Fast Flow Pumps Fast Flow 3 User manual

Revision 5—03/01/2021

2

FF-3D-SM C E N T R I F U G A L S U B M E R S I B L E H Y D R A U L I C P U M P

Operation and Maintenance Manual

Fast Flow Pumps LLC

9700 Highway 63

Moss Point, MS 39562

Phone 228) 475-2468 • Web fastflowpump.com

Manual: FF-3D-SM Language: English Revision: 4

3

!"#$%&!%&!

Safety Informaon ........................................................................................................................... 4

Descripon ....................................................................................................................................... 5

Technica Data ............................................................................................................... 5

Patent Informaon ......................................................................................................... 5

Insta aon ....................................................................................................................................... 6

Unpacking and Hose Insta aon .................................................................................... 6

Hydrau ic Power Unit Insta aon & Pump Connecon ................................................. 7

Hydrau ic Connecons……………………………………………………………………………………………….8

Pump Tesng Procedures .............................................................................................. 9

Shutdown and Disassemb y ........................................................................................................... 10

Exp oded View Diagrams ............................................................................................................... 11

Major Pump Parts ........................................................................................................ 11

Torque Spec Sheet ....................................................................................................... 12

Impe er Remova and Rep acement .............................................................................................. 13

Troub eshoong ............................................................................................................................. 14

Warranty ........................................................................................................................................ 15

4

•Read and fami iarize yourse f with both the FF-3D-SM Manua and the HPU’( 0=%(

!( && > :: )!(?.@,;".(6(0(

(A

8B ))6() %( (&%%% >&>&

8 >( %&>)%&( ( %(

%&

8( 0 &%4$((( 0 &0> (&

( 5(&%(

84&4# 0&0 & : (&( 5(

&%(

84$((0 )((% >&(()0

2& (

8C0 )"D ( &(0E)0

87 F%(>( F%6((0& )%(>&%>&

)%E(&(

84$(( >( &0( $)>%)&(&%&%

%"

8CGC &&() (

8CGC) %) %(H6( %0&&%

&((5(

8CGC()(%((

8CGC F(00 (0&(

8CGC0&

8B )&&( (0%

$"'&

((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((

((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((

((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((

((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((

((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((

&( :: )!(& ::;;4(00 (>&(

)5(&((&0:: )!(&'&( 4(&

!('&&((() 6(( &(&( &

&( )(

(&;&( 0 &&%) & &&(

(6(&(0 ((&%((0& > %

( &%:: ) $)(% (& &

::(& 0)(%>(%>0% %>

&)%>&)&) (% (& &! ((

(&& (&%(! &( (% 0(%

(

:: )!(&0#!G">/>.>G,>>>G.>>>G>.>./

&#!C!!&%>1(#!>&& (&!

+

"

I%(> %(% )%(&J

)

8&& 9( )( () ( 2

&)>()(

8(&&&%( 0 >$>&>%05>

&%&&

8+$&% =>$(( % &&&(

&(0 $&% $AK%1(&( ( %

( %&

81((>( ( &0( $)%)&

&%

*+

81(()$% &&()&6(&

%&$%

8 %&$%

8+( ( &&0>&( )(>&&(

((

81( $% 0&((%&

81(&( &( %0 $%>0&%&>&

8+:: )!(&&0

&%&>&>

8+)(;(A>)(%L(

(( &0&& 9&()

8:( %)%( %

81(E)&'&( : )( &0( $))&&%

,

,*-*.

8: ))%$&( $'!#>) &%(

81('!#E);M!4?;,/H!4@N;!?;"I@&$(

%(0)!!?;"I@ (

.!

81(%(&2&!?,I@

8+$( >$(&0&

8B )&&( 0%(

+//0

120!/3

*0

/

8+'!#(>(%0 )&%

8()(&(>&0&2%

8+ F%$ ::HF%%>&( )(E(&0%(&

'& %(0&( ( %(6(&%

/

4

.

5

"

5&

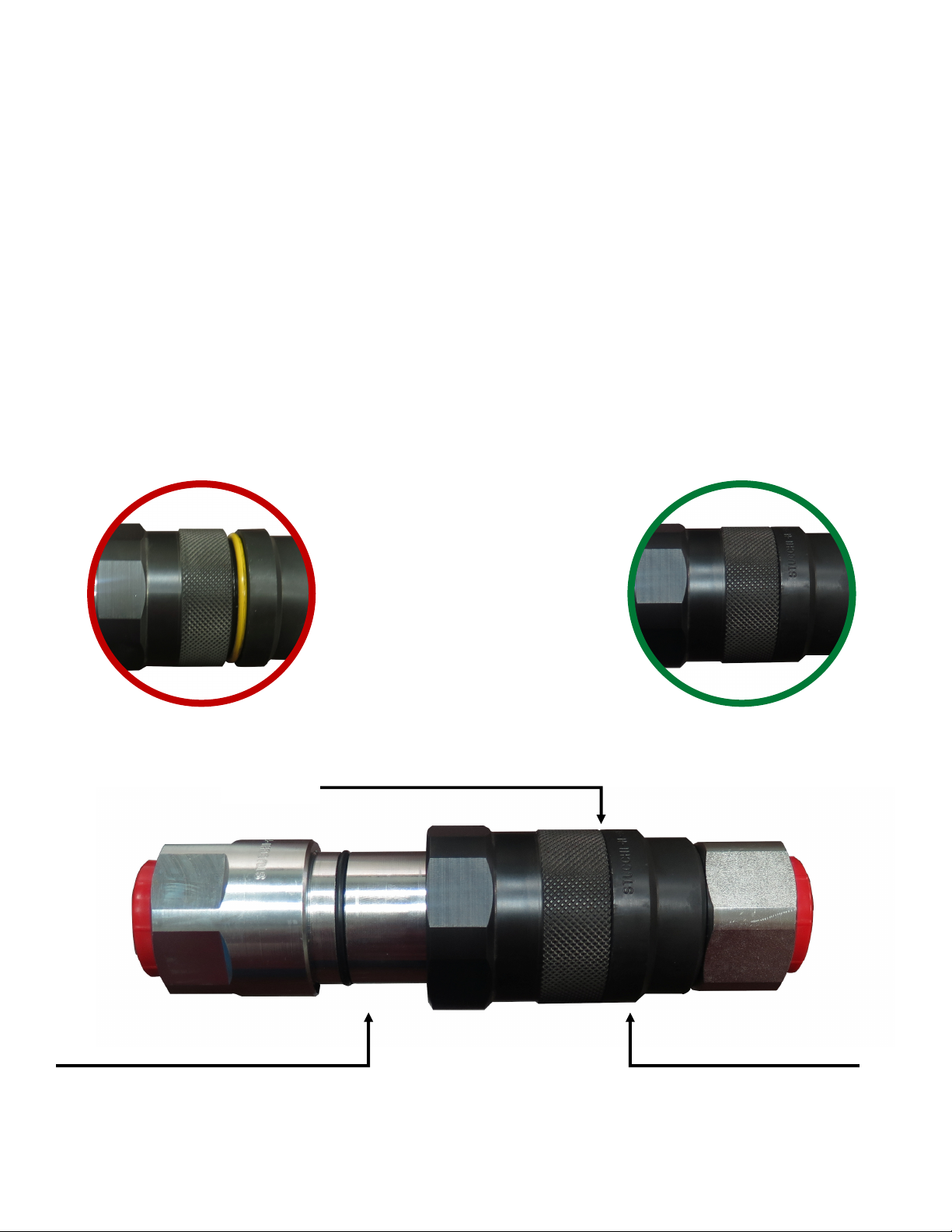

Incorrect Coupling—O-Ring Exposed Correct Coupling— Metal to Metal Contact

C ean the mang surface of the coup ings to avoid contaminang the circuit.

2. Pu the connecon s eeve of the fema e coup ing forward

3. A ign the fema e and ma e coup ing ho ding the connecon s eeve and thread together and turning the

s eeve.

4. Keep coup ers a igned during connecon process. Do not push the coup ings together.

5. Screw the connecng s eeve of the fema e un meta surface contact with the ma e coup ing is comp ete,

the ye ow O-ring shou d be concea ed.

6. To disconnect turn the s eeve from the contact posion using a wrench, then unscrew making sure the

coup ings stay a igned through the enre process.

6)7///0

9

!

4!

::;;40 (%2&&&>&0(

&0(%(>A&(0 $ &( ( %(

%&>&( &(::;;4(&)%&;

(( B )(&0 F(%)(

&%

/3+/

*3*/+

6"4&&89!/3**:/

//0

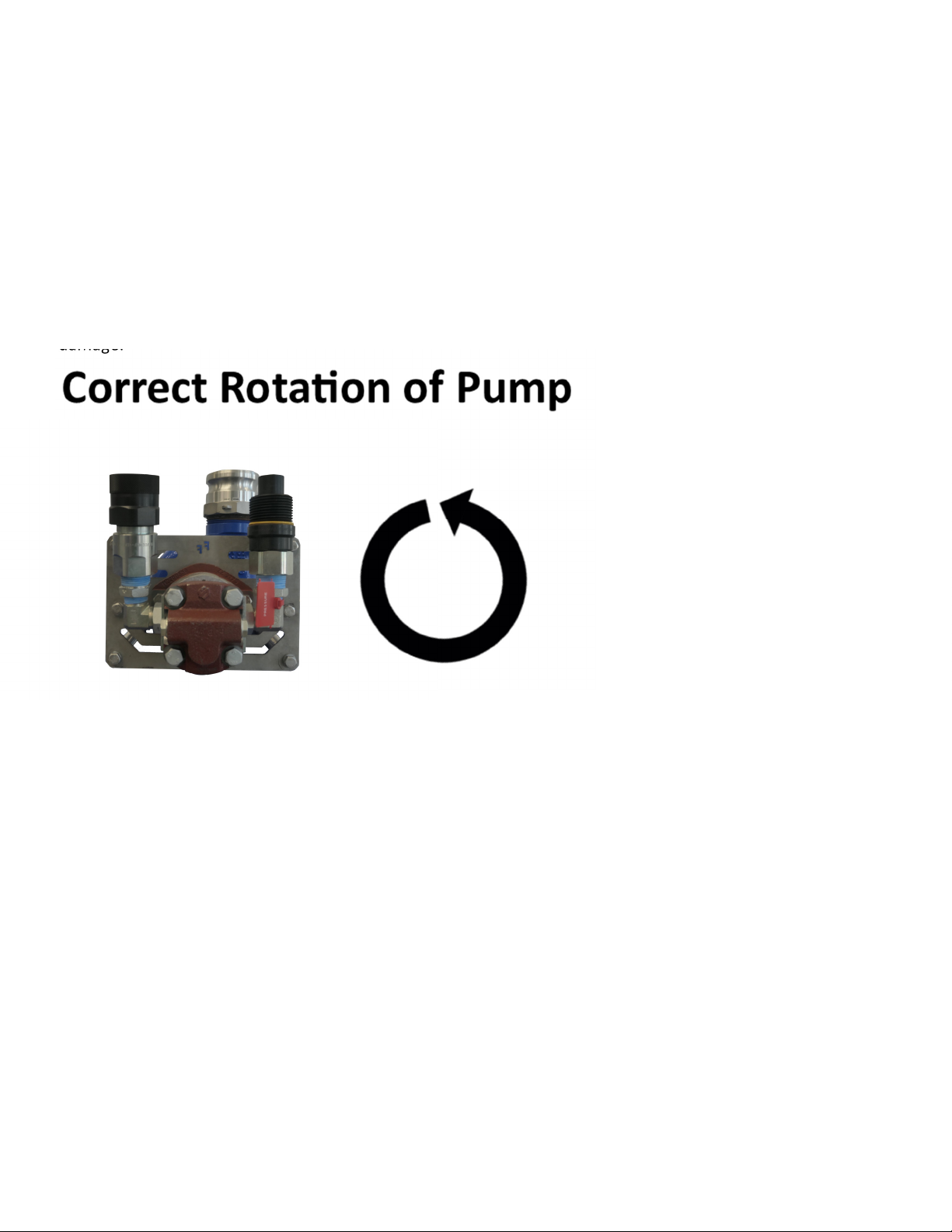

A ways dry run spin test pump before p acing pump into pit. Do not skip this test. That wi eak test the

enre hydrau ic system, verify impe er direcon, and funcon test the hydrau ic motor.

Use on y screw together drip ess hydrau ic coup ings

A hydrau ic coup ings must be fu y ghtened.

Check hydrau ic tank oi eve

Check hydrau ic fi ter and c ear fluid co or

Check engine oi and fue eve s

Leak check hydrau ic hose and coup ings for damage

Inspect hydrau ic ines for cuts, jacket abrasion.

10

/

/

8 ) (&))(>%%E(&E)(&& (&%(&

%:////0!/

;;0410

81( %

8(&)'!#&($)L

8! (&E(

81(&&( (

8&( ( (

8+ &( (00 (F(

8B&&( E(&> &( %( &0

%<=5$

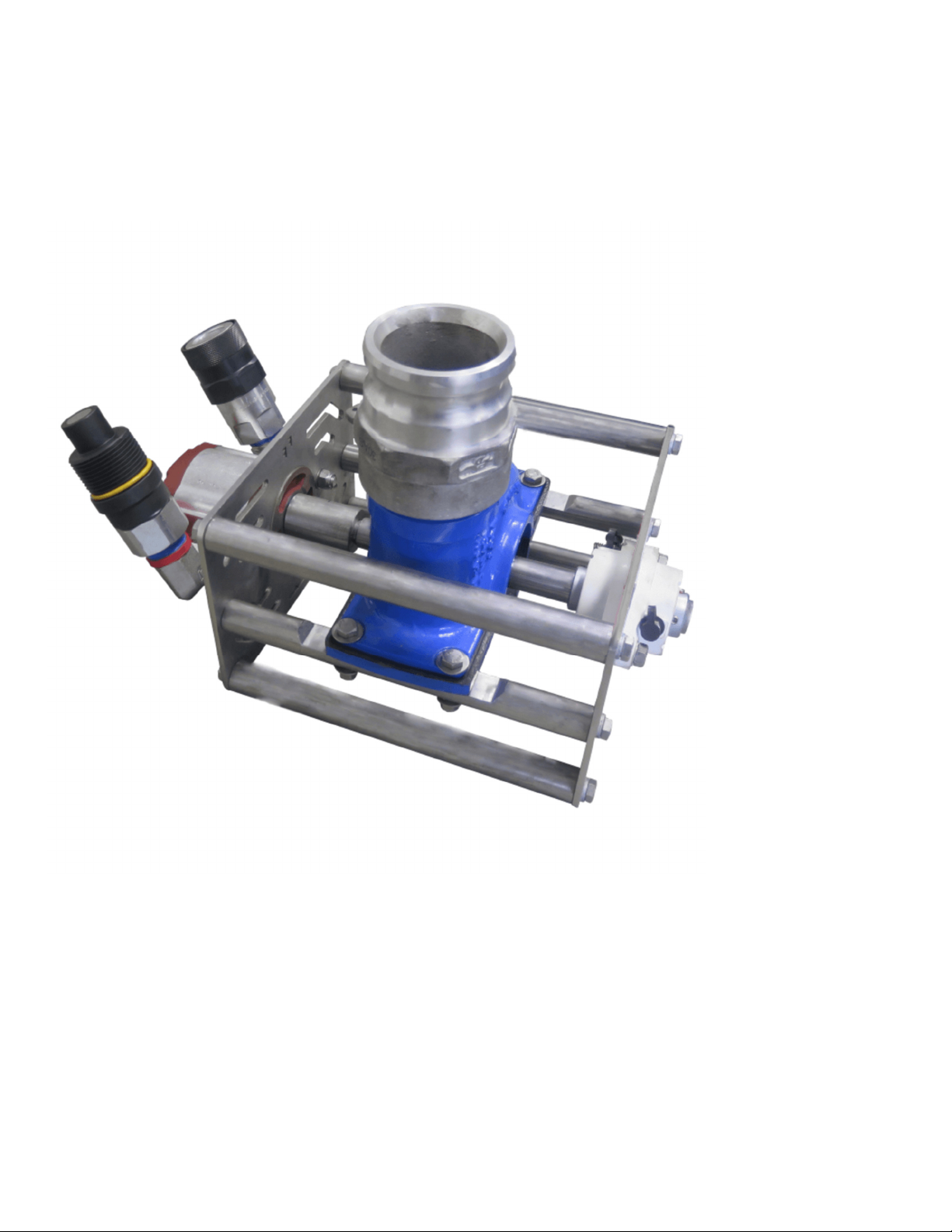

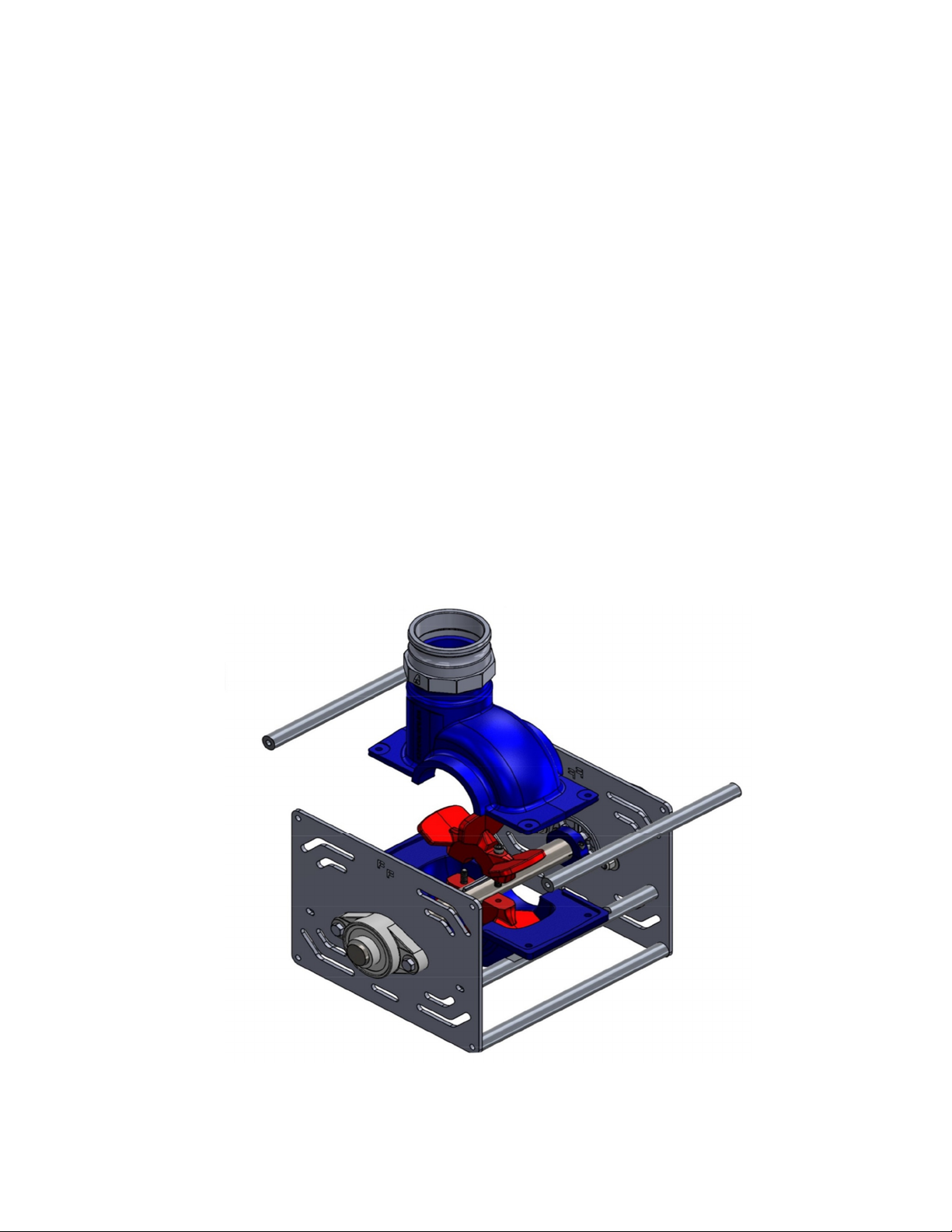

Description Part No. Qty

1. Motor Plate MP-3D-SS 1

2. Bearing Plate BP-3D-SS 1

3. Upper Volute Casting VU-3D 1

4. Lower Volute Casting VL-3D 1

. Impeller IM-3D-10 1

6. Shaft Coupling CC-3D-SS 1

7. Frame Bar FB-3D-SS 4

8. Mount Bar MB-3D-SS 2

9. Drive Shaft DS-3D-SS 1

10. Driving Motor MTR001 1

11. 1" Male VEP Hyd Coupling HPU087 1

Description Part No. Qty

12. 1" Female VEP Hyd Coupling HD HPU089 1

13. 3/4" Male O-Ring Boss x 3/4" Male Pipe 90° ADP086 2

14. Camlock CAM003 1

1 . Bearing TB-3D-10 2

Not Shown

16. Serial Tag TAG001 1

17. Keystock MK-3D-SS 1

18. Keystock IK-3D-SS 1

19. 1” Male Pipe x 3/4” Female Pipe ADP117 2

20. Red Pressure Tag 6-CRE 1

2

>

?

@

A

B

C

D

E

F

G

H

I

J

K

D

D

D

E

K

J

&

33 3

!1/5$

Description Qty Torque Specs Anti-Seize Loctite Primer

1. 3/8"-16 1" (SS) HCS [He Head Bolt] 12 17 ft-lb/23 Nm

2. 3/8" 7/8" O.D. Flatwasher (SS) 8Not Applicable

3. 3/8”-16 2” (SS) HCS [He Head Bolt] 417 ft-lb/23 Nm

4. 3/8”-16 Nylon Locknut (SS) 4Not Applicable

5. 5/16”-18 1 3/4” (SS) SHCS [Socket Head Cap] 210 ft-lb/13 Nm

6. 5/16” Nordlock Washers 2Not Applicable

7. 3/8” Nordlock Washers 12 Not Applicable

8. 7/16”-14 1 1/2” (SS) HCS [He Head Bolt] 228 ft-lb/37 Nm

9. 7/16”-14 2” (SS) HCS [He Head Cap] 228 ft-lb/37 Nm

10. 7/16” 15/16” O.D. Flatwasher (SS) 6Not Applicable

11. 7/16”-14 Nylon Locknut (SS) 4Not Applicable

Part No.

HDW113

HDW065

HDW026

HDW077

HDW100

HDW073

HDW063

HDW098

HDW103

HDW066

HDW090

12. 1/4”-28 3/4” (SS) SHCS [Socket Head Screw Cap] HDW127 4Not Applicable

H:,"/

$+H

4!/$+

Hardware List

>

@

G

B

E

4

L0 (&

M04$&( (&(

0LE(&0%(&&

N0! (& &E()&6()$%

O0)(0

P0(0 (*(

Q00 P

!;;';0"R

:///0//;/

/0!/1//3

10/+/1

0

//0

!/

4

! L0 &/S0

M0 #/

/

0 2

N0

O0 /R/

0

L0!/

S;

/S0

M0/

//:+

/0/S5

7/0

04;/;0!/

:::0

N04

O0/++0

$4

L0 S;0

M0 /S

S0

0 20

N0 //

O0

P0

Q0 0

L0 +/

:O0

M0!/

S;

/S0

0/+

;04;/

;0

N0*//

S

O04:

+0

P0/

/+/

'/0

Q0:+:

#+

L0 4 L0/+/0

M0T//

6

Warranty for Submersible Pumps, Fast Flow Pumps warrants to the original purchaser only that this

product is free from defects in material and workmanship, and agrees to repair or replace, at Fast Flow’s

option, any submersible pump part found to be defective within 12 months from the date of purchase. This

warranty is not transferable. This warranty does not cover damages resulting from shipping damage,

improper installation, lack of service, incorrect power, or faulty severe service applications such as pumping

abrasives, rocks, corrosives, or fluids in e cess of 160°F. Warranty coverage is normally not available for

wear parts such as: Pump Volutes, Impellers, drive shaft, and hydraulic motor seals. Any modification or

alteration of this equipment will void the warranty. Any claim for warranty damage must include photos of

the defective part or parts, the serial number from the equipment, and a detailed description of the defect

and possible causes. All warranty claims should be emailed to www.fastflowpump.com or mailed to our

Moss Point MS address.

Submersible Pumps judged by Fast Flow Pumps to have been defective in workmanship or materials when

shipped from the factory and within the warranty period will be either repaired or replaced at option free of

charge e cluding motor freight both ways, within the continental United States.

Fast Flow LLC Limited Warranty for Hydraulic Power Units. Fast Flow Pump warrants to the original

purchaser that this product is free from defects in material and workmanship, and agrees to repair or

replace, at our option, any part found to be defective within 12 months or 500 hours of use (whichever

comes first) from the date of purchase. This warranty is not transferable. This warranty does not cover

damages resulting from normal wear, abuse, careless handling, lack of service / proper preventatives

mainentance, improper fueling, improper application, and improper operation. Warranty coverage is not

normally applied for items such as: Tires, belts, hoses, (fuel, oil, hydraulic oil) filters, batteries, and paint.

Fast Flow LLC does not warranty engines – warranty claims for engines must be handled through the

engine distributor. Any modification or alteration of this equipment will void the warranty. Any claim for

warranty damage must be accompanied by digital photos of the defective part or parts, the serial number

from the equipment, and a detailed description of the defect and possible causes.

All warranty claims should contact Fast Flow Pumps at 9700 Hwy 63, Moss Point, MS 39562. Power Units

judged by Fast Flow Pumps to have been defective in workmanship or materials when shipped from the

factory and within the warranty period, will be either repaired or replaced at the discretion of Fast Flow

Pumps free of charge e cluding motor freight both ways.

Fast Flow Pumps shall not be liable for any damages, including consequential damages arising out of any

breach of warranty and whether or not arising out of or based on Fast Flow’s negligence, whether actual or

implied, and for damages to any property or person arising out of the purchase or the use, operation or

maintenance of the equipment. Fast Flow shall not be responsible for repairs or alterations made by

others. No person is authorized to make any representations or warranties on behalf of Fast Flow Pumps

and no other person is authorized to alter or e tend any of the conditions contained in this warranty.

Table of contents

Popular Water Pump manuals by other brands

March Pumps

March Pumps 893-06 Safety Instructions & Preventive Maintenance

Grundfos

Grundfos UPM3 manual

Larzep

Larzep HEP0020 INSTRUCTIONS & MAINTENANCE SHEET

BLACKMER

BLACKMER TRANSMAX TX206A Installation, operation and maintenance instructions

Intex

Intex Quick-Fill 58609 operating instructions

ARO

ARO PP10A-XXX-XXX-A Series Operator's manual