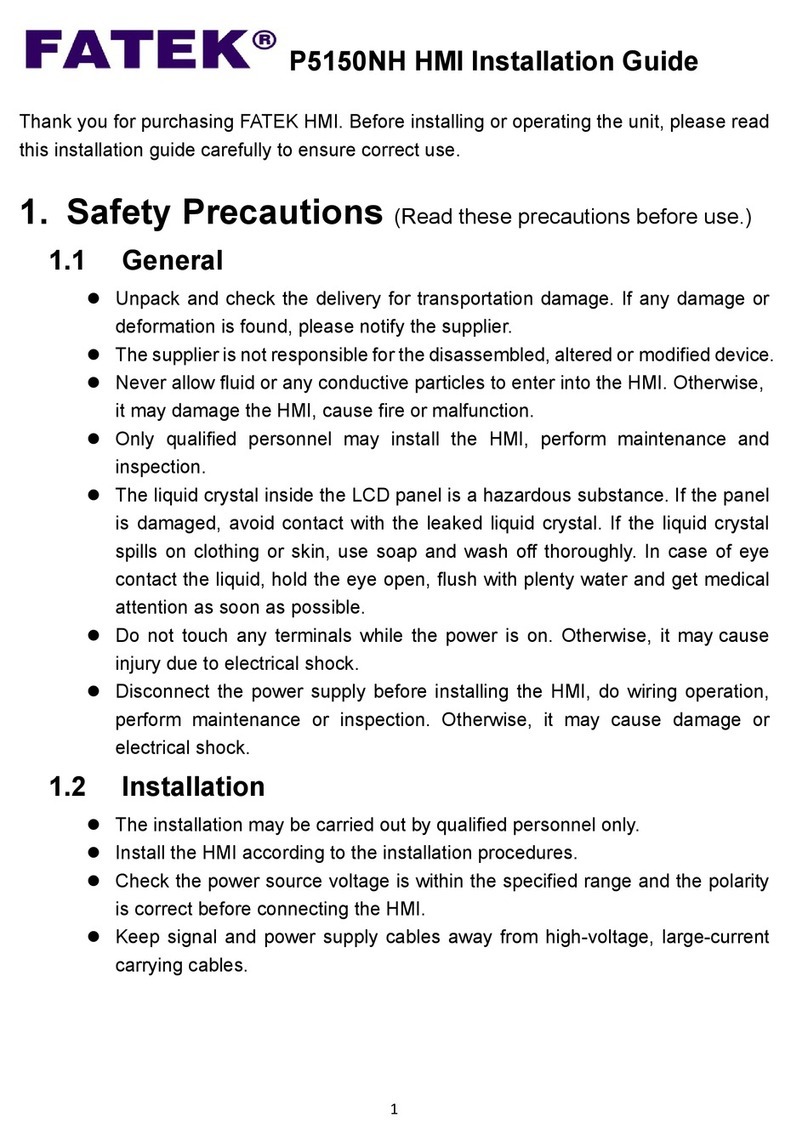

FATEK P5 Series Instruction manual

1

P5Series

2

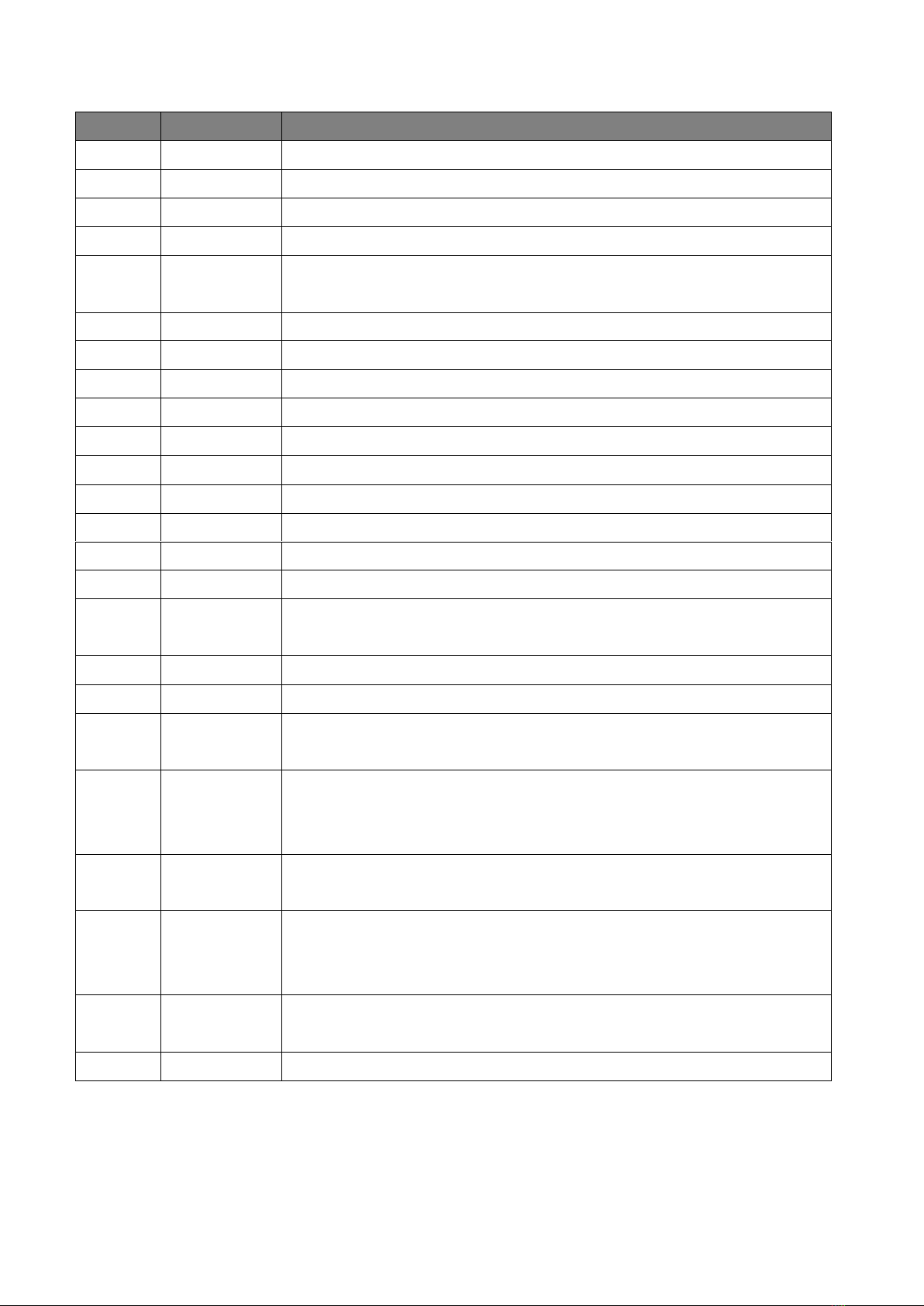

Version

Date

Modification

V1.0.0

July 15,2015

First Draft

V1.0.1

July 16,2015

Update HMI Model Information (43 & C series)

V1.0.2

July 16,2015

Update Hitachi and Schneider

V1.0.3

July 17,2015

Add Siemens S7-1200 and fix maximum value of bitsInBytedeivce

V1.0.4

July 20,2015

Fix P5043 series

-Both Male Diagram

V1.0.5

Aug 10, 2015

Add Hitachi EHV Series( Ethernet )

V1.0.6

Sep 16, 2015

Add Allen-Bradley CompactLogix Series

V1.0.7

Dec 9, 2015

Add TAIE FY Series

V1.0.8

Dec 17, 2015

Add Delta DVP Series and AH500 series

V1.0.9

Jan 21, 2016

Add Panasonic FP Series

V1.0.10

Mar 7, 2016

Add Panasonic FP Series ( Ethernet )

V1.0.11

Mar 7, 2016

Add DB access function for SIEMENS S7 1200

V1.0.12

Apr 14, 2016

Add Mitsubishi FX5U Series

V1.0.13

Apr 28, 2016

Update Mitsubishi FX3U/FX2N driver for new type WX/WY/WM/WS

V1.0.14

May 24, 2016

Add YASKAWA Extended MEMOBUS

V1.0.15

Jun 20, 2016

Add Keyence KV-3000/5000/5500/7500 (ethernet) and

KV-L21V/3000/5000/5500

V1.0.16

Jul 6, 2016

Add Allen-Bradley SLC and MicroLogix Series

V1.0.16

Jul 15, 2016

Update KV-Nano (host link)

V1.0.17

Nov 25 2016

Add QSeries-Serial Communication, Q/L Series-ENET and

Update FBe(PLC setting)

V1.0.17

Nov 29 2016

Add Omron SYSMAC CP Series Ethernet and

Update Omron SYSMAC CP Series(PLC setting),Omron SYSMAC CS/CJ

Series(PLC setting), Omron SYSMAC CS/CJ Series Ethernet(PLC setting)

V1.0.17

Dec 2 2016

Update Siemens S7-200 SMART(PLC setting), Schneider MODBUS

RTU/TCP (PLC setting), Allen-Bradley SLC Series(PLC setting)

V1.0.17

Dec 7 2016

Update Taiwan Instrument & Control Co., Ltd FY Series(PLC setting)

Delta DVP Series(PLC setting), YASKAWA Extended MEMOBUS(PLC

setting)

V1.0.17

May 17, 2017

Add FBs/B1/B1z/HB1 (UDP), Omron SYSMAC CPM Series,

MP Series Extension (Ethernet) , Beckhoff Automation

V1.0.17

Aug 11, 2017

Add Koyo, Siemens LOGO

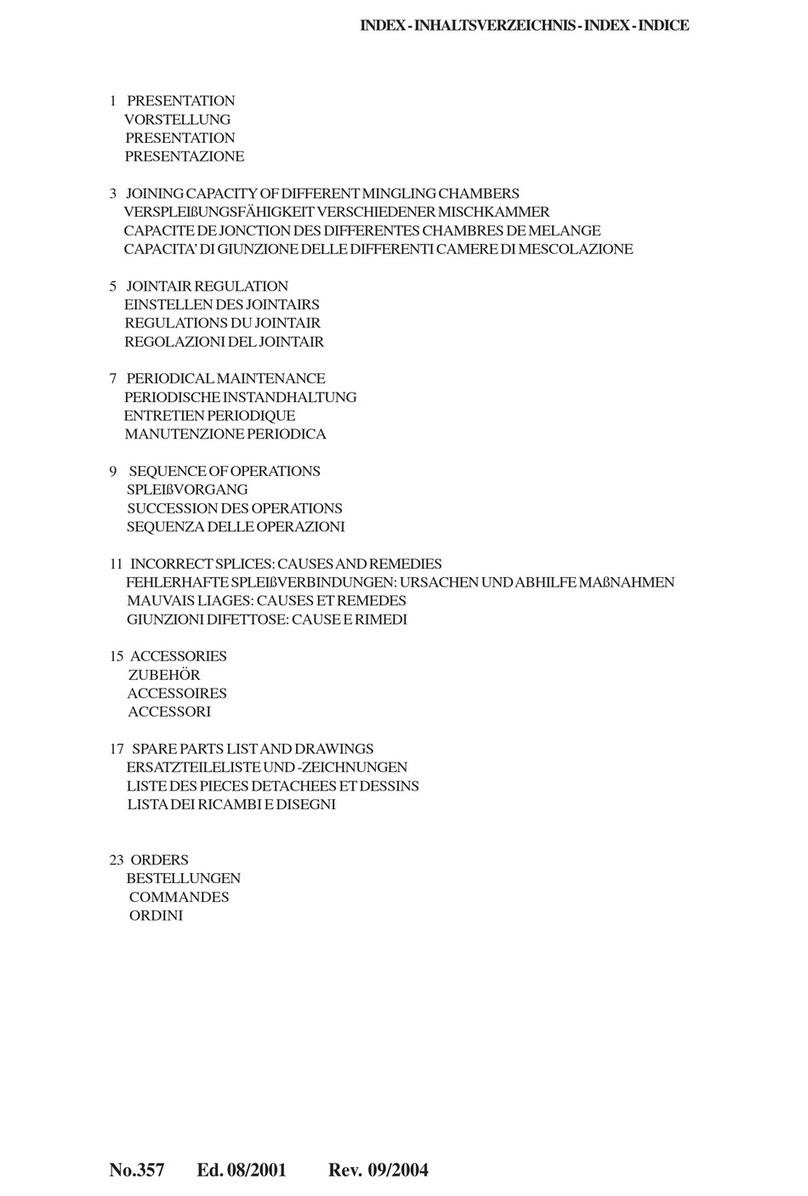

1. HMI Model Serial Information .......................................................................................................4

3

2. PLC Connection ..............................................................................................................................6

2.1 FATEK Automation Corp. ....................................................................................................6

2.1.1 FBs/B1/B1z/HB1.....................................................................................................6

2.1.2 FBe........................................................................................................................11

2.1.3 FBs/B1/B1z/HB1 (TCP) .........................................................................................17

2.1.4 FBe (TCP) ..............................................................................................................20

2.1.5 FBs/B1/B1z/HB1 (UDP) ........................................................................................22

2.2 Mitsubishi.........................................................................................................................25

2.2.1 FX2N CPU ............................................................................................................. 26

2.2.2 FX2N-485BD .........................................................................................................29

2.2.3 FX3U CPU .............................................................................................................37

2.2.4 FX3U-485BD .........................................................................................................41

2.2.5 FX3U Ethernet ......................................................................................................48

2.2.6 FX5U-Serial........................................................................................................... 54

2.2.7 FX5U Ethernet ......................................................................................................63

2.2.8 QSeries-Serial Communication(Link Port)............................................................69

2.2.9 QSeries-Serial Communication(CPU Port) ...........................................................77

2.2.10 Q/L Series-ENET ...................................................................................................82

2.3 Omron ..............................................................................................................................86

2.3.1 Omron SYSMAC CP Series ....................................................................................86

2.3.2 Omron SYSMAC CP Series Ethernet .....................................................................91

2.3.3 Omron SYSMAC CS/CJ Series ...............................................................................94

2.3.4 Omron SYSMAC CS/CJ Series Ethernet ................................................................98

2.3.5 Omron SYSMAC CPM Series...............................................................................103

2.4 Siemens..........................................................................................................................107

2.4.1 Siemens S7-200 SMART .....................................................................................107

2.4.2 Siemens S7-200 SMART Ethernet ......................................................................113

2.4.3 Siemens S7-1200 Ethernet.................................................................................118

2.4.4 Siemens S7-200..................................................................................................122

2.4.5 Siemens LOGO....................................................................................................129

2.5 Hitachi ............................................................................................................................132

2.5.1 EHV Series ..........................................................................................................132

2.5.2 EHV Series ( Ethernet ).......................................................................................135

2.6 Schneider .......................................................................................................................136

2.6.1 MODBUS RTU.....................................................................................................136

2.6.2 MODBUS TCP .....................................................................................................140

2.7 Allen-Bradley..................................................................................................................142

2.7.1 CompactLogix/ControlLogix/FlexLogix Tag Series..............................................142

4

2.7.2 SLC series (EtherNet/IP) .....................................................................................146

2.7.3 SLC Series ...........................................................................................................150

2.7.4 MicroLogix Series (EtherNet/IP).........................................................................155

2.7.5 MicroLogix Series ...............................................................................................159

2.8 Taiwan Instrument & Control Co., Ltd............................................................................164

2.8.1 FY Series .............................................................................................................164

2.9 Delta...............................................................................................................................174

2.9.1 DVP Series ..........................................................................................................174

2.9.2 AH500 Series ......................................................................................................177

2.10 Panasonic .......................................................................................................................184

2.10.1 FP Series .............................................................................................................184

2.10.2 FP Series (Ethernet)............................................................................................188

2.11 YASKAWA........................................................................................................................190

2.11.1 Extended MEMOBUS .........................................................................................190

2.11.2 MP Series Extension (Ethernet) .........................................................................193

2.12 Keyence ..........................................................................................................................196

2.12.1 KV-3000/5000/5500/7500(Ethernet) ................................................................196

2.12.2 KV-L21V/3000/5000/5500 (host link) ................................................................201

2.12.3 KV-Nano (host link) ............................................................................................210

2.13 Beckhoff Automation.....................................................................................................214

2.13.1 Twincat(Ethernet) ..............................................................................................214

2.14 Koyo................................................................................................................................218

2.14.1 Direct..................................................................................................................218

1. HMI Model Serial Information

P5043S/P5043N/P5070VS/P5102VS

Serial Interface

COM1(RS-232[TXD,RXD]), COM2(RS-422/485),

COM3(RS-485)

Serial Layout

RS-232/

RS-422/

RS-485

PIN#

COM1

COM2

(RS-422)

COM2

(RS-485)

COM3

5

1

TX+

DATA+

2

RX

3

TX

4

RX+

5

GND

GND

GND

GND

6

TX-

DATA-

7

DATA+

8

DATA-

9

RX-

P5070S/ P5070N/ P5070N1/ P5102S/ P5102N/ P5102N1

Serial Interface

COM1(RS-232[TXD,RXD,RTS,CTS]),

COM3(RS-422/485), COM4(RS-485)

Serial Layout

RS-232

PIN#

COM1

1

2

RX

3

TX

4

5

GND

6

7

RTS

8

CTS

9

RS-422/

485

Old Model

PIN#

COM3

(RS-422)

COM3

(RS-485)

COM4

6

1

TX-

DATA-

2

TX+

DATA+

3

RX-

4

RX+

5

ISO_GND

6

7

DATA-

8

DATA+

9

New Model

PIN#

COM3

(RS-422)

COM3

(RS-485)

COM4

1

DATA+

2

DATA-

3

ISO_GND

ISO_GND

ISO_GND

4

RX+

5

RX-

6

TX+

DATA+

7

TX-

DATA-

2. PLC Connection

2.1 FATEK Automation Corp.

FBs/B1/B1z/HB1

2.1.1.1 Communication Setting

Item

Default Setting

Remark

Signal Level

RS232

Baud Rate

9600

Data Length

7

Stop Bit

1

Parity

Even

PLC Station No.

1

Must match PLC

7

port setting

Communication Method

FATEK Communication

Protocol

2.1.1.2 Memory Resource Review

Device

Data Bits

Address

Format

Min.

Max.

Description

X

1

DDDD

0

255

Input Discrete

Y

1

DDDD

0

255

Output Relay

M

1

DDDD

0

2001

Internal Relay

S

1

DDDD

0

999

Step Relay

T

1

DDDD

0

255

Timer Discrete

C

1

DDDD

0

255

Counter Discrete

WX

16

DDDD

0

255

Input Discrete

WY

16

DDDD

0

255

Output Relay

WM

16

DDDD

0

2001

Input Relay

WS

16

DDDD

0

999

Step Relay

RT

16

DDDD

0

255

Timer Register

RC

16

DDDD

0

199

Counter Register

DRC

32

DDDD

200

255

Counter Register

R

16

DDDD

0

8071

Data Register

D

16

DDDD

0

4095

Data Register

F

16

DDDD

0

8191

File Register

2.1.1.3 Connecting to PLC

Configuring the PLC

Use the application WinProLadder (ver. 3.25) to configure the serial port of the PLC.

Connect the PLC to a computer. In the application, under the PLC tab, select the

On-Line option. In the dialog, select RS232 for the Connection Name and press ‘Edit’.

Within the edit dialog, select the port number the PLC is connected to. Press OK to

confirm the settings.

8

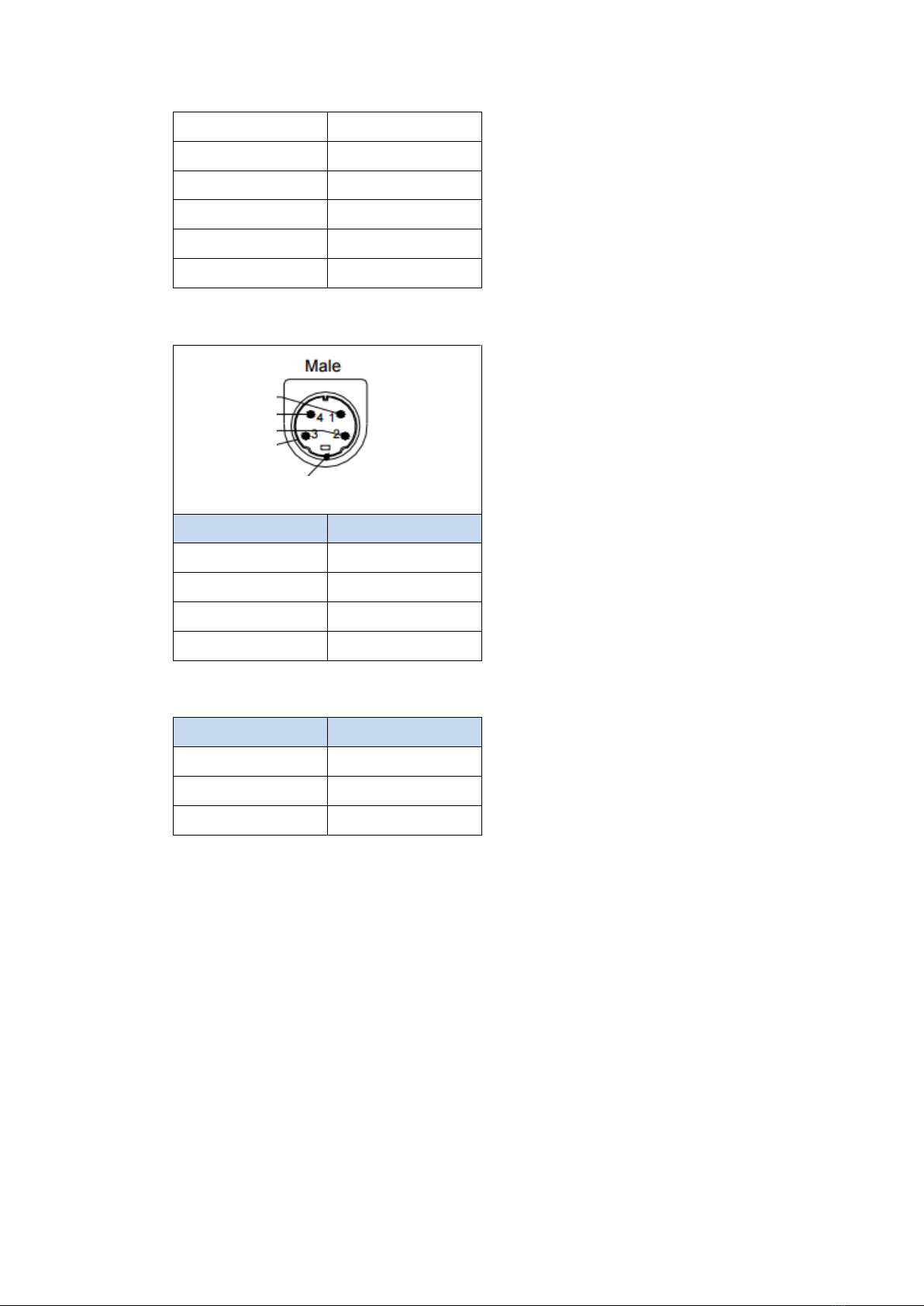

Under the PLC tab, select the Setting option and choose Port 0. Here, the Baud rate

and other parameters of the serial port can be configured.

Note: For more detailed information please refer to the PLC manual.

Connecting PLC to HMI

9

Within the Link configuration window in FvDesigner:

Under Interface Type select Serial

Under Manufacturer select FATEK Automation Corp

Under Product Series select FATEK FBs/B1/B1z/HB1

Under Port select COM1

Verify the other parameters are consistent with the settings on the PLC.

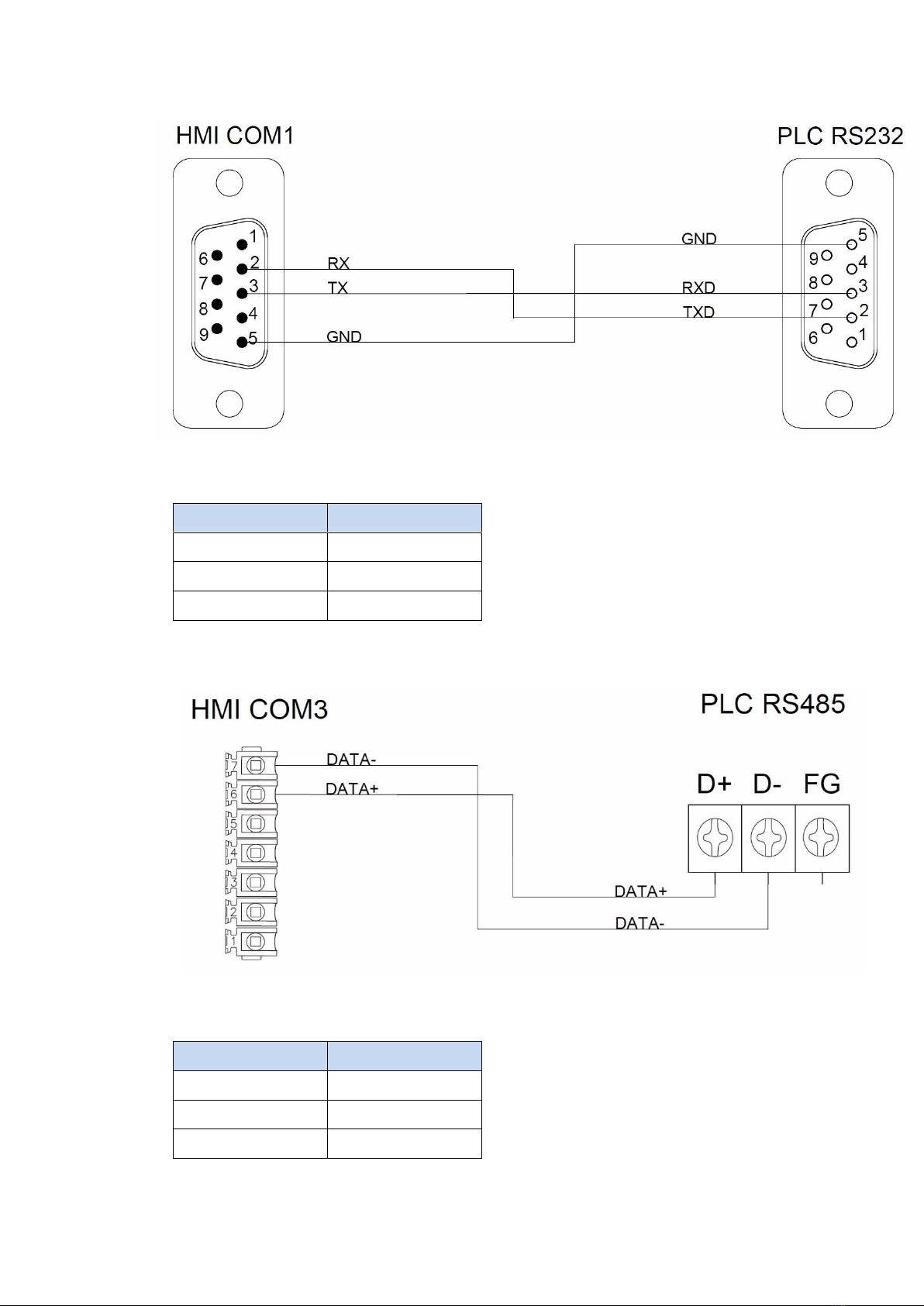

2.1.1.4 Wiring Diagrams

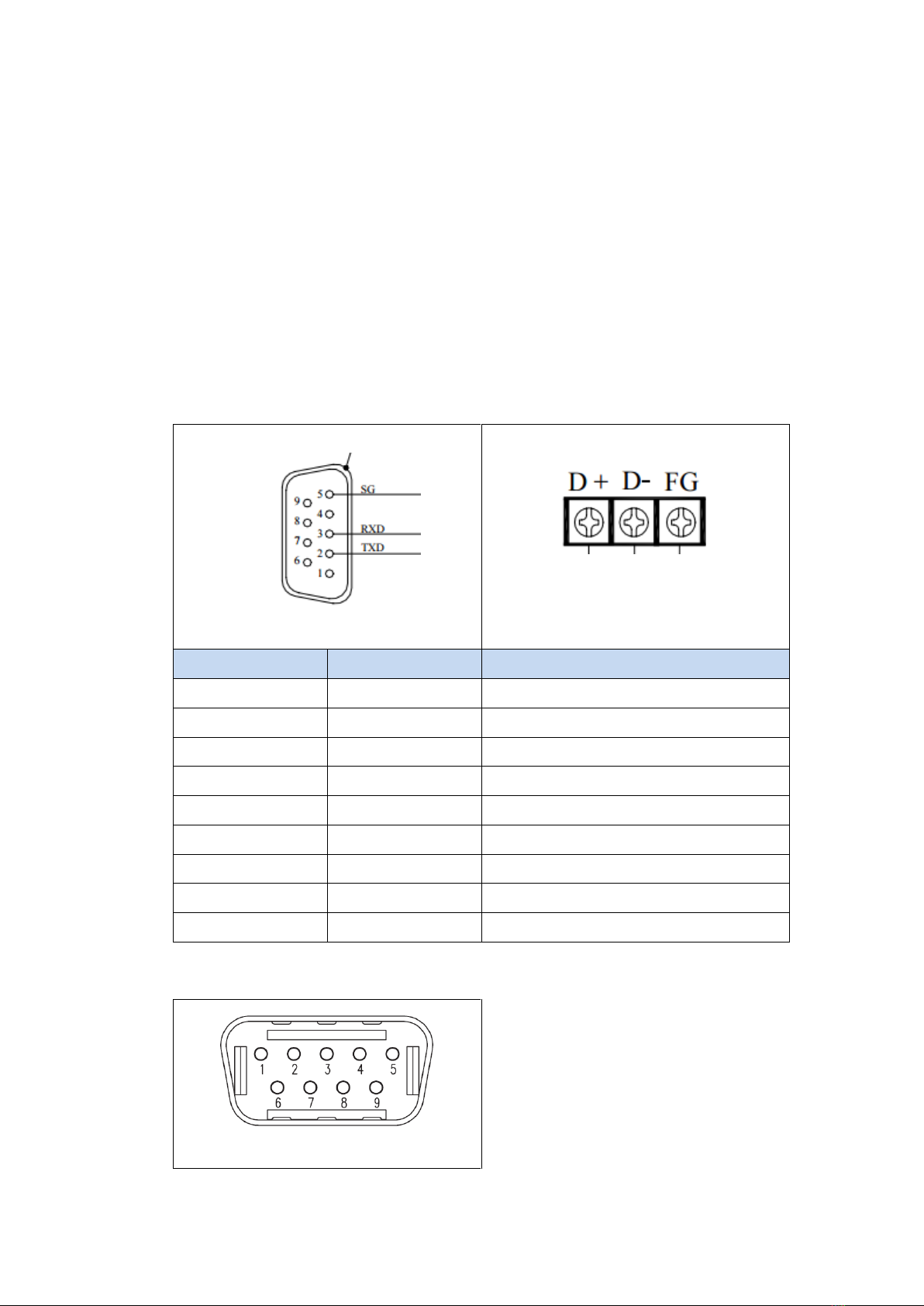

HMI COM1 Pinout

*Looking into COM1 Port

PIN#

COM1 (RS232)

1

2

RX

3

TX

10

4

5

GND

6

7

RTS

8

CTS

9

PLC RS232 Pinout

*Looking into PLC

PIN#

Signal

1

2

GND

3

TX

4

RX

All P5 Series

HMI COM1

PLC RS232 Port

2 RX

3 TX

3 TX

4 RX

5 GND

2 GND

Wiring Diagrams:All P5Series

11

FBe

2.1.2.1 Communication Setting

Item

Default Setting

Remark

Signal Level

RS232 / RS485

Baud Rate

9600

Data Length

7

Stop Bit

1

Parity

Even

PLC Station No.

1

Must match PLC

port setting

Communication Method

FATEK Communication

Protocol

2.1.2.2 Memory Resource Review

Device

Data Bits

Address

Format

Min.

Max.

Description

X

1

DDDD

0

255

Input Discrete

Y

1

DDDD

0

255

Output Relay

M

1

DDDD

0

2001

Internal Relay

S

1

DDDD

0

999

Step Relay

T

1

DDDD

0

255

Timer Discrete

C

1

DDDD

0

255

Counter Discrete

WX

16

DDDD

0

255

Input Discrete

12

WY

16

DDDD

0

255

Output Relay

WM

16

DDDD

0

2001

Input Relay

WS

16

DDDD

0

999

Step Relay

RT

16

DDDD

0

255

Timer Register

RC

16

DDDD

0

199

Counter Register

DRC

32

DDDD

200

255

Counter Register

R

16

DDDD

0

8071

Data Register

D

16

DDDD

0

4095

Data Register

2.1.2.3 Connecting to PLC

Configuring the PLC

Use the application WinProLadder (ver. 3.25) to configure the serial port of the PLC.

Connect the PLC to a computer. In the application, under the PLC tab, select the

On-Line option. In the dialog, select RS232 for the Connection Name and press ‘Edit’.

Within the edit dialog, select the port number the PLC is connected to. Press OK to

confirm the settings.

Under the PLC tab, select the Setting option and choose Port 0. Here, the Baud rate

and other parameters of the serial port can be configured.

13

Note: For more detailed information please refer to the PLC manual.

Connecting PLC to HMI

Within the Link configuration window in FvDesigner:

14

Under Interface Type select Serial

Under Manufacturer select FATEK Automation Corp.

Under Product Series select FATEK FBe

Under Port select the port corresponding to the connection to the PLC

Verify the other parameters are consistent with the settings on the PLC

2.1.2.4 Wiring Diagrams

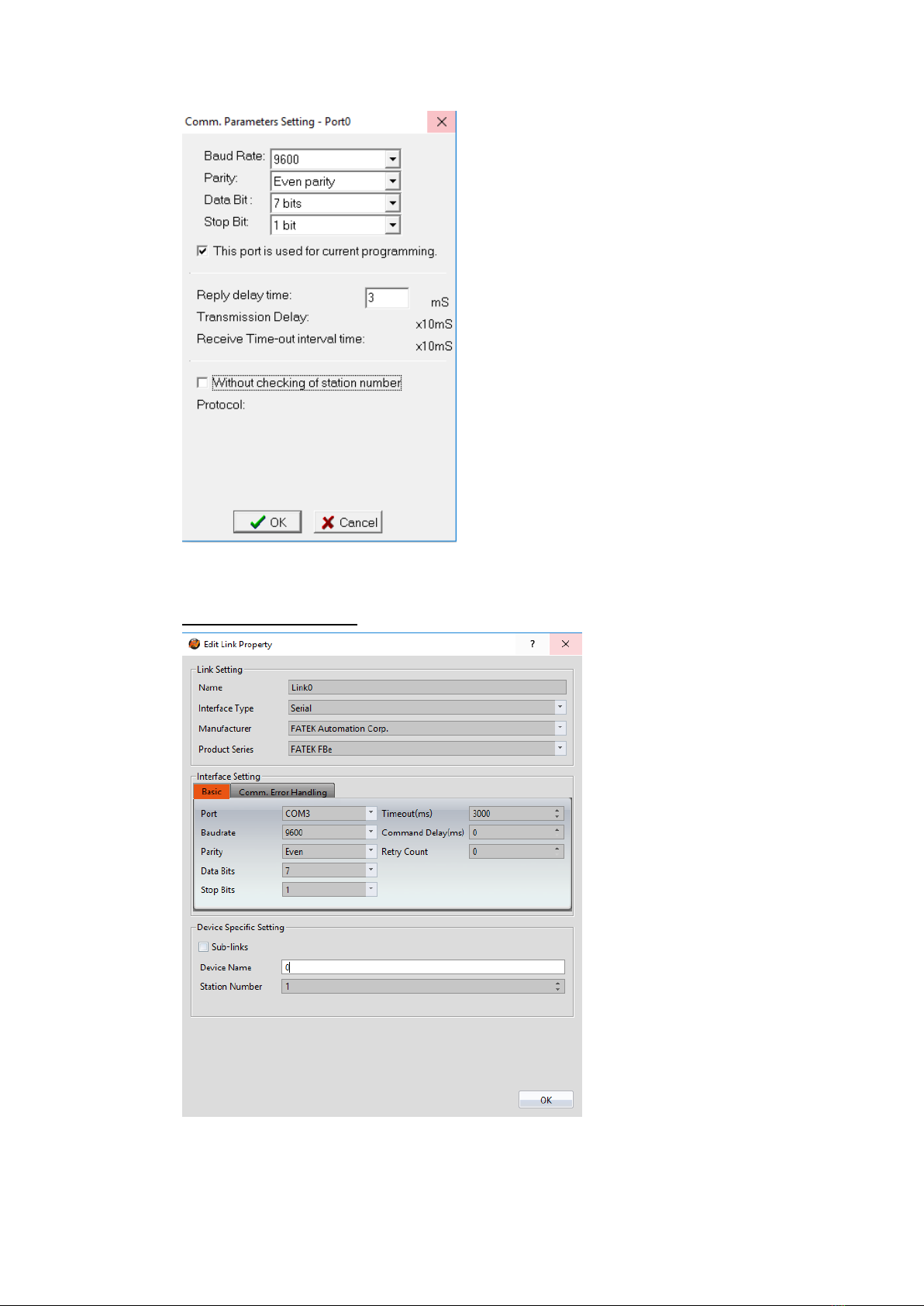

Note: The connections were made between the HMI and the FB-DTBR-E module. The

module provides ports for each connection type.

PLC RS232 Pinout

*Looking into port0

PLC RS485 Pinout

PIN#

Port 0 (RS-232)

Port 2 (RS-485)

1

DATA+

2

TXD

DATA-

3

RXD

FG

4

5

GND

6

7

8

9

HMI COM1 Pinout

*Looking into COM1 Port

15

PIN#

COM1 (RS232)

1

2

RX

3

TX

4

5

GND

6

7

RTS

8

CTS

9

HMI COM3 Pinout

*Looking into HMI Device

PIN#

COM3

(RS-422/RS-485)

1

2

3

ISO_GND

4

5

6

DATA+

7

DATA-

All P5 Series

HMI COM1

PLC RS232 Port

2 RX

2 TXD

3 TX

3 RXD

5 GND

5 GND

Wiring Diagrams:All P5Series

16

P5070S/ P5070N/ P5070N1/ P5102S/ P5102N/ P5102N1

HMI COM3

PLC RS485 Port

6 DATA+

DATA+

7 DATA-

DATA-

Wiring Diagrams: P5070S/ P5070N/ P5070N1/ P5102S/ P5102N/ P5102N1

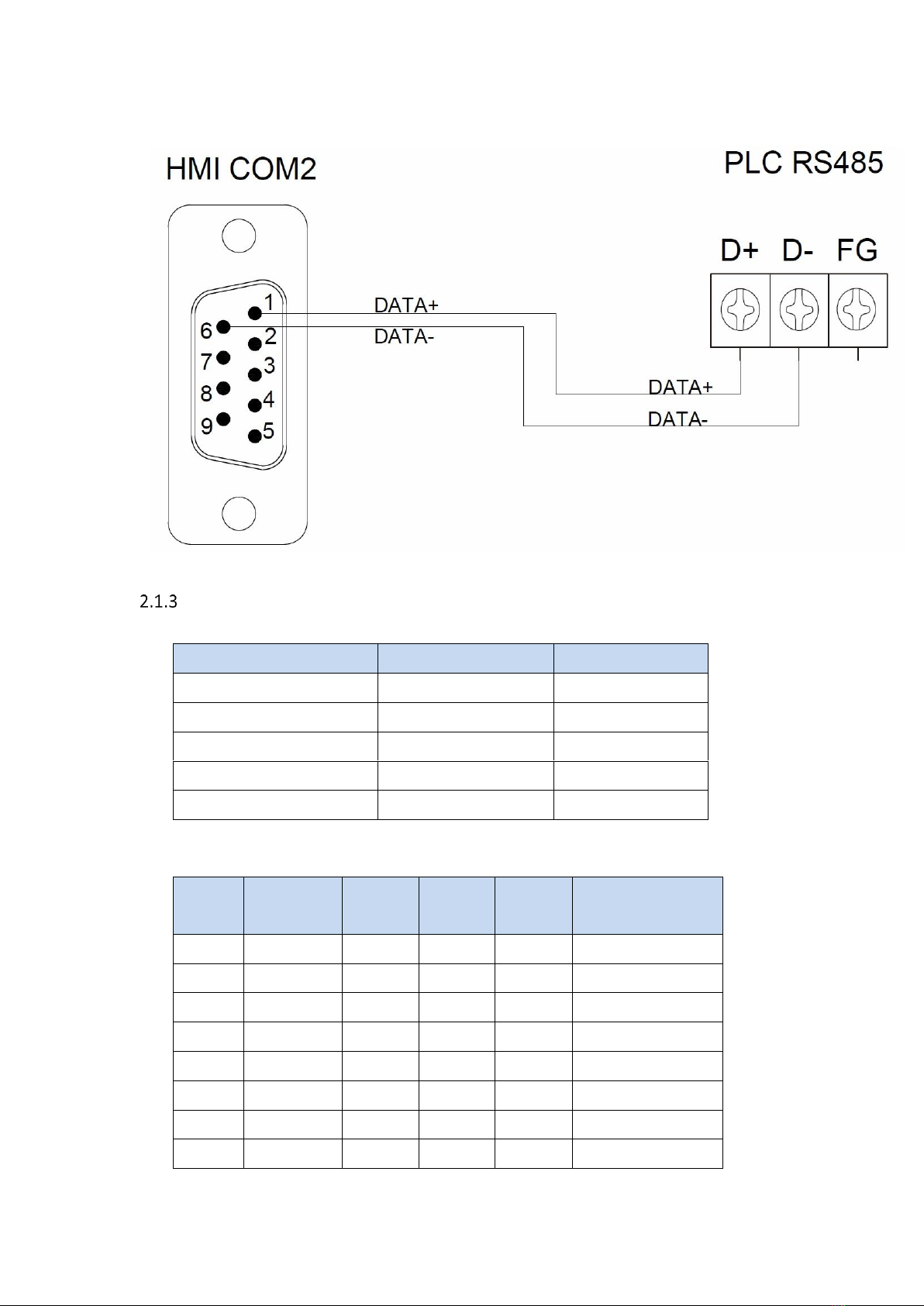

P5043S/P5043N/P5070VS/P5102VS

HMI COM2

PLC RS485 Port

1 DATA+

DATA+

6 DATA-

DATA-

17

Wiring Diagrams:P5043S/P5043N/P5070VS/P5102VS

FBs/B1/B1z/HB1 (TCP)

2.1.3.1 Communication Setting

Item

Default Setting

Remark

Signal Level

Ethernet

Internet Protocol

192.168.1.3

Port

500

PLC Station No.

0

Communication Method

TCP

2.1.3.2 Memory Resource Review

Device

Data Bits

Address

Format

Min.

Max.

Description

X

1

DDDD

0

255

Input Discrete

Y

1

DDDD

0

255

Output Relay

M

1

DDDD

0

2001

Internal Relay

S

1

DDDD

0

999

Step Relay

T

1

DDDD

0

255

Timer Discrete

C

1

DDDD

0

255

Counter Discrete

WX

16

DDDD

0

255

Input Discrete

WY

16

DDDD

0

255

Output Relay

18

WM

16

DDDD

0

2001

Input Relay

WS

16

DDDD

0

999

Step Relay

RT

16

DDDD

0

255

Timer Register

RC

16

DDDD

0

199

Counter Register

DRC

32

DDDD

200

255

Counter Register

R

16

DDDD

0

8071

Data Register

D

16

DDDD

0

4095

Data Register

F

16

DDDD

0

8191

File Register

2.1.3.3 Connecting to HMI

Configuring IP Address on PLC

Use the application FATEK Ethernet Module Configuration Tool to configure the IP

address of the PLC. Connect an Ethernet cable to the PLC. Under Attached Media,

select LAN and press scan.

Select the PLC to connect to and right click or press Properties to change the IP.

Note: The default IP address for the PLC has 1 for its third octet. If the IP address of the

computer has a different number at that position, the PLC will not show up in the scan.

Configure network settings on the computer to be able to see the PLC in the local

network.

In the dialog window, the IP address and other parameters of the PLC can be

configured. In the Service Ports tab, the port number of the PLC can be changed.

19

Note: For more detailed information please refer to the PLC manual.

Connecting PLC to HMI

Within the Link configuration window in FvDesigner:

Under Interface Type select Ethernet

Under Manufacturer select FATEK Automation Corp

Under Product Series select FATEK FBs/B1/B1z/HB1 (TCP)

20

Use the IP address and port number assigned on the PLC

FBe (TCP)

2.1.4.1 Communication Setting

Item

Default Setting

Remark

Signal Level

Ethernet

Internet Protocol

192.168.1.3

Port

500

PLC Station No.

0

Communication Method

TCP

2.1.4.2 Memory Resource Review

Device

Data Bits

Address

Format

Min.

Max.

Description

X

1

DDDD

0

255

Input Discrete

Y

1

DDDD

0

255

Output Relay

M

1

DDDD

0

2001

Internal Relay

S

1

DDDD

0

999

Step Relay

T

1

DDDD

0

255

Timer Discrete

C

1

DDDD

0

255

Counter Discrete

WX

16

DDDD

0

255

Input Discrete

WY

16

DDDD

0

255

Output Relay

WM

16

DDDD

0

2001

Input Relay

WS

16

DDDD

0

999

Step Relay

RT

16

DDDD

0

255

Timer Register

RC

16

DDDD

0

199

Counter Register

DRC

32

DDDD

200

255

Counter Register

R

16

DDDD

0

8071

Data Register

D

16

DDDD

0

4095

Data Register

2.1.4.3 Connecting to HMI

Configuring IP Address on PLC

Use the application FATEK Ethernet Module Configuration Tool to configure the IP

address of the PLC. Connect an Ethernet cable to the PLC. Under Attached Media,

select LAN and press scan.

This manual suits for next models

10

Table of contents

Other FATEK Industrial Equipment manuals