TABLE OF CONTENTS

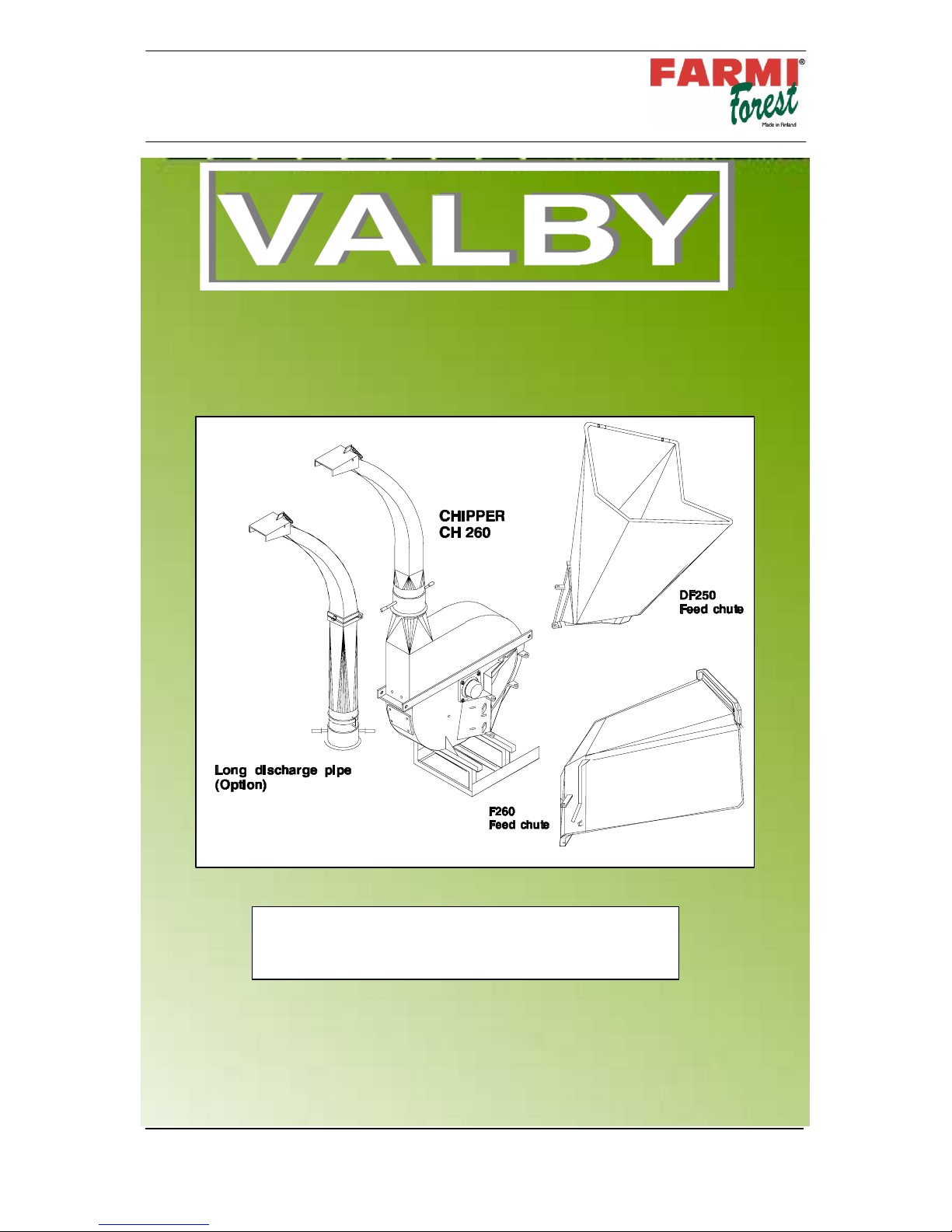

CH 260 CHIPPER

www.farmiforest.fi

--- 8 ---

1.TO THE OWNER---OPERATOR 3..............................................

2.SAFETY INSTRUCTIONS 4...................................................

2.1.TERMS AND SYMBOLS USED IN INSTRUCTIONS 4....................................

3.GENERAL SAFETY 5........................................................

3.1.ROTATING KNIVES 6.................................................................

3.2.SAFETY INSTRUCTIONS FOR THE HYDRAULIC FEEDER AND FEED CHUTE 6........

3.3.SAFETY INSTRUCTIONS FOR THE HYDRAULIC UNIT 7...............................

3.4.SAFETY INSTRUCTIONS FOR THE SEPARATE HYDRAULIC MOTOR USE 7.............

4.PRESENTATION 10..........................................................

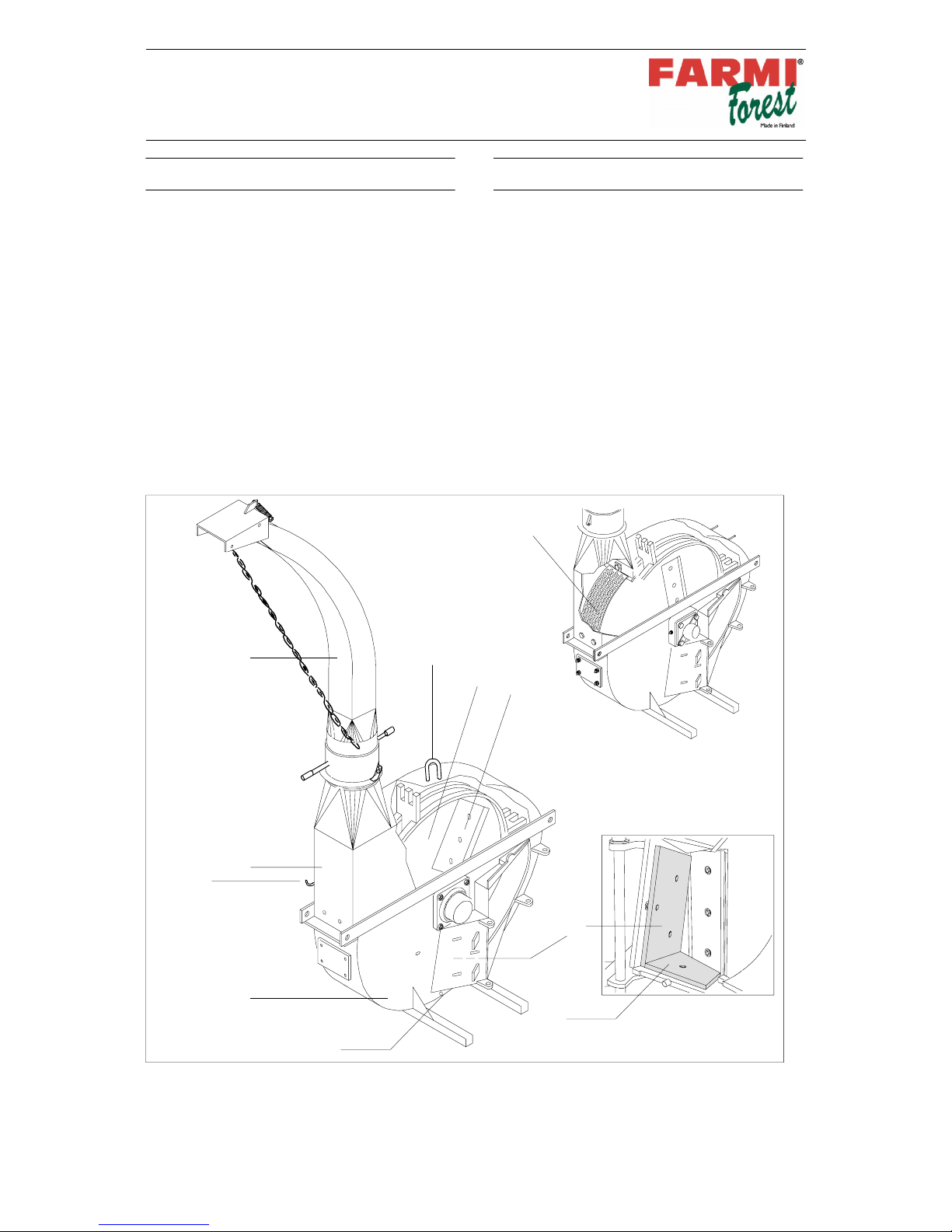

5.MAIN COMPONENTS 10.....................................................

6.DIMENSIONS 11............................................................

7.TECHNICAL DATA 11........................................................

8.PLATES AND STICKERS 12..................................................

9.LIFTING 15.................................................................

10.MOUNTING 15.............................................................

10.1.MOUNTING ON A TRACTOR 15........................................................

10.2.CUTTING THE PTO SHAFT TO THE CORRECT LENGTH 16...............................

10.3.INSTALLING THE SCREEN AND BREAKER 17...........................................

11.OPERATING THE CHIPPER 18..............................................

11.1.INSPECTIONS PRIOR TO OPERATION 18...............................................

11.2.STARTING THE CHIPPER 18...........................................................

11.3.STOPPING A TRACTOR---DRIVEN CHIPPER 18..........................................

11.4.STOPPING A HYDRAULIC MOTOR DRIVEN CHIPPER 18..................................

11.5.CHIPPING 18........................................................................

11.6.ADJUSTING THE DISCHARGE PIPE AND LID 19.........................................

12.STORAGE 19..............................................................

13.PERIODIC MAINTENANCE 20...............................................

13.1.LUBRICATING THE BEARINGS 20......................................................

13.2.LUBRICATING THE PTO SHAFT 20.....................................................

13.3.PERIODIC INSPECTIONS 21...........................................................

14.KNIFE AND ANVIL MAINTENANCE 22........................................

14.1.OPENING AND REMOVING THE UPPER CHAMBER 22...................................

14.2.REMOVING THE KNIVES FROM THE KNIFE BRACKETS 22...............................

14.3.SHARPENING THE KNIVES 23.........................................................

14.4.REMOVING THE ANVILS 23...........................................................

14.5.SHARPENING THE ANVILS 24.........................................................

14.6.INSTALLING THE KNIVES AND ANVILS 24..............................................

14.7.ADJUSTING AND CHECKING THE KNIFE---TO---ANVIL CLEARANCE 24....................

14.8.ADJUSTING THE CHIP LENGTH 25.....................................................

15.REPLACING THE SPLINED SHAFT 26........................................

16.INSTALLING THE BEARINGS 27.............................................