Ambient Air and Water

Temperature

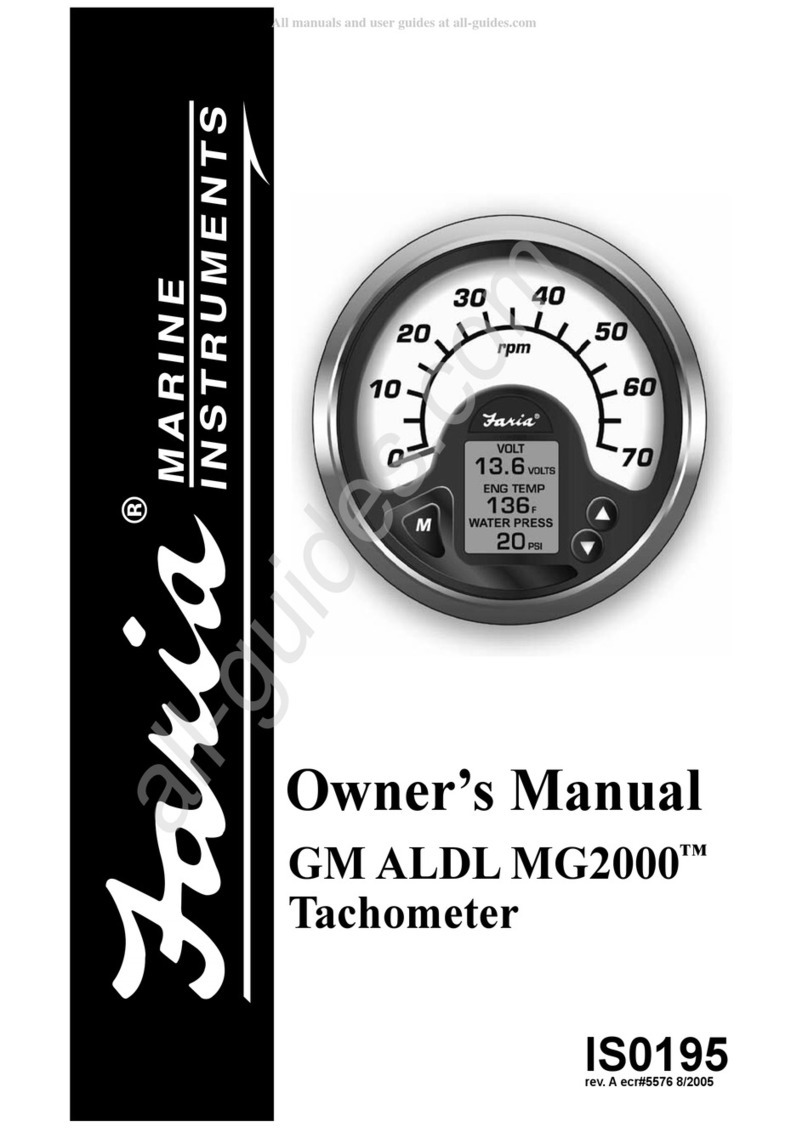

Description

The Faria Commander Tachometer/ Water-

Air Temperature/ Fuel Level/ Engine

Hourmeter combines the features of

several instruments into one unit. The

LCD displays the information for the other

instruments:

1) Water Temperature - Displays the

current water temperature.

2) Ambient Air Temperature - Displays

shows current air temperature

3) Fuel Level - Displays fuel level in fuel

tank (based on level sender) in percent.

4) Engine Hours - Displays the number of

hours the engine has been run.

Water Temperature

The Water Temperature display shows

current water temperature based on a Faria

supplied temperature probe. The probe

must be mounted so as to always be

submerged to the depth desired. There are

no adjustments for this function.

Air Temperature

The Air Temperature display shows

current air temperature based on a Faria

supplied temperature probe.

The probe must be mounted so as to be

exposed to free air but preferably not in

direct sunlight. There are no adjustments

for this function.

Fuel Level

See description above.

M

LCD Display Modes

Figure 2

Quick

Press

Water

Temp.

Ambient

Air Temp.

Page 12

Fuel Management Functions

Description

The Faria Commander Tachometer/ Fuel

Monitor/ Engine Hourmeter combines the

features of several instruments into one

unit. The LCD displays the information for

the other instruments:

1) Fuel Flow - Displays current fuel usage

in Gallons or Liters per hour.

2) Fuel Used - Displays fuel used since

last reset (trip fuel meter).

3) Total Fuel Used - Displays fuel used

since last reset (total fuel meter).

4) Fuel Remaining - Displays the fuel

remaining since last set (based on fuel

flow).

5) Fuel Level - Displays fuel level in fuel

tank (based on level sender) in percent.

6) Engine Hours - Displays the number of

hours the engine has been run.

Fuel Flow

The Fuel Flow display shows current fuel

consumption in gallons per hour (G) or

liters per hour (L).

The fuel flow sensor can be calibrated if

necessary using the Fuel Used “settings”

menu (see Fuel Used description below).

The units displayed may be changed using

the submenu. Pressing and holding the

“Mode” button causes the display to change

to the “UNITS” submenu (see Figure 1).

Fuel Flow “UNITS” Menu

Pressing the “Up” and “Down” buttons will

change the setting between GH and LH.

Fuel Used

The Fuel Used display shows the amount

of fuel used since the gauge was reset.

The display is based on the fuel flow

system and therefore filling the fuel tank

will not disturb the reading. The Fuel Used

gauge may be reset to zero and the Fuel

Used and Fuel Flow system calibrated

using the sub menus.

Pressing and holding the “Mode” button

M

Mode

Button

Down

Button

Up

Button

Page 6