17 823 606

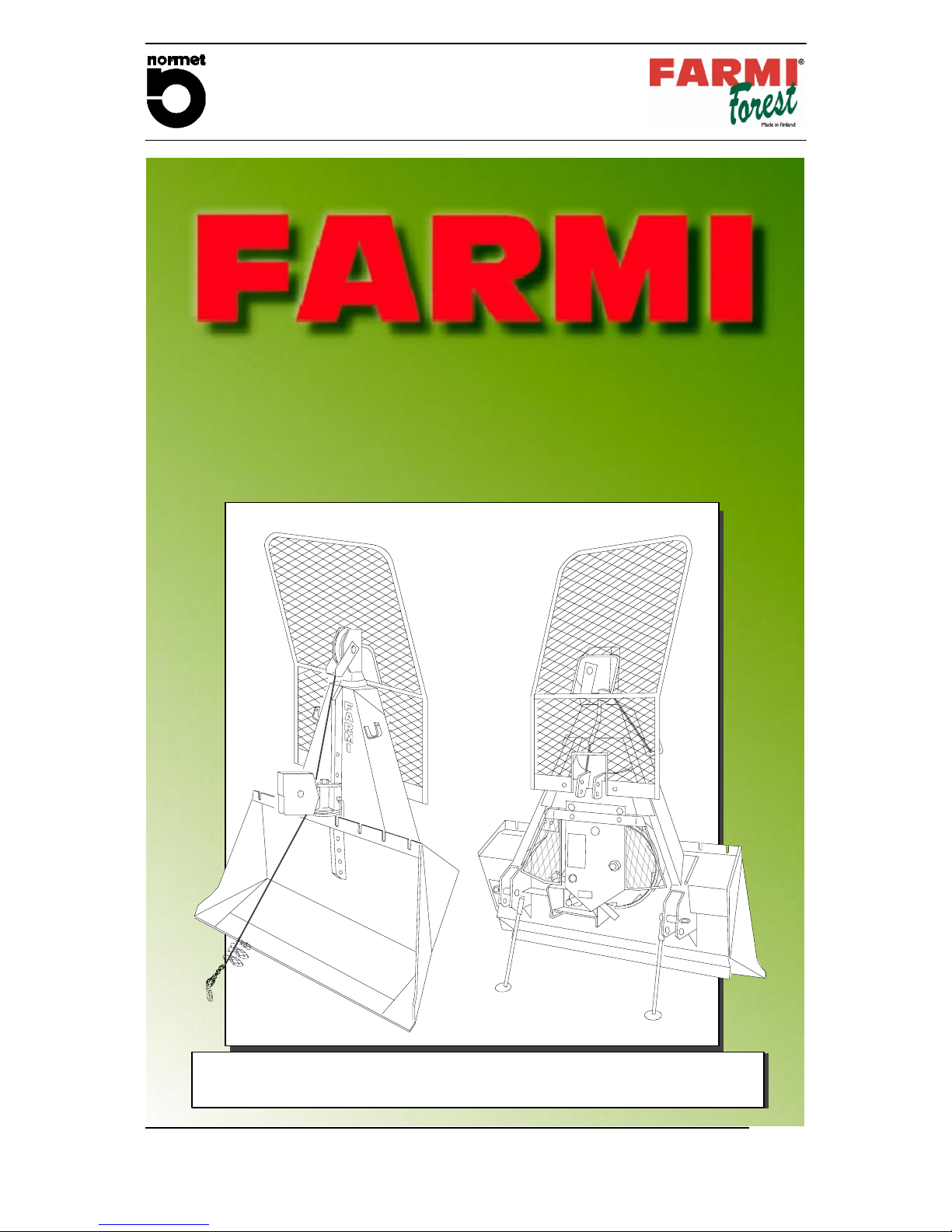

4Page

SAFETY INSTRUCTIONS 5..............................................

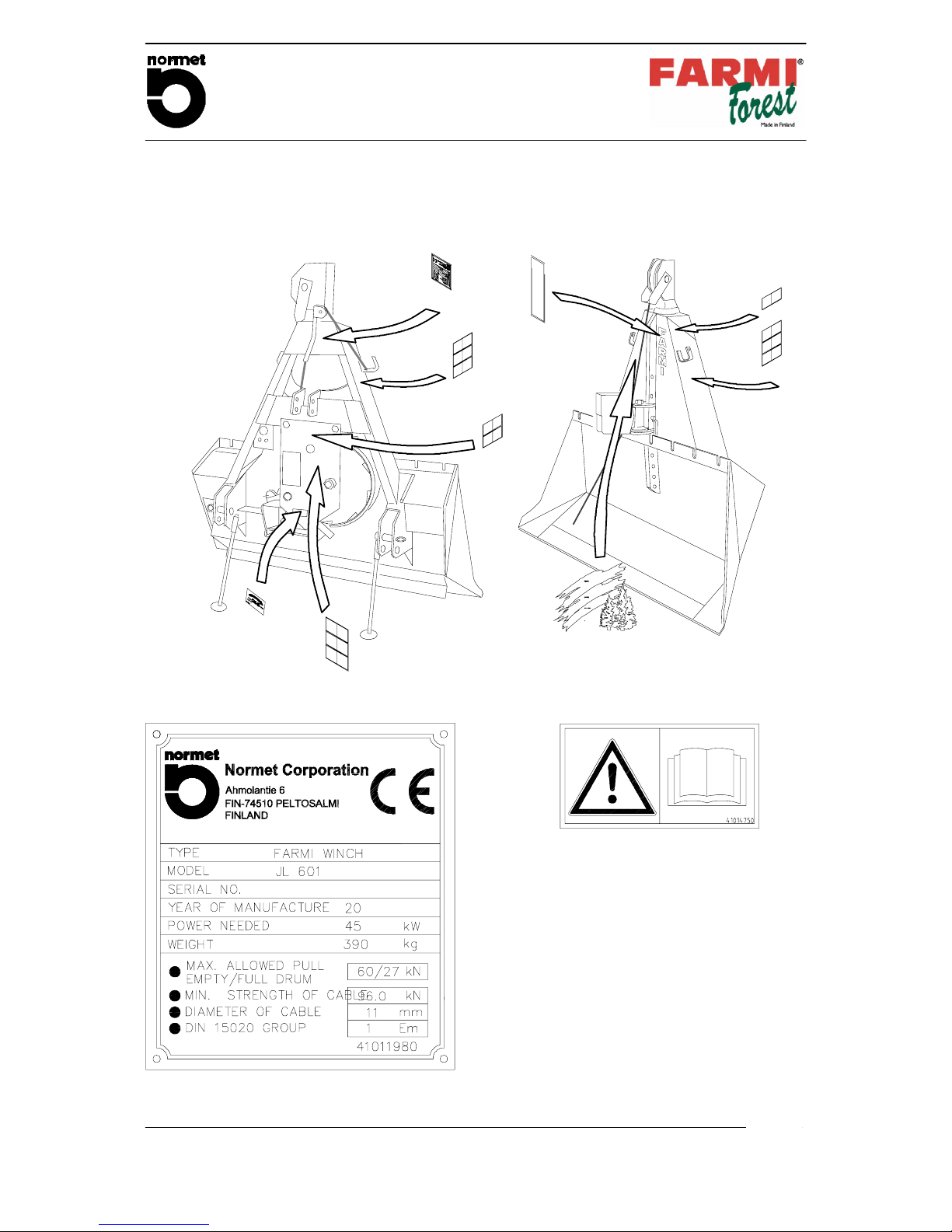

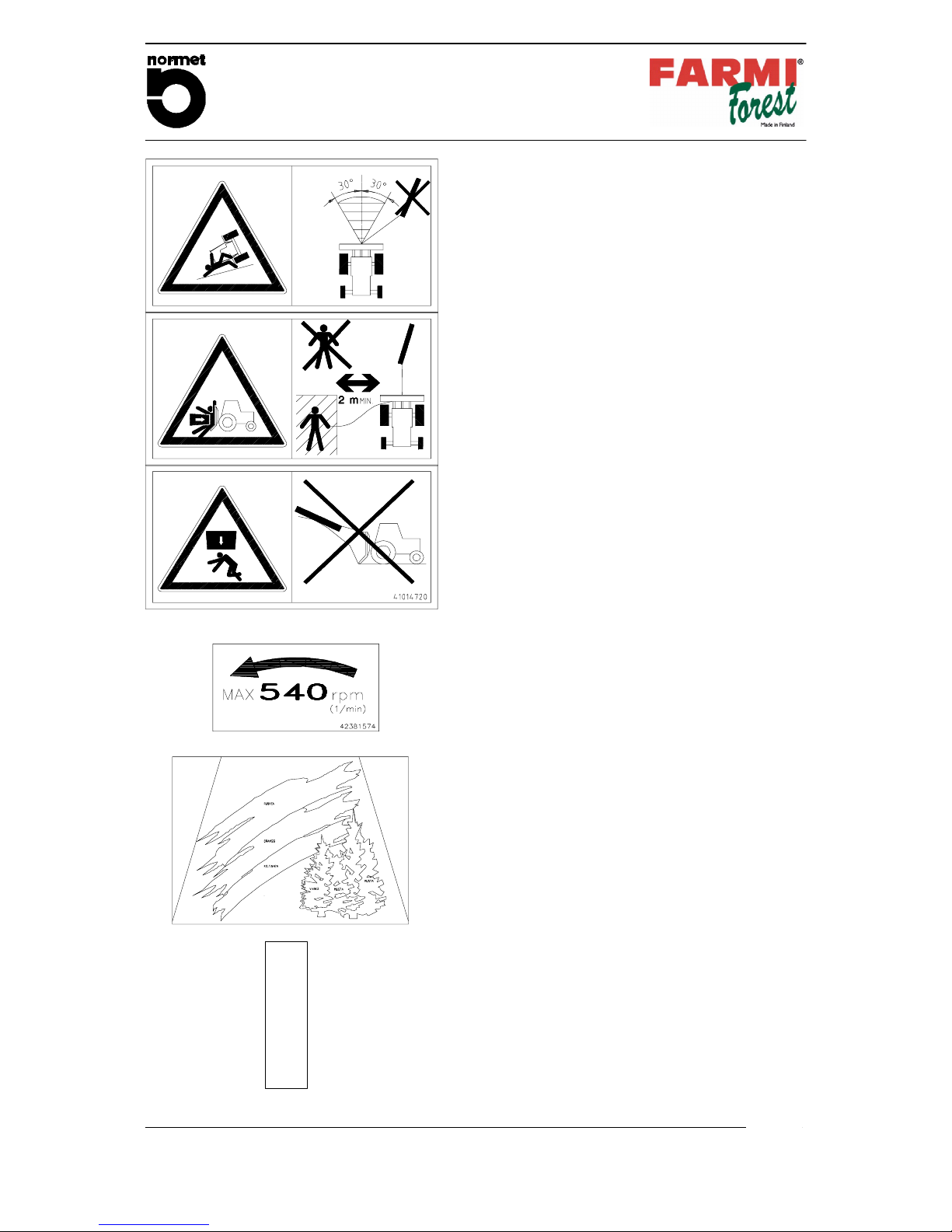

STICKERS AND SIGNS 7...............................................

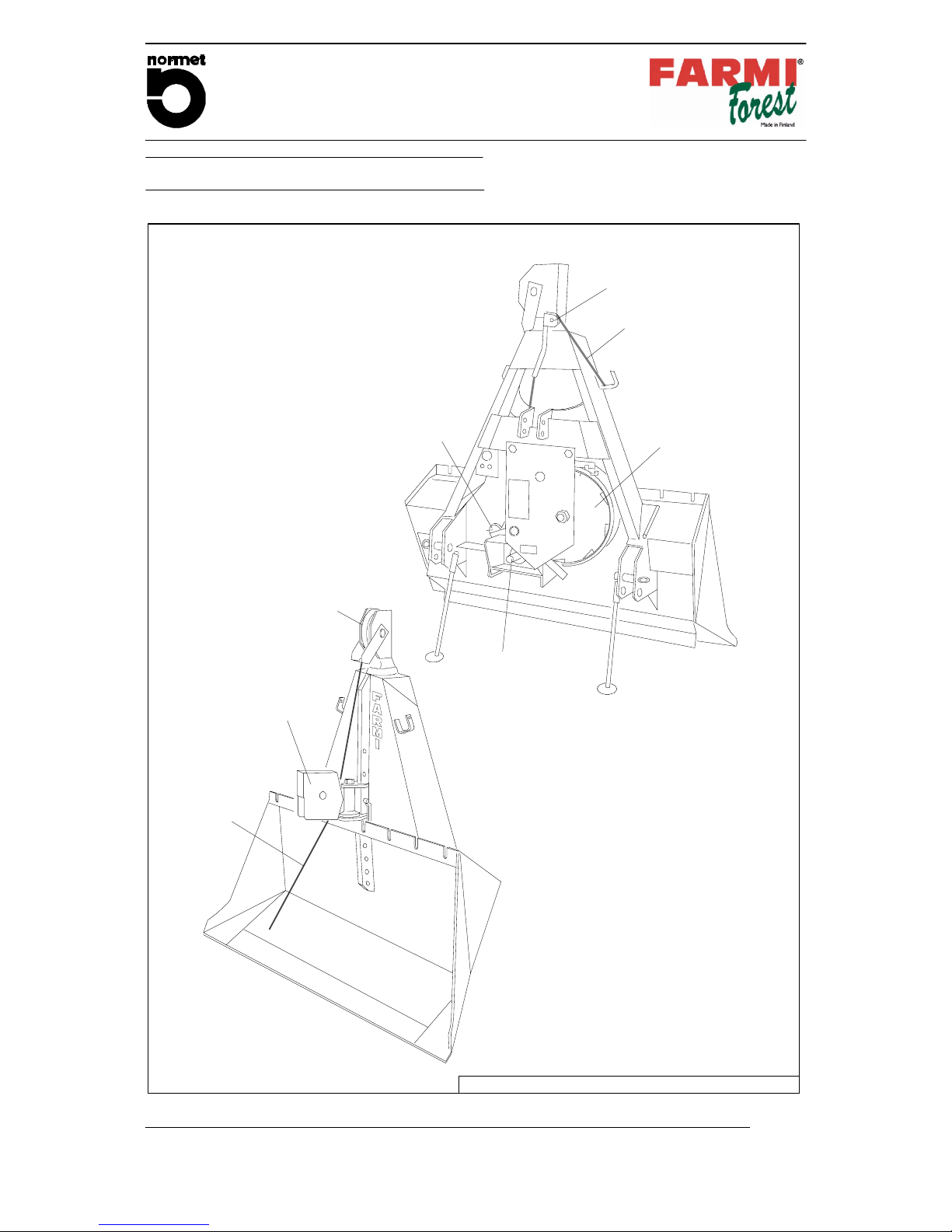

1. MAIN PARTS AND ACCESSORIES 10...................................

2. TECHNICAL DATA 11..................................................

3. DIMENSIONS 11.......................................................

4. MOUNTING INSTRUCTIONS 12.........................................

4.1. MOUNTING TO THE 3---POINT HITCH 12...........................................

4.2. ASSEMBLY OF THE PTO SHAFT 12...............................................

4.3. SHORTENING THE PTO SHAFT 12................................................

4.4. FASTENING THE CABLE TO THE DRUM 13........................................

5. PRE---OPERATION CHECKS 13.........................................

CABLE 13..........................................................................

Check that: 13......................................................................

WINCH: 13..........................................................................

Check that: 13......................................................................

MOUNTING TO THE TRACTOR 13.....................................................

Check that: 13......................................................................

6. CONTROLS 14........................................................

6.1. PULLING OUT THE CABLE 14....................................................

6.2. WINCHING 14..................................................................

7. OPERATION 14........................................................

7.1. SAFETY PRECAUTIONS 14.......................................................

7.2. PRE--- OPERATION CHECKS 15...................................................

MOUNTING AND USE OF THE LOWER SNATCHBLOCK 16...............................

7.3. WINCHING 16..................................................................

7.4. SKIDDING 16...................................................................

WORKING IN ROUGH TERRAIN: 17....................................................

IF YOU GET STUCK WITH THE TRACTOR: 17...........................................

7.5. DROPPING THE LOAD 17........................................................

7.6. TRANSPORTATION 17...........................................................

8. SAFETY 18............................................................

9. LUBRICATION 18......................................................

10. SERVICE 18...........................................................

10.1. CLUTCH ADJUSTMENT 18......................................................

10.2. ADJUSTING THE ROLLER CHAI TIGHTNESS 19...................................

10.3. ADJUSTING THE DRUM BRAKE 19..............................................

10.4. REMOVING THE WINCH MECHANISM 19.........................................

10.5. REASSEMBLING THE WINCH MECHANISM 20....................................

11. ORDERING OF SPARE PARTS 21.......................................

12. TROUBLE SHOOTING 21...............................................

SPARE PARTS 22.........................................................