Table of Contents II

Table of contents

1Range of application.............................................................................. 1

2Safety instructions ................................................................................. 2

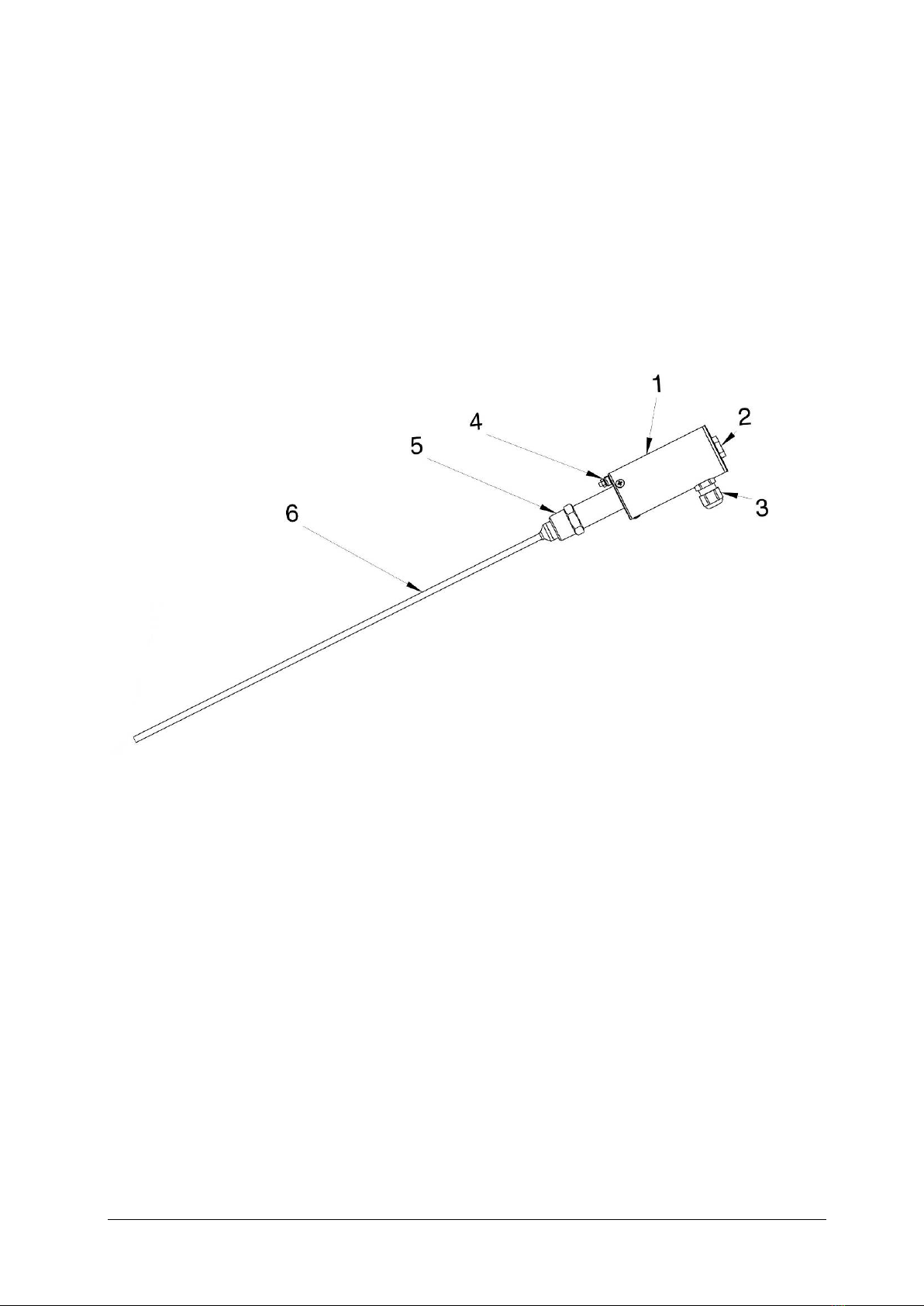

3Design and function............................................................................... 3

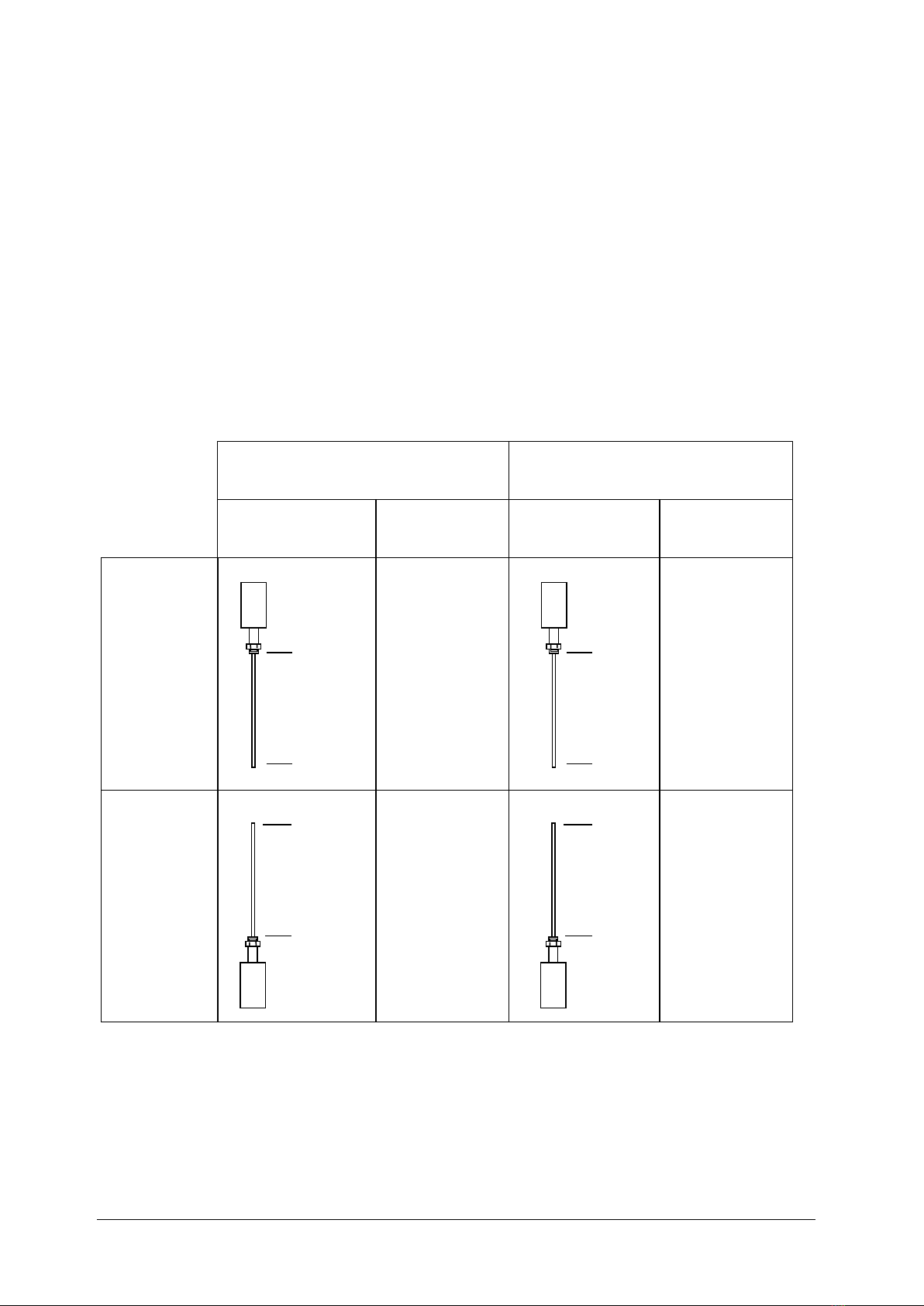

4Installation.............................................................................................. 5

4.1 CONDURIX Mono (single rod).............................................................................6

4.2 CONDURIX DU (two rods)...................................................................................6

4.3 CONDURIX MA (jacketed pipe)...........................................................................6

5Electrical connection .............................................................................. 7

6Parametrisation ...................................................................................... 9

6.1 Measuring span at the level sensor .....................................................................9

6.2 Current consumption in failure mode ...............................................................10

7Maintenance......................................................................................... 11

7.1 Overhaul ..........................................................................................................11

7.2 Return shipment...............................................................................................11

8Technical Data ...................................................................................... 12

9List of figures........................................................................................ 13

10 Annex.................................................................................................... 14

10.1 EC Declaration of Conformity ...........................................................................14

10.2 EC-Type Examination Certificate .......................................................................15

10.3 Safety instructions ............................................................................................18

© Copyright:

Reproduction and

translation are permitted only with the written consent of the FAFNIR GmbH. FAFNIR GmbH reserves

the right to make changes to products without prior notice.