SAFETY INSTRUCTIONS

CH 222 CHIPPER

www.normet.fi

03294030

--- 5 ---

3.SAFETY

3.1.GENERAL SAFETY

IMPORTANT!

Do not operate this machine until you have read and

understood the manual page by page.

Theownerofthismachineisresponsiblefor

instructing all operators and support personnel in the

operation and safety precautions of this chipper.

Proper training prior to operating the chipper is

obligatory.

D

DD

D

Inform everyone who works with the chipper about the risks and how they can

avoid accidents.

D

DD

D

Before the chipper is running, ensure that the working place is clear of any by-

stander within a minimum risk zone of 100 ft. (30 meter).

D

DD

D

Do not let children or untrained persons operate the chipper.

D

DD

D

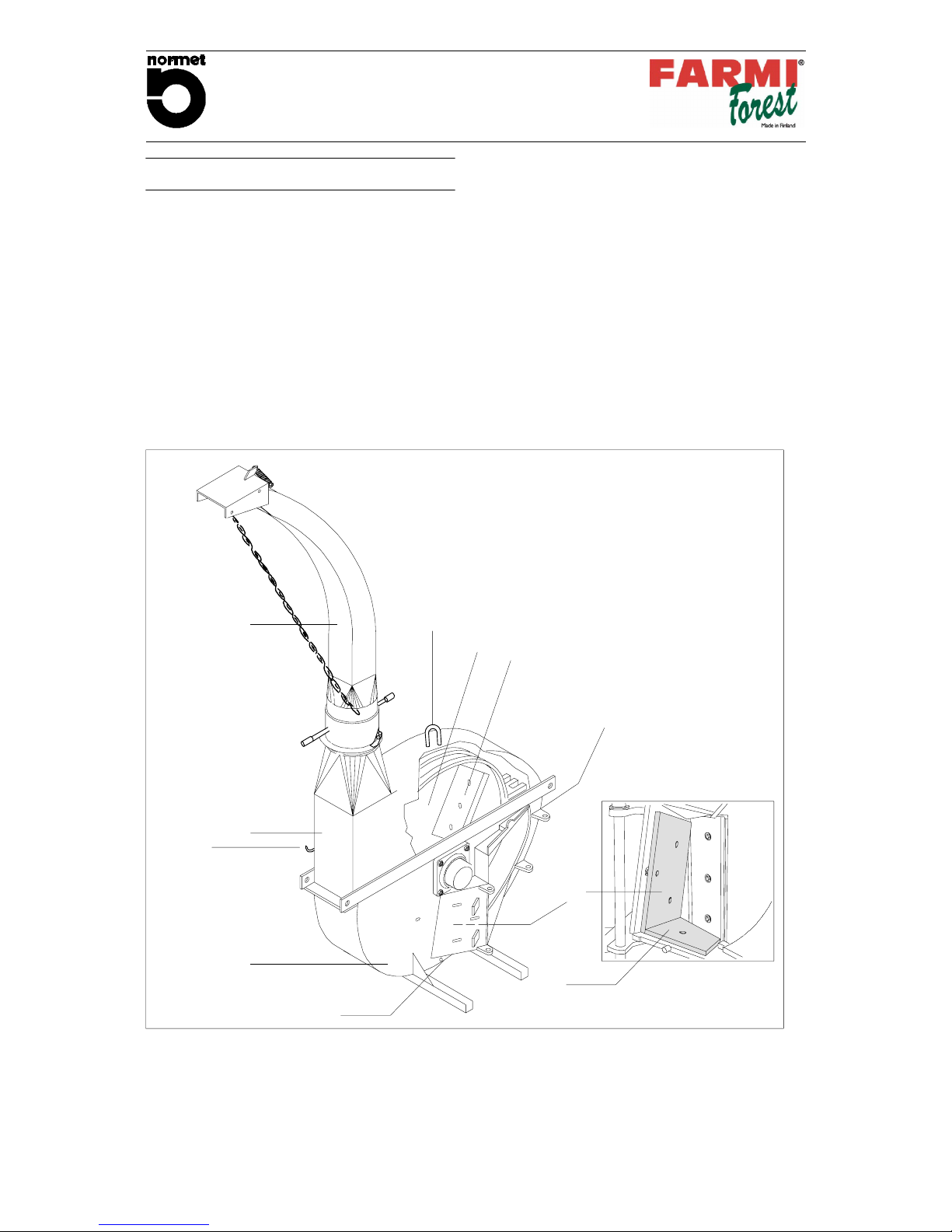

Always have the chipper mounted on the 3--point hitch of the tractor. Other-

wise the chipper will tip over.

D

DD

D

There is a serious crushing hazard between tractor and chipper. Do not go be-

tween the tractor and the chipper in any case, for example when you are

mounting the chipper to the tractor.

D

DD

D

Check that the covers of the universal shaft are in their place and the ransmis-

sion chains are fastened.

D

DD

D

Safety goggles, earmuffs and a hard hat are obligatory when chipping. Use

respirator mask, if necessary.

D

DD

D

Do not wear loose clothing, loose sleeves, scarves or long uncovered hair

around moving parts of machinery. Also avoid gloves of poor condition or

with loose fitting, because they might get caught in the branches.

D

DD

D

Stay alert! Do not operate the chipper when fatigued, or under the influence of

alcohol or drugs.

D

DD

D

IMPORTANT! Never leave the chipper running and unattended.

D

DD

D

IMPORTANT! Failure to obey the warnings on the chipper or in the operator’s

manual will result in personal injury and / or death and / or equipment dam-

age.

D

DD

D

Check the material before you feed it. The material must be free from nails,

stones and all other materials that are not wood, paper or plastic. IMPOR-

TANT! Feeding wire and barbed wire into the chipper is very dangerous as it

might pull in the operator.

D

DD

D

Make sure that no one is in the path of flying chips. Point the discharge pipe

away from windows, doorways and other areas where people or animals may

be.

D

DD

D

Keep the work area clean so there is nothing to trip over.