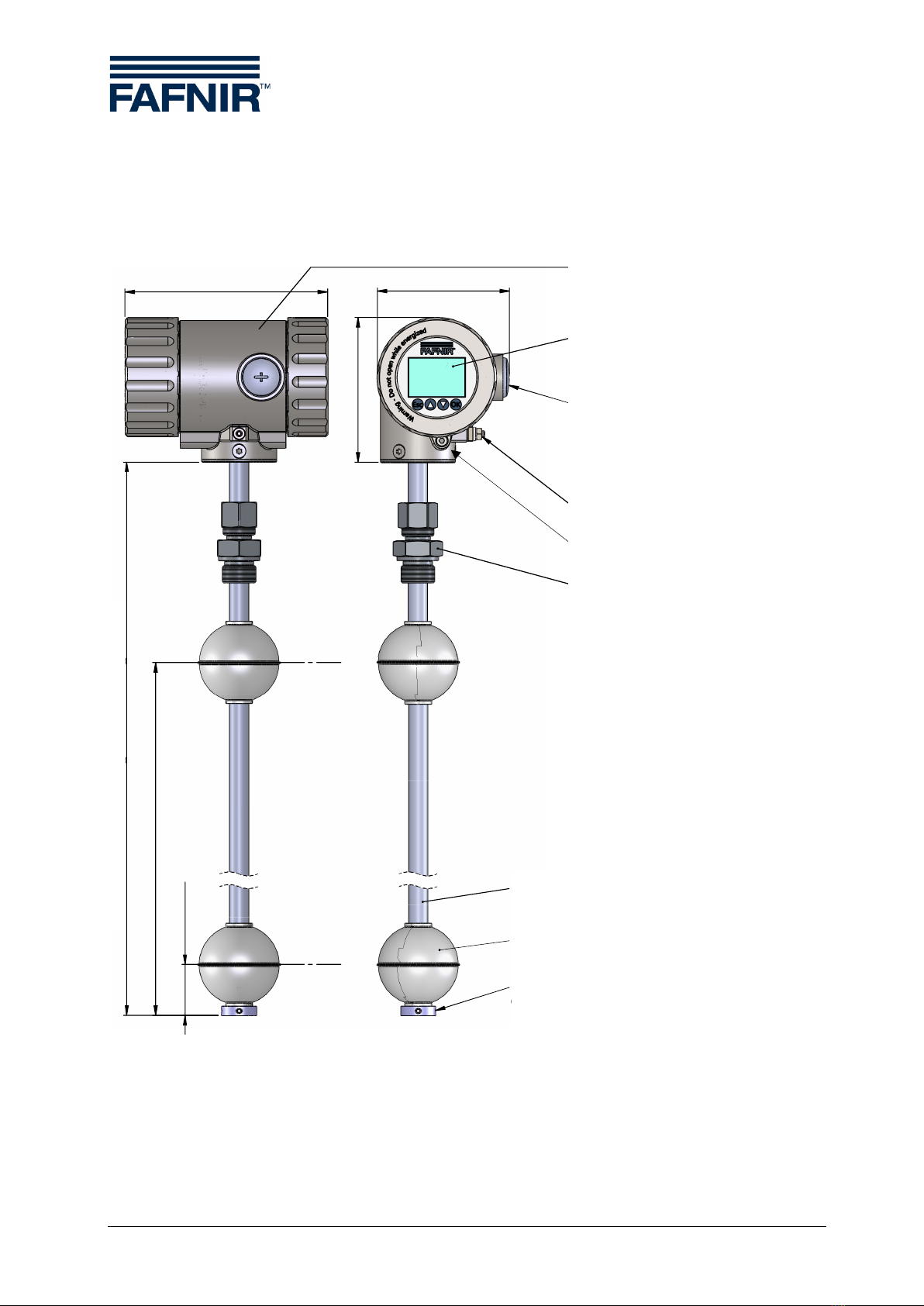

1.1 TORRIX XTS Variants..........................................................................................................................2

2Safety Instructions ................................................................................................3

3Design and Function ............................................................................................4

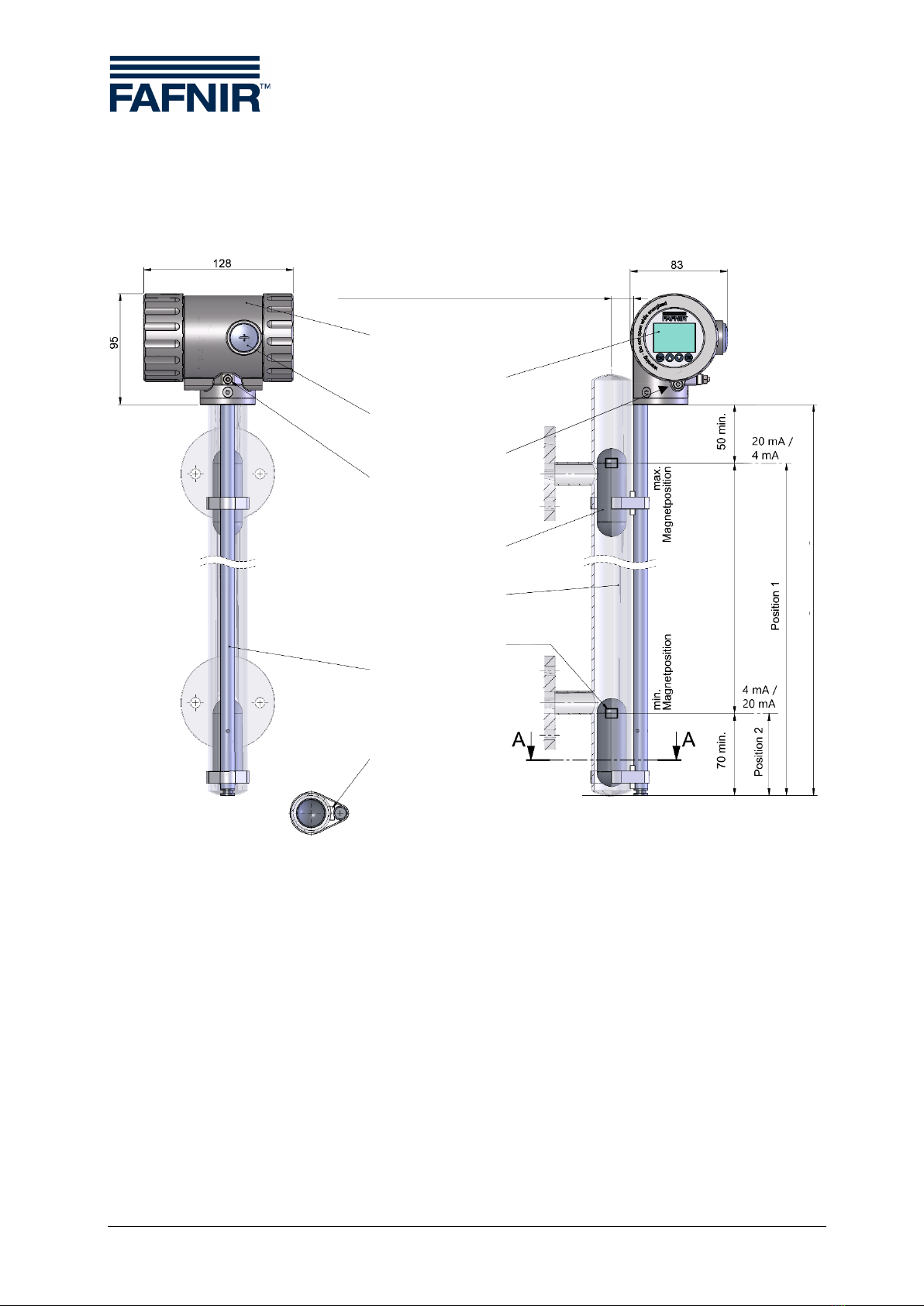

3.1 TORRIX XTS with Screw Connection............................................................................................5

3.2 TORRIX XTS with Flange ..................................................................................................................6

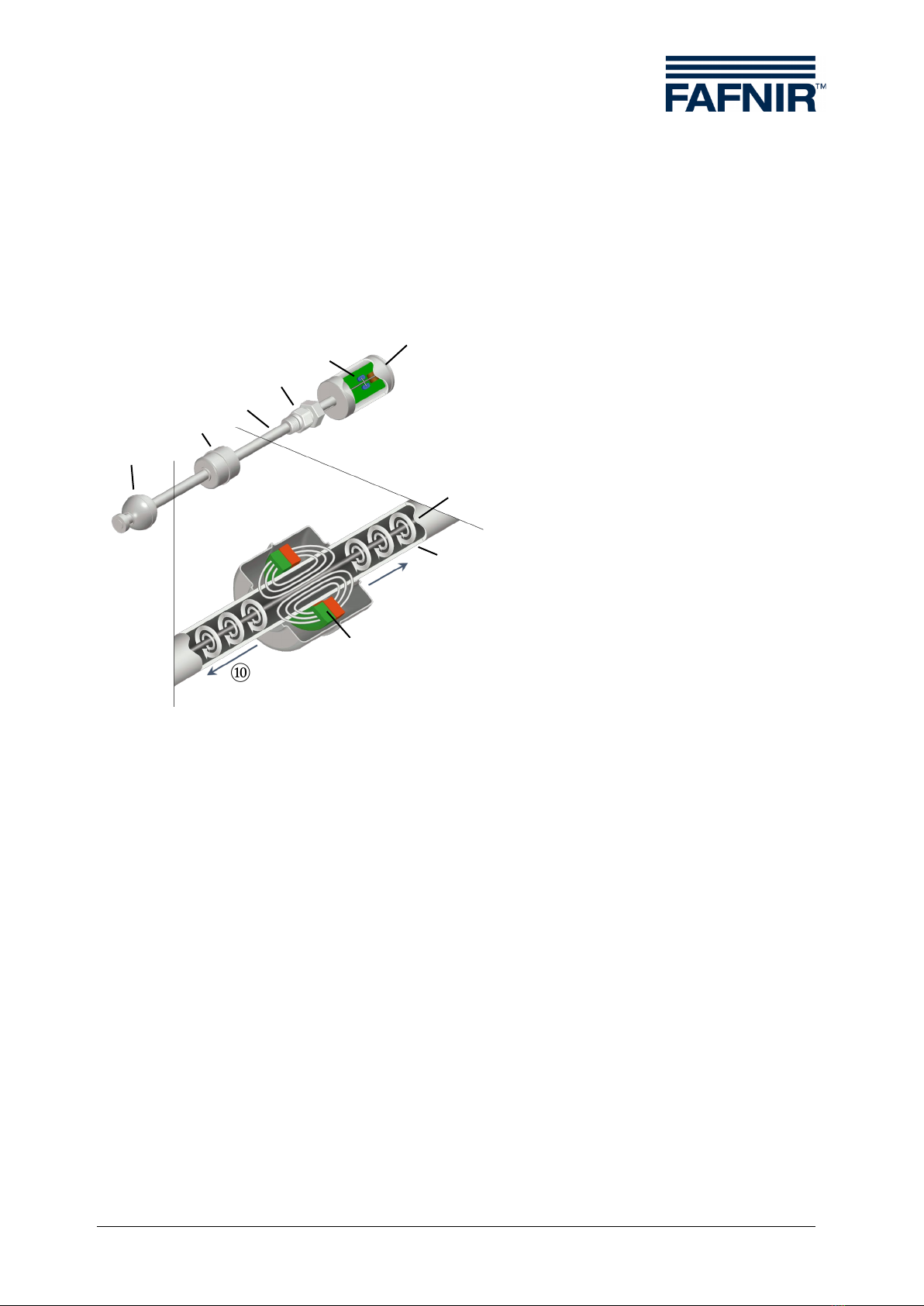

3.3TORRIX XTS for Bypass.....................................................................................................................7

4Installation ..............................................................................................................8

4.1 Installation with screw-in unit .......................................................................................................9

4.2 Installation with flange...................................................................................................................10

5Electrical connection ...........................................................................................11

5.1 Connection Diagrams.....................................................................................................................11

5.1.1Wiring diagram TORRIX XTS ........................................................................................................11

5.1.2 Wiring diagram TORRIX Ex XTS...................................................................................................12

5.1.3 Wiring diagram TORRIX Exd XTS................................................................................................13

5.2 Maximum Length of the Connection Cable ...........................................................................14

5.3 Wiring ...................................................................................................................................................15

5.3.1 Wiring the TORRIX (Ex) XTS..........................................................................................................16

5.3.2 Wiring the TORRIX (Exd) XTS with Heater...............................................................................17

6Indication and adjustment module................................................................18

6.1 Rotation of the display and adjustment module..................................................................18

6.2 Operation ............................................................................................................................................18

6.2.1 Arrangement of the keys / magnet sensors...........................................................................19

6.2.2 Function of the keys / magnet sensors....................................................................................19

6.3 Measured value display .................................................................................................................20

6.4Simulation ...........................................................................................................................................21

6.5 Error display .......................................................................................................................................22

6.6 Icons......................................................................................................................................................22

7Adjustment .......................................................................................................... 23