Teikoku USA | Chempump Instruction Manual HE-12270 (1219)7

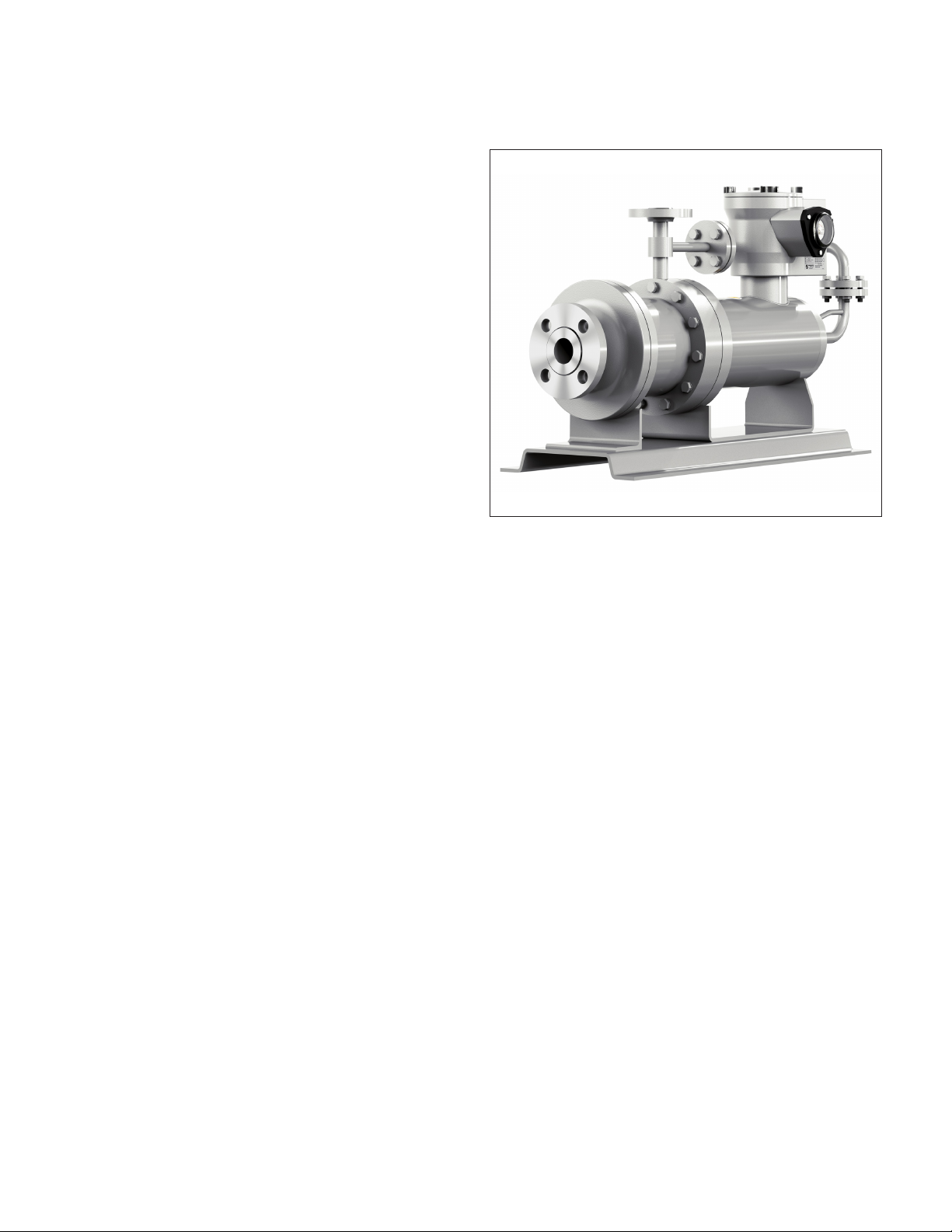

The Type-F (Plan 1-SD) pressurized circulation ALP multi-stage

pump is a precision built unit that with proper operation and

maintenance will provide years of trouble-free, leakproof ser-

vice. The entire unit is mounted on a fabricated steel base cradle.

Operation is unaffected by the mounting or operating position,

eliminating the need for any costly alignment procedures.

1.2 Stator Assembly

The stator assembly consists of a set of three-phase windings

designed for use with Pulse Width Modulated (PWM) Variable

Frequency Drive (VFD) power for 50 HZ to 120 HZ operation. Sta-

tor laminations are of low-silicon grade steel. Laminations and

windings are mounted inside the cylindrical stator band. End

bells, welded to the stator band, close off the ends of the stator

assembly. The stator liner is, in effect, a cylindrical can placed in

the stator bore and welded to the rear end bell and front end bell

to hermetically seal off the windings from contact with the liquid

being pumped.

Terminal leads from the windings are brought into an electrical

terminal box. Motor lead wires are isolated from the users’ con-

duit line by a leakproof terminal plate assembly mounted inside

the terminal box. The design of the stator assembly in conjunction

with the leakproof terminal plate assembly provides an advanced

low probabilty true positive secondary containment.

1.3 Rotor Assembly

The rotor assembly is a squirrel cage induction rotor constructed

and machined for use in the Type-F (Plan 1-SD) pressurized

circulation ALP multi-stage pump. It consists of a machined

corrosion-resistant shaft, laminated core with cast aluminum bars

and end rings, corrosion-resistant end covers, and a corrosion-

resistant can.

The rotor end covers are welded to the shaft and also to the

rotor can which surrounds the outside of the rotor, thus

hermetically sealing off the rotor core from contact with the liquid

being pumped.

The impellers are keyed to the shaft and held in place with a lock

bolt and lock washer. The shaft is fitted with replaceable shaft

sleeves and thrust collars. These parts are pinned or keyed to pre-

vent rotation. Axial movement is restricted by the thrust collars

contacting the face of the front and rear motor bearings.

1.4 Liquid Film Journal Bearings

The liquid film journal bearings for the Type-F (Plan 1-SD) pres-

surized circulation ALP multi-stage pump are carbon graphite as

standard and are machined with special helix grooves through

the bore to assure adequate liquid circulation at the journal area.

Each liquid film journal bearing is manufactured to close toler-

ances for a high degree of concentricity and is held in a bearing

housing by a retaining screw. Liquid film journal bearings are eas-

ily replaced by removing the retaining screw and sliding the bear-

ing from its housing.

1.5 Thrust Collars and Shaft Sleeves

All Type-F (Plan 1-SD) pressurized circulation ALP multi-stage

pump models are equipped with thrust collars, providing a re-

placeable surface against which axial loads can be carried during

process upset conditions. The shaft is also fitted with replaceable

shaft sleeves. Both the thrust collars and shaft sleeves are con-

structed of 316SS with a Stellite wear surface for long life. These

parts are pinned or keyed to prevent rotation.

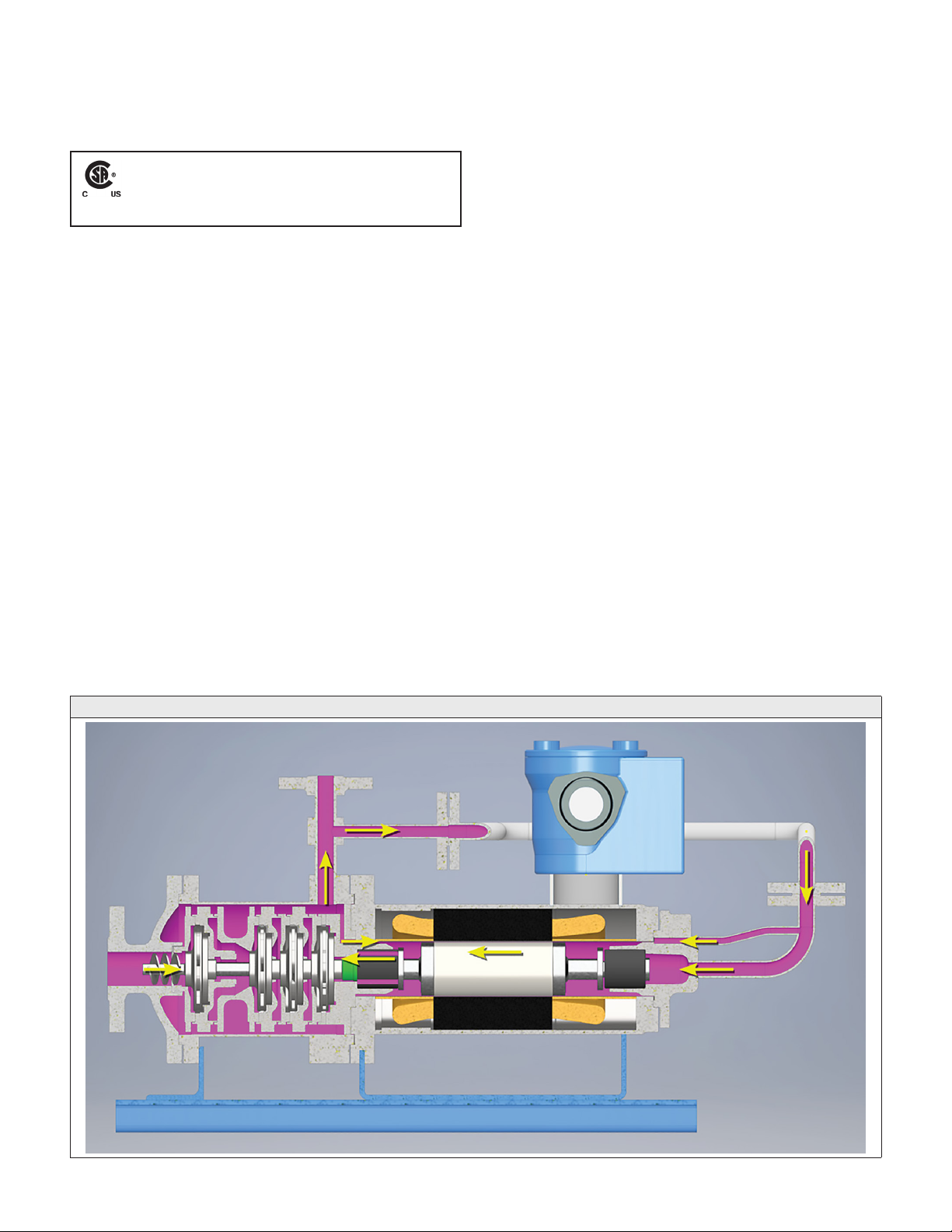

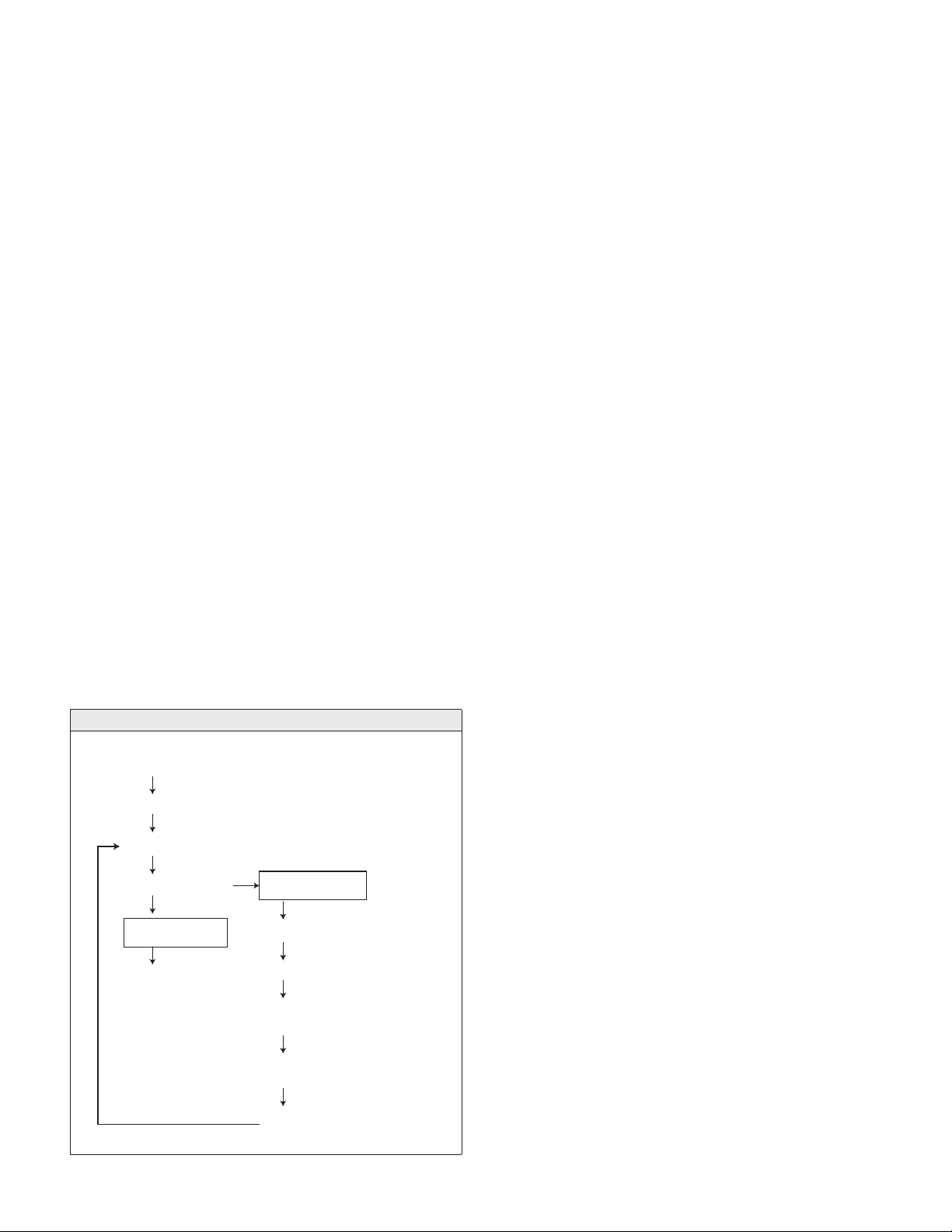

1.6 Internal Cooling Flow

Flow paths of the Type-F (Plan 1-SD) pressurized circulation ALP

multi-stage pumps are shown in Figure 1-1 and Figure 1-2. The

circulating liquid is channeled into the motor section by the cir-

culation pipe connected to the discharge flange. The circulating

liquid lubricates the rear liquid film journal bearing, passes over

the rotor core cooling the motor, lubricates the front liquid film

journal bearing and then returns to the main flow at the inlet of

the final stage impeller. The flow rate is controlled by a restriction

orifice mounted in the circulation pipe.

1.7 Automatic Thrust Balance

Based on hydraulic principles, Type-F (Plan 1-SD) pressurized circu-

lation ALP multi-stage pump automatic thrust balance is accom-

plished by the pressure of the pumped liquid itself, operating in a

balance chamber at the front and rear of the impeller.

When a change in load shifts the position of the impeller away

from the balance condition, there is an equalizing change of hy-

draulic pressure in the balance chamber, which immediately re-

turns the impeller-rotor assembly to the balanced position.

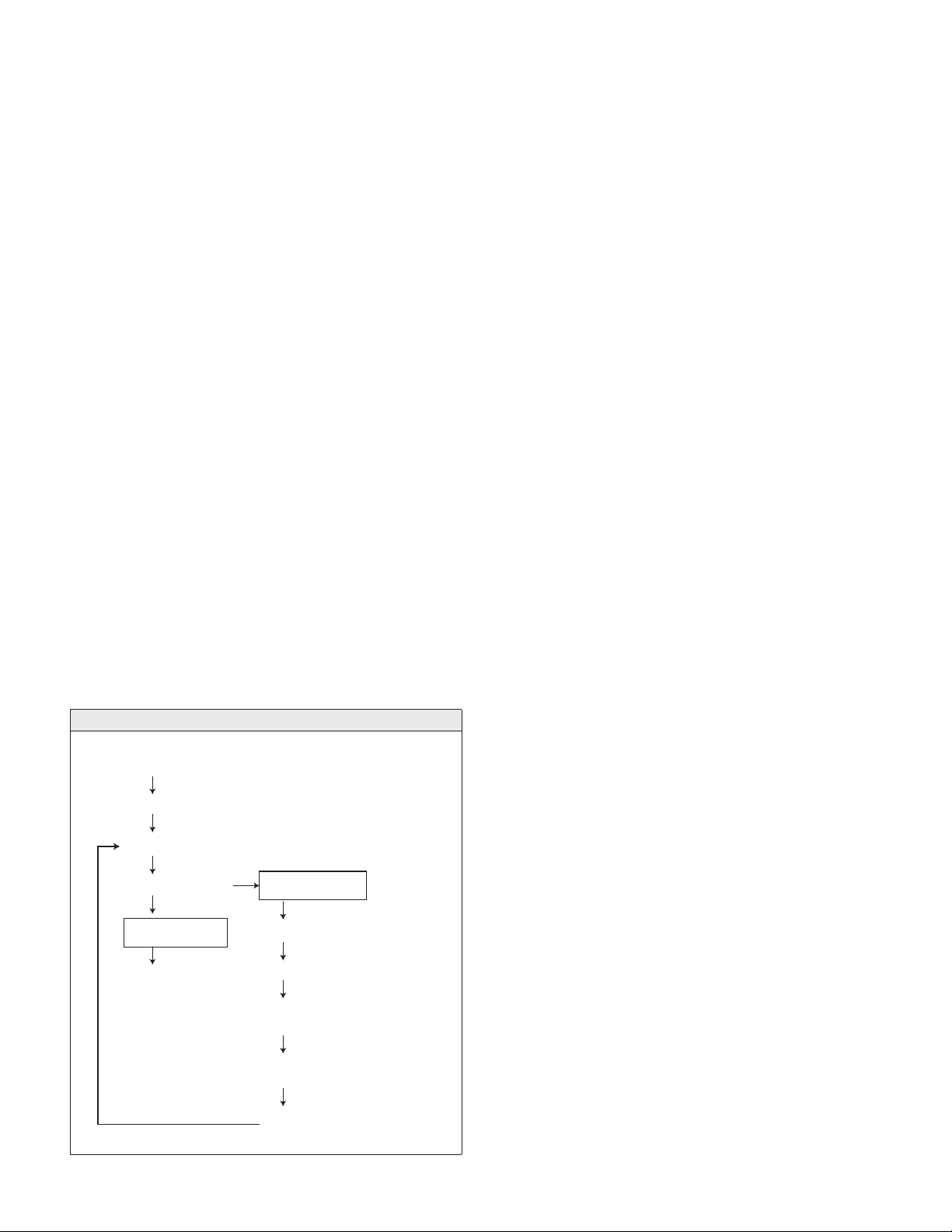

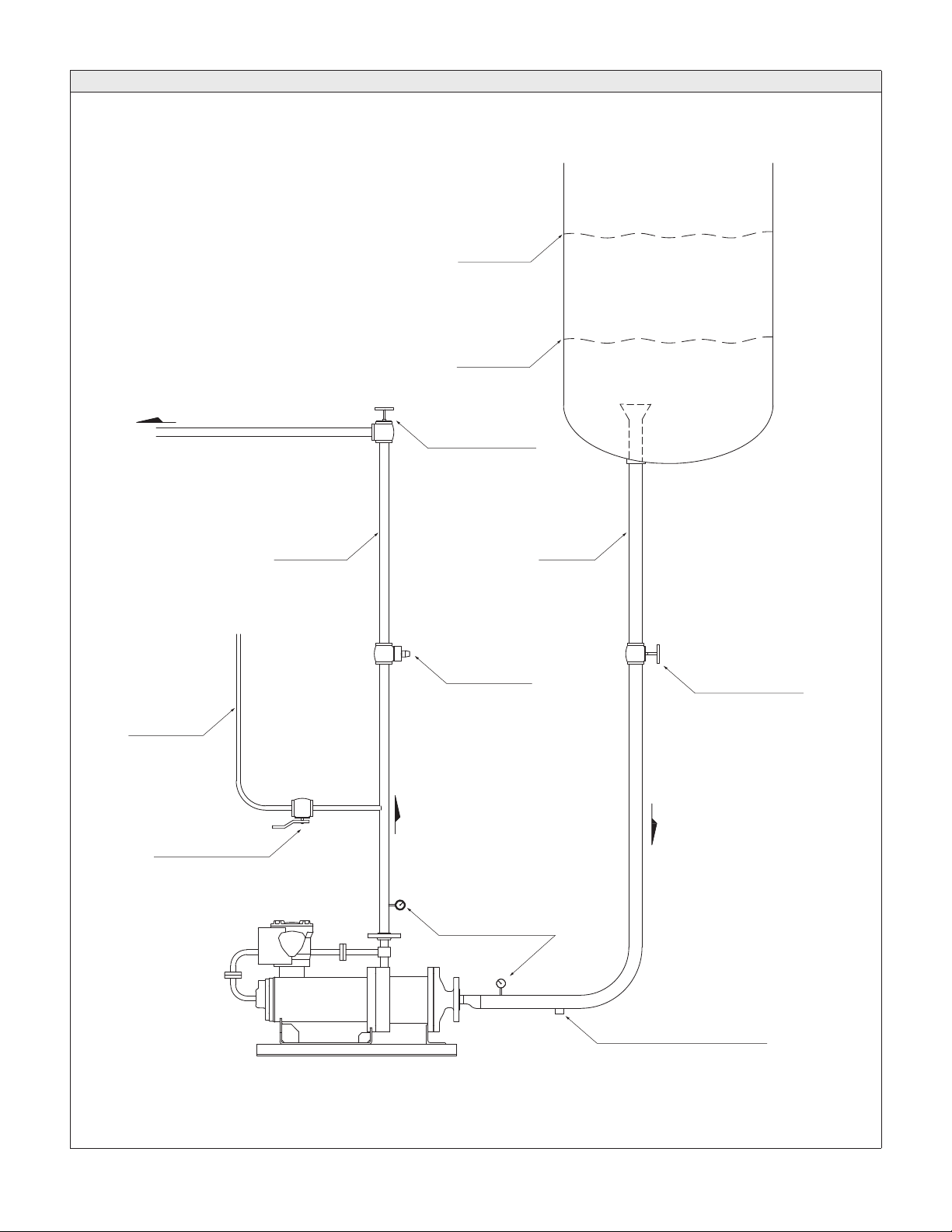

1.8 ALP Pump NH3Transfer System Requirements

Figure 1-3 shows a typical anhydrous ammonia transfer system

setup to support a Type-F (Plan 1-SD) pressurized circulation ALP

multi-stage pump for installation, commissioning and operation.

Figure 1-2. Flow Path

Casing Cover inlet

First Stage Impeller

Final Stage Impeller

Pipe Casing Outlet Circulation Flow

Circulation Pipe

Rear Bearing Housing

Gap between Rear Bearing

and Rear Shaft Sleeve

Gap between Stator Can

and Rotor Can

Gap between Front Bearing

and Front Shaft Sleeve

Main Flow

To the Process Line