Bolt the tie rod to both the clevis bracket and the drive

anchor bracket and tighten the bolts until seated against the

brackets. DO NOT bend the bracket as clearance between

the clevis brackets and tie rod is necessary.

9. JR—Thread the bushing nut onto the hollow shaft one to

two turns. NOTE: The bushing nut threads have been coated

with an anti-seize compound at Falk. This compound should

not be removed. Before re-installing a previously used nut,

recoat the nut threads only with an anti-seize compound.

Keep the tapered surface of the bushing and hollow shaft

bore free from all anti-seize or lubricating compounds.

WARNING: Overtightening can fail the internal retaining

ring. (See Appendix H, for listing of retaining rings).

a) Preferred Method — Use a spanner (Table 6), chain or pipe

wrench to tighten the bushing nut to the torque value

indicated in Table 6. Tighten the setscrew on the bushing

nut.

b) Alternate Method (To be used when exact torque can not

be measured.) — Use a spanner (Table 6), chain or pipe

wrench to tighten the bushing nut just until the drive can

no longer be moved by hand axially on the driven shaft.

Loosen nut ONLY until it can be turned by hand but do

not unseat the taper. Retighten the nut hand tight. Now

mark a spot on the bushing nut. Next mark a spot on the

driven shaft 180° from the first mark. Use the spanner

wrench to tighten the nut until the two marks are aligned

i.e. one half turn. Tighten the setscrew on the bushing

nut.

10. JR — Install backstop, motor mount, motor, sheaves

(Mount sheaves as close to the drive and motor housing

as possible), belts and guard. Refer to Appendix D for

instructions.

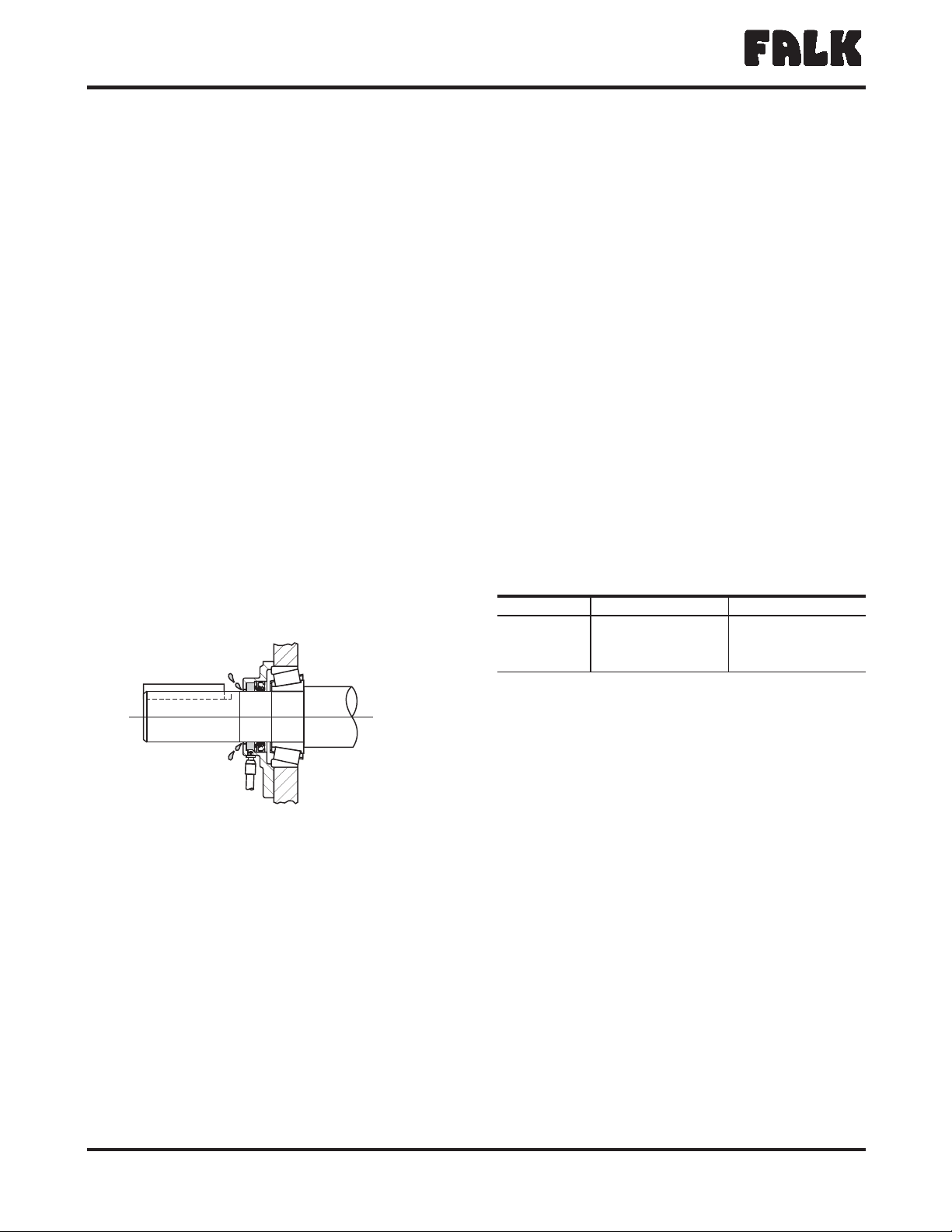

11. JF (Using tapered drive shaft) — Put key into the driven

shaft. Lift drive into position and slide onto the driven shaft

taking care that the driven shaft key seats into the hollow

shaft keyway. DO NOT hammer or use excessive force.

Secure the drive to the foundation with fasteners and torque

values shown in Table 7. Next, secure the drive to the shaft

with the thrust plate fastener. Refer to Table 8 for torque

value. Reinstall the hollow shaft cover. Install motor mount,

motor, sheaves, belts and guard. Refer to Appendix D for

instructions.

12. JSC (4407 only) — Assemble drive to trough, using

fasteners & torques given in Table 8, and install drive shaft

coupling bolts per screw conveyor manufacturer’s

instructions. Install motor mount, motor, sheaves, belts and

guard. Refer to Appendix D for instructions.

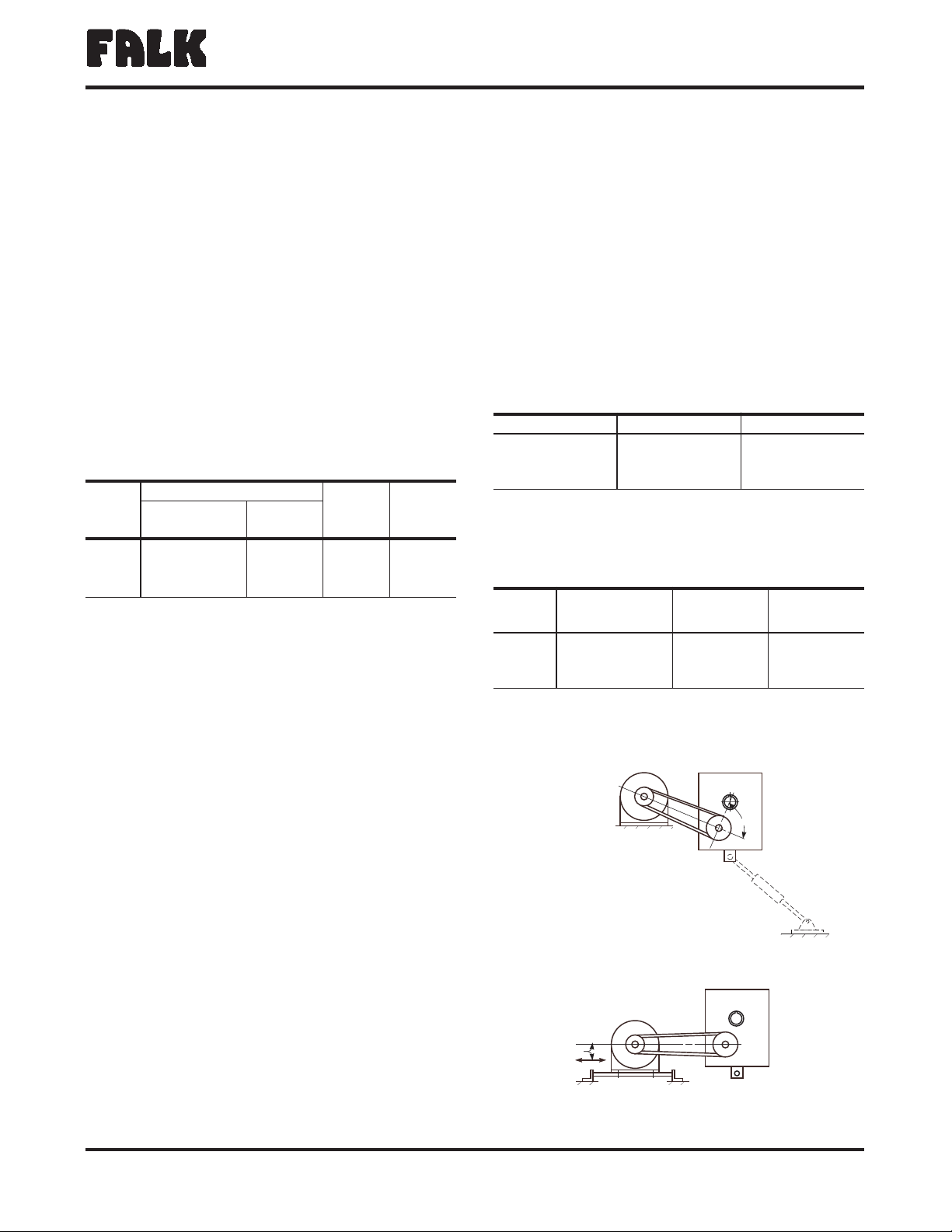

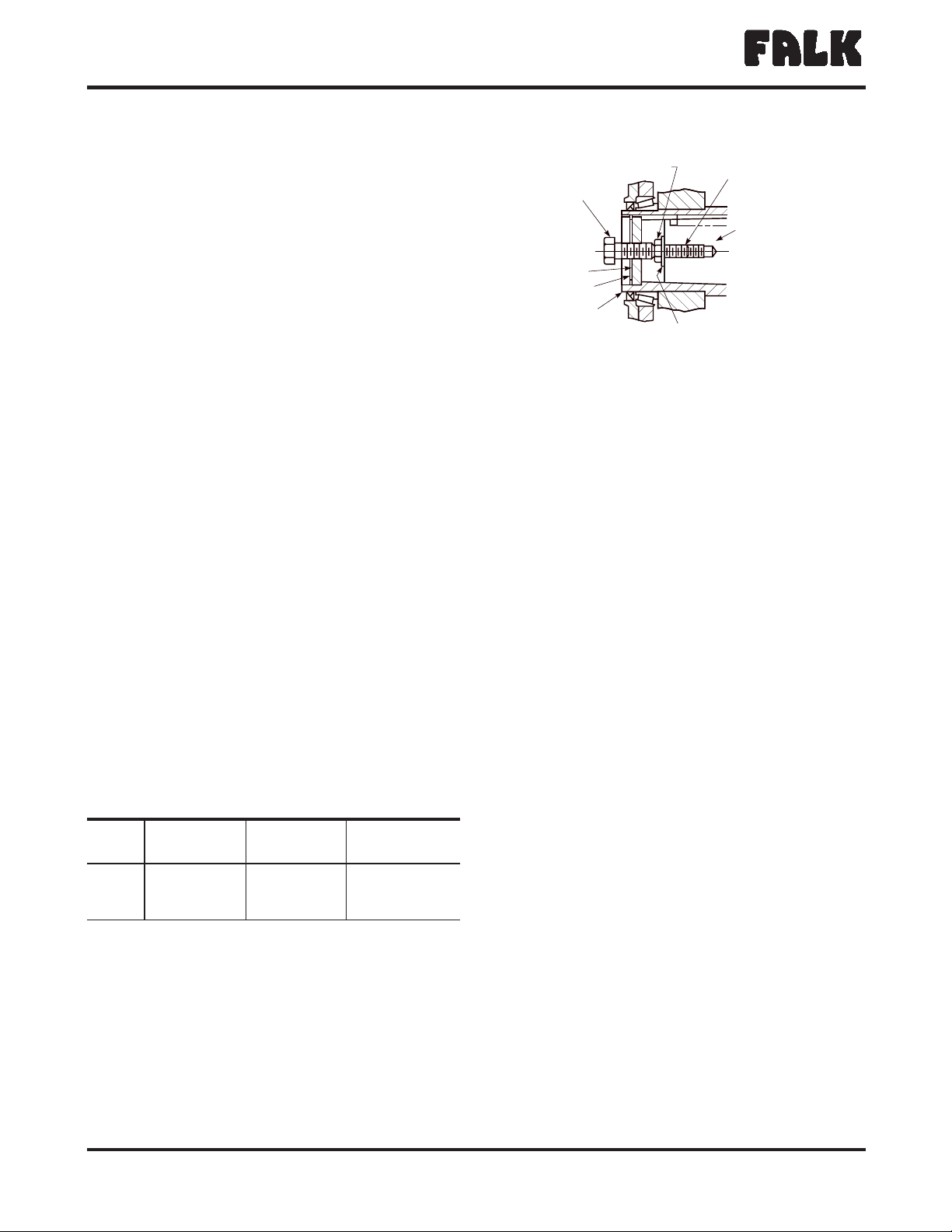

13. JR — When the tie rod turnbuckle is used for belt tension

adjustment, position the motor so that the belt pull will be

about 90° to a line through the drive input shaft and hollow

shaft as shown in Figure 9. For drives where the motor is

moved to adjust belt tension, mount the motor slide base so

that the belt tension adjustment is approximately parallel to

the belt centers. Refer to Appendix D, for instructions relative

to alignment of sheaves and belts.

The Falk Corporation, P.O. Box 492, Zip 53201-0492 378-102

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone : 414-342-3131 August 2004

®

a good name in industry

Quadrive Shaft Mounted Drives •Owners Manual

Sizes 4407/M4407-4608/M4608 (Page 7 of 56)

TABLE 6 — Spanner Wrench Type and

Spanner Nut Tightening Torque

Drive

Size

Adjustable Hook Spanner Wrench Spanner Nut

Tightening

Torque

lb-in (Nm)

Nut Rotation

from Seated

Condition

Armstrong Tools Williams

4407 34-313 6 1/8"-8 3/4" 474B 4000 (452) 180

4415 34-313 6 1/8"-8 3/4" 474B 4000 (452) 180

4507 73-213 HCT-15-2 H4000 (452) 180

4608 73-213 HCT-15-2 H4000 (452) 180

HThese are chain wrenches where standard spanner wrenches are not

available.

TABLE7—JFandJSCDrives—Foundation

Fastener & Tightening Torque

(Non-Lubricated Fasteners)

Drive Size Fastener Size & Grade Torque lb-in (Nm)

4407 .750-10UNC, Gr. 5 2940 (332)

4415 1.250-7UNC, Gr. 5 12600 (1 424)

4507 1.250-7UNC, Gr. 5 12600 (1 424)

4608 1.500-6UNC, Gr. 5 22100 (2 497)

90°

BELT TENSION ADJUSTED

WITH TORQUE ARM

BELT TENSION ADJUSTED

WITH MOVABLE MOTOR

PARALLEL

Figure 9

TABLE8—Thrust Plate Fastener Data

(Non Lubricated Fasteners)

Drive Size Fastener Size

& Grade HTorque lb-in (Nm)

Minimum Thread

Depth

Inches (mm)

4407 1.000-8UNCx4.00, Gr. 8 9500 (1 073) 2.75 (69,9)

4415 1.250-7UNCx4.00, Gr. 8 19150 (2 164) 2.75 (69,9)

4507 1.250-7UNCx4.00, Gr. 8 19150 (2 164) 2.75 (69,9)

4608 1.250-7UNCx4.00, Gr. 8 19150 (2 164) 2.75 (69,9)

HFastener lengths given are for applications using tapered (JSC type driven

shafts. Other lengths may be needed for applications using tapered bushings.