OTHER RISKS

IT IS FORBIDDEN to use the washing gun for the spraying of food or medical products

IT IS FORBIDDEN to use the pistol in areas where machines ry such as conveyor belts, robots, etc. are working

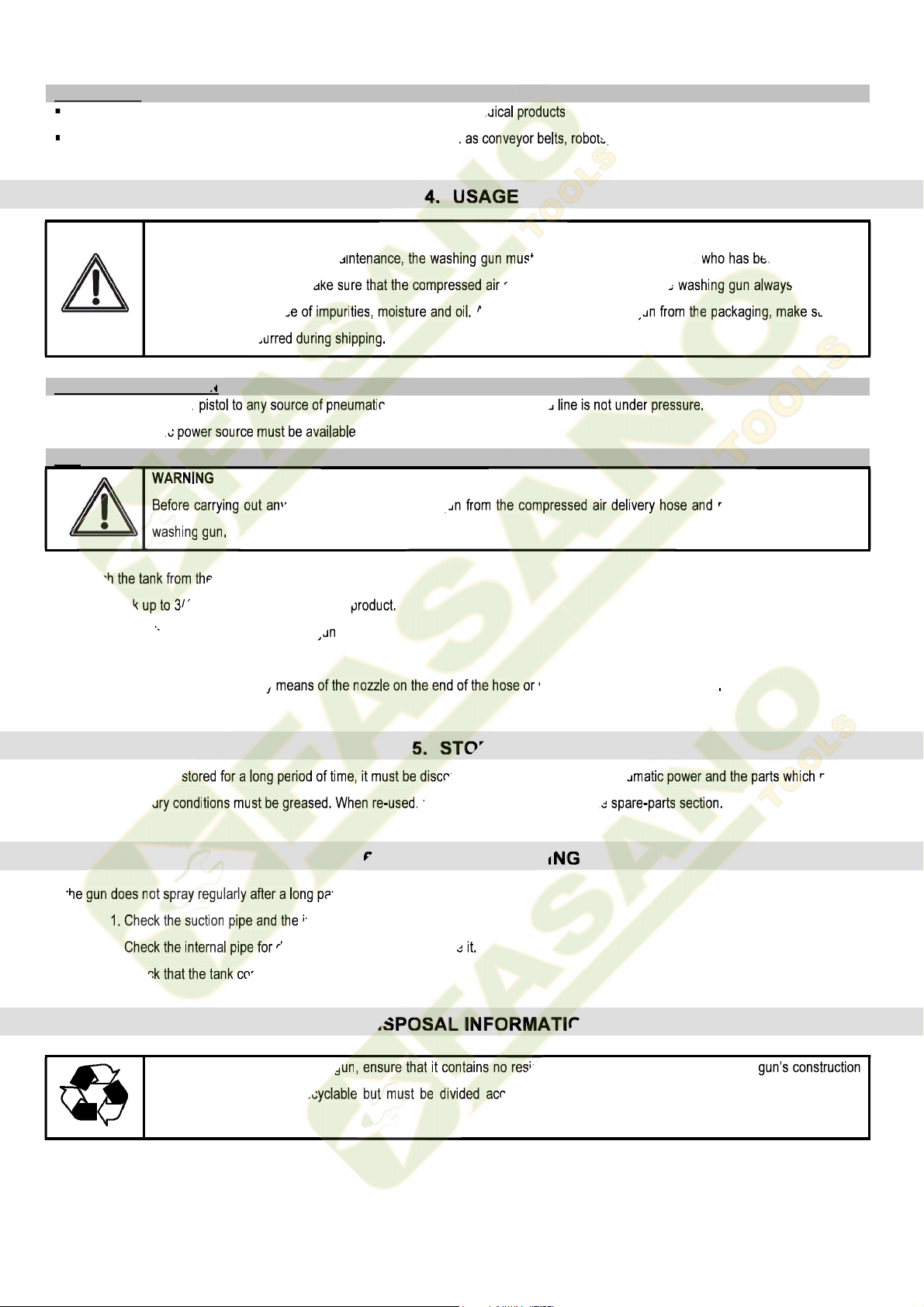

WARNING

For safe operation and correct maintenance, the washing

gun must be used only by an operator who has been provided with

the adequate preparation. Make sure that the compressed air system that supplies air to the washing

that has been filtered free of impurities, moisture and oil. After removing the washing

gun from the packaging, make sure that

no damage has occurred during shipping.

PNEUMATIC CONNECTION

Before connecting the air pistol to any source of pneumatic power make sure the air-feed line is not under pressure.

An 10-bar pneumatic power source must be available at the site of installation.

USE

WARNING

B

efore carrying out any operation, disconnect the gun from the compressed air delivery hose and release the air inside the

washing gun.

1. Detach the tank from the gun

2. Fill the tank up to 3/4 of its total capacity with the product.

3. Screw it onto the coupling mounted on the gun

4. Connect it to the air supply hose.

5. Pull the lever and adjust the gun by means of the nozzle on the end of the hose or using the side regulation control.

If the air pistol is to be stored for a long period of time, it must be dis

connected from the source of pneumatic power and the parts which may be

damaged in very dry conditions must be greased. When re-used, replace the seals indicated in the spare-parts section.

If the gun does not spray regularly after a long pause:

1. Check the suction pipe and the internal pipe for clogging.

2. Check the internal pipe for damage and if necessary replace it.

3. Check that the tank contains product.

Before dismantling the washing gun, ensure that it contains no residue of solvent or product. The washing

materials are completely recyclable but must be divided according to type and eliminated using the respective collection