General Maintenance Cont. General Maintenance Cont.

sand paper on a sanding block

taking care not to rub the

surrounding gelcoat areas to any

great extent.

7. Finish using automotive rubbing

compound in the same manner

as for scratches.

8. Restore the shine with a

recommended car or marine

polish.

NOTE:- IF YOU ARE IN DOUBT as

to the extent of gelcoat damage or

you suspect that the fibreglass

beneath the gouge may be damaged

consult your Farr 6000 marine dealer

before attempting repairs.

Woodwork maintenance

The exterior handrails, hatch covers,

tiller and interior ladder are painted

with a top quality marine varnish

before leaving the factory. They will

periodically need recoating and the

following procedure should be

followed.

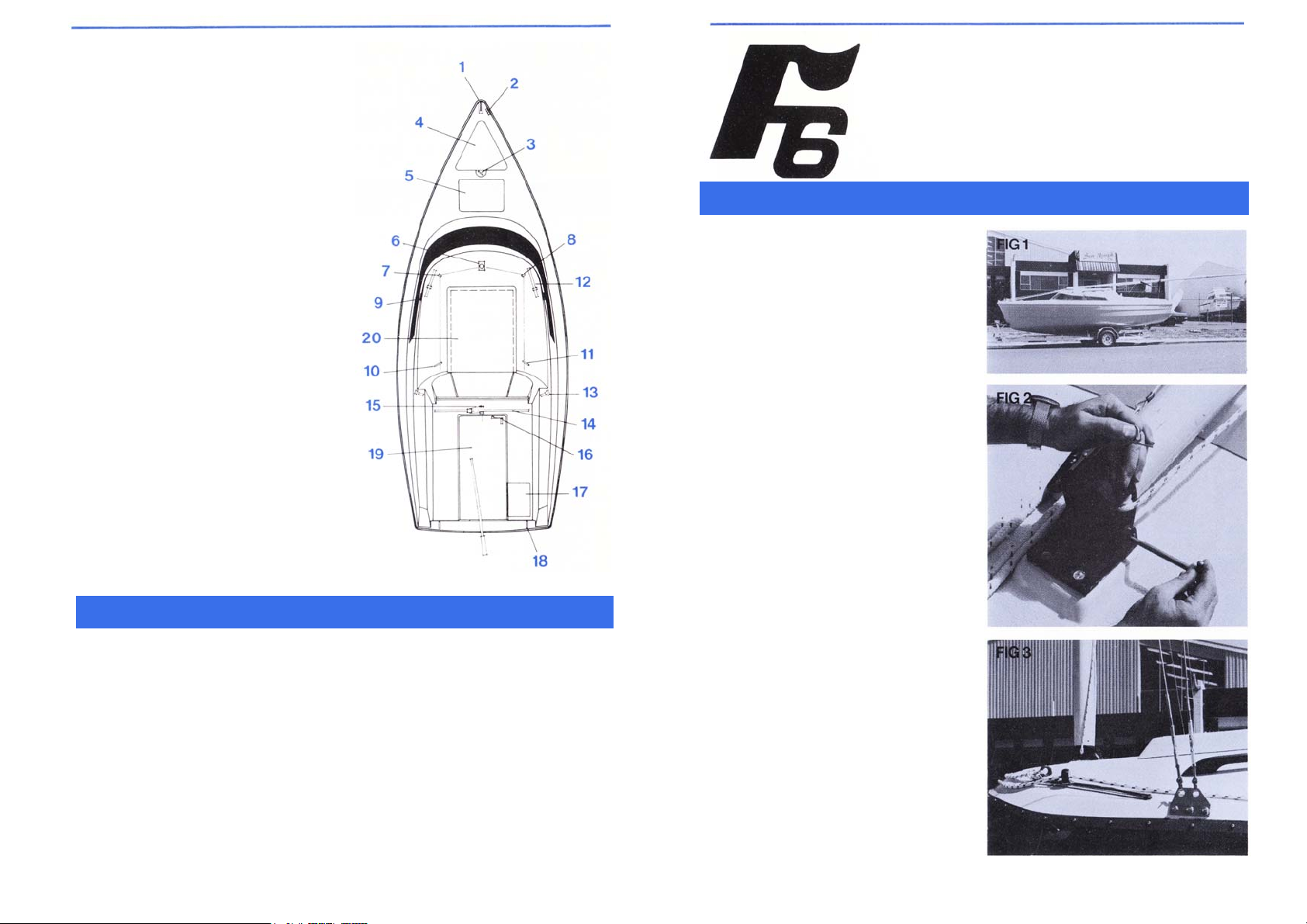

1. Wash to remove all salt and dry

thoroughly.

2. Sand lightly with a fine grade of

dry paper.

3.Apply 2 to 3 coats of any

recommended marine varnish

with a light sand between coats.

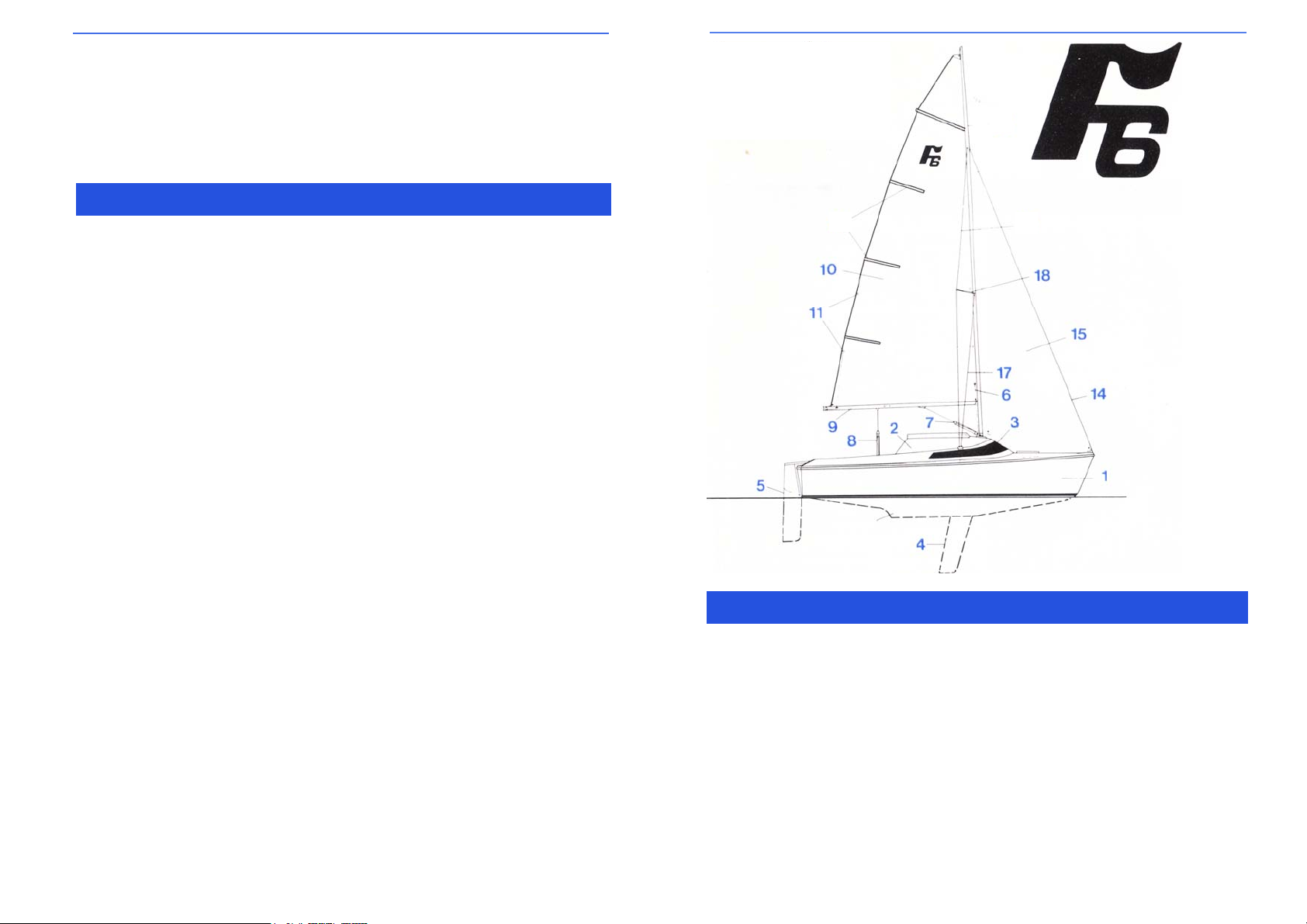

Rigging

It is a natural tendency to forget to

look at your rigging until something

wears out completely. Make it a

habit to check rigging screws,

shackles, and mast fittings each time

before you sail. A periodic spray with

"CRC" or similar lubricant on rigging

screws, snap shackles etc. will keep

them corrosive free and in top

5

working order.

Silicone spray on the luff groove of

the mast will make for easier

hoisting of the mainsail.

Sails

If possible fold your sails before

bagging them. This minimises

wrinkling and helps the set. Try not

to bag wet sails. If you cannot find

anywhere else to dry them spread

them out inside the boat if they are

damp and not in use. A periodic

hose with fresh water will help to

keep your sails in good condition.

Have any small rips or tears repaired

immediately they are noticed before

they become large rips and tears.

Vinyl upholstery

Resistance: All vinyl coated fabrics

are remarkably resistant to most

stains. A sponge dipped in warm,

soapy water and wiped over lightly

will remove most marks easily.

However, a few substances when

spilt or smeared on vinyl coatea

fabrics will stain unless care is taken

promptly. In all cases, the faster the

stain is attacked, the easier it will be

to remove. Whenever removing any

stain or mark, always wipe from the

outside of the stain towards its

centre to avoid spreading it.

Ballpoint Pen Ink: Method A. Make

a paste with Fuller's Earth (Available

from local Chemists) and a

household bleach, mixed with a few

drops of methylated spirits. Apply to

the surface of the stain and allow the

paste to dry for 3 hours. Remove

with soap and water. More than one

application may be needed if the

stain has been present for some

time.

Method B. Apply methylated spirits

alone, by swabbing with cotton wool

(do not rub too severely or the print

may be removed). Follow by washing

with soap and water if the stain is

seen to within one hour of

occurrence. After one hour Method

A is recommended as the surface of

the stain is removed using

methylated spirits.

Lipstick, Shoe Polish: With a dry rag

carefully remove as much of the

stain as possible. Gently wipe the

affected area with a cotton cloth

moistened with methylated spirits.

Follow by washing over with warm

soapy water. Prompt attention will

minimise any discolouration.

Butter: Easily removed by warm

soapy water. If left longer than a

couple of days severe stiffening of

the vinyl occurs.

Tomato Sauce: A mild staining

agent, easily removed by warm

soapy water up to one week after

occurrence.

Chewing Gum: Set the gum hard

with ice then scrape clean. Wipe

with methylated spirits, then with

warm soapy water.

Blood: Cold water will remove blood

stains if applied immediately. If

marks persist, use ammonia. Then

wash with warm, soapy water.

Chocolate: Remove excess

chocolate and wipe over with a cloth

moistened with methylated spirits.

Wash with warm, soapy water.

Toffee: Scrape the stained surface

clean and wash with very hot

water. Wipe with a cloth moistened

with methylated spirits, then with

warm soapy water.

Battery acid: Battery acid is a severe

corrosive agent which may destroy

the surface of your fabric or

permanently stain it. Apply ammonia

quickly to the acid to neutralise it.

Wash with warm, soapy water.

Always dilute the acid quickly.

Liquor and Fruit Stains: Wash

stained area with very hot water and

allow to dry thoroughly. Wipe with

clean cloth moistened with

methylated spirits. Do not use warm,

soapy water as this sets the stain.

Ice Cream: Try warm, soapy water.

If not successful, wash repeatedly

with very hot soapy water, then

cold water. Wipe with a cloth

moistened with methylated spirits,

then warm, soapy water again. Stain

may

become permanent unless removed

quickly.

Tar: Tar is virtually impossible to

remove if left for any length of time.

Quick action with a little kerosene or

mineral turpentine on a clean cloth

is recommended. Then wash with

warm, soapy water.

Paint: While the paint is still wet or

tacky, apply mineral turpentine with

a clean cloth. Wash with warm,

soapy water. Again, immediate

action is essential as dry paint

cannot be removed without

damaging the fabric.

It is important to note that no

abrasive cleaners or cleaning agents

containing solvents other than those

6