Application guidelines

4FRCC.PC.004.A9.22

Contents

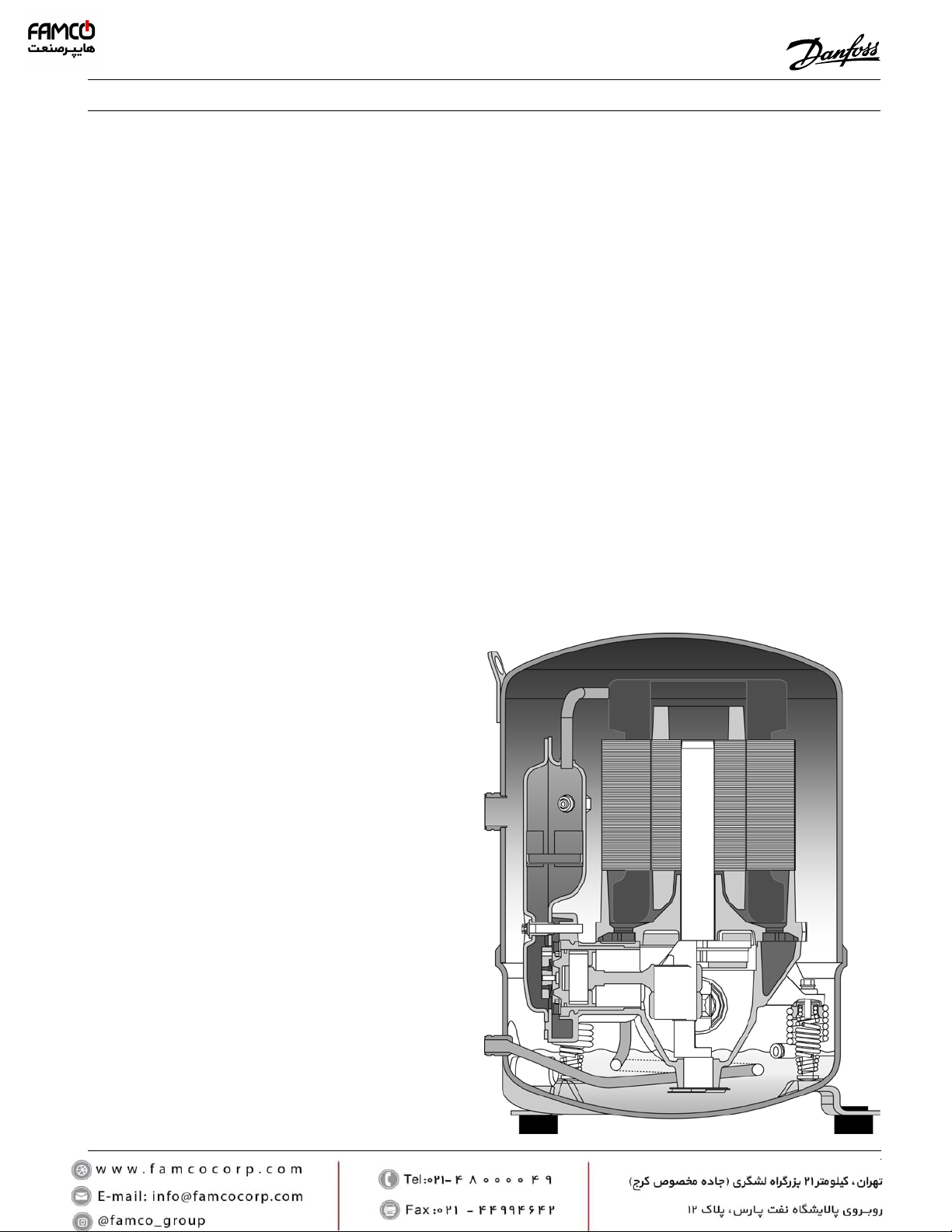

Maneurop® reciprocating compressors.......... 5

Compressor model designation ...................... 6

Code numbers (for ordering) ........................................... 6

Compressor reference (indicated on the compressor

nameplate).............................................................................. 6

Specications.................................................... 7

Technical specications...................................................... 7

Approvals and certicates................................................. 7

Pressure equipment directive 2014/68/EU ................. 7

Low voltage directive 2014/35/EU................................. 7

Machinery directive 2014/30/EU.................................... 7

Internal free volume............................................................ 7

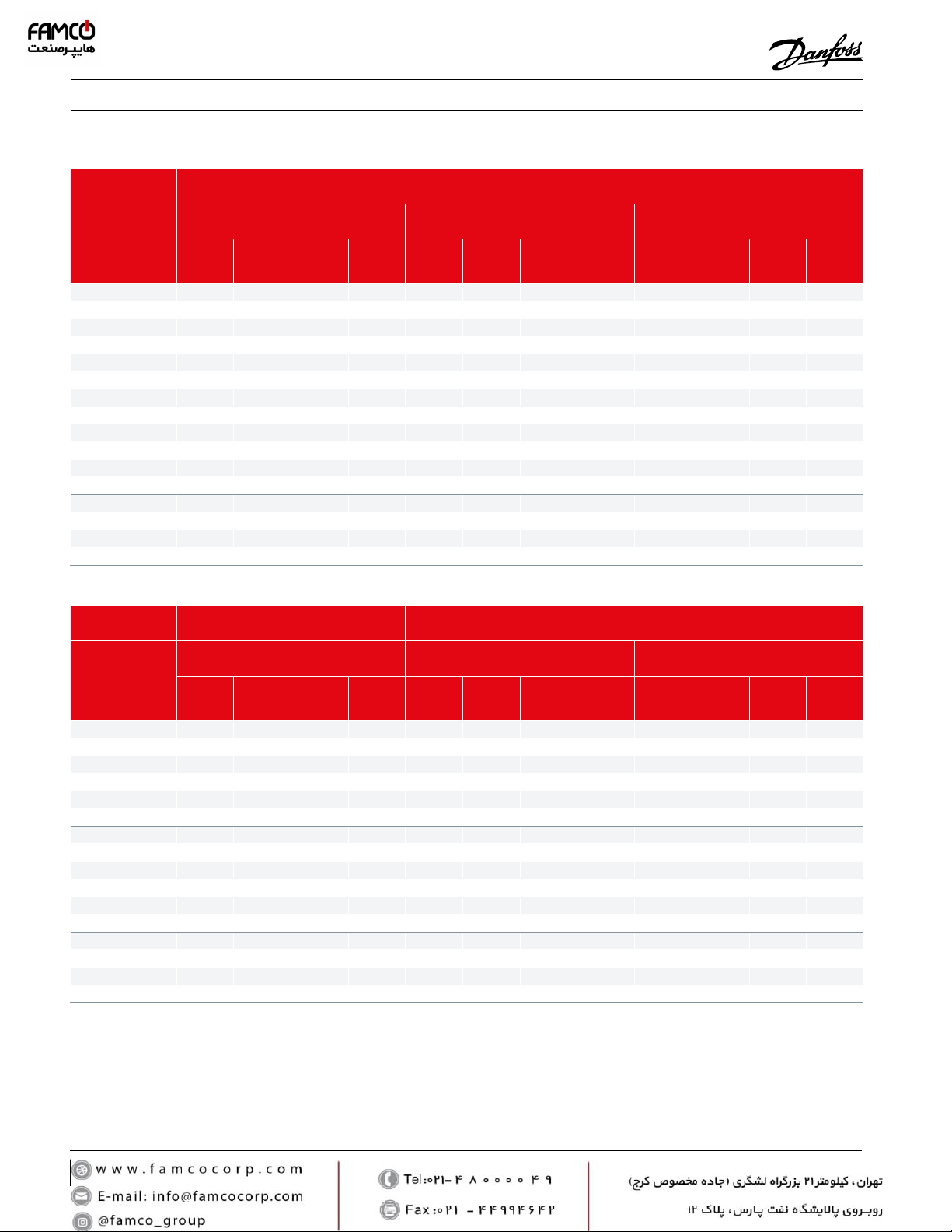

Nominal performance data for R404A and R22 ....... 8

Nominal performance data for R407C and R134a.... 9

Nominal performance data for R407A and R407F..10

Operating envelopes......................................11

Discharge temperature protection..............................12

Zeotropic refrigerant mixtures ......................................13

Phase shift.............................................................................13

Temperature glide..............................................................13

Dew temperature and Mean temperature for

R407A/C/F .............................................................................13

Outline drawings ............................................14

1 cylinder...............................................................................14

2 cylinders .............................................................................15

4 cylinders .............................................................................16

Electrical connections and wiring .................17

Single phase electrical characteristics ........................17

Nominal capacitor values and relays...........................17

Trickle circuit ........................................................................17

PSC wiring.............................................................................17

CSR wiring.............................................................................17

Suggested wiring diagrams............................................18

Three phase electrical characteristics .........................19

Winding resistance.............................................................19

Motor protection and suggested wiring diagrams19

Soft starters...........................................................................21

Voltage application range...............................................21

IP rating..................................................................................21

Refrigerants and lubricants........................... 22

General information ..........................................................22

R22...........................................................................................22

Alternatives R22, HFC retrot.........................................22

R407C......................................................................................23

R134a ......................................................................................23

R404A......................................................................................23

R507.........................................................................................23

R407A......................................................................................24

R407F ......................................................................................24

Hydrocarbons ......................................................................24

System design recommendations................. 25

Piping design .......................................................................25

Operating limits ..................................................................26

Operating voltage and cycle rate.................................27

Liquid refrigerant control and charge limit...............27

Sound and vibration management...............29

Sound .....................................................................................29

Vibration ................................................................................29

Installation and service..................................30

System cleanliness .............................................................30

Compressor handling, mounting and connection to

the system.............................................................................30

System pressure test .........................................................31

Leak detection.....................................................................31

Vacuum pull-down moisture removal........................31

Start-up ..................................................................................32

Ordering information and packaging...........34

Packaging..............................................................................34