FATEK P5150NH User manual

1

Thank you for purchasing FATEK HMI. Before installing or operating the unit, please read

this installation guide carefully to ensure correct use.

1. Safety Precautions (Read these precautions before use.)

1.1 General

Unpack and check the delivery for transportation damage. If any damage or

deformation is found, please notify the supplier.

The supplier is not responsible for the disassembled, altered or modified device.

Never allow fluid or any conductive particles to enter into the HMI. Otherwise,

it may damage the HMI, cause fire or malfunction.

Only qualified personnel may install the HMI, perform maintenance and

inspection.

The liquid crystal inside the LCD panel is a hazardous substance. If the panel

is damaged, avoid contact with the leaked liquid crystal. If the liquid crystal

spills on clothing or skin, use soap and wash off thoroughly. In case of eye

contact the liquid, hold the eye open, flush with plenty water and get medical

attention as soon as possible.

Do not touch any terminals while the power is on. Otherwise, it may cause

injury due to electrical shock.

Disconnect the power supply before installing the HMI, do wiring operation,

perform maintenance or inspection. Otherwise, it may cause damage or

electrical shock.

1.2 Installation

The installation may be carried out by qualified personnel only.

Install the HMI according to the installation procedures.

Check the power source voltage is within the specified range and the polarity

is correct before connecting the HMI.

Keep signal and power supply cables away from high-voltage, large-current

carrying cables.

P5150NH HMI Installation Guide

2

Caution

Make sure the HMI is properly grounded to prevent electrical

shock, fire or malfunction.

HMI unit and other equipment should have the same electrical grounding

(reference voltage level), otherwise communication errors may occur.

1.3 Operation

Do not use sharp objects or excessive force to press the touch screen. This

may damage the touch screen.

Do not use the output signal of the device as any safety function or system

emergency stop. It may result in personal injury or equipment damage if a

malfunction of the touch occurs.

1.4 Maintenance and Service

The agreed guarantee applies.

Only qualified personnel should make repairs and perform maintenance.

Disconnect the device from the power supply before carrying out cleaning or

maintenance.

Clean the front panel with a soft cloth and mild detergent.

Please use original replacement spare parts or accessories.

3

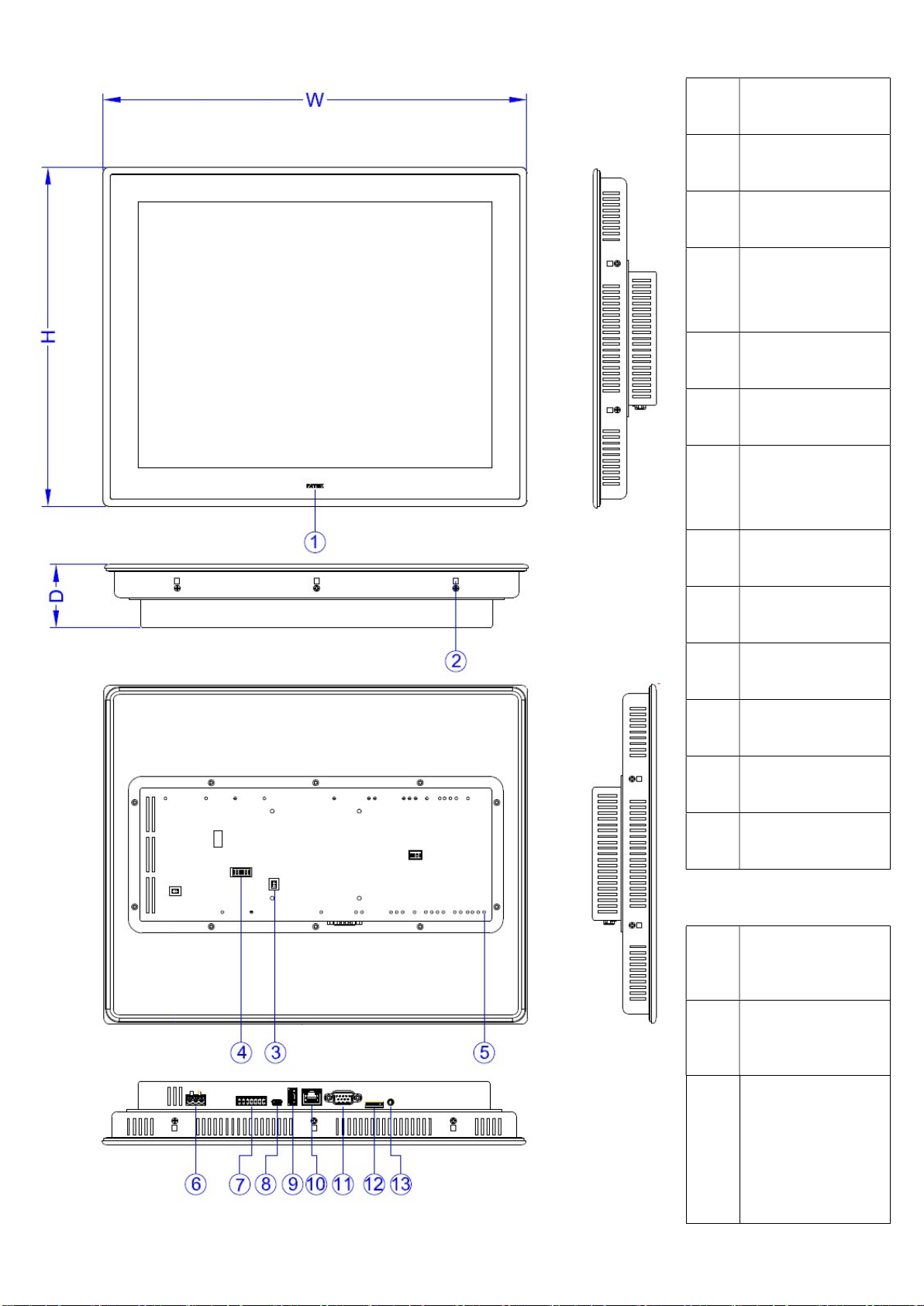

2. Part Names and Dimensions

①

Power Indicator

Light

②

Mounting Hole

③

HB1 PLC

Connector

④

COM3/COM4

Termination

Switch

⑤

HB1 PLC

Screw Hole

⑥

Power

Connector

⑦

COM3/COM4:

Pluggable

Terminal Block

⑧

Mini USB

Connector

⑨

USB Connector

⑩

Ethernet RJ45

Connector

⑪

COM1: DB-9

Male Connector

⑫

Micro-SD Card

Slot

⑬

Audio Phone

Jack

W 365 mm

H 292 mm

D 54.7 mm

4

3. Specifications

Model P5150NH

UL 61010-1

Technical

Consideration

Type of item tested Control

Product Description Operator Panel

Connections to mains

supply Permanent

Overvoltage category II

Pollution degree 2

Means of Protection Class III

Environmental conditions

Operating Temp. 0~50°C

Storage Temp. -20 ~ 60 ℃

For use in wet locations

No

Equipment mobility Built in

Operating conditions Continuous

Overall size 365 x 292 x 54.7 (mm)

Weight 2950 (g)

Marked degree of

protection

Front panel: IP65 / Rear Case: IP20 to IEC 60529

Type 1 to UL 50E

Equipment classification Industrial, Professional, Commercial

Equipment class Class III

Equipment type Permanently connected, Fixed

I/O Port

Serial 1 Connector: D-Sub 9-Pin

COM1: RS-232 (4W)

Serial 2

Connector: Pluggable Terminal Block

COM3: RS-422/485

COM4: RS-485

LAN 10M/100M

USB USB2.0 Type-A (Host)x1

USB2.0 Type mini-B (Device)x1

Micro SD Yes

Audio Yes

PLC Extension HB1 main units + B1 extension modules

Termination

Switch Yes (For RS-422/485)

Power

Power Input 24VDC

±

20% (Isolated Power)

Consumption 833mA@24VDC

Insulation 50MΩ at 500VDC

Environment

Relative Humidity 10%~90%@ 40°C (non-condensing)

Withstand Voltage AC500V/20mA/1 Min. (between charger & FG terminals)

Vibration

5 to 9Hz Half-amplitude: 3.5mm

9 to 150 Hz Constant acceleration: 19.6m/s2 (2G)

3 directions of X, Y, Z: 10times (IEC61131-2 complaints)

Noise Suppression 1000Vp-p, width 1us, rising time 1ns

Grounding Resistance Below 100Ω

Dimension Cut-out 351 x 278 (mm)

5

4. Unpacking the Unit

FATEK HMI x1

Hook and Screw x10

FATEK PLC

Connector x1

A4 Double-sided Installation Guide x1

Power Connector x1

Pluggable Terminal

Block x1

5. Installation Procedures

Push the HMI into the cutout

until the

waterproof ring contacts the plate.

Insert a hook into each mounting hole

on the

HMI, and then tighten the screws

evenly with a moderate torque.

Failure to tighten the screws may cause

the HMI to fall, malfunction or short-

circuit. Excessive

tightening may cause

deformation. The necessary torque is

about 0.16N·m.

6

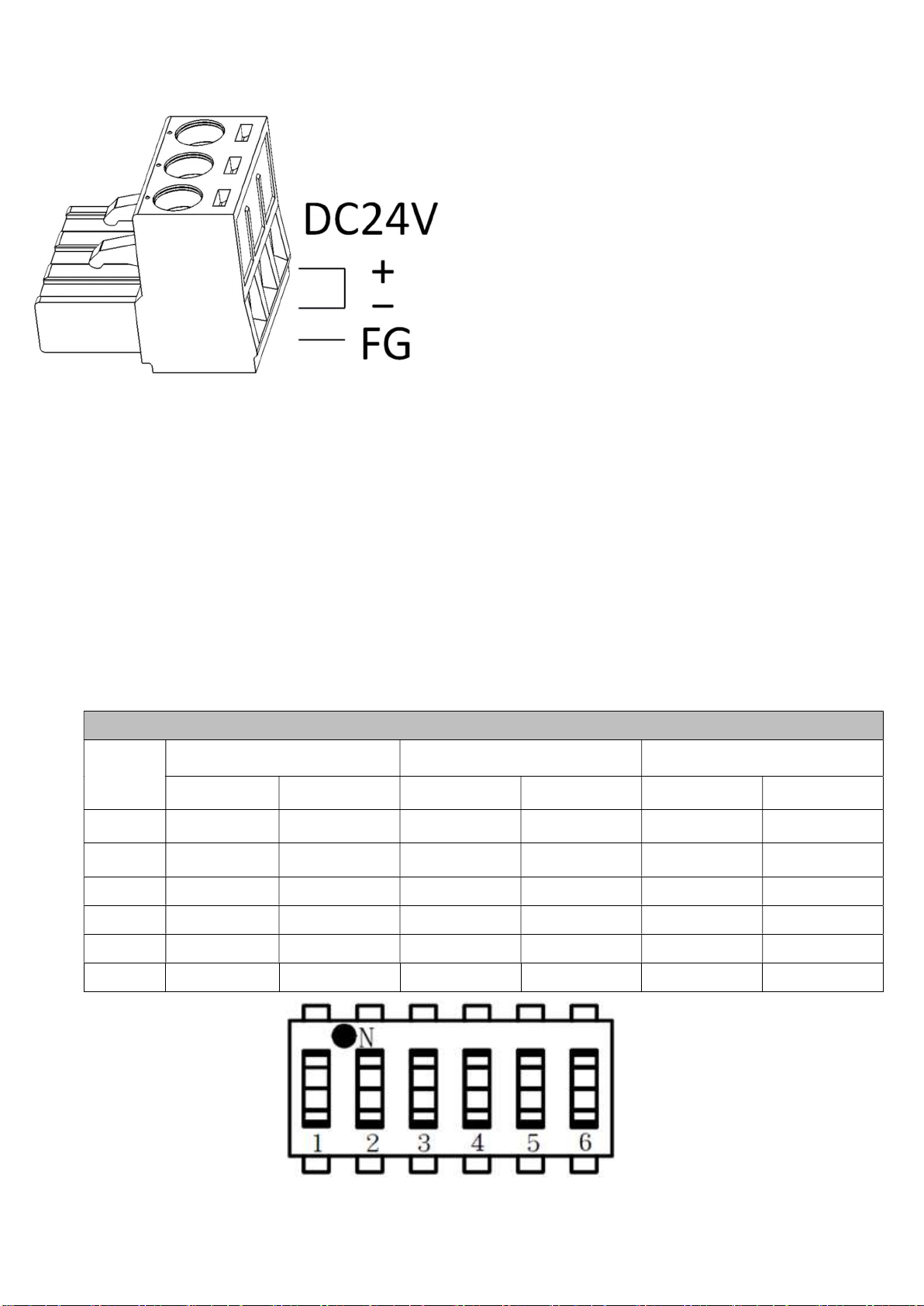

6. Power Connection

Be sure to connect the ground FG

terminal to a class-

3 ground (Ground

resistance should not exceed 100Ω).

Try to make the ground wire

as short

as possible.

Use 28–12 AWG (0.5–1.5 mm2)

wire

for the power connections.

7. Termination Switch

P5150NH HMI has a built-in termination resistor switch.

To enable or disable the termination resistor please follow the configuration

shown in the table below. The termination switch is for COM3 [RS-422 / RS-

485] and COM4 [RS-485].

Configuration of Termination Resistor Switch.

Termination Resistor

No. COM3 [RS-422] COM3 [RS-485] COM4 [RS-485]

Enable Disable Enable Disable Enable Disable

6 OFF OFF OFF OFF ON OFF

5 OFF OFF OFF OFF ON OFF

4 ON OFF ON OFF OFF OFF

3 ON OFF ON OFF OFF OFF

2 ON OFF OFF OFF OFF OFF

1 ON OFF OFF OFF OFF OFF

7

8. Pin-out of COM Ports

DB-9 Male Connector

PIN# COM1

[RS-232]

1 NC*1

2 RX

3 TX

4 NC

5 GND

6 NC

7 RTS

8 CTS

9 NC

*1 NC: No Connection

P

luggable Terminal Block

PIN# COM3

[RS-422]

COM3

[RS-485]

COM4

[RS-485]

1 NC NC DATA+

2 NC NC DATA-

3 GND GND GND

4 RX+ NC NC

5 RX- NC NC

6 TX+ DATA+ NC

7 TX- DATA- NC

8

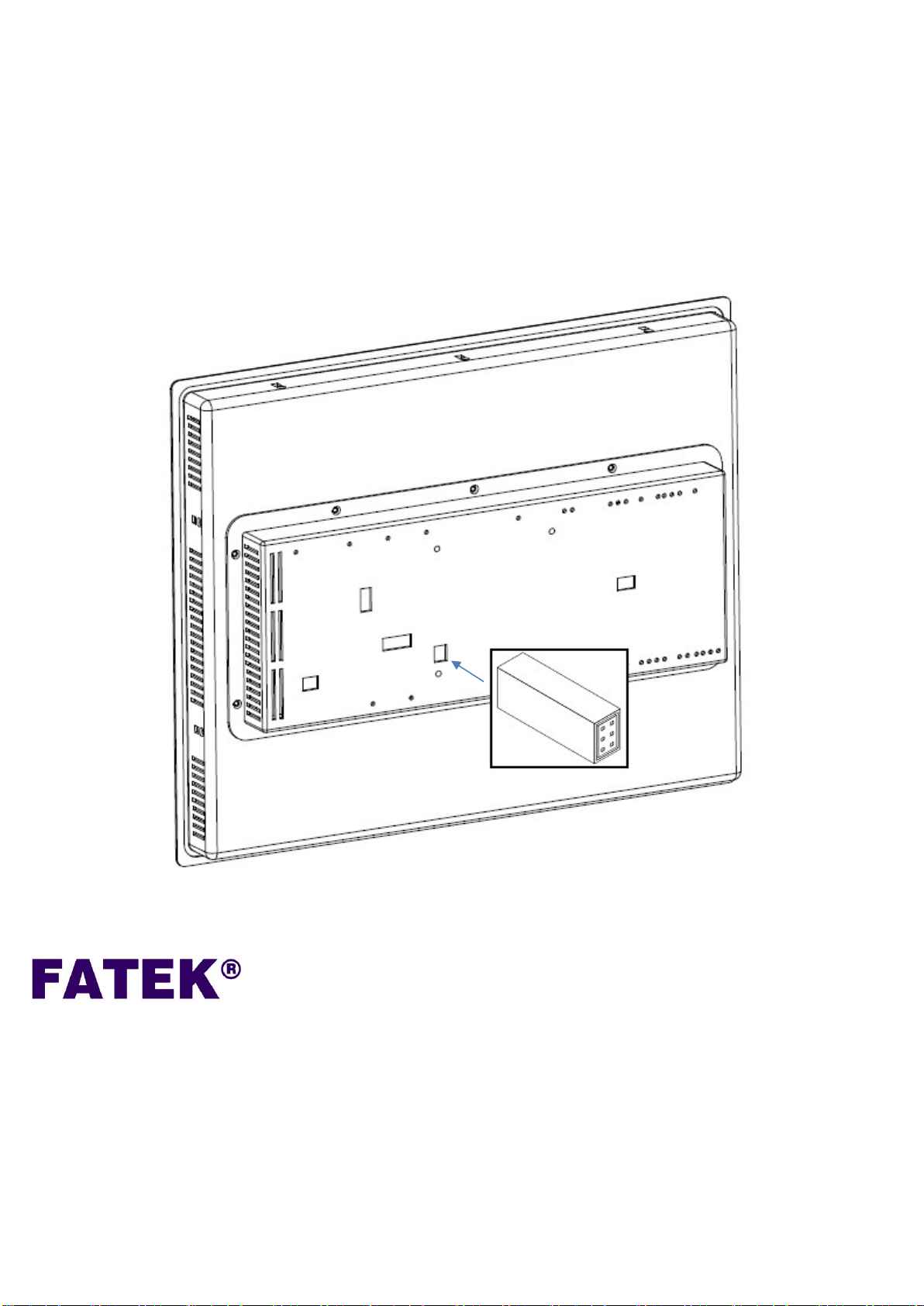

9. PLC Extension Tips

For compact size and saving space, using FATEK HB1 main units + B1

extension modules is recommended.

To connect FATEK PLC main unit, first use the FATEK PLC connector to

connect the main unit and then insert into the HB1 connector hole on the back

cover of the HMI to complete the connection.

26FL., NO. 29, SEC. 2, JUNGJENG E. RD.,

DANSHUEI DIST., NEW TAIPEI CITY 25170, TAIWAN, R.O.C

TEL : +886-2-2808-2192

FAX : +886-2-2809-2618

E-mail : sales@fatek.com

tech@fatek.com

Website : www.fatek.com

AUTOMATION CORP

ORATION

Table of contents

Other FATEK Industrial Equipment manuals