BRADEN PD12C Series Manual

1

SERIES

PD12C

PD15B

PD17A HYDRAULIC HOIST

LIT2103 R4

07-2013

PRINTED IN U.S.A.

P.O. BOX 547 Broken Arrow, OK 74013

Tel 918-251-8511 / Fax 918-259-1575

www.paccarwinch.com

WINCH

INSTALLATION, MAINTENANCE, AND SERVICE MANUAL

X-rigs

model

PD12C-SPL-59034-02L-1

2

Table of Contents

GENERAL SAFETY RECOMMENDATIONS ................................................................4

THEORY OF OPERATION............................................................................................5

HOIST INSTALLATION..................................................................................................7

RECOMMENDED FASTENER TORQUE.....................................................................9

WIRE AND BRAIDED ROPE INSTALLATION ..............................................................9

TWO SPEED MOTOR CASE DRAIN PLUMBING......................................................10

PREVENTIVE MAINTENANCE...................................................................................10

RECOMMENDED OIL CHANGE INFORMATION.......................................................11

TROUBLE SHOOTING ...............................................................................................12

HOIST DISASSEMBLY................................................................................................16

EXPLODED VIEW DRAWING AND PARTS KEY..................................................18-19

PLANET CARRIER SERVICE.....................................................................................20

MOTOR SUPPORT – BRAKE CYLINDER SERVICE.................................................22

BRAKE CLUTCH SERVICE........................................................................................26

HOISTASSEMBLY......................................................................................................28

BRAKE VALVE SERVICE............................................................................................32

REVERSING DIRECTION OF DRUM ROTATION......................................................34

PD17A ROTATION INDICATION PROXIMITY SENSOR............................................36

3

FOREWORD

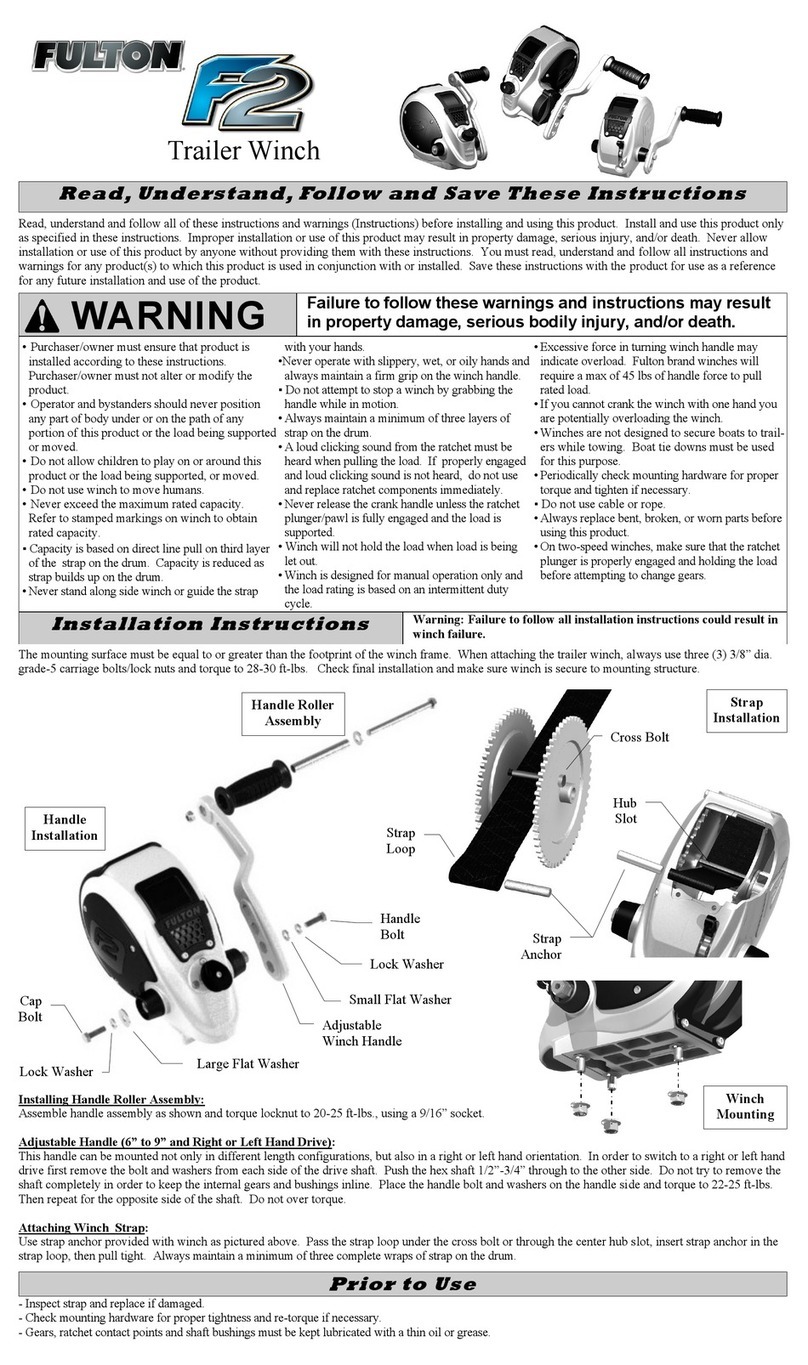

Read this entire publication and retain it for future reference.

If you have any questions regarding your Braden Planetary Hoist or this publication, call the Braden Service Depart-

ment at 1-918-251-8511, 08:00-1630 hours, CT, Monday through Friday.

The minimum service intervals specified are for operating hours of the prime mover.

The following service instructions have been prepared to provide assembly, disassembly and maintenance informa-

tion for the BRADEN Model PD12C, PD15B and PD17A series hoist. It is suggested that before doing any work on

these units, all assembly and disassembly instructions should be read and understood.

Some pictures in this manual may show details or attachments that are different from your hoist.Also, some compo-

nents have been removed for illustrative purposes. Illustrations and pictures in this manual are of a “typical” unit sold

through our distribution channels. Some hoists, particularly those sold directly to original equipment manufacturers

(OEM), may differ in appearance and options.

Whenever a question arises regarding your BRADEN HOIST, please contact BRADEN Service Department for the

latest available information.

Serial Numbers and Model Numbers are located to

the left hand side of the hydraulic motor, stamped

into the base.Always refer to the Serial Number and

Model Number when requesting information or ser-

vice parts.

PD DESIGNATES POWER DRUM

12 DESIGNATES 12,000 LB. APPROXIMATE FIRST LAYER LINE PULL

C DESIGNATES THE MODEL SERIES RELATING TO DESIGN CHANGES

29 DESIGNATES TOTAL GEAR REDUCTION (OTHER RATIOS INCLUDE 21, 41, 59, 34, ETC.)

064 DESIGNATES HYDRAULIC MOTOR DISPLACEMENT IN CU. IN/REV

(DECIMAL POINT ELIMINATED. EXAMPLE 064 = 6.4 CU IN/REV)

02 DESIGNATES THE DRUM OPTION (OTHER DRUMS INCLUDE 01, 04, 05, 23G, ETC.)

U DESIGNATES UNDERWOUND CABLE DRUM - OPTIONAL

L DESIGNATES LEFT HAND BASE - OPTIONAL, BLANK IS STANDARD RIGHT HAND BASE

1 PERMITS TESTINGAND INSPECTION PERAPI 2C FOR OFFSHORE CRANES - OPTIONAL

EXPLANATION OF MODEL NUMBER

PD 12 C 29 064 - 02 - U - L - 1

POWER

DRUM MAX

RATING DESIGN

SERIES GEAR

RATIO MOTOR

SIZE DRUM

OPTION OPTIONROTATION BASE

4

CAUTION – This emblem is used to warn against

potential or unsafe practices which COULD result

in personal injury and product or property damage if

proper procedures are not followed.

GENERAL SAFETY RECOMMENDATIONS

Safety and informational callouts used in this manual include:

WARNING – This emblem is used to warn against

hazards and unsafe practice which COULD result in

severe personal injury or death if proper procedures

are not followed.

CAUTION

!

!

!WARNING !

Safety for operators and ground personnel is of prime concern. Always take the necessary precautions to ensure

safety to others as well as yourself. To ensure safety, the prime mover and hoist must be operated with care and

concern by the operator for the equipment and a thorough knowledge of the machine’s performance capabilities.

The following recommendations are offered as a general safety guide. Local rules and regulations will also apply.

1. Be certain equipment (boom, sheave blocks,

pendants, etc.) is either lowered to the ground or

blocked securely before servicing, adjusting, or re-

pairing hoist.

2. Be sure personnel are clear of work area BEFORE

operating hoist.

3. Read all warning and caution tag information pro-

vided for safe operation and service of hoist.

4. Inspect rigging and hoist at the beginning of each

work shift. Defects should be corrected immediately.

5. Keep equipment in good operating condition. Per-

form scheduled servicing and adjustments listed in

the “Preventive Maintenance” section of this manu-

al.

6. An equipment warm-up procedure is recommended

for all start-ups and essential at ambient tempera-

tures below +40°F (4°C). Refer to “Warm-up Proce-

dure” listed in the “Preventive Maintenance” section

of this manual.

7. Operate hoist line speeds to match job conditions.

8. Leather gloves should be used when handling wire

rope.

9. Never attempt to handle wire rope when the hook

end is not free. Keep all parts of body and clothing

clear of cable rollers, cable entry area of fairleads

and hoist drum.

10. When winding wire rope on the hoist drum, never

attempt to maintain tension by allowing wire rope to

slip through hands. Always use “Hand-Over-Hand”

technique.

11. Never use wire rope with broken strands. Replace

wire rope.

12.Do not weld on any part of the hoist.

13.Use recommended hydraulic oil and gear lubricant.

14.Keep hydraulic system clean and free from contami-

nation at all times.

15.Use correct anchor for wire rope and pocket in

drum.

16.Do not use knots to secure or attach wire rope.

17.The BRADEN designed wire rope anchors are ca-

pable of supporting the rated load when installed

properly. For additional safety, ALWAYS maintain a

minimum of five (5) wraps of wire rope on the drum.

18.Never attempt to clean, oil or perform any mainte-

nance on a machine with the engine or prime mover

running, unless instructed to do so in this manual.

19.Never operate hoist controls unless you are prop-

erly positioned at the operators station and you are

sure personnel are clear of the work area.

20.Assure that personnel who are responsible for hand

signals are clearly visible and that the signals to be

used are thoroughly understood by everyone.

21.Ground personnel should stay in view of the opera-

tor and clear of hoist drum. Do not allow ground per-

sonnel near hoist line under tension.Asafe distance

of at least 1-1/2 times the length of the cable should

be maintained.

22.Do not exceed the maximum pressure, PSI (kPa),

or flow, GPM (LPM), stated in the hoist specifica-

tions.

23.Install guarding to prevent personnel from get-

ting any part of body or clothing caught at a point

where the cable is wrapped onto the drum or drawn

through guide rollers.

24.“Deadman” controls, which automatically shut off

power to the hoist whenever the operator leaves his

station, should be installed whenever practicable.

25.Never allow anyone to stand under a suspended

load.

26.Avoid sudden “shock” loads or attempting to “jerk”

load free. This type of operation may cause heavy

loads, in excess of rated capacity, which may result

in failure of cable and hoist.

5

DESCRIPTION OF HOIST

The hoist has four basic component parts:

1. Hoist base

2. Hydraulic motor and brake valve

3. Brake cylinder and motor support

4. Drum assembly

The drum assembly consists of three basic assem-

blies:

1. Drum with integral ring gear

2. Output planetary gear set

3. Primary planetary gear set

Thehydraulicmotoris boltedtothemotor support which

in turn is bolted to the brake cylinder and the base. The

motor end of the drum, running on a ball bearing, is

supported by the brake cylinder. The other end of the

drum runs on a ball bearing on the support bolted to the

base. The ring gear for both planetary sets is machined

into the drum’s inside surface.

HOIST OPERATION

The hydraulic motor drives the sun gear of the primary

planetary gear set through the splined inner race of the

overrunning brake clutch. When driven by the sun gear,

the primary planet gears walk around the ring gear in

the drum and drive the primary planet carrier.

The primary planet carrier drives the output planet

sun gear which, in turn drives the output planet gears.

The output planet carrier is splined to the bearing sup-

port and cannot rotate. Therefore, as the output planet

gears are driven by the sun gear, they will drive the ring

gear/drum.

DUAL BRAKE SYSTEM - DESCRIPTION

The dual brake system consists of a dynamic brake

system and a static brake system.

The dynamic brake system has two operating compo-

nents:

1. Brake valve assembly

2. Hydraulic motor

The brake valve is basically a counterbalance valve

with good metering characteristics. It contains a check

valve to allow free flow of oil to the motor in the hoist-

ing direction and a pilot operated, spring-loaded spool

valve that blocks the flow of oil out of the motor when

the control valve is placed in neutral. When the control

valve is placed in the lowering position, the spool valve

remains closed until sufficient pilot pressure is applied

to the end of the spool to shift it against spring pres-

sure and open a passage. After the spool valve cracks

open, the pilot pressure becomes flow-dependent and

modulates the spool valve opening which controls the

lowering speed. Refer to figures 1, 2, and 3.

Figures 1, 2, and 3.

THEORY OF OPERATION

The static brake system has three operating compo-

nents:

1. Spring Applied, Multiple Friction Disc Static Brake

2. Overrunning Brake Clutch Assembly

3. Hydraulic Piston and Cylinder

Motor

Control Valve

Pump

To Tank

Brake Valve

Static Brake

Medium

Pressure

Low

Pressure

High

Pressure

Figure 1

HOISTING

Motor

Control Valve

Pump

To Tank

Brake Valve

Static Brake

Medium

Pressure

Low

Pressure

High

Pressure

Figure 2

LOWERING 1

6

Motor

Control Valve

Pump

To Tank

Brake Valve

Static Brake

Medium

Pressure

Low

Pressure

High

Pressure

Figure 3

LOWERING 2

The static brake is released by the brake valve pilot

pressure at a pressure lower than that required to open

the pilot operated spool valve. This sequence assures

that dynamic braking takes place in the brake valve and

that little, if any, heat is absorbed by the friction brake.

The friction brake is a load holding brake only and has

nothing to do with dynamic braking or rate of descent

of a load.

The overrunning brake clutch is splined to the primary

sun gear shaft between the motor and the primary sun

gear. It will allow this shaft to turn freely in the direction

to raise a load and lock up to force the brake discs to

turn with the shaft in the direction to lower a load. Refer

to figures 4 and 5.

The hydraulic cylinder, when pressurized, will release

the spring pressure on the brake discs, allowing the

brake discs to turn freely.

Dual Brake System – Operation

When hoisting a load, the brake clutch which connects

the motor shaft to the primary sun gear, allows free rota-

tion. The sprag cams lay over and permit the inner race

to turn free of the outer race. Figure 4. The friction brake

remains fully engaged. The hoist, in raising a load, is

not affected by any braking action. Figure 1.

When the lifting operation is stopped, the load attempts

to turn the primary sun gear in the opposite direction.

This reversed input causes the sprag cams to instantly

roll upward and firmly lock the shaft to the fully engaged

friction brake. Figure 5.

When the hoist is powered in reverse, to lower the load,

the motor cannot rotate until sufficient pilot pressure is

present to open the brake valve. Figures 2 & 3. The

friction brake within the hoist will completely release at

a pressure lower than that required to open the brake

valve. The extent to which the brake valve opens will

determine the amount of oil that can flow through it and

the speed at which the load will be lowered. Increas-

ing the flow of oil to the motor will cause the pressure

to rise and the opening in the brake valve to enlarge,

speeding up the descent of the load. Decreasing this

flow causes the pressure to lower and the opening in

the brake valve to decrease thus slowing the descent

of the load.

When the control valve is shifted to neutral, the pres-

sure will drop and the brake valve will close, stopping

the load. The friction brake will engage and hold the

load after the brake valve has closed.

When lowering a load very slowly for precise position-

ing, no oil flow actually occurs through the hoist motor.

The pressure will build up to a point where the brake will

release sufficiently to allow the load to rotate the motor

through its own internal leakage. This feature results in

a very slow speed and extremely accurate positioning.

The friction brake receives very little wear in the lower-

ing operation. All of the heat generated by the lowering

and stopping of a load is absorbed by the hydraulic oil

where it can be readily dissipated.

Sprag Cams

Static Friction Brake Applied

Permits free shaft rotation

while hoisting

Sprag Cams

Static Friction Brake Applied

Load attempts to rotate shaft in opposite direction

Brake clutch locks sun gear shaft to friction brake

Figure 4

Figure 5

7

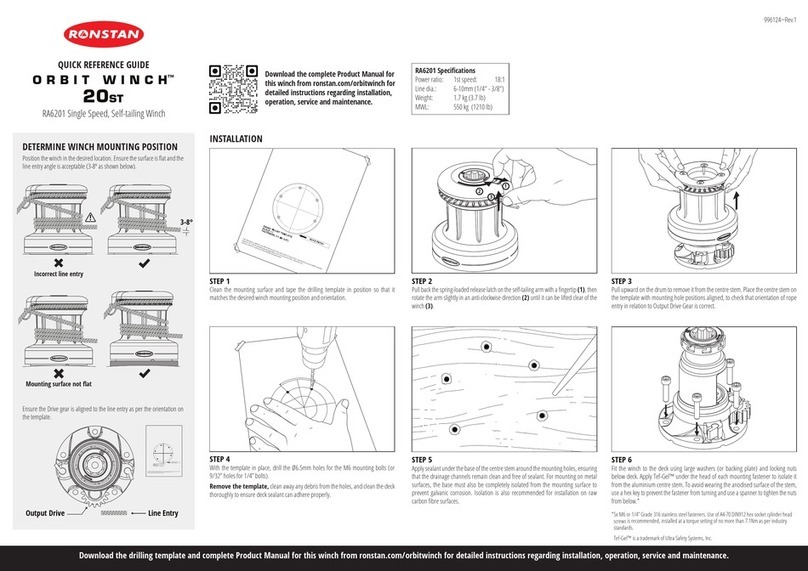

HOIST INSTALLATION

1. The hoist should be mounted with the centerline

of the drum in a horizontal position. The mounting

plane of the base may be rotated in any position

around this centerline.

2. Because of the design of the mounting base, the

direction of line pull should only be as shown in the

above illustration. Line pulls in any other direction

must be approved by BRADEN Engineering.

3. When mounting the hoist, use all eight (8) mounting

holes and grade 8 capscrews and nuts. Tighten to

recommended torque.

It is important that the hoist is mounted on a surface

that will not flex when in use, and cause binding of

the gear train. Binding in the gear train will result in

accelerated wear and heat. Also, be sure the hoist

is mounted on a flat surface. If necessary, use shim

stock to insure the mounting surface is flat within

0.020 in. (0.5 mm). Use stainless steel shim stock

as required.

4. The vent plug must always be located above the

horizontal centerline. If the hoist is mounted on a

pivoting surface, be sure vent plug remains above

the centerline in all positions. If necessary, reposi-

tion bearing support and vent plug as follows:

A. Remove bearing support bolts.

B. Rotate bearing support until vent plug

is positioned correctly and bolt holes

are aligned.

C. Evenly tighten bolts to recommended

torque.

5. Hydraulic lines and components that operate the

hoist must be of sufficient size to assure minimum

back-pressure at the hoist motor ports. The hydrau-

lic back-pressure measured at the motor work ports

must be less than 100 PSI (690 kPa) at full operating

flow. Back-pressure in excess of 100 PSI (690 kPa)

will shorten motor shaft seal life and partially release

the load holding brake. The standard hoist is sup-

plied with the gear motor internally drained and con-

nected the drain by-pass port on the Braden brake

valve. If high back-pressures are encountered, the

motor should be externally drained directly to the

reservoir and the “DRAIN” port on the brake valve

capped. All piston motors MUST be drained directly

to the reservoir. The piston motor case drain port

must NEVER be exposed to more than 42 PSI (290

kPa); shaft seal damage will occur.

6. The hoist should be mounted perpendicular to an

imaginary line from the center of the drum to the first

sheave to insure even spooling. Make certain the

fleet angle does not exceed 1-1/2 degrees.

TO LOAD

OR

FIRST SHEAVE

A = B

A

B

1/2 MIN

1 1/2 MAX

O

O

FLEET ANGLE

CenterLine

VENT PLUG

ABOVE CENTERLINE

This hoist m er

SIONS

BROKE 4012

U.S.A.

SERIAL NO. 76381

BRADEN Gearmatic

HOIST

BRADEN Gearmatic Service Manual.

76381

SERIAL NO.

U.S.A.

BROKEN ARROW,OK.,74012

WINCH DIVISIONS

This hoist must be maintained per

HOIST

8

The directional control valve must be a three po-

sition, four- way valve without detents and with a

spring centered motor spool such that the valve re-

turns to the centered position whenever the handle

is released, and both work ports are open to tank

(open center, open port).

7. High quality hydraulic oil is essential for satisfactory

performance and long hydraulic system component

life.

HOIST BRAKE

BRAKE

VALVE

PUMP

CONTROL

VALVE

HOIST ASSEMBLY

W/BRAKE VALVE

& STATIC BRAKE

BR

DR

DO NOT use a control valve with any detents or

latching mechanism that would hold the control valve

in an actuated or running position when the operator

releases the control handle. Use of the wrong type

of control valve could lead to unintentional operation

of the hoist, which could result in property damage,

personal injury, or death.

WINCH BRAKE

BRAKE

VALVE

2-SPEED

SELECTOR

VALVE

PUMP

CONTROL

VALVE

WINCH ASSEMBLY

W/BRAKE VALVE

& STATIC BRAKE

TP

BR

DR

A

Oil having 150 to 330 SUS (30-60 cSt) viscosity at

104°F (40°C) and viscosity index of 100 or greater

will give good results under normal temperature

conditions. The use of an oil having a high viscosity

index will minimize cold-start trouble and reduce the

length of warm-up periods. A high viscosity index

will minimize changes in viscosity with correspond-

ing changes in temperature.

Maximum cold weather start-up viscosity should not

exceed 5000 SUS (1000 cSt) with a pour point at

least 20°F (11°C) lower than the minimum tempera-

ture.

Under continuous operating conditions the tempera-

ture of the oil at any point in the system must not

exceed 180°F (82°C). Optimum oil temperature is

generally considered to be 120-140°F (49-60°C).

In general terms; for continuous operation at am-

bient temperatures between 50 and 110°F (10 to

43°C) use ISO 46; for continuous operation between

10 and 90°F (-12 to 32°C) use ISO 32; for applica-

tions colder than 10°F (-12°C), contact the BRADEN

Service Department. The use of multi-viscosity oils

is generally not recommended.

8. The hydraulic oil filter should have a 10 micron nom-

inal rating and be full flow type and meet the require-

ments of the hydraulic pump manufacturer.

9

ANCHORING BRAIDED ROPEANCHORING WIRE ROPE

RECOMMENDED FASTENER TORQUE

Higher or lower torques for special applications will be specified such as the use of spanner nuts, nuts on shaft

ends, jam nuts and where distortion of parts or gaskets is critical.

Lubricated torque values based on use of SAE 30wt engine oil applied to threads and face of bolt or nut.

Avoid using thread lubricants (such as anti-seize compound) as the applied torque may vary by 10 - 40%, de-

pending upon the product used.

7RUTXH/%)71P 7RUTXH/%)71P

%ROW

'LDP

,QFKHV

7KUHDG

SHU

LQFK

*UDGH *UDGH %ROW

'LDP

,QFKHV

7KUHDG

SHU

LQFK

*UDGH *UDGH

'U\ /XEHG 'U\ /XEHG 'U\ /XEHG 'U\ /XEHG

7RFRQYHUW/%)7WR.

J

PPXOWL

S

O

\

/%)7YDOXHE

\

WIRE AND BRAIDED ROPE INSTALLATION

Take the free end of the wire rope and insert it through

the small opening of the anchor pocket. Loop the wire

rope and push the free end about half of the way back

throughthepocket.Installthe wedge, thenpull the slack

out of the wire rope. The wedge will slip into the pocket

and secure the wire rope into the drum. The early style

anchor wedge is designed to accommodate several dif-

ferent sizes of wire rope. You may anchor 7/16 and 1/2

in. (11 & 13 mm) wire rope by inserting the wedge, large

end first. Anchor 9/16 and 5/8 in. (14 & 16 mm) wire

rope by inserting the wedge, small end first.

Early Style

Wire Rope

Anchor

A special wedge is used to anchor 1 and 1 1/8 in. (25

& 28 m) braided synthetic rope. The installation proce-

dure is the same as for anchoring wire rope.

CORRECT INSTALLATION INCORRECT INSTALLATION

Figure 7 Figure 8 Figure 9 Figure 10

Drive from

this side

Wedge and wire

rope fully seated

in pocket

Wedge not

fully Seated Wedge pulled

too far through

anchor pocket

10

The following minimum service intervals are speci-

fied for operating hours of the prime mover.

TWO SPEED MOTOR CASE DRAIN PLUMBING

Some hoists with two speed gear motors may have

been installed with the motor case drain connected to

the drain port of the brake valve. This system may result

in accelerated motor shaft seal wear and leakage. The

following modification should be made to the motor hy-

draulic piping to prevent this type of seal damage.

1. Remove the motor case drain hose from the

brake valve drain port and install plug, Item

1, into the valve port. Remove the hose from

the case drain port elbow, Item 4.

2. Install a new case drain hose, Item 2, onto

the motor case drain elbow, Item 4.

3. Install the tee adapter, Item 3, into the two-

speed motor shift valve drain port (identified

by long end cap).

4. Install the new motor case drain hose, Item

2, onto the tee adapter.

5. Install a case drain hose for the tee directly

to the reservoir. Minimum hose size is –6,

3/8 in. (9.5 mm). Maximum drain line back

pressure is 100 PSI (690 kPa) measured at

the motor case drain port.

ITEM DESCRIPTION QTY PART #

1 Plug, -4 ORB 1 25663

2Hose, 17-in. OAL

(-4 JIC Fml Svl/-4 Hose/ 1/8 NPT ml) 1 13707

3 Tee -4 (ORB Branch -4 JIC Run) 1 29078

1

2

3

PREVENTIVE MAINTENANCE

A regular program of preventive maintenance for your planetary hoist is strongly recommended to minimize the

need for emergency servicing and promote safe, reliable hoist operation.

Field experience, supported by engineering tests, indicate the three (3) service procedures listed below are the

MOST critical to safe, reliable hoist operation and must be observed.

• Regular Gear Oil Changes – every 1000 hours or six (6) months

• Use of Proper Gear Oil – recommended type for prevailing ambient temperature

• Periodic disassembly and inspection of all wear items.

1. OIL LEVEL

The gear oil level should be checked every 500

operating hours or three (3) months, whichever occurs

first. To check the oil level, remove the large plug locat-

ed in the center of the drum support. The oil should be

level with the bottom of this opening or approximately

half-way up in a sight glass. This is extremely impor-

tant due to the accelerated wear that can be caused

by insufficient lubricating oil in the hoist. If addi-

tional oil in needed, refer to “Recommended Planetary

Gear Oil”.

11

2. OIL CHANGE

The gear oil should be changed after the first

one hundred (100) hours of operation, then every 1,000

operating hours or six (6) months, whichever occurs

first. The gear oil must be changed to remove wear

particles that impede the reliable and safe operation of

the brake clutch and erode bearings, gears and seals.

Failure to change gear oil at these suggested minimum

intervals may contribute to intermittent brake slippage

which could result in property damage, severe personal

injury or death.

The gear oil should also be changed whenever

the ambient temperature changes significantly and an

oil from a different temperature range would be more

appropriate. Oil viscosity with regard to ambient tem-

perature is critical to reliable brake clutch operation.

Our tests indicate that excessively heavy or thick gear

oil may contribute to intermittent brake clutch slippage.

Make certain that the gear oil viscosity used in your

hoist is correct for your prevailing ambient temperature.

Failure to use the proper type and viscosity of planetary

gear oil may contribute to brake clutch slippage which

could result in property damage, severe personal injury

or death. Refer to “Recommended Planetary Gear Oil”

for additional information.

3. VENT PLUG

The vent plug is located in the drum support as

shown. It is very important to keep this vent clean and

unobstructed. Whenever gear oil is changed, remove

vent plug, clean in solvent and reinstall.

Do not paint over the vent or replace with a solid plug.

4. HYDRAULIC SYSTEM

The original filter element should be replaced

after the first fifty (50) hours of operation, then every

500 operating hours or three (3) months, or in accor-

dance with the equipment manufacturer’s recommen-

dations.

5. WIRE ROPE

Inspect entire length of wire rope according to

wire rope manufacturers recommendations.

6. MOUNTING BOLTS

Tighten all hoist base mounting bolts to recom-

mended torque after the first one hundred (100) hours

of operation, then every 1000 operating hours or six (6)

months, whichever occurs first.

7. WARM-UP PROCEDURES

Awarm-up procedure is recommended at each

start-up and is essential at ambient temperatures below

+40°F (4°C).

The prime mover should be run at its lowest

recommended RPM with the hydraulic hoist control

valve in neutral allowing sufficient time to warm up

the system. The hoist should then be operated at low

speeds, raise and lower, several times to prime all lines

with warm hydraulic oil, and to circulate gear lubricant

through the planetary gear sets.

8. INSPECTION

A. Bearings and Gears – Refer to

DISASSEMBLY OF Hoist, page 15; and

PLANET CARRIER SERVICE, page 20.

B. Brake Cylinder – Refer to MOTOR

SUPPORT – BRAKE CYLINDER SERVICE,

pages 22 and 23.

C. Brake Clutch – Refer to BRAKE CLUTCH

SERVICE, page 26.

Failure to properly warm up the hoist, particularly un-

der low ambient temperature conditions, may result

in temporary brake slippage due to high back pres-

sures attempting to release the brake, which could

result in property damage, severe personal injury or

death.

9. RECOMMENDED PLANETARY GEAR OIL

Use of the proper planetary gear oil is essential

to reliable and safe operation of the brake clutch and

obtaining long gear train life.

For simplicity, BRADEN has listed one (1) read-

ily available product in each temperature range which

has been tested and found to meet our specifications.

Failure to use the proper type and viscosity of plan-

etary gear oil may contribute to intermittent brake

clutch slippage which could result in property dam-

age, severe personal injury or death. Some gear lu-

bricants contain large amounts of EP (extreme pres-

sure) and anti-friction additives which may contribute

to brake clutch slippage and damage to brake friction

discs or seals. Oil viscosity with regard to ambient

temperature is also critical to reliable brake clutch

operation. Our tests indicate that excessively heavy

or thick gear oil may contribute to intermittent brake

clutch slippage. Make certain that the gear oil viscos-

ity used in your hoist is correct for your prevailing

ambient temperature.

12

RECOMMENDED PLANETARY GEAR OIL

PREVAILING AMBIENT TEMPERATURE

o

F -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130

o

F

AGMA 5 EP, ISO VG 220

AGMA 4 EP, ISO VG 150

MOBILGEAR SHC 150

SYNTHETIC OR EQUIVALENT

o

C -40 -30 -20 -10 0 10 20 30 40 50

o

C

NOTE: SHADED TEMPERATURE RANGE IN THE CHART ABOVE NOT RECOMMENDED FOR SEVERE APPLICATIONS SUCH AS: OFFSHORE

CRANES, SUSTAINED FAST DUTY CYCLES OR FREQUENT LIFTING.

i

TexacoShell

Meropa 150

Meropa 220

Omala 150

Omala 220

Chevron

Gear Compounds EP 150

Gear Compounds EP 220

RECOMMENDED PLANETARY GEAR OIL

PREVAILING AMBIENT TEMPERATURE

o

F -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130

o

F

AGMA 5 EP, ISO VG 220

AGMA 4 EP, ISO VG 150

SYNTHETIC OR EQUIVALENT

o

C -40 -30 -20 -10 0 10 20 30 40 50

o

C

NOTE: SHADED TEMPERATURE RANGE IN THE CHART ABOVE NOT RECOMMENDED FOR SEVERE APPLICATIONS SUCH AS: OFFSHORE

CRANES, SUSTAINED FAST DUTY CYCLES OR FREQUENT LIFTING.

i

TexacoShell

Meropa 150

Meropa 220

Omala 150

Omala 220

Chevron

Gear Compounds EP 150

Gear Compounds EP 220

TexacoMobil Shell

Meropa 150

Meropa 220

Omala 150

Omala 220

Chevron

Gear Compounds EP 150

Gear Compounds EP 220

MOBILGEAR 600 XP 220 OR EQUIVALENT

MOBILGEAR 600 XP 150 OR EQUIVALENT

Mobilgear 600 XP 150

Mobilgear 600 XP 220

Planetary hoists are factory filled with Mobilgear 600 XP 150, or equivalent. Consult your oil supplier for other equivalent

oils if required.

OIL CAPACITIES:

(PD12C/PD15B) 01, 02 & 22 DRUM - 6 PINTS (2.8 L)

(PD12C/PD15B) 04, 05 & 23G DRUM - 7 PINTS (3.3 L)

(PD12C/PD15B) 06 DRUM - 18 PINTS (8.6 L)

(PD12C/PD15B) 24G & 25G DRUM - 11.5 PINTS (5.4 L)

(PD17A) 27G DRUM - 20 PINTS (9.5 L)

NOTE: Capacities are approximate. Refer to “Oil

Level” earlier in this section

If a hoist ever exhibits any sign of erratic operation, or load control difficulties (i.e. load creeping or chattering)

appropriate troubleshooting tests and repairs should be performed immediately. Continued operation in this

manner may result in property damage, serious personal injury or death.

TROUBLESHOOTING

TROUBLE PROBABLE CAUSE REMEDY

A

The hoist will not lower the load or

not lower the load smoothly. 1. The problem could be a plugged

or loose pilot orifice. The pilot ori-

fice is a small pipe plug with a hole

drilled through it, located behind the

pilot port fitting on the brake valve.

If it becomes plugged, it will prevent

the pilot pressure, from the mani-

fold, from opening the brake valve.

If it becomes loose, it will allow an

unregulated amount of oil in to op-

erate the brake valve which cause

erratic brake valve operation.

2. The friction brake may not be

releasing as a result of a defective

brake cylinder seal.

NOTE: If the brake cylinder seal

is defective you will usually find oil

leaking from the hoist vent plug.

Remove the pilot hose and fitting

from the brake valve, then use a

5/32 inch Allen wrench to remove

the pilot orifice. The diameter of the

orifice is approximately .020 inches.

Clean and install the pilot orifice

tightly in the brake valve.

Check brake cylinder seal as fol-

lows:

A. Disconnect the swivel tee from

the brake release port. Connect a

hand pump with accurate 0-2000

psi gauge and shut-off valve to the

–4 J.I.C. fitting in the brake release

port.

AMS ISO220-EP

AMS ISO150-EP

Amsoil cross

13

1. Friction brake will not release as

a result of damaged brake discs. A. Apply 1000 PSI (6,900 kPa) to

the brake. Close shut-off valve and

let stand for five (5) minutes.

B. If there is any loss of pressure

in five (5) minutes, the brake cylin-

der should be disassembled for in-

spection of the sealing surfaces and

replacement of the seals. Refer to

“Motor Support-Brake Cylinder Ser-

vice”.

Disassemble brake to inspect brake

discs. Check stack-up height as

described in “Motor Support-Brake

Cylinder Service”.

A

The hoist will not lower the load or

not lower the load smoothly.

TROUBLE PROBABLE CAUSE REMEDY

B

Oil leaks from vent plug. 1. Same as A2.

2. Motor seal may be defective as

a result of high system back pres-

sure or contaminated oil.

Same as A2.

System back pressure must not ex-

ceed 150 PSI (1,035 kPa). Inspect

hydraulic system for a restriction in

the return line from the control valve

to the reservoir. Be sure control

valve and plumbing is properly sized

to hoist motor.

Oil analysis may indicate contami-

nation has worn motor shaft and

seal. Thoroughly flush entire hy-

draulic system and install new filters

and oil. Install new motor seal.

C

The brake will not hold a load with

the control lever in neutral. 1. Excessive system back pressure

acting on the brake release port.

2. Friction brake will not hold due to

worn or damaged brake discs.

3. Brake clutch is slipping.

The same as Remedy 2 of Trouble

B2.

Same as Remedy 3 of Trouble A3.

Improper planetary gear oil may

cause the brake clutch to slip. Drain

old gear oil and flush hoist with sol-

vent. Thoroughly drain solvent and

refill hoist with recommended plan-

etary gear oil listed in “Preventive

Maintenance”.

Brake clutch may be damaged or

worn. Disassemble and inspect

brake clutch as described in “Brake

Clutch Service”.

14

TROUBLE PROBABLE CAUSE REMEDY

D

The hoist will not hoist the rated

load. 1. The hoist may be mounted on

an uneven or flexible surface which

causes distortion of the hoist base

and binding of the gear train. Bind-

ing in the gear train will absorb

horsepower needed to hoist the

rated load and cause heat.

2. System relief valve may be set

too low. Relief valve needs adjust-

ment or repair.

3. Be certain hydraulic system tem-

perature is not more than 180 de-

grees F. Excessive hydraulic oil

temperatures increase motor inter-

nal leakage and reduce motor per-

formance.

4. Hoist line pull rating is based on

1st layer of wire rope.

5. Rigging and sheaves not operat-

ing efficiently.

Reinforce mounting surface.

If necessary, use shim stock to level

hoist. Refer to “Hoist Installation”.

First loosen, then evenly retighten

all hoist mounting bolts to recom-

mended torque.

Check relief pressure as follows:

A. Install an accurate 0-4000 psi

(27,580 kPa) gauge into the inlet

port of the brake valve.

B.Apply a stall pull load on the hoist

while monitoring pressure.

C. Compare gauge reading to hoist

specifications. Adjust relief valve as

required.

NOTE: If pressure does not in-

crease in proportion to adjustment,

relief valve may be contaminated or

worn out. In either case, the relief

valve may require disassembly or

replacement.

Same as remedies for Trouble D1 &

D2.

Same as remedies for Trouble E2.

Refer to hoist performance charts

for additional information.

Perform rigging service as recom-

mended by crane manufacturer.

E

The hoist runs hot. 1. Same as D1.

2. Be certain that the hydraulic sys-

tem temperature is not more than

180 degrees F. Excessive hydrau-

lic oil temperatures may be caused

by:

A. Plugged heat exchanger.

B. Too low or too high oil level in hy-

draulic reservoir.

C. Same as D2.

Same as remedies for Trouble D1.

Thoroughly clean exterior and flush

interior.

Fill/drain to proper level.

Same remedies as D2

15

TROUBLE PROBABLE CAUSE REMEDY

E

The hoist runs hot. Same as remedies for Trouble D2.

Prime mover low on horsepower or

R.P.M. Tune/adjust prime mover.

Check suction line for damage.

If pump is belt driven, belts are slip-

ping. Replace/tighten belts.

Pump worn. Replace pump.

Disassemble hoist to inspect/re-

place worn parts.

D. Hydraulic pump not operating

efficiently.

3. Excessively worn or damaged

internal hoist parts.

F

Hoist “chatters” while raising rated

load. 1. Same as D2.

2. Hydraulic oil flow to motor may

be too low.

3. Controls being operated too

quickly.

Same as remedies for Trouble D2.

Same as remedies for Trouble E2.

Conduct operator training as re-

quired.

G

The wire rope does not spool

smoothly on the drum. 1. The hoist may be mounted too

close to the main sheave, caus-

ing the fleet angle to be more than

1-1/2 degrees.

2. The hoist may not be mounted

perpendicular to an imaginary line

between the center of the cable

drum and the first sheave.

3. Could possibly be using the

wrong lay rope. There is a distinct

advantage in applying rope of the

proper direction of lay. When the

load is slacked off, the several coils

on the drum will stay closer to-

gether and maintain an even layer.

If rope of improper lay is used, the

coils will spread apart each time

the load is removed. Then, when

winding is resumed, the rope has a

tendency to criss-cross and overlap

on the drum. The result is apt to be

a flattened and crushed rope.

4. The hoist may have been over-

loaded, causing permanent set in

the wire rope.

Check mounting distance and fleet

angle. Reposition hoist as required.

Refer to “Hoist Installation”.

Consult wire rope manufacturer for

recommendation of wire rope that

best suits your application.

Replace wire rope and conduct

operator/rigger training as required.

16

SERVICE PRECAUTIONS

• Before any part is removed from the hoist, all service instructions should be read and understood.

• Work in a clean, dust free area as cleanliness is of utmost importance when servicing hydraulic equipment.

• Inspect all replacement parts, prior to installation, to detect any damage which might have occurred in ship-

ment.

• Use only genuine BRADEN replacement parts for optimum results. Never reuse expendable parts such as oil

seals and O-rings.

• Inspect all machined surfaces for excessive wear or damage . . . before reassembly operations are begun.

• Lubricate all O-rings and oil seals with gear oil prior to installation.

• Use a sealing compound on the outside surface of oil seals and a light coat of thread sealing compound on

pipe threads. Avoid getting thread compound inside parts or passages which conduct oil.

• Thoroughly clean all parts in a good grade of non-flammable safety solvent. Wear protective clothing as re-

quired.

After troubleshooting the hoist and its hydraulic system as covered in the “Troubleshooting” section, and the prob-

lem is determined to be in the hoist, use the following procedure to disassemble the hoist.

DISASSEMBLY OF HOIST

1. Remove the wire rope from the cable drum and

align the drain hole in the drum with a hole in the

support side plate before removing the hoses and

mounting bolts. After the hoist is removed from its

mounting, thoroughly clean the outside surfaces. To

drain the oil, install a short piece of 1 inch pipe in the

larger threads of the drain hole. If necessary, insert

a bar into the anchor pocket and manually rotate the

drum in the direction to hoist a load until the drain

holes are aligned.

2. Use a 5/16 inch Allen wrench to remove the drain

plug through the pipe.

3. Begin disassembly by removing the oil level plug

or sight glass and standing the hoist on the bearing

support end. Tag and remove the hydraulic hoses

that connect the brake valve and manifold to the

brake cylinder.

4. Remove the capscrews securing the motor, and lift

the motor off the hoist. Remove and discard the O-

ring installed on the pilot of the motor.

5. Tag and remove the hoses and fittings from the

brake cylinder release port.

17

6. Remove the brake clutch assembly from the motor

support. Refer to “Brake Clutch Service” for addi-

tional information.

7. Remove the motor support capscrews and install

two (2) capscrews and a short piece of chain into

the motor mounting bolt holes. Using the chain as

a handle, lift the motor support out of the brake

cylinder being careful to avoid damaging the seal-

ing surfaces. Remove and discard the O-ring and

back-up ring from the motor support. Refer to “Mo-

tor Support-Brake Cylinder Service” for additional

information. Note the location of the brake release

port in relation to hoist prior to removing the brake

cylinder

8. Remove the brake cylinder capscrews and install

two (2) capscrews and a short piece of chain into

the motor support mounting bolt holes. Using the

chain as a handle, lift the brake cylinder out of the

drum and base, being careful to avoid damaging

the sealing or bearing surfaces. Refer to “Motor

Support-Brake Cylinder Service” for additional in-

formation.

For PD15B hoists, the drum closure cannot be re-

moved through the opening in the base. If your hoist

has a one-piece cast base, remove the bearing sup-

port, as described in step 15, and remove the drum

from the base. Then proceed with steps 9 thru 14. If

your hoist has a three piece base, remove the motor

end side plate and continue with step 9.

9. Using two heel type pry bars placed between the

primary planet carrier and the drum closure, pry

upward to remove the drum closure. Remove and

discard the O-ring from the outside of the drum clo-

sure. Some drum closures have 3/8-16 tapped lift-

ing eye holes that may be used in place of the heel

bars

10. Remove the seal and bearing from inside of clo-

sure.

11. Remove the primary sun gear and thrust washer

from the primary planet carrier.

12. Remove the primary planet carrier from the drum.

Refer to “Planet Carrier Service” for additional infor-

mation.

18

13. Remove the output sun gear and thrust washer

from the output planet carrier.

14. Remove the output planet carrier from the drum.

Refer to “Planet Carrier Service” for additional infor-

mation.

15. Stand hoist on motor end with bearing support up;

then remove eight (8) bearing support capscrews

and bearing support being careful to avoid damag-

ing the sealing or bearing surfaces.

16. Slide drum out of base onto a work bench and re-

move seal and bearing from support end.

17. Thoroughly clean and inspect drum and base.

Check ring gear (machined into inside surface of

drum) teeth for nicks, spalling or excessive wear.

Replace if wear is greater than 0.015 in. (0.4 mm)

when compared to unworn area of teeth.

BRADEN PD12C/PD15B/PD17A COMPONENTS

ITEM QTY DESCRIPTION

1 1 Brake Cylinder

2 1 Piston Seal

3 1 Pressure Plate

4 1 Piston Back-up Ring

512Spring

6 7 Friction Disc

7 8 Brake Disc

10 1 Primary Planet Carrier

11 3 Primary Planet Gear

12 3 Primary Planet Gear Shaft

13 3 Roller Bearing

14 6 Thrust Washer

15 6 Spirol Pin

16 1 Output Planet Carrier

17 3 Output Planet Gear

18 3 Output Planet Gear Shaft

19 6 Roller Bearing

20 3 Bearing Spacer

21 6 Thrust Washer

22 1 One-Piece Base

23 1 Bearing Support

24 1 Cable Drum

25 1 Cable Drum Closure

26 2 Ball Bearing

27 1 Oil Seal

28 1 O-ring

29 1 Oil Seal

30 1 Retaining Ring

31 1 Thrust Washer

32 1 Motor Support

33 1 O-Ring

34 1 Output Sun Gear

35 1 Primary Sun Gear

36 2 Spacer

37 1 Primary Sun Gear

38 1 Output Thrust Plate

40 16 Capscrew

41 24 Lockwasher

ITEM QTY DESCRIPTION

42 4 Capscrew

43 1 Thrust Washer

44 1 Plug- Hex Head

45 1 Plug- Flush

46 1 Vent Plug

47 1 O-Ring

48 1 Back-up Ring

49 1 Brake Race- Outer

50 1 Brake Race- Inner

51 2 Sprag Bushing

52 2 Sprag Bushing Retainer

53 2 Retaining Ring

54 1 Sprage Clutch

55 1 Retaining Ring

57 1 Cable Clamp

58 1 Manifold

59 2 O-ring

60 4 Capscrew

61 4 Capscrew

62 1 Brake Valve

63 1 Hose Assembly

64 2 Hose Assembly 12-inch

65 1 Adapter- straight

66 1 Elbow

67 1 swivel tee

68 1 elbow

69 1 Reducer elbow

70 4 Capscrew

72 1 Hydraulic Motor

90 1 Base Plate

91 1 Side Plate (bearing support end)

92 1 Side Plate (motor end)

93 16 Capscrew (special)

94 16 Washer

95 1\2 Tie Bar

96 2\4 Capscrew

97 2\4 Lockwasher

99 1 Spring Spacer

19

26

29

92

9796

61 64

63

68

69

59

62

72

66

64

65

59

67

58

60

41

70 To Item 1

BRAKE RELEASE

HOIST

LOWER

MOTOR

CASE

DRAIN

PD17A hoists use an

internal retaining ring (item

16, not shown) to hold item

38 into the output planet

carrier

PD17A

hoists

use only

1 each of

items 52

and 53

due to the

shoulder

on item 50.

(shoulder

is toward

motor)

Retaining

ring (item 30)

is not used

on PD17A

hoists

1 Piece Base

3 Piece Base

20

OUTPUT PLANET CARRIER

DISASSEMBLY

1. Remove the planet gears by driving the roll pins

into the center of the planet shafts.

2. Use a punch to drive the roll pins from the planet

shafts. Do not reuse the roll pins.

3. Now you can remove the planet shafts, bearings,

spacer, thrust washers and gears. Thoroughly clean

all parts and inspect for damage and wear. The

bearing rollers should not exhibit any irregularities.

If the rollers show any sign of spalling, corrosion,

discoloration, material displacement or abnormal

wear, the bearing should be replaced. Likewise, the

cage should be inspected for unusual wear or de-

formation, particularly the cage bars. If there is any

damage that will impair the cage’s ability to sepa-

rate, retain and guide the rollers properly, the bear-

ing should be replaced. The thrust washer contact

areas should be free from any surface irregularities

that may cause abrasions or friction. The gears and

shafts should be inspected for abnormal wear or pit-

ting. Replace if necessary.

ASSEMBLY

1. Place the output planet carrier on workbench with

splined coupling side down. Install output thrust

plate in center of carrier.

PLANET CARRIER SERVICE

PD17A hoists have an internal retaining ring to hold

the thrust plate into the carrier. This retaining ring

MUST be properly installed and fully seated before

the planet gears are installed.

CAUTION

!

!

Other manuals for PD12C Series

2

This manual suits for next models

3

Table of contents

Other BRADEN Winch manuals

Popular Winch manuals by other brands

Einhell Global

Einhell Global SHZ 300-2 operating instructions

Winchmax

Winchmax WMSL13500 Fitting and Operating Guide

Startax

Startax 9201-100192 User instructions

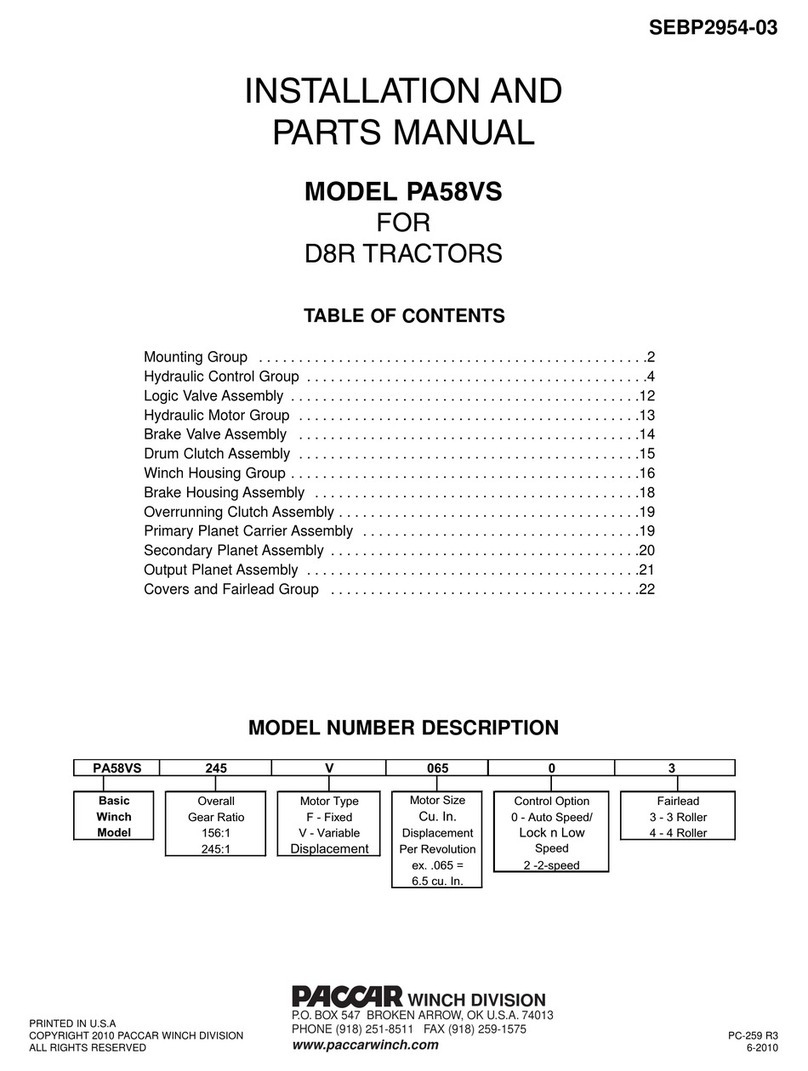

Paccar Winch

Paccar Winch PA58VS INSTALLATION AND PARTS MANUAL

Antal

Antal W 6 Instructions For Fitting

Starter

Starter 3000 ACI Operating and maintenance manual