SWAN-MATIC C900 User manual

1

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

2

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

C-900 Continuous Thread Capper

Thank You for purchasing the C-900 Swan-Matic Capper. The C900 is proudly built in

the USA by Swan-Matic, a division of Automation Devices in Fairview, PA.

For any technique assistance please feel free to call 814-474-5561.

Contents

Set-up 3

Clutch Adjustment 5

Maintenance 6

Insert Sizing Chart 8

Insert and Driver Shells 9

FAQ 10

Machine Specifications 12

Parts Diagram 13

Parts List 14

Swan-Matic Warranty 15

3

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

Set-up and Operation Instruction

Carefully unpack the m a c h i n e and any other associated equipment which

may be in the container and check for damage. Set the machine on a level

surface. Please observe all a safety regulations in your facility.

Do not place fingers between driver shell and cap being installed.

Always tie back hair and loose clothing.

1. Add oil to air supply oiler on the side of the machine. Use

any type of light weight air tool oil. Food grade air tools oils

are also permissible. The oiler is located after the high

pressure air regulator (HPR). The fill cap is the small Philips

screw on top of the oiler. Fill to the top of the glass bowl. Put

cap back on.

2. Locate your drive shell, insert, C532 hex drive adaptor. Put

them together as seen in picture to the right. Slide into quick connect on the

bottom of the driver.

3. Before connecting your air supply line, take note

that the driver head will move to the up position

when air supply line is connected.

4. Connect to clean air supply. Recommended line in

pressure is 120psi.

5. Use CAUTION when loosening head lock handles, the

head assembly may feel heavy to certain individuals.

Loosen head lock handles on each side of the capping

head and slide head to upmost position. Slightly tighten

lock handles to temporarily hold head in place.

6. Adjust the high pressure regulator (HPR) to 80 psi by lifting (unlocking) and

rotating the knob counter clockwise to decrease and clockwise to increase

regulated pressure. Note: There are arrows printed in the top of the HPR knob

indicating pressure change directions.

4

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

7. If your capper is equipped with the optional C929 Low

Pressure Regulator (LPR), set it to 30 PSI. An LPR is a nice

option to have because it allows the operator to adjust the

down force of the ram cylinder independently from the driver

head main regulator. This is particularly useful on more

sensitive applications such as fine thread bottles, serrated

driver applications and 4 lug steel caps.

8. Place bottle directly under driver shell.

9. V-BLOCK SET UP

Adjust the bottle locator blocks up to the back side of the bottle in a “V”

formation. Each locator block can be adjusted left and right in addition to the

angle of each can be changed. Tighten down locator bolts.

BOTTLE HOLDER SET UP

If your machine came with the optional bottle holder bracket (C985) and a

custom made bottle holder, screw the bottle holder to the bracket. Adjust the

bracket forward or back to align the bottle directly under the driver shell. Tighten

knobs.

10. Adjust the head assembly down to a position that will place the end of the driver

shell approximately .75 inch (2cm) above the cap.

11. Tighten handles firmly.

12. Remove the bottle from the locator blocks.

13. With the HPR still set at 80psi, cycle the capper. The capper

should cycle down when the peddle is depressed, then

return when the peddle is released. If the cycle is abrupt or

to fast for the operator, adjust the flow control valve; located

on either the oiler or the LPR (if equipped) in a clockwise

direction. This will slow down cycle time.

5

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

14. The driver has a clutch built into it. This clutch is

adjustable. The clutch will determine the torque that

is placed on your caps. The clutch is adjustable

through the hole under the cover. Rotate the Driver

Shell until you see the indent (see Picture lower

right) in the gear thru the adjustment window. Use

the adjustment tool provided to rotate the adjustment

wheel.

NOTE: The capper will not engage until a bottle is

actually placed in the capper and the driver shell

comes in contact with the cap. When the drive shell

comes in contact with cap it will triggers the driver to

rotate.

15. Place the cap on the bottle, place the bottle in the V

block or bottle holder you previously set up. Check

the alignment of the bottle one more time.

16. With safety glasses on, cycle the machine.

17. It is very likely the cap did not go on perfect the first

time. That’s OK. If the cap went on correctly and met your torque spec, you rock!

Happy capping from here on out.

18. If the bottle “wobbled” when the capper engaged the cap then you do not have

the bottle centered under the capping head.

19. If the cap is not tight enough and the clutch disengaged (stopped rotating) then

increase the clutch tension. This is done by rotating the clutch adjustment dial

counter clockwise.

20. If the cap is not tight enough and the clutch did not disengage then your down

force pressure is to low and/or you have selected the wrong insert for your cap.

If you have the optional LPR, increase your down pressure with this regulator. If

you only have the HPR, rotate the HPR knob to the right (clockwise). If the

problem persists call Swan-Matic at 814-474-5561 for further instructions.

6

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

Maintenance

There is only one required maintenance item. Add oil to air

supply oiler on the side of the machine when low. Use any type

of light weight air tool oil. Food grade air tools oils are also

permissible. Disconnect the air supply before adding oil.

The oiler is located after the high pressure regulator. The fill

cap is the small Philips screw on top of the oiler. Fill to the top

of the glass bowl. Put cap back on.

The oil flow adjustment has a range of 0-10. Swan-Matic

machines are designed to run at <1 on the dial. Just below the

adjustment knob there is a sight glass. In that sight glass is a

drip nipple. There should be a drop of oil on the end of that

nipple after cycling the machine several times. After running the

machine for an hour or so, you should see or feel a light

amount of oil in your airline to the cylinder. You should never

see oil dripping from any air cylinders or driving tools.

7

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

Swan-Matic C900 Series Options

Air Driver Upgrade with a Precision Clutch C527

Required for caps greater than 50mm

This is an upgrade on the driver itself. It comes with a Torque range (soft draw) 3.0 to

47.8 in.-lb. / 0.3 - 5.4 Nm at Speeds: 250 to 2800 RPM. C527 Air Driver comes with a 1

year warranty.

Functionality of Anti-Tie Down Bar C965

This start bar is an OSHA compliant, ergonomic two-hand start.

Low Press Regulator Kit (LPR) C929

An LPR is a nice option to have because it allows the operator to adjust the

down force of the ram cylinder independently from the driver head main

regulator. This is particularly useful on more sensitive applications such as

fine thread bottles, serrated driver applications and 4 lug steel caps.

Adjustable Flow Control Valves C919

Adjustable Flow Control Valves are a nice option to have because it

allows the operator to adjust both the driver head approach speed

and retreat speed from the cap. This is particularly useful on more

sensitive applications such as fine thread bottles, serrated driver

applications and 4 lug steel caps. This also allows the operator to

fine tune machine cycle times.

Bottle and Vial Holders

Swan-Matic Bottle Capping Machines and Equipment designs

and manufactures bottle holders for any style and size bottle.

Whether it’s 1 or 100, we can make bottle holders for every

application. To receive an accurate quote, send in 12 caps and 2

empty bottles to: Swan-Matic Test Lab, 7050 West Ridge Road,

Fairview, PA 16415.

8

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

PRODUCTION NOTES

Although they may last longer,

harder inserts are not always

better. Harder inserts do not grip

as well as lower durometer

(softer) inserts. The friction

caused by the harder material

can damage; even burn, the

edges of plastic caps.

Insert Sizing Cart and Cap Toque Spec Guide

Our inserts are in stock and ready to ship

Measure the diameter of the cap or closure and select an

insert or driver shell that has a range that includes that

diameter.

FOR BETTER RESULTS: When the diameter of your

cap/closure is close to the Insert's Upper Cap Range,

choose the next larger size insert and shell.

FOR BEST RESULTS: Send 12 sample caps and 2 bottles

and our engineers will make a recommendation.

CONTACT INFO

Automation Devices

7050 West Ridge Rd

Fairview, PA. 16415

9

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

10

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

Frequently Asked Questions

Who do I call for technical support?

Call during normal hours. 814-474-5561. Monday thru Friday 8am to 4pm.

Where can I get my benchtop capper rebuilt?

Make sure the oil is drained from the capper. Capper must be shipped upright on a skid

by Freight only. Include contact information and return shipping address.

Send capper to: Swan-Matic (rebuild)

7050 West Ridge Rd

Fairview, PA 16415

How fast can a benchtop capper cap?

A benchtop capper can do 50 bottles a minute. The actual rate is determined by

the operator.

What is the life expectancy of an insert?

The life of an insert is determined by several factors. Torque specs, work conditions,

cap texture, insert material and clutch settings. The number one killer of inserts is

improper clutch settings. The general rules is the insert should never slip on the cap.

The clutch should disengage before the insert slips on the cap. To help get the

maximum life out of your inserts, send 12 caps and 2 containers to Swan-Matic testing

labs for a free evaluation of your application.

Send caps to: Swan-Matic Test Lab

7050 West Ridge Rd

Fairview, PA 16415

How do I measure cap torque?

Swan-Matic offers a variety of torque testers. Contact Swan-Matic to find the one

best for you.

Does Swan-Matic have cappers that remove caps?

Yes. Several cappers in the Swan-Matic line up have a reversing (de-capping)

feature.

Does Swan-Matic have corrosion resistant cappers?

Yes. Any Swan-Matic benchtop capper can be Nickel Coated to make it

resistant to chemical wash downs.

Does Swan-Matic have explosion proof cappers?

Yes. The C900, C500 and C400 series capper have multiple hazardous ratings.

11

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

How do I set the height of my capper correctly to the bottle?

The driver shell should be about 1 inch above the cap before it is screwed down.

How can I pay for my capper and supplies?

Swan-Matic accepts All major credit cards and wire transfers.

What is your warranty on cappers?

Refer to last page of this manual.

Why won’t my caps tight anymore?

There are several reasons why a capper will not torque correctly all the time.

1. The insert material is not matched to the cap.

Swan-Matic offers 5 different types of material that inserts are made from. Refer

to the Inserts and Driver Shells page for an explanation of each type if insert. To

get the best match, send in 12 caps, 2 containers and your contact information

to:

Swan-Matic Test Lab

7050 West Ridge Rd

Fairview, PA 16415

2. The insert has worn down.

As the insert wears, the pressure on the cap is reduced because the distance

from the insert to the cap increases. To correct it, just move the head of the

capper down slightly or install a new insert.

3. Capper head is set to low.

If the capper is pressing too hard on the container being capped, it can cause the

threads of the container to bind with the cap threads.

4. The insert is slipping inside the driver shell.

Clean the driver shell out and replace the insert.

12

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

Machine Specifications

C900 Continuous Thread Capper

By Swan-Matic

Cycles per Minute Variable Speed 50 cpm max

Down Force 90 @ 100PSI.

Stroke 2” inches

Weight 29 lbs

Shipping weight 55 lbs

Finish Hard Anodize Black

Air Supply Clean 120psi max

Taller Columns and Driver Spacer Blocks can

be Ordered for Larger Bottles

13

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

C900 Parts Call Out

14

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

C920 Air Driver Capper

C901 Main Column

C902L Base Plate, Left

C902R Base Plate, Right

C903 Base Plate, Front Rail

C904 Column Support Bracket 6 Hole

C905 Slide Block

C906 Unibearing Assembly

C907 T Handle Locks

C908 V Block Mount Bracket

C909 V Block Back Stop

C910 Bolt Assembly: M8 x 16.00mm Black

C911 Anchor Fastener, Column

C912 Fasteners Push-in Plastic

C913 End Cap Plastic

C914 Tread Strip 10"

C917 Pneumatic Tubing, Polyurethane, Black, 1/4" OD,per foot

C919 Fitting Elbow 1/4" tube to 1/4" NPT Flow Control

C920 Air Driver Push to Start

C924 Fitting Straight 1/4" tube to 1/4" NPT

C925 Fitting Elbow 1/4" tube to 1/4" NPT

C927 Air Cylinder 1 1/16" 3" Stock Dbl Action

C928 Regulator 20-130psi

C930 Pneumatic Lubricator

C932 T-Bracket Modular

C933 Pneumatic Foot Pedal 4 Way 5 Port

C934 Driver Clamp 2 Halves

C963 Mounting Plate Air Cylinder to Unibearing

C963 Mounting Plate Air Cylinder to Slide

C941 6m-100 60mm SHCS

C942 M8-1.50 x 25mm SHCS

C943 M10-1.50 x 20mm FHHS

C945 5/16 Black-Oxide 18-8 Stainless Steel Washer

C946 Street Elbow 1/4" NPT

C947 Quick Disconnect 1/4 M NPT

HC002 Hand Capper Stud

15

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

SWAN-MATIC WARRANTY

Automation Devices, Inc. warrants the materials and goods supplied

under the subject customer’s purchase order to be as specified and of

good quality. No specific time life shall be stated, since the results of

good workmanship are of timeless age, and good quality, properly used,

shall be self-evident.

This warranty does not cover damage resulting from accident,

transportation, normal wear of parts, negligent use or misuse of the

product, incorrect electrical voltage or current, usage contrary to

operating instructions, alterations or repairs by other than Automation

Devices, Inc., factory personnel. In the case of transportation damage,

please pursue recovery for damage through your freight carrier.

If the product should become defective, we will repair or replace it, at

our option, free of charge. This service is available by returning the

product to our factory, freight prepaid, and we will return your product

to you, freight collect.

This warranty does not include cost of inconvenience, damage due to

product failure, transportation damage, or the like. This warranty

applies only to the physical repair or replacement of the defective goods

and specifically excludes any incidental or consequential damages or

additional liability thereof. Some states do not allow exclusion or

limitation of incidental or consequential damages. This warranty also

gives specific legal rights, although you may have other rights, which

vary from state to state.

Table of contents

Other SWAN-MATIC Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

SCHUNK

SCHUNK MRU Assembly and operating manual

SCHUNK

SCHUNK GWB 34 Assembly and operating manual

SCHUNK

SCHUNK NSR maxi 220 Assembly and operating manual

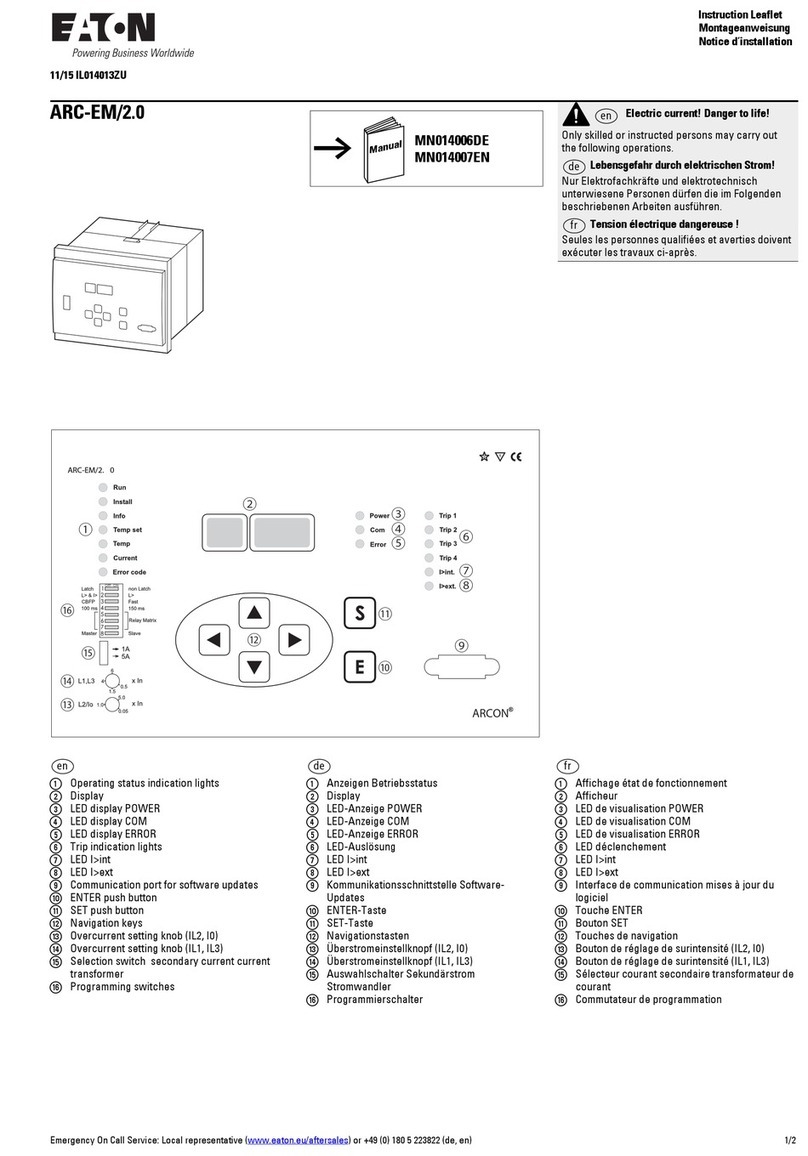

Eaton

Eaton ARCON ARC-EM/2.0 Instruction leaflet

GPS

GPS iMEASURE-D Installation, operation & maintenance manual

Elan Cite

Elan Cite Evolis Solution user guide