6. Brush Redeposits Lint on Carpet

a. Clean machine as in steps 2 and 3 of maintenance

section. This occurs on new or plush carpets.

7. Machine Streaks Floor

a. Brushes are not overlapping on successive passes.

b. Weepholes of Solution Tank are clogged. Flush,

use a pin or remove water distributor and clean.

c. Prespray chemical before cleaning.

d. Heavy soil accumulation, run machine in crisscross

direction.

e. Replace Stripper Blade if worn.

f. Clean machine as in steps 2 and 3 of maintenance

section.

8. Machine Vibrates Or No Longer Floats On Surfaces

a. Machine is out of alignment.

b. Brushes are worn excessively and once rotated create

too much friction.

c. Brush end caps may be rounded out and worm.

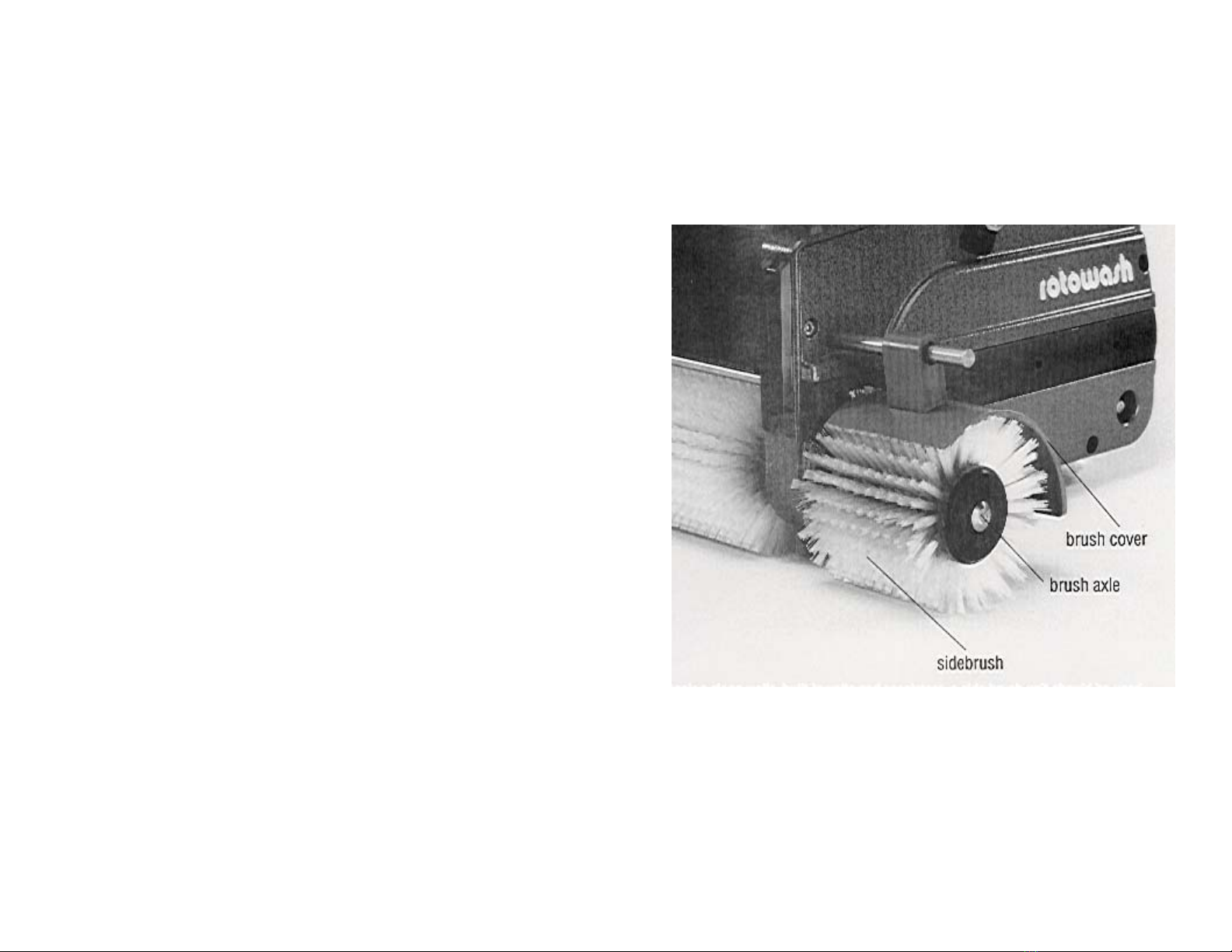

9. Axle Is Hard To Push In Or Out

a. Machine is out of alignment

b. Debris between brush and machine.

10.Tanks Are Hard To Get In And Out

a. Machine is out of square.

11.Wheels Will Not Retract

a. Lever-part is bent, usually occurs by dropping mach-

ine on wheels.

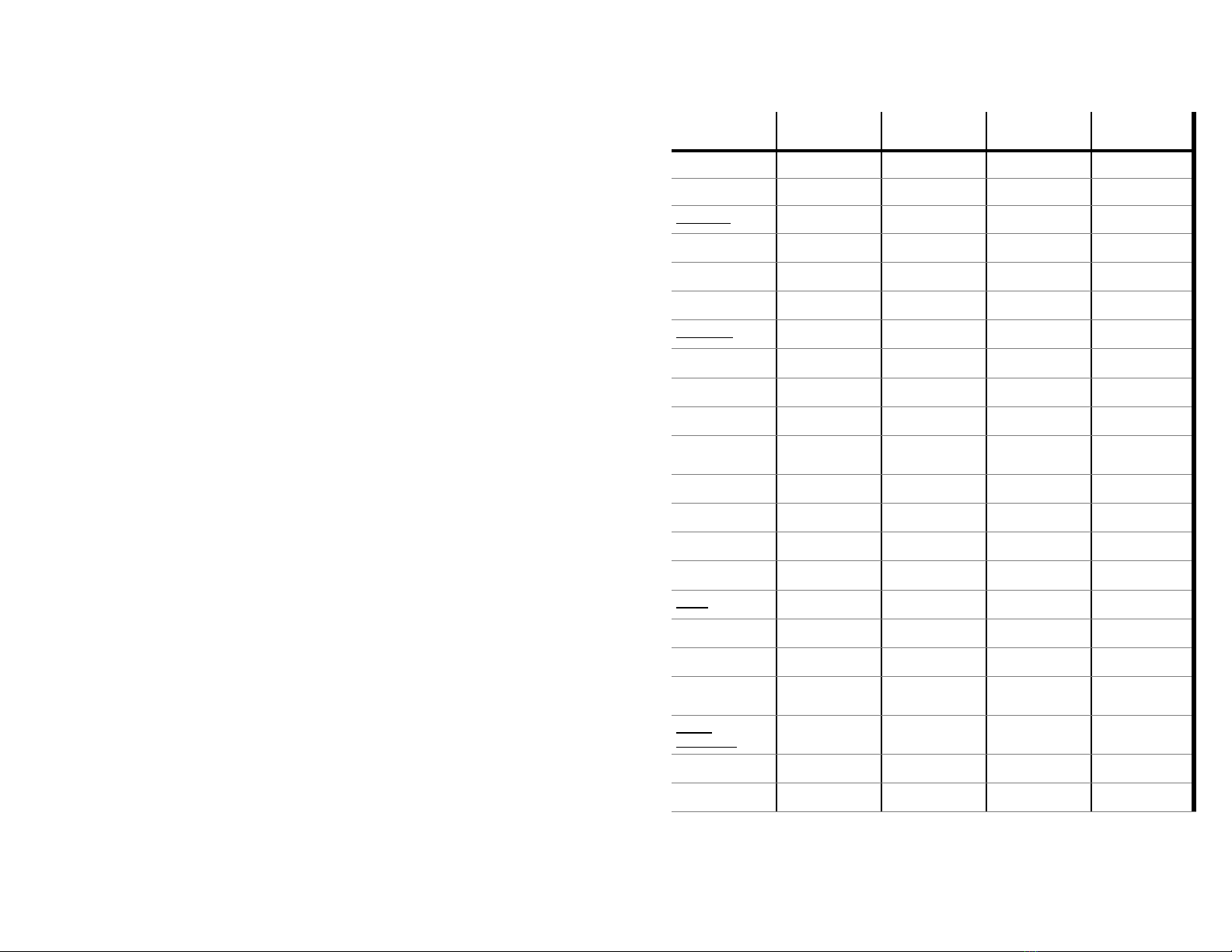

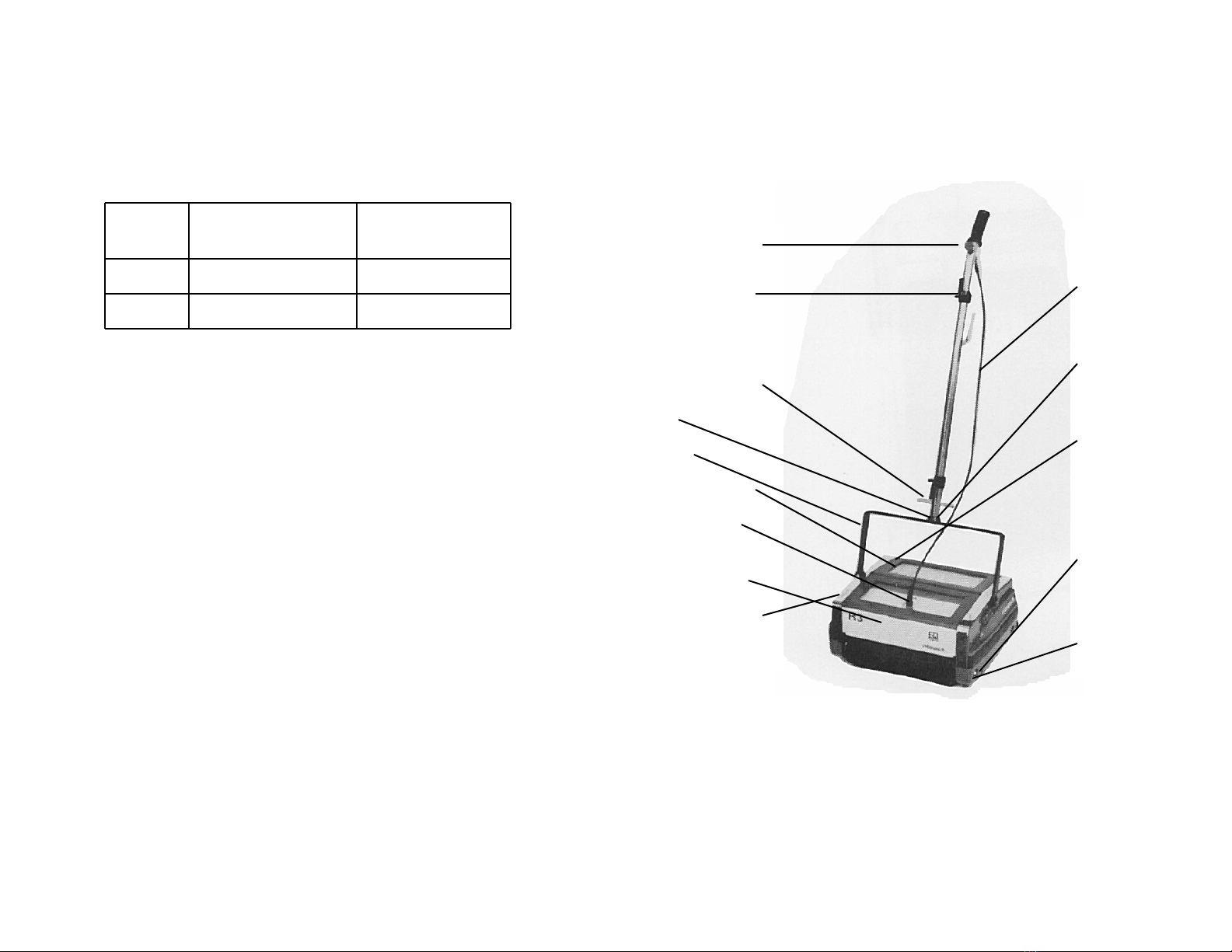

ROTO WASH SPECIFICATIONS

Dimensions

Model Weight Width Depth Height Brush Width

R3 45 lbs. 16” 12” 9” 11”

R4 60 lbs. 20” 12” 9” 15”

Length of handle & fork: 38”. Handle folds down

parallel with machine enabling it to clean under 9”

clearances.

Model R3: Stick Handle Model R4: Loop Handle

10

7. Depress the solution control button (R-3) or pull upward on

the Solution Control Handle (R-4) to release the cleaning

solution as needed. PLEASE NOTE: A little goes a long

way and over-saturation of the brushes is self defeating.

Solution should be fed only momentarily - not continuously.

8. When cleaning, the machine should be run so that the

cleaning paths of the brushes slightly overlap.

9. When cleaning, we recommend the area be pre-sprayed

by spraying the proper chemical on the surface using a

tank sprayer. The dirt will be activated by the chemical

prior to the brushing action. Do not use a foaming cleaner.

Use rinse water in the solution tank, to reduce residue.

10.When cleaning carpets and a rinse is required, follow Step 9.

The solution tank should only be filled with clear water to

facilitate proper rinsing.

11.If the electric cable or anything else should get caught in

the brushes by accident, stop the machine immediately.

This is done by pushing the handle forward to its off

position. Disconnect power cord. Remove the obstruction.

If the machine will not start again, push the Overload

Button located just below the cable until it clicks.

Hint: A pen or small object may be needed to push it

in far enough.

12.When the Recovery Tank is near full, shut the machine off. Lift

the rear cover of the container, remove the tray and empty.

13.Do not use machine for wet pick up where liquid level

exceeds 1/8” or in flood type conditions.

14.Remove liquid from the Solution Tank only if Solution

Release Cable is in place, otherwise leakage will occur.

15.A spring loaded pin, located in the lid, compresses as the

lid is removed and holds the lid firmly in place after lid

installation.

16.The Roto Wash can be moved over short distances using

the wheels on the machine. This can be done by placing

the handle in a vertical position, lifting straight up on the handle

7