Faudi SLUGGUARD User manual

Version 5

Operating instructions

SLUGGUARD

®

Page:

1

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

SLUGGUARD

®

Bulk water sensor according EI 1592 for use in aviation

fuelling applications.

Version 5

Operating instructions

SLUGGUARD

®

Page:

2

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

1 Amendment Record...................................................................................................... 3

Notes on safety icons and symbols.................................................................................... 3

1.1 Purpose................................................................................................................... 4

1.2 Safety instructions................................................................................................... 4

1.3 Designated use ....................................................................................................... 4

1.4 Installation, commissioning and operation............................................................... 4

1.5 Operational safety ................................................................................................... 5

1.6 Return ..................................................................................................................... 5

1.7 Contact.................................................................................................................... 5

1.8 Identification............................................................................................................ 5

1.8.1 Incoming acceptance, transport, storage.......................................................... 6

1.9 Scope of delivery.................................................................................................... 6

2 Applications.................................................................................................................... 7

2.1 Bulk water sensor according EI 1592 in pipe section............................................... 7

2.2 SLUGGUARD

®

in water sump of filter water separator............................................ 7

2.3 SLUGGUARD

®

below water sump on filter vessels ................................................. 8

2.4 Available SLUGUARD

®

versions and accessories................................................... 8

2.5 Ball valve for SLUGGUARD

®

................................................................................... 9

3 General safety and user instructions .............................................................................10

3.1 Safety.....................................................................................................................10

3.2 Installation for different applications .......................................................................10

3.3 Electrical connection ..............................................................................................11

3.4 Electrical connection in explosion hazard areas .....................................................11

3.5 Explosive gas atmospheres zone 0 and zone 1......................................................11

3.6 Isolation barrier for SLUGGUARD

®

........................................................................12

3.7 Relays output of barrier ..........................................................................................13

3.8 Cleaning, maintenance and repair..........................................................................13

3.9 Disposal .................................................................................................................13

4 Technical data...............................................................................................................14

5 ATEX approval ..............................................................................................................16

6 Declaration of conformity..……………...…………………………………………………......18

Version 5

Operating instructions

SLUGGUARD

®

Page:

3

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

1

Amendment Record

Revision

Number Revision Details and Date Received and

Entered by Date

0

Standard manual

Matthias

Aden

23/07/2019

3 ATEX certificate no page 12

Matthias

Aden

15.1.2020

Notes on safety icons and symbols

Warning!

This symbol alerts you to hazards. They can cause serious damage to the

instrument or to persons if ignored.

Caution!

This symbol alerts you to possible faults which could arise from incorrect

operation. They could cause damage to the instrument if ignored

.

Note!

This symbol indicates important items of information.

Version 5

Operating instructions

SLUGGUARD

®

Page:

4

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

1.1

Purpose

The SLUGGUARD

®

bulk water sensor has been designed for the detection of bulk quantity of

free water in flowing aviation fuel or for the diversification of media (fuel / water) in low points

like sumps.

1.2

Safety instructions

This manual provides operation and routine maintenance instructions for the FAUDI Aviation

SLUGGUARD

®

.

Read this manual and ensure that you fully understand its content before you attempt

to install, use or maintain the SLUGGUARD

®

.

Work on electrical equipment is to be conducted by trained specialists only, according to

valid regulations.

Attention must be paid to the requirements of VDE 0100 when setting up high-power

electrical units with nominal voltages of up to 1000V, including associated standards and

stipulations.

Check the details on the type plate to ensure that the equipment is connected to the correct

mains voltage.

Protect against touching dangerously high electrical voltages. Opening the equipment is

strictly prohibited.

The equipment is only to be used within the permitted temperature and operation ranges.

All CHANGEs of the SLUGGUARD

®

with parts which are not specified or approved by

FAUDI Aviation GmbH, as well as repair and service with unspecified parts will result in loss

of the CE conformity and guarantee.

In case of doubt, please turn directly to FAUDI Aviation GmbH, respectively to your FAUDI

Aviation Distributor or Service organization.

1.3

Designated use

The SLUGGUARD

®

is suitable for bulk water indication in aviation fuelling applications. This

could be applications in flowing aviation fuel as well as diversification of media in low points

like water sumps.

The manufacturer is not liable for damages caused by improper or non-designated use

1.4

Installation, commissioning and operation

Please refer to installation manual for cabling and mechanical setup of SLUGGUARD

®

.

Installation, electrical connection, commissioning, operation and maintenance of the sensor

must only be carried out by trained technical personnel. The technical personnel must be

authorized by the system operator to conduct the specified activities. Technical personnel must

have read and understood these Operating Instructions and must adhere to them.

Before commissioning the entire measuring point, check all the connections for correctness.

Ensure that electrical cables are not damaged. Do not operate damaged products and secure

them against unintentional commissioning. Mark the damaged product as being defective.

Measuring point faults may only be rectified by authorised and specially trained personnel. If

faults cannot be rectified, the products must be taken out of service and secured against

unintentional commissioning.

Repairs may only be carried out by manufacturer or by a designated service organisation.

Version 5 Operating instructions

SLUGGUARD®

Page: 5 of: 18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf Manual_SLUGGUARD_Rev5

1.5 Operational safety

The SLUGGUARD® has been designed and tested according to the state of the art and left

the factory in perfect functioning order. Relevant regulations and European standards have

been met.

As the user, you are responsible for complying with the following safety conditions:

- Installation instructions

- Local prevailing standards and regulations.

1.6 Return

If the device requires repair, please send it in cleaned condition to the appropriate sales

centre. Please use the original packaging, if possible.

When sending for repair, please enclose a note with a description of the error and the

application.

Please enclose the certificate of decontamination (to be found on the download section if

FAUDI-Aviation-Sensor homepage.

1.7 Contact

Contact address of manufacturer:

FAUDI Aviation GmbH

Scharnhorststrasse 7 B

D- 35260 Stadtallendorf

Germany

Telephone:

Fax:

Mail:

Web:

+49 6428 44652- 570

+49 6428 44652- 221

www.faudi-aviation.com

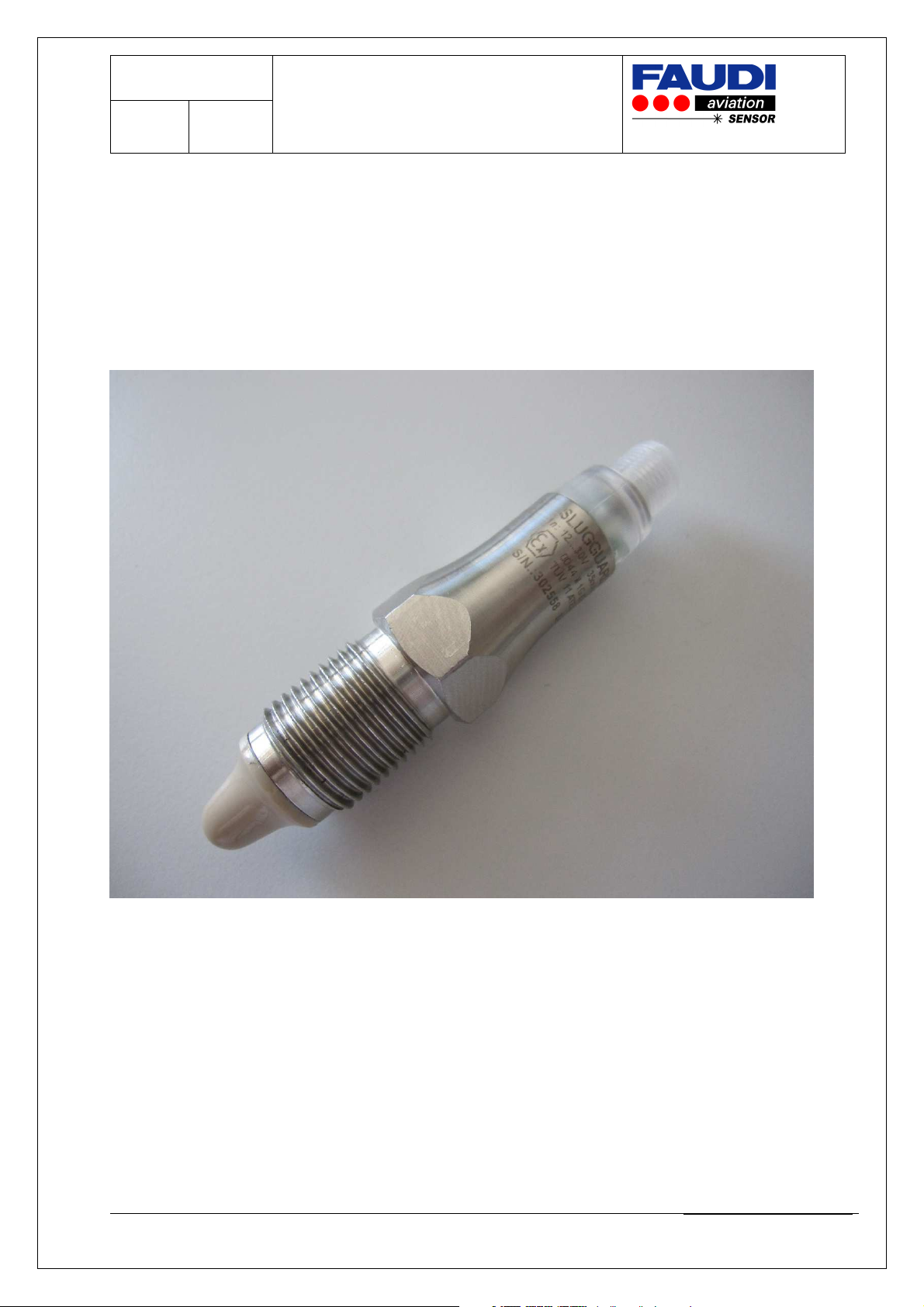

1.8 Identification

SLUGGUARD®with LED

Version 5 Operating instructions

SLUGGUARD®

Page: 6 of: 18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf Manual_SLUGGUARD_Rev5

1.8.1 Incoming acceptance, transport, storage

You should have received a device like above.

Make sure the packaging is undamaged!

Inform the supplier about damage to the packaging.

Keep the damaged packaging until the matter has been settled.

Make sure the contents are undamaged!

Inform the supplier about damage to the delivery contents. Keep the damaged products until

the matter has been settled.

Check that the scope of delivery is complete and agrees with your order and the shipping.

The packaging material used to store or to transport the product must provide shock

protection and humidity protection. The original packaging offers the best protection. Also,

keep to the approved ambient conditions (see "Technical data").

If you have any questions, please contact your supplier or your sales centre responsible.

1.9 Scope of delivery

The following items are included in the delivery:

A set comprises of:

① SLUGGUARD®

②- Dedicated barrier for hazardous area installation of SLUGGUARD®in zone 0 / 1

③- connection cable between sensor and barrier

①

②

③

Version 5 Operating instructions

SLUGGUARD®

Page: 7 of: 18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf Manual_SLUGGUARD_Rev5

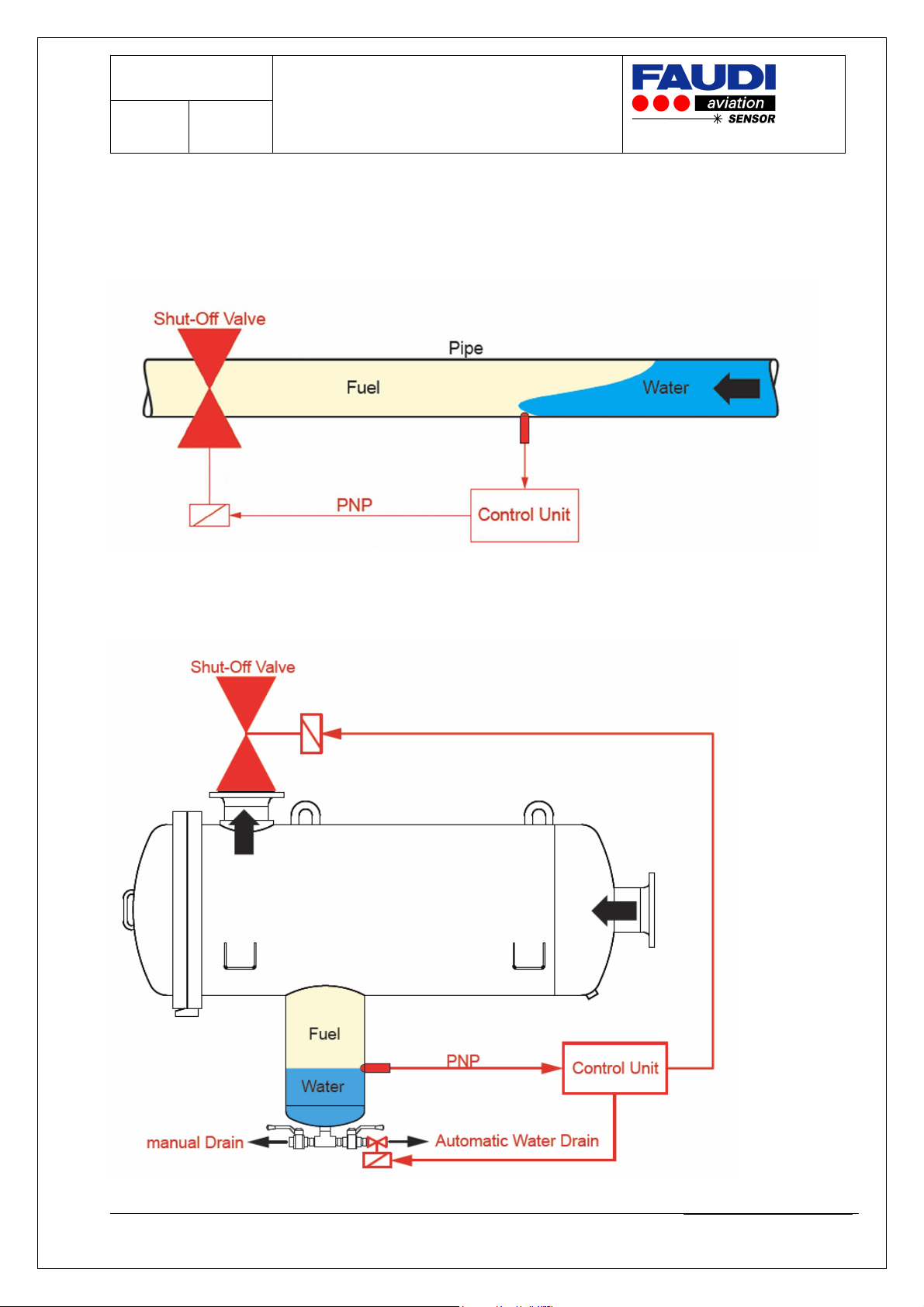

2 Applications

2.1 Bulk water sensor according EI 1592 in pipe section

2.2 SLUGGUARD®in water sump of filter water separator

Version 5

Operating instructions

SLUGGUARD

®

Page:

8

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

2.3

SLUGGUARD

®

below water sump on filter vessels

2.4

Available SLUGUARD

®

versions and accessories

SLUGGUARD

®

Stainless Steel without LED, G1/2 process

connection, M12 plug connector, PNP output

Part No. 600040

Or SLUGGUARD

®

Stainless Steel with LED, G1/2 process

connection, M12 plug connector, PNP output

Part No. 600001

Barrier with power supply and

relays

output

Part No. 600041

Connection cable with M12 connector, 10 m length Part No. 526000

Measuring ball valve for SLUGGUARD

®

Part No. 600511

Version 5

Operating instructions

SLUGGUARD

®

Page:

9

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

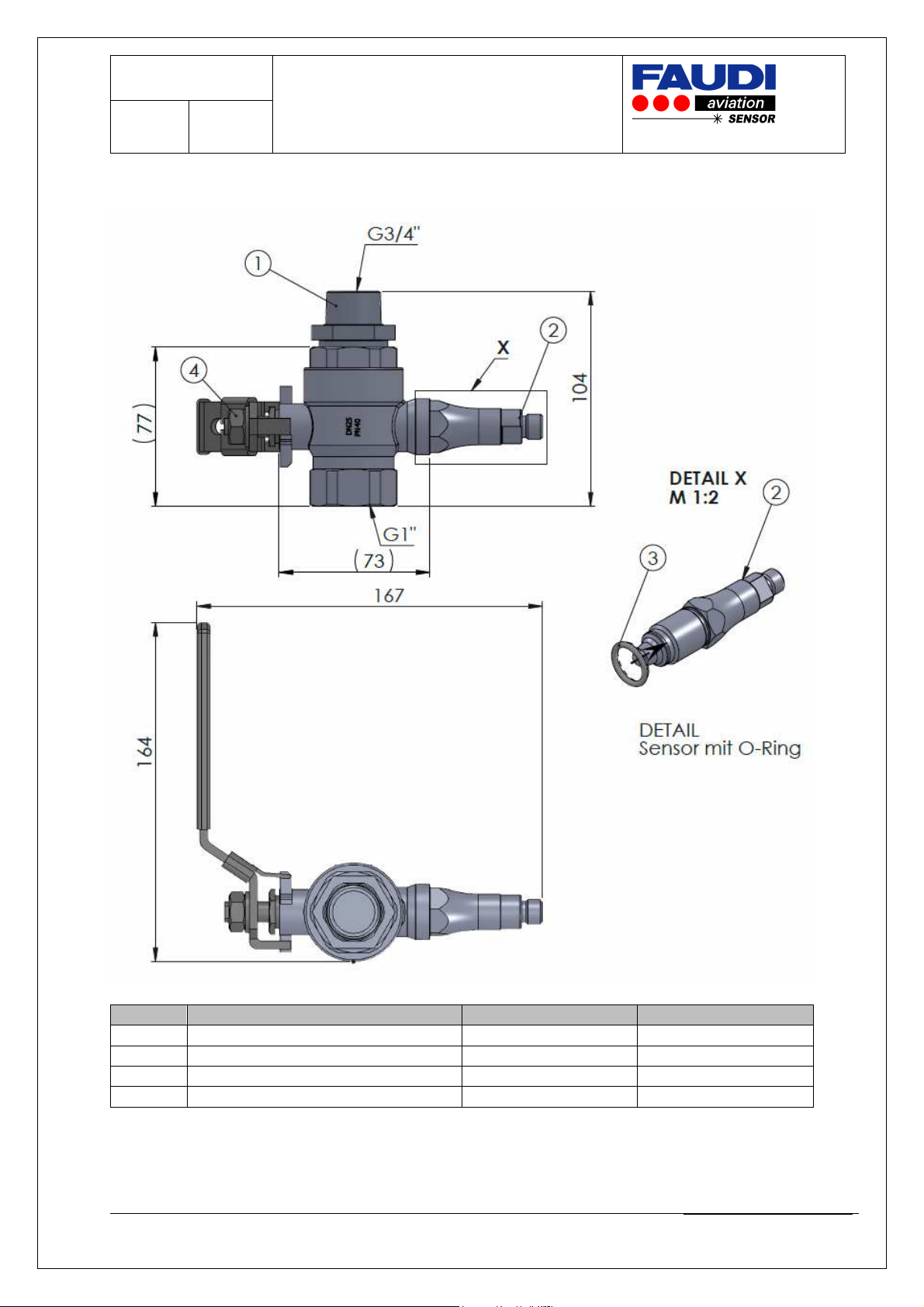

2.5

Ball valve for SLUGGUARD

®

Pos

Description

Description 2

Material

1 Double nipple R 1” / 3/4” 1.4571

2

SLUGGUARD

®

Without LED

-

3

O

-

Ring

NBR

4 Ball valve SLUGGUARD

®

SS

When using the ball valve for the SLUGGUARD

®

– the sealing will be generated via O-Ring.

No need to use Teflon tape!

Tightening torque: 20 – 30 Nm max.

Version 5

Operating instructions

SLUGGUARD

®

Page:

10

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

3 General safety and user instructions

3.1

Safety

Intended use

The sensor must be used solely for the level detection of liquids in applications which are

specified and approved by FAUDI Aviation GmbH.

The sensor must only be used for media against which the housing material and sensor tip

are resistant.

Staff qualification

Only use staff who are trained for the activities described. This applies in particular to

assembly, installation and explosion protection. Make sure that the staff have read and

understood these instructions.

Technical condition

Use the sensor only when in perfect technical condition. Only use FAUDI Aviation GmbH

accessories.

FAUDI Aviation GmbH will accept no liability for other manufacturers’ accessories.

Risk of burns from hot media

During operation the sensor housing may warm up to over 50 °C. When working with hot

media provide protection against burns.

Explosion hazard areas

Ensure that safety requirements are complied with. Do not use equipment that would be

exposed to hard impacts.

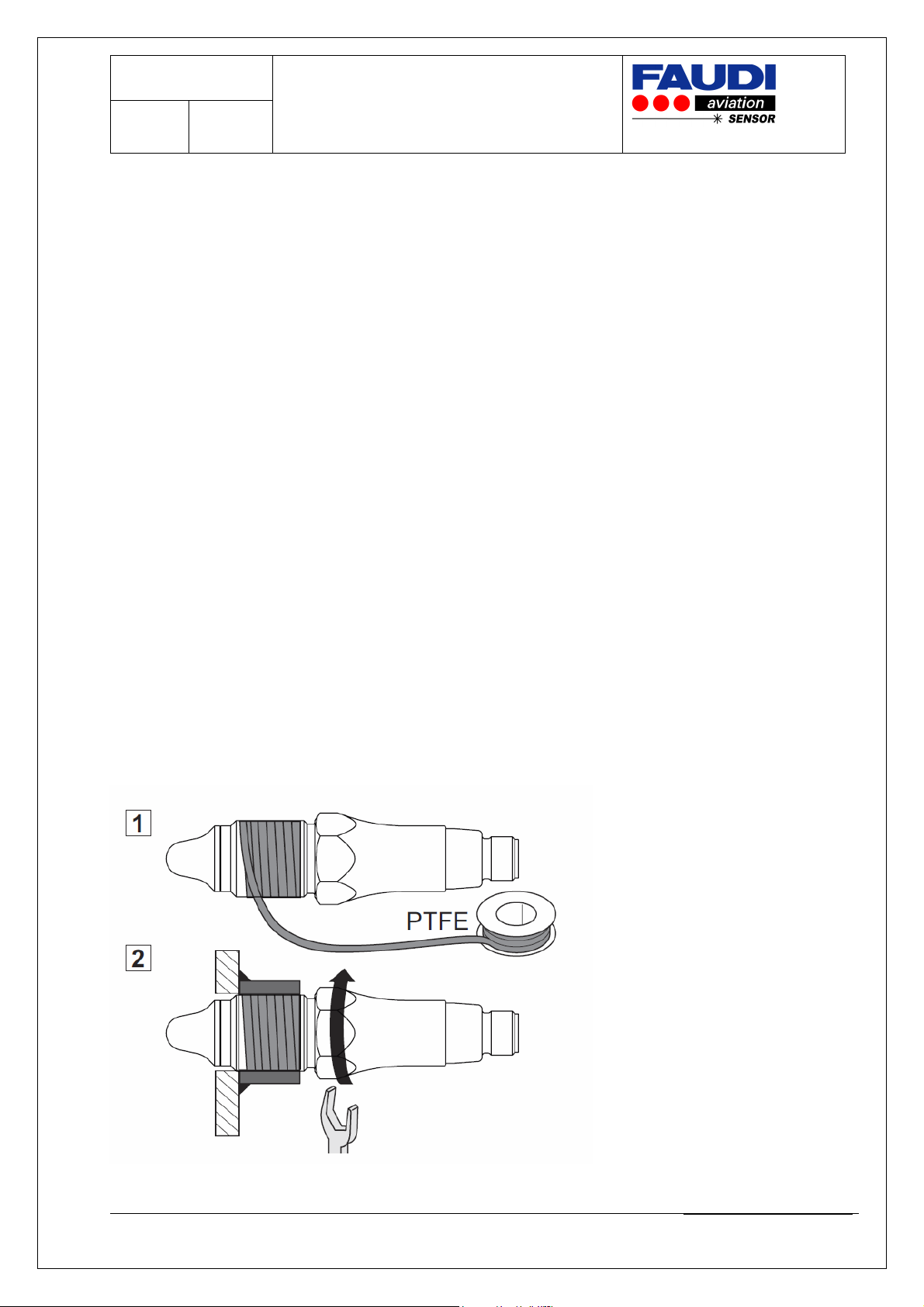

3.2

Installation for different applications

When using the SLUGGUARD

®

without the dedicated ball valve – use sufficient sealant

material like PTFE (Teflon tape) to seal the sensor.

Version 5

Operating instructions

SLUGGUARD

®

Page:

11

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

SLUGGUARD

®

with common G ½ process connection:

Ensure that Vessel and pipelines are free of media

Seal thread on sensor with Teflon tape (PTFE).

Screw in SLUGGUARD

. Tightening torque G 1/2: 30 Nm max.

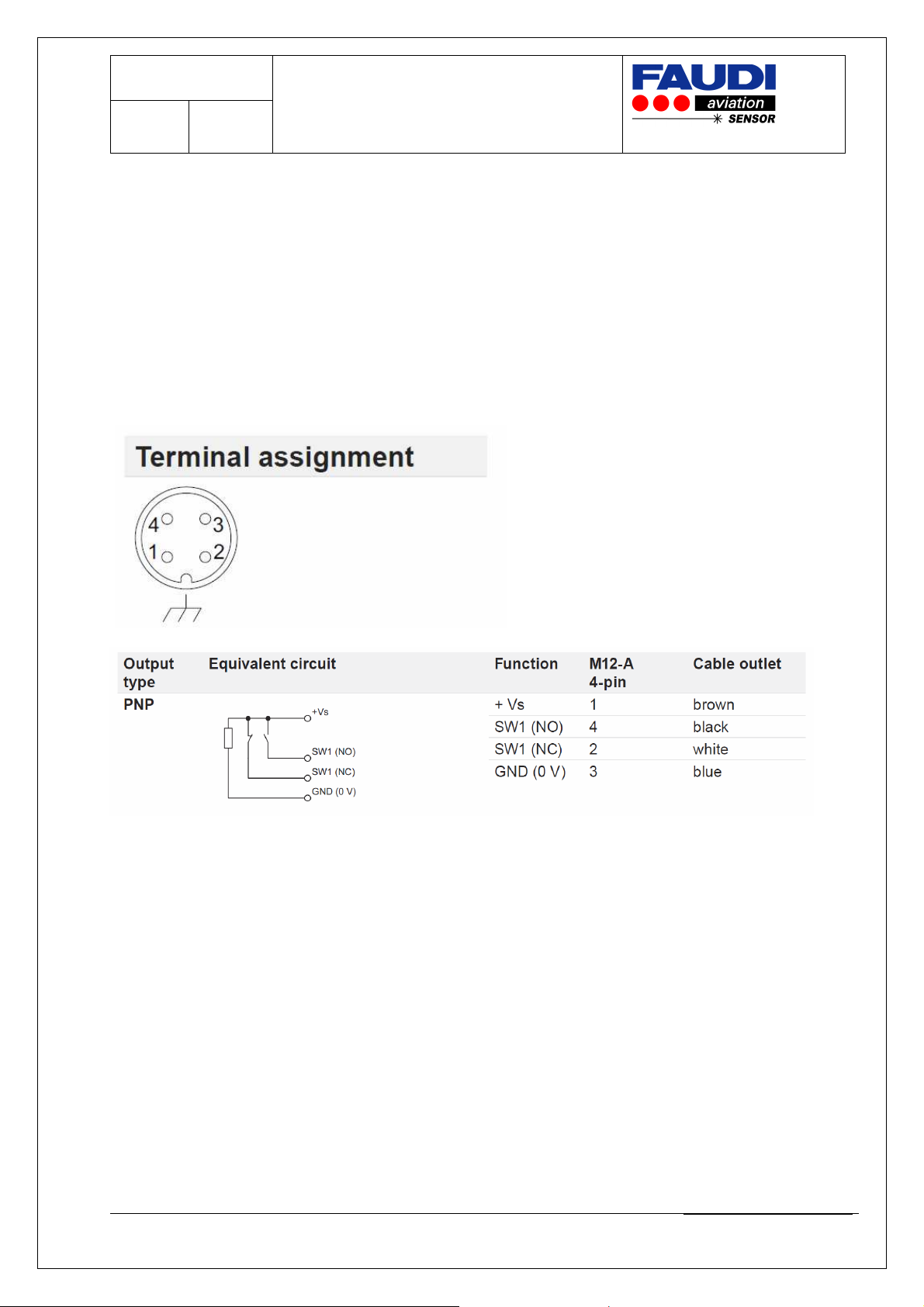

3.3

Electrical connection

A voltage supply of 12 V to 30 V DC should be provided.

Switch off supply voltage.

Connect sensor in accordance with the pin assignment.

3.4

Electrical connection in explosion hazard areas

Depending on the variant, the SLUGGUARD

®

is approved for most explosion hazard areas.

DANGER

Risk of fatal accident due to a wrongly connected sensor

In explosive gas atmospheres of zone 0 or 1, use FAUDI Aviation GmbH isolation barriers.

Use in minimum insulated cable conforming to IP67 specification.

Allow only persons trained in explosion protection to perform the installation.

3.5

Explosive gas atmospheres zone 0 and zone 1

The SLUGGUARD

®

can be used in explosion hazard areas of zone 0 or zone 1.

Sensors with PNP can only use FAUDI Aviation GmbH isolation barriers which are easy to

install.

Version 5

Operating instructions

SLUGGUARD

®

Page:

12

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

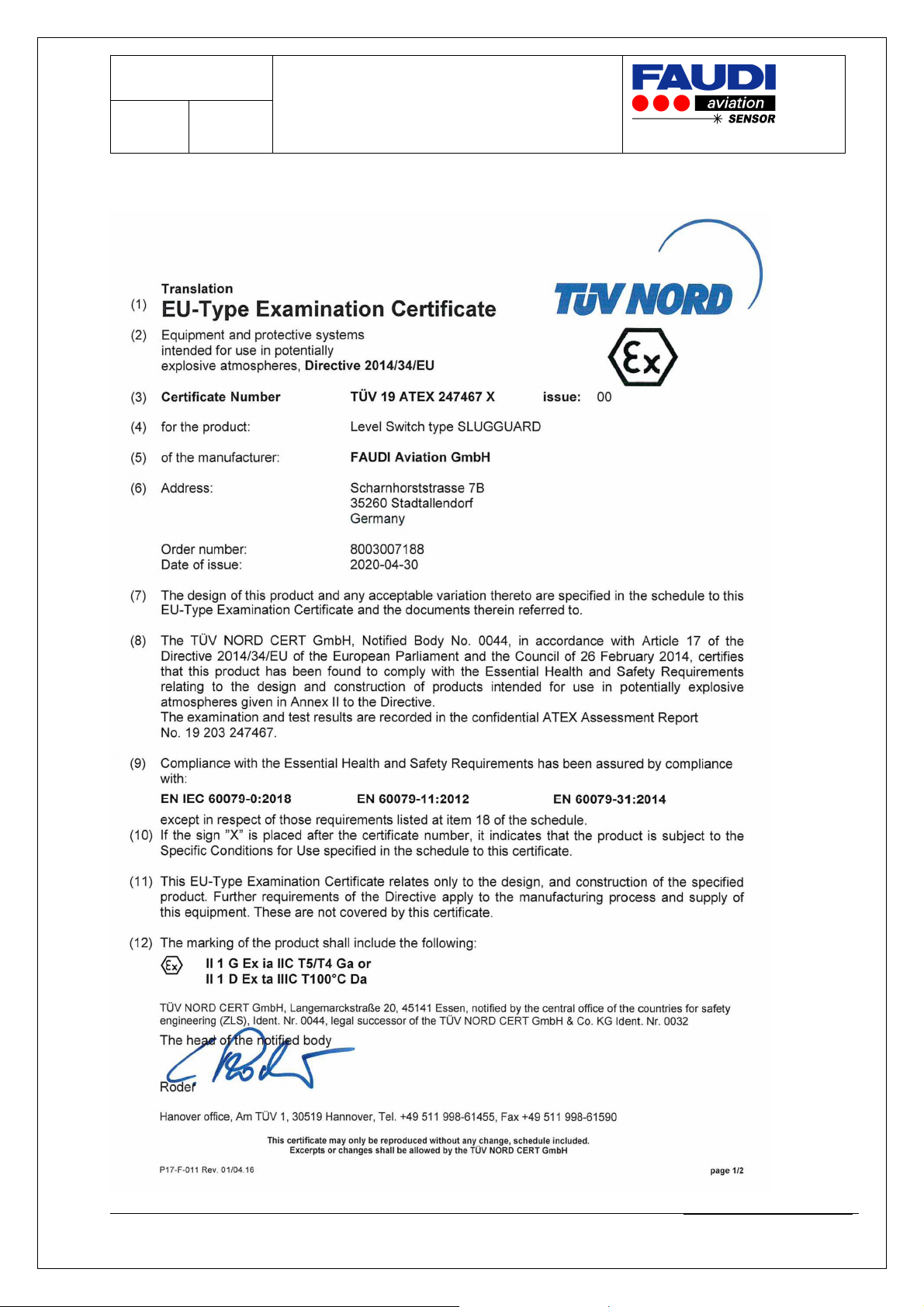

Approval for SLUGGUARD

®

with certificate number: TÜV 19 ATEX 247467 X

SLUGGUARD

®

uses a 4-wire cable. IN PNP connection – only black, brown and blue cables

are in use – white is only needed for programming.

3.6

Isolation barrier for SLUGGUARD

®

Version 5

Operating instructions

SLUGGUARD

®

Page:

13

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

3.7

Relays output of barrier

SLUGGUARD and barrier are configured to use relay connectors 1 (COM) and 3 (NO)

If you connect like this – missing SLUGGUARD or broken cable will create an ALARM to

indicate fail safe error.

For the connection of relay output 1 and 3 – internal switch inside the barrier must be set to

normal.

Open front cover

Check switch to sit like above:

3.8

Cleaning, maintenance and repair

Cleaning

Clean SLUGGUARD

®

as needed - preferable during quarterly check.

Maintenance

Regular maintenance is not required.

Repair

Do not repair the SLUGGUARD

®

yourself.

Send damaged sensor to FAUDI Aviation GmbH.

3.9

Disposal

Do not dispose of in household waste.

Separate materials and dispose of in compliance with nationally

applicable regulations

Version 5

Operating instructions

SLUGGUARD

®

Page:

14

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

4 Technical data

Version 5

Operating instructions

SLUGGUARD

®

Page:

15

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

Version 5

Operating instructions

SLUGGUARD

®

Page:

16

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

5 ATEX approval

Version 5

Operating instructions

SLUGGUARD

®

Page:

17

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

Version 5

Operating instructions

SLUGGUARD

®

Page:

18

of:

18

FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf

Manual_SLUGGUARD_Rev5

6 Declaration of Conformity

Other manuals for SLUGGUARD

1

Table of contents

Other Faudi Accessories manuals