Faulhaber 3242 BX4 Series User manual

WE CREATE MOTION

Technical Manual

MCS 3242 BX4

MCS 3268 BX4

MCS 3274 BP4

EN

Imprint

2

Version:

4th edition, 26-08-2020

Copyright

by Dr. Fritz Faulhaber GmbH & Co. KG

Daimlerstr. 23 / 25 · 71101 Schönaich

All rights reserved, including those to the translation.

No part of this description may be duplicated, reproduced,

stored in an information system or processed or

transferred in any other form without prior express written

permission of Dr. Fritz Faulhaber GmbH & Co. KG.

This document has been prepared with care.

Dr. Fritz Faulhaber GmbH & Co. KG cannot accept any

liability for any errors in this document or for the

consequences of such errors. Equally, no liability can be

accepted for direct or consequential damages resulting

from improper use of the equipment.

The relevant regulations regarding safety engineering

and interference suppression as well as the requirements

specified in this document are to be noted and followed

when using the software.

Subject to change without notice.

The respective current version of this technical manual is

available on FAULHABER's internet site:

www.faulhaber.com

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Content

3

1 About this document ....................................................................................................... 5

1.1 Validity of this document ...................................................................................... 5

1.2 Associated documents ............................................................................................ 5

1.3 Using this document .............................................................................................. 5

1.4 List of abbreviations ............................................................................................... 6

1.5 Symbols and designations ...................................................................................... 7

2 Safety ................................................................................................................................ 8

2.1 Intended use ........................................................................................................... 8

2.2 Safety instructions .................................................................................................. 8

2.3 Environmental conditions ...................................................................................... 9

2.4 EC directives on product safety ............................................................................. 9

3 Product description ........................................................................................................ 10

3.1 General product description ................................................................................ 10

3.2 Product information ............................................................................................. 11

3.3 Product variants .................................................................................................... 12

3.4 Cable outlet of the Motion Control System ....................................................... 13

3.4.1 Axial cable outlet (standard) ................................................................ 13

3.4.2 Radial cable outlet (option 5451) ........................................................ 13

3.4.3 Gearhead combination ......................................................................... 14

3.5 Connector overview ............................................................................................. 15

4 Installation ...................................................................................................................... 16

4.1 Mounting .............................................................................................................. 16

4.1.1 Mounting instructions .......................................................................... 16

4.1.2 Mounting on the front flange ............................................................. 17

4.1.3 Mounting with baseplate..................................................................... 19

4.2 Electrical connection ............................................................................................ 20

4.2.1 Notes on the electrical connection ...................................................... 20

4.2.2 Connecting the Motion Control System .............................................. 22

4.2.2.1 Power supply.......................................................................... 22

4.2.3 Connector pin assignment.................................................................... 23

4.2.4 I/O circuit diagrams ............................................................................... 25

4.2.5 External circuit diagrams ...................................................................... 26

4.3 Electromagnetic compatibility (EMC) .................................................................. 30

4.3.1 Considered systems ............................................................................... 30

4.3.2 Functional earthing .............................................................................. 32

4.3.3 Cable routing ........................................................................................ 33

4.3.4 Shielding................................................................................................ 34

4.3.4.1 Establishing the shield connection ....................................... 35

4.3.4.2 Establishing shield connection with cable lug ..................... 36

4.3.5 Using filters ........................................................................................... 37

4.3.5.1 Input-side filters..................................................................... 37

4.3.5.2 Insulation resistance .............................................................. 37

4.3.6 Error avoidance and troubleshooting ................................................. 38

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Content

4

5 Maintenance and diagnostics ........................................................................................ 39

5.1 Maintenance instructions .................................................................................... 39

5.2 Maintenance tasks ................................................................................................ 39

5.3 Diagnosis ............................................................................................................... 40

5.4 Troubleshooting ................................................................................................... 40

6 Accessories ...................................................................................................................... 41

7 Warranty ......................................................................................................................... 42

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

About this document

5

1 About this document

1.1 Validity of this document

This document describes the installation and use of the following series:

MCS 3242 BX4

MCS 3268 BX4

MCS 3274 BP4

This document is intended for use by trained experts authorised to perform installation and

electrical connection of the product.

All data in this document relate to the standard versions of the series listed above. Changes

relating to customer-specific versions can be found in the corresponding data sheet.

1.2 Associated documents

For certain actions during commissioning and operation of FAULHABER products additional

information from the following manuals is useful:

These manuals can be downloaded in pdf format from the web page www.faulhaber.com/

manuals.

1.3 Using this document

Read the document carefully before undertaking configuration, in particular chapter

“Safety”.

Retain the document throughout the entire working life of the product.

Keep the document accessible to the operating and, if necessary, maintenance person-

nel at all times.

Pass the document on to any subsequent owner or user of the product.

Manual Description

Motion Manager 6 Operating instructions for FAULHABER Motion Manager PC software

Quick start guide Description of the first steps for commissioning and operation of FAULHABER Motion

Control Systems

Drive functions Description of the operating modes and functions of the drive

Accessories manual Description of the accessories

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

About this document

6

1.4 List of abbreviations

Abbreviation Meaning

AC Alternating Current

AnIn Analogue input

AGND Analogue Ground

CAN Controller Area Network

CAN_L CAN-Low

CAN_H CAN-High

CS Chip Select

DC Direct Current

DigIn Digital input

DigOut Digital output

EFS Electronics Filter Supply

EGND Electronic Ground

EMC Electromagnetic compatibility

ESD Electrostatic discharge

ET EtherCAT (Ethernet for Control Automation Technology)

GND Ground

I/O Input/Output

PLC Programmable Logic Controller

PWM Pulse Width Modulation

RxD Receive Data

TTL Transistor Transistor Logic

TxD Transmit data

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

About this document

7

1.5 Symbols and designations

CAUTION!

Hazards due to hot surfaces. Disregard may lead to burns.

Measures for avoidance

NOTICE!

Risk of damage.

Measures for avoidance

Pre-requirement for a requested action

1. First step for a requested action

Result of a step

2. Second step of a requested action

Result of an action

Request for a single-step action

Instructions for understanding or optimising the operational procedures

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Safety

8

2 Safety

2.1 Intended use

The Motion Control Systems described here consist of a combination of a base motor and

an integrated Motion Controller within a common housing with standard protection class

IP 54.

The Motion Control Systems are intended for use as slaves, and are particularly suitable for

positioning tasks in the following application fields:

Robotics

Toolbuilding

Automation technology

Industrial equipment and special machine building

Medical technology

Laboratory technology

When using the Motion Control Systems the following aspects should be observed:

Motion Control Systems contain electronic components and should be handled in

accordance with the ESD regulations.

Do not use the Motion Control Systems in environments where it will come into contact

with chemicals, nor in explosion hazard areas.

The Motion Control Systems should be operated only within the limits specified in the

corresponding data sheet.

Please ask the manufacturer for information about use under individual special

environmental conditions.

2.2 Safety instructions

NOTICE!

Electrostatic discharges can damage the electronics.

Wear conductive work clothes.

Wear an earthed wristband.

NOTICE!

Penetration of foreign objects can damage the electronics.

Do not open the housing.

NOTICE!

Inserting and withdrawing connectors whilst supply voltage is applied at the device can

damage the electronics.

Do not insert or withdraw connectors whilst supply voltage is applied at the device.

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Safety

9

2.3 Environmental conditions

Select the installation location so that clean dry air is available for cooling the Motion

Control System.

When installed within housings take particular care to ensure adequate cooling of the

Motion Control System.

Select a power supply that is within the defined tolerance range.

Protect the Motion Control System against chemical pollutants.

Motion Control Systems satisfy protection class IP54 acc. to DIN EN 60259.

2.4 EC directives on product safety

The following EC directives on product safety must be observed.

If the Motion Control Systems are being used outside the EU, international, national

and regional directives must be also observed.

Machinery Directive (2006/42/EC)

Because of their small size, no serious threats to life or physical condition can normally be

expected from electric miniature drives. Therefore the Machinery Directive does not apply

to our products. The products described here are not “incomplete machines”. Therefore

installation instructions are not normally issued by FAULHABER.

Low Voltage Directive (2014/35/EU)

The Low Voltage Directive applies for all electrical equipment with a nominal voltage of 75

to 1500 V DC and 50 to 1000 V AC. The products described in this technical manual do not

fall within the scope of this directive, since they are intended for lower voltages.

EMC Directive (2014/30/EU)

The directive concerning electromagnetic compatibility (EMC) applies to all electrical and

electronic devices, installations and systems sold to an end user. In addition, CE marking can

be undertaken for built-in components according to the EMC Directive. Conformity with

the directive is documented in the Declaration of Conformity.

Depending on the application, additional shaft seals may optionally be installed in the

base drive, which have to be maintained at regular intervals.

When combined with attachments (e.g., gearboxes) or for enhanced motor protection

an additional seal (O-ring) to enhance the protection class is optionally available (see

chap. 3.4.3, p. 14, chap. 4.1.2, p. 17 and chap. 5.2, p. 39).

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Product description

10

3 Product description

3.1 General product description

The FAULHABER Motion Control Systems described here are intended for controlled opera-

tion of various integrated base motors. They offer different functions and operating

modes, allowing complex drive tasks to be performed. Thanks to their compact design and

flexible connection options, the units can be used in a wide variety of applications and

require only basic wiring.

The Motion Control System can offer the following communication interfaces:

RS232

CANopen

RS232 and EtherCAT

Connections are also available for common or separate voltage supplies between motor

and controller, and also for a wide variety of inputs and outputs. Configuration of the

Motion Control System is performed using the FAULHABER Motion Manager V6.

The drives can be operated in the network via the CANopen or EtherCAT fieldbus interface.

In smaller setups, networking can also be performed via the RS232 interface. The Motion

Control Systems operate in the network in principle as a slave; master functionality for actu-

ating other axes is not provided. After basic commissioning via Motion Manager, the

Motion Control Systems can alternatively also be operated without communication inter-

face.

Motion Control Systems are normally secured using the tapped holes of the front panel.

Where cabling is connected axially, optionally the drive can be secured from below on a flat

base plate (see chap. 4.1, p. 16).

Analogue Hall sensors are used as feedback components.

Motion Control Systems with RS232, CANopen or EtherCAT interfaces can also be oper-

ated independently of the communication interface, if a function or a sequence pro-

gram has been programmed previously without digital command control.

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Product description

11

3.2 Product information

Fig. 1: Designation key

G...MCS 32 ... ... ...

BP4:

RS:

CO:

ET:

BX4:

G:

42:

68:

74:

32:

MCS:

024:

Serielle Schnittstelle RS 232

Schnittstelle CANopen

Schnittstelle EtherCAT

Motorfamilie (BL, 4-Pol-Technologie)

Wellendurchmesser 5 mm

Länge Vorbaumotor 42 mm

Länge Vorbaumotor 68 mm

Länge Vorbaumotor 74 mm

Durchmesser Vorbaumotor 32 mm

Motion Control System

Motornennspannung 24 V

Motorfamilie (BL, 4-Pol-Technologie)

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Product description

12

3.3 Product variants

The following product variants are possible:

Motion Control System with axial cable outlet

Motion Control System with radial cable outlet

In addition to the cable outlet, the following communication interfaces can be selected:

RS232

CANopen

RS232 and EtherCAT

The following motors are available for selection for each product variant:

3242 BX4

3268 BX4

3274 BP4

Depending on the motor, interface and cable outlet selected, the installed length and/

or height of the MCS will vary. Details can be found on the respective product data

sheet or in the relevant dimensional drawing.

Depending on the application, additional shaft seals may optionally be installed in the

base drive, which have to be maintained at regular intervals.

When combined with attachments (e.g., gearboxes) or for enhanced motor protection

an additional seal (O-ring) to enhance the protection class is optionally available (see

chap. 3.4.3, p. 14, chap. 4.1.2, p. 17 and chap. 5.2, p. 39).

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Product description

13

3.4 Cable outlet of the Motion Control System

3.4.1 Axial cable outlet (standard)

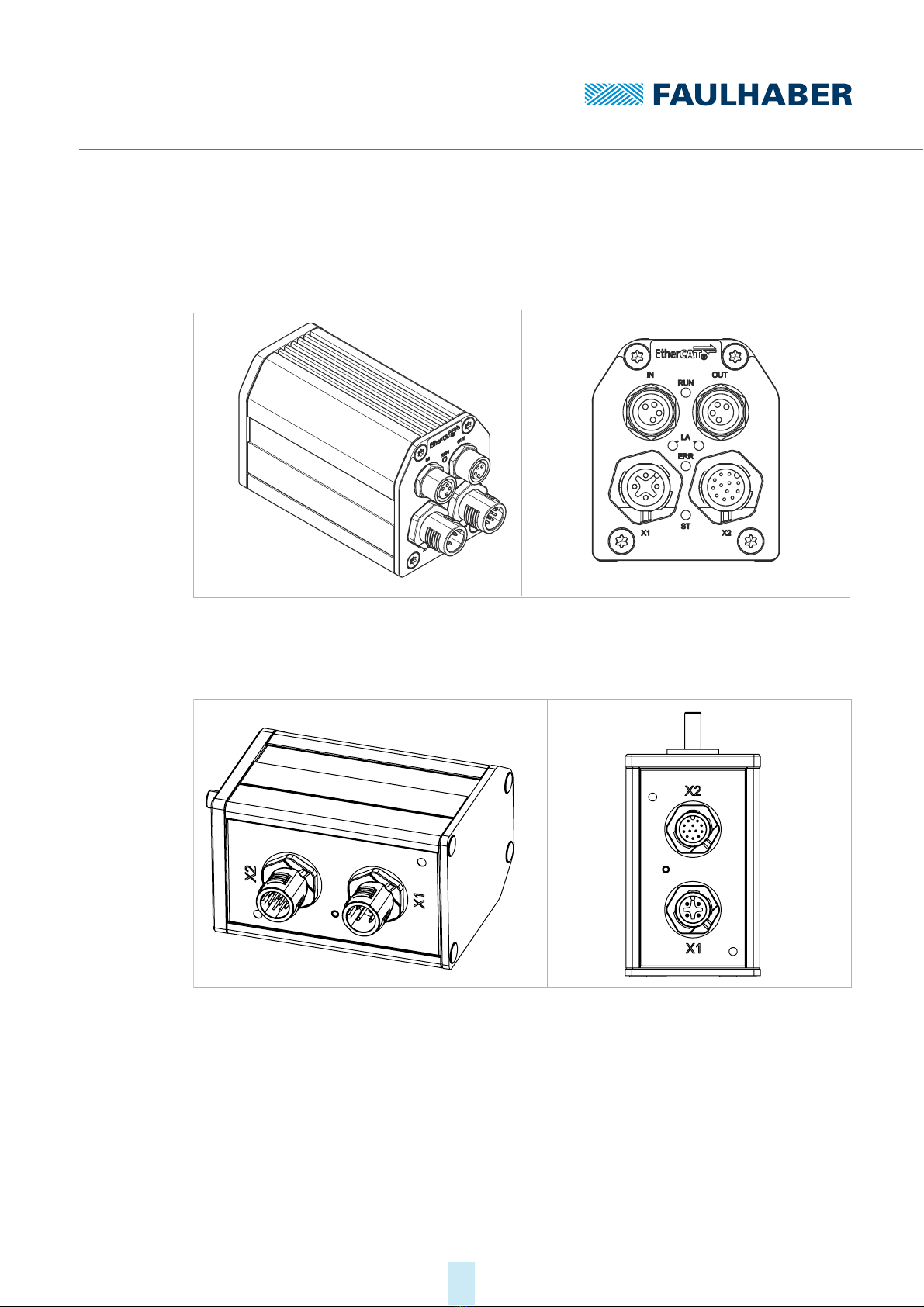

Fig. 2: Isometric view (left) and connector view (right) for axial cable outlet

3.4.2 Radial cable outlet (option 5451)

Fig. 3: Isometric view (left) and connector view (right) for radial cable outlet

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Product description

14

3.4.3 Gearhead combination

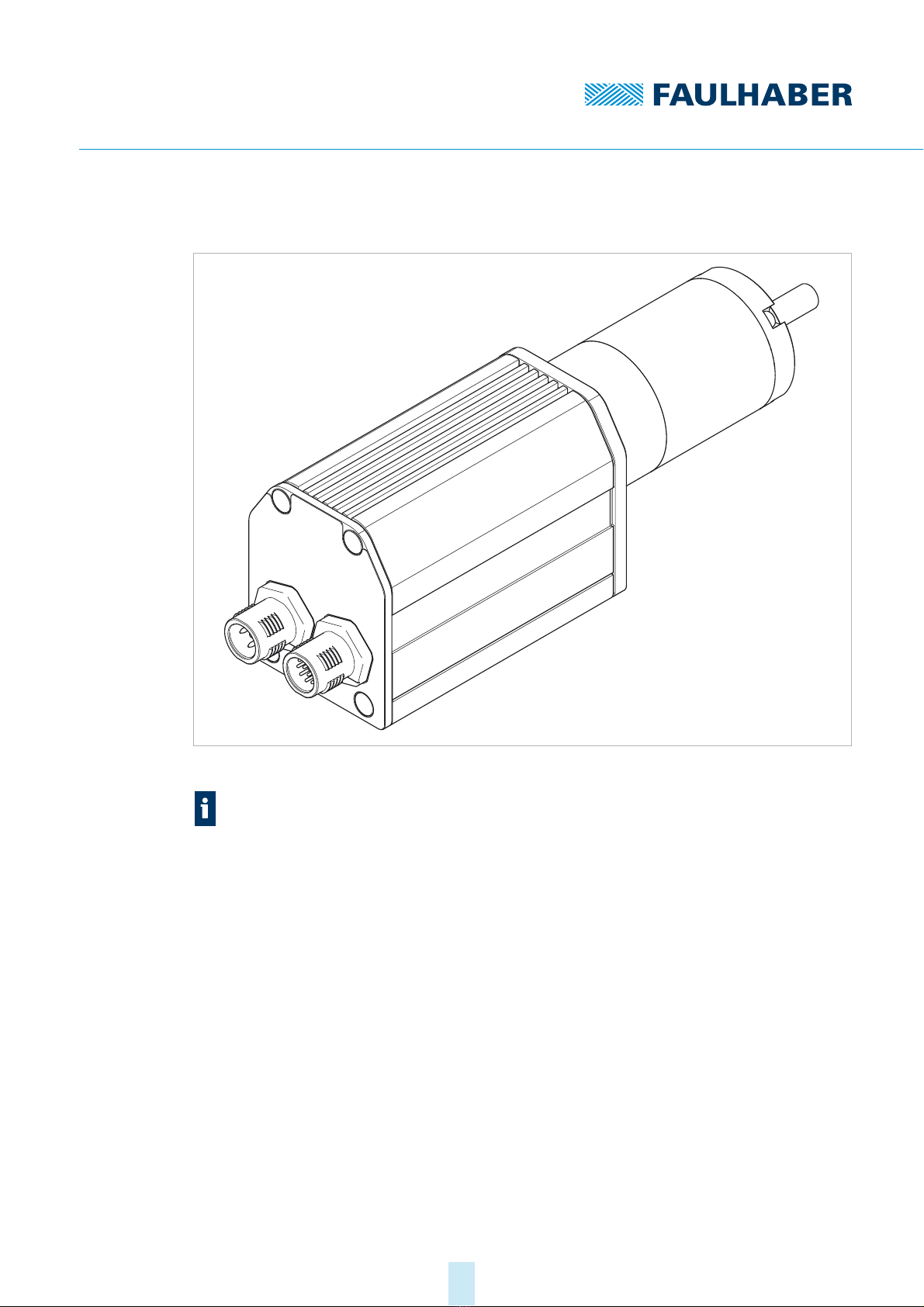

Fig. 4: Combination example with gearhead 32A

Using option 5657 and when the base drive is directly flange-mounted or in combina-

tion with attachments (e.g. gearboxes), an additional seal (O-ring), to enhance the pro-

tection class of the complete system, may be installed between the drive and the

attachment (see chap. 4.1.2, p. 17, and chap. 5.2, p. 39).

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Product description

15

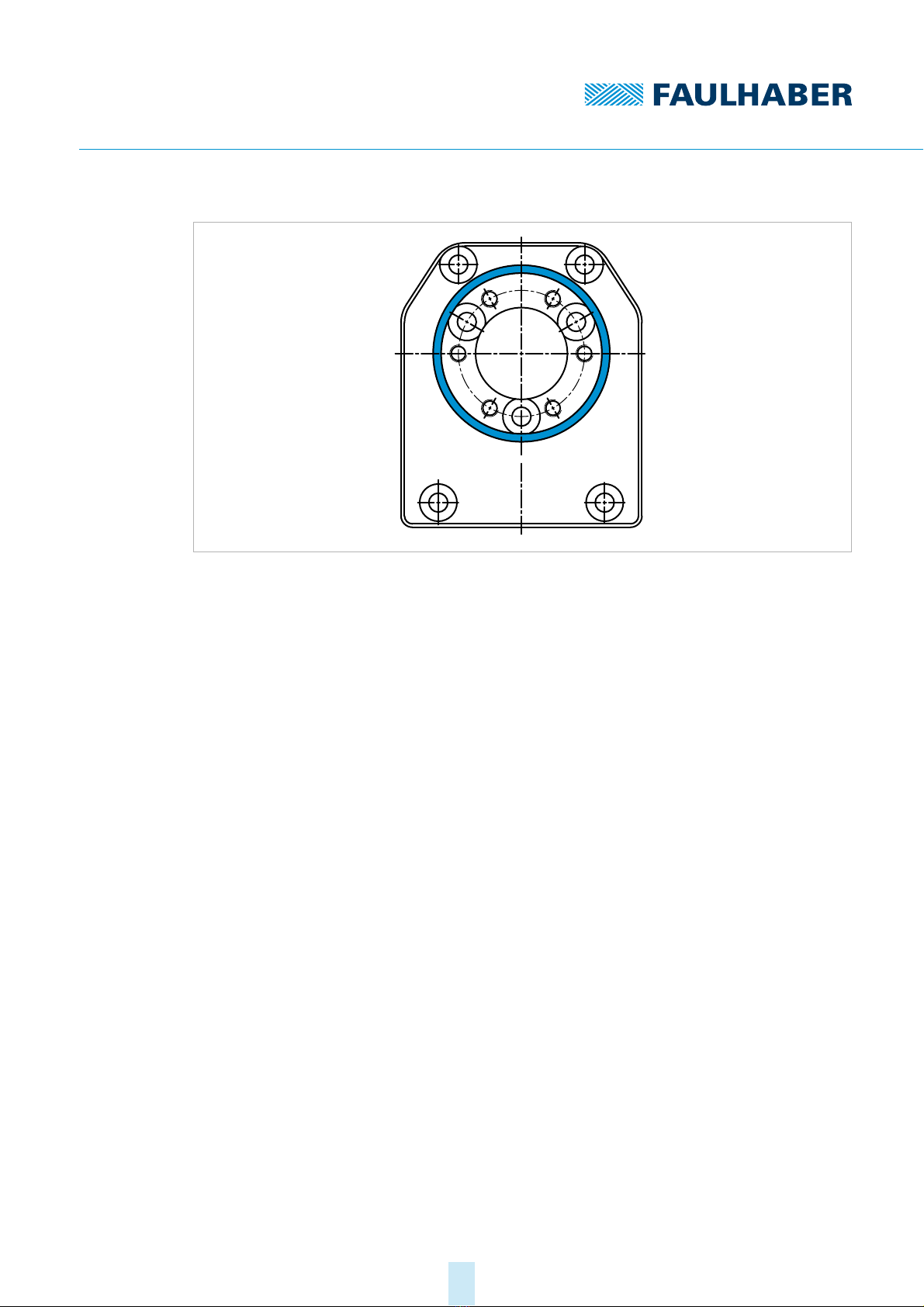

Fig. 5: Front view of the motor flange A-side with radial groove (blue)

3.5 Connector overview

Tab. 1: Connector overview of the Motion Control System

Tab. 2: LED overview

Designation Function

IN/OUT Connection of the EtherCAT communication

X1 (supply) Power supply of the Motion Control System

X2 (I/O) Interface connection RS232/CAN and inputs or outputs for external circuits

Designation Interface Function

State LED all Green (continuous light): Device active.

Green (flashing): Device active. However the state machine has not yet reached

the Operation Enabled state.

Red (continuously flashing): The drive has switched to a fault state. The output

stage will be switched off or has already been switched off.

Red (error code): Booting has failed. Please contact FAULHABER Support.

RUN LED EtherCAT Green (continuous light): Connection present. Device is ready for use.

Green (flashing): Device is in the Pre-Operational. state

Green (single flash): Device is in the Safe-Operational. state

Off: Device is in the Initialisation state.

ERR LED EtherCAT Red (flashing): Faulty configuration.

Red (single flash): Local error.

Red (double flash): Watchdog timeout.

Off: No connection error

LA LED EtherCAT Green (continuous light): No data transfer. Connection to another participant

established.

Green (flashing): Data transfer active.

Off: No data transfer. No connection to another participant.

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Installation

16

4 Installation

Only trained experts and instructed persons with knowledge of the following fields may

install and commission the Motion Control System:

Automation technology

Standards and regulations (such as the EMC Directive)

Low Voltage Directive

Machinery Directive

VDE regulations (DIN VDE 0100)

Accident prevention regulations

This description must be carefully read and observed before commissioning.

Also comply with the supplementary instructions for installation (see chap. 2.3, p. 9).

4.1 Mounting

4.1.1 Mounting instructions

CAUTION!

The Motion Control System can become very hot during operation.

Place a guard against contact and warning notice in the immediate proximity of the

Motion Control System.

NOTICE!

Improper installation or installation using unsuitable attachment materials can damage the

Motion Control System.

Comply with the installation instructions.

NOTICE!

Installation and connection of the Motion Control System when the power supply is

applied can damage the Motion Control System.

During all aspects of installation and connection work on the Motion Control System,

switch off the power supply.

NOTICE!

Installation and connection of the Motion Control System on a surface that is not flat can

damage the Motion Control System.

Install the Motion Control System on a flat surface.

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Installation

17

4.1.2 Mounting on the front flange

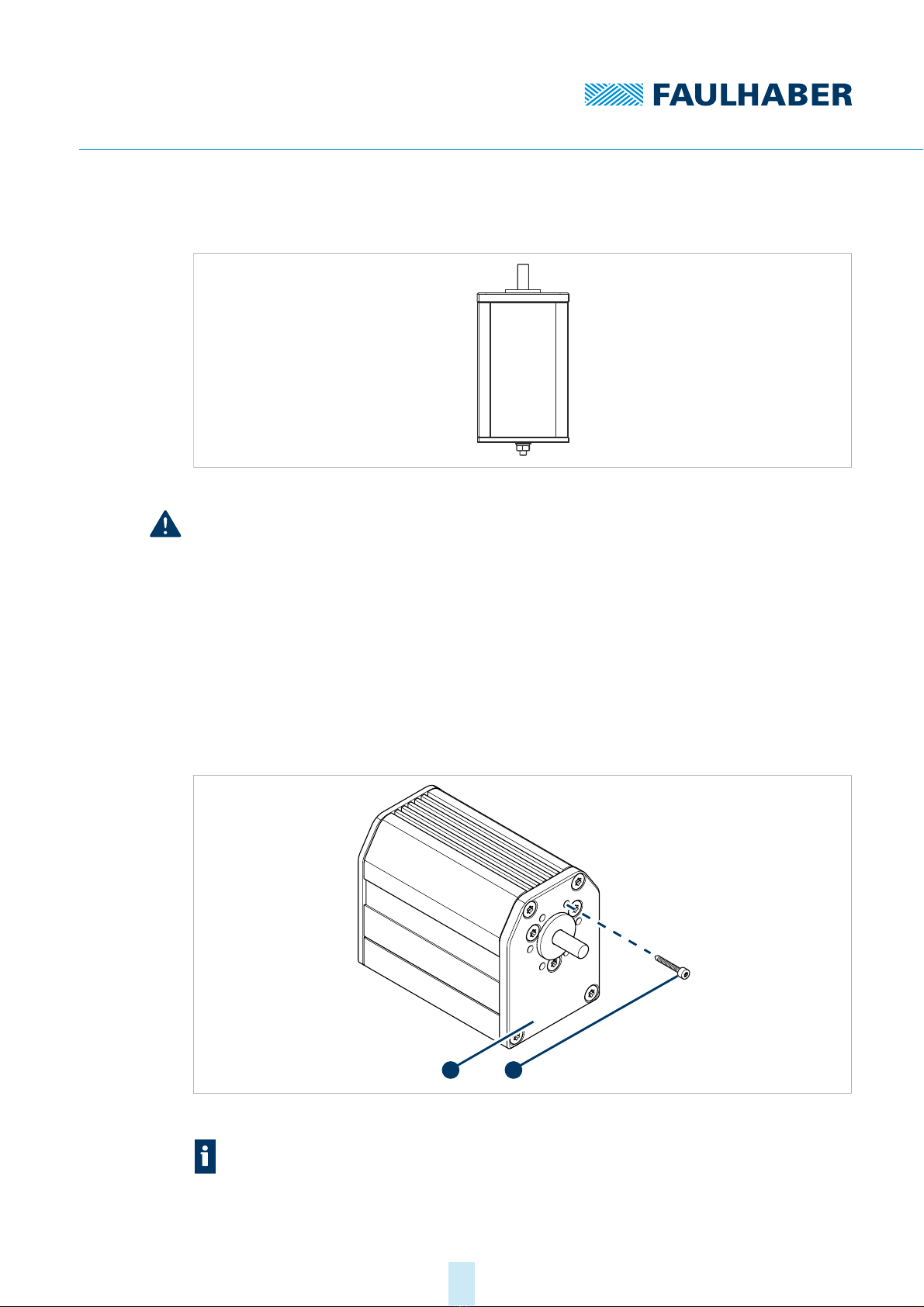

Fig. 6: V3 installation schematic diagram

NOTICE!

If the Motion Control System is installed with the shaft end facing upwards, liquids can

accumulate on the upward-facing surface and damage the device.

With V3 installation (see Fig. 6), make sure that no liquids can penetrate the bearings.

Optional: Use a Motion Control System with an additional shaft seal. Fitting a shaft seal

may reduce the motor performance (see chap. 4.1, p. 16)

Secure the Motion Control System (1) with screws (2) using the tapped bore holes on

the cover plate as shown in Fig. 7.

The maximum tightening torque of the screws is 130 Ncm.

The maximum screw-in depth is 4 mm.

Fig. 7: Mounting on the front flange

Using option 5657 and when the base drive is directly flange-mounted or in combina-

tion with attachments (e.g. gearboxes), an additional seal (O-ring), to enhance the pro-

tection class of the complete system, may be installed between the drive and the

attachment (see chap. 5.2, p. 39).

1 2

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Installation

18

Fig. 8: Front view of the motor flange A-side with radial groove (blue)

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Installation

19

4.1.3 Mounting with baseplate

1. Secure the Motion Control System (1) with screws (3) to the base plate (2).

Screw type ST 2.2

The maximum tightening torque of the countersunk screws is 50 Ncm.

The maximum screw-in depth of the countersunk screws is 5 mm

Fig. 9: Mounting with baseplate

Screws and base plate are not part of the FAULHABER product portfolio and they must

be provided by the user.

Screw spacing 3274 BP4 RS/CO/ET 3268 BX4 RS/CO/ET 3242 BX4 RS/CO/ET

X 29 mm 29 mm 29 mm

Y103 mm 94 mm 68 mm

1

2

3

X

Y

4th edition, 26-08-2020 7000.05058, 4th edition, 26-08-20207000.05058

Installation

20

4.2 Electrical connection

4.2.1 Notes on the electrical connection

NOTICE!

Electrostatic discharges to the Motion Control Systems connections can damage the elec-

tronic components.

Observe the ESD protective measures.

NOTICE!

Incorrect connection of the wires can damage the electronic components.

Connect the wires as shown in the connection assignment.

NOTICE!

A short-term voltage peak during braking can damage the power supply or other con-

nected devices.

For applications with high load inertia, the FAULHABER Braking Chopper of the BC

5004 series can be used to limit overvoltages and thereby protect the power supply. For

more detailed information see the data sheet for the Braking Chopper.

The Motion Control Systems contain a PWM output stage for controlling the motors. Power

losses arising during operation and alternating electrical fields arising due to the pulsed

control of the motors, must be dissipated and damped by appropriate installation.

Connect the Motion Control System to an earthing system. This should be done prefera-

bly by mounting it on an earthed base plate, or alternatively by connecting it to an

earthed flange. Alternatively the earthing can be achieved by shielding the connecting

cables to the connection sockets.

Make sure that potential equalisation is present between all coupled parts of the sys-

tem.

If several electrical devices or controllers are networked by means of RS232 or CAN,

make sure that the potential difference between the earth potentials of the various

parts of the system is less than 2 V.

The EGND connection, and if necessary the shielding around the supply connection, are

available for potential equalisation.

Other manuals for 3242 BX4 Series

1

This manual suits for next models

7

Table of contents

Other Faulhaber Engine manuals

Popular Engine manuals by other brands

geos

geos LC 165 FS manual

Chris-Craft

Chris-Craft 350-Q Operator's manual

KEM

KEM KODIAK MARINE Operator's manual

Mercury

Mercury 200 Verado FourStroke Operation and maintenance manual

Briggs & Stratton

Briggs & Stratton 950 Series Advance Product Service Information

O.S. engine

O.S. engine MAX-50SX Owner's instruction manual