Fdjtool DC1200 User manual

Owner's Manual

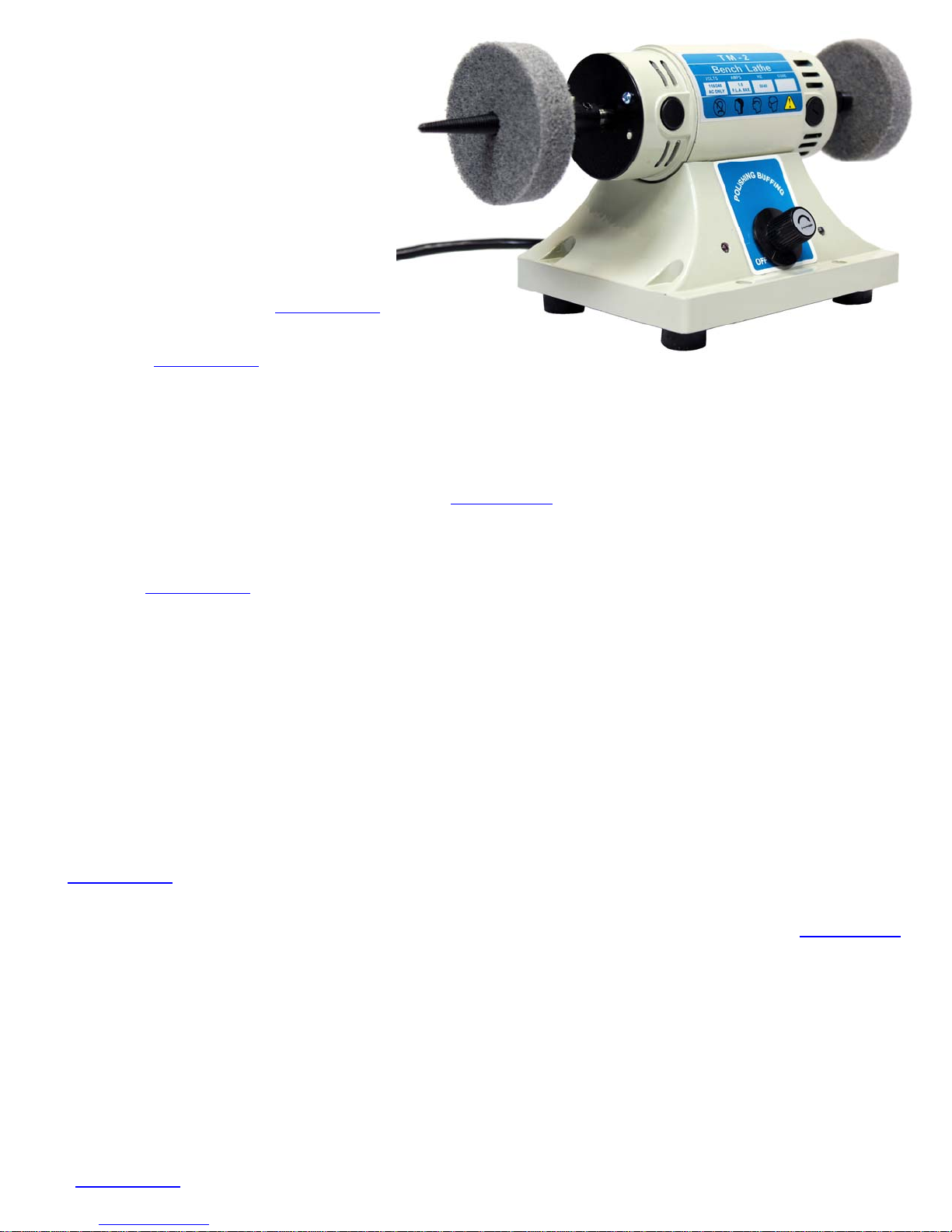

DC1200 - BENCH POLISHER

- 1/4" Diameter Shaft -

You have purchased a fine quality power tool

which will perform a wide variety of tasks difficult

do with any other kind of power tool. This tool

manufactured to high standards of precision and

performance and, with proper use and

maintenance, will give you years of trouble-free

performance.

to

is

- For Your Own Safety -

Read owner's manual before operating. Always

wear eye protection while using the Bench Polisher

or other power tools.

Before using your Bench Polisher, please read all

safety instructions. They are for your protection and should always be followed to reduce the risk of personal injury or damage to

the tool.

Not a toy.

Safety Instructions

ALWAYS WEAR PROPER EYE AND FACE PROTECTION. Safety glasses or face shields should be worn whenever you

operate any power tool to prevent serious eye or face injuries. Do not wear loose clothing or jewelry and be sure to tie back long

hair.

Never operate any accessory at speeds above its maximum speed rating. Only accessories rated for 7,500 RPM or more should

be used with the Bench Polisher. Always determine the manufacturer's speed rating before using accessories. Safety

requirements for the use, care, and protection of abrasive wheels are contained in ANSI Standards B7.1-1978 which are available

from ANSI, 1430 Broadway, New York, New York 10018.

Never use or continue to use any accessory which appears to be damaged, loose, vibrating, or out of balance. Inspect each

accessory for cracks or flaws before using it.

Always insert the shank or arbor of an accessory or mandrel into the collet (or collet holder chuck or chuck arbor) as far as

possible in order to provide proper support. Tighten the collet or chuck securely.

Never use excessive side pressures which may tend to bend or break the shank or arbor or an accessory. Let the speed of the

accessory do the work.

Do not stall the motor by jamming or using excessive pressure on the polishing wheel, buff, wheel, or accessory. This can result

in damage to the motor.

Assembly Instructions

Each Bench Polisher with 1/4" diameter shaft comes with the following: standard attachments Tapered Spindle (left hand),

Tapered Spindle (right hand), two medium grit abrasive wheels, and two replacement motor brushes. These are precision made

spindles suitable for speeds up to 7,5000 RPM. Similar spindles and mandrels supplied for slower speed polishing motors often

do not run as true which can cause vibration and be a potential hazard. Their use is not recommended with this bench polisher.

Mounting Base: The base should be bolted or screwed down to a solid work bench or table to prevent movement while pressure is

applied to a buff or wheel on the lathe. There are four mounting holes in the base for this purpose.

Attach the spindles or mandrels by sliding them onto the motor shaft until there is a 1/8" space between the motor housing and

inside edge of the spindle or mandrel. Be sure that the two set screws line up with the flat on the motor shaft. Tighten both

screws securely.

Plug in the motor and run polisher at slow speed without a buff (or wheel) to see that the spindles (or mandrel) on the polisher are

running true.

Never use a buff, brush, abrasive wheel, or any other accessory that is not rated for at least 7,5000 RPM and never use one that

appears to wobble or vibrate. It could damage the polisher and cause injury to you. Buffs over 4" in diameter should not be used

on the Bench Polisher. Never use a grinding wheel over 2" diameter.

Operation

Because of the higher maximum speed (approximately 9,000 RPM to 10,000 RPM) and variable speed control, the Bench

Polisher has several advantages over conventional single or two speed polishing and buffing machines.

1. The same size buffing wheel can be used to obtain different surface speeds, as measured in surface feet per minute

(SFPM). A 3" or 4" diameter buff can provide the 1,750 to 3,450 SFPM recommended for polishing and the 3,450 and

higher SFPM recommended for buffing. The chart below shows the SFPM obtained with different diameter wheels at full,

medium, and low speeds.

2. The SFPM can be varied while using the same wheel. This will give better results on different types of material.

3. The 10,000 RPM maximum speed will enable you to get much higher SFPM with smaller buffs such as 1" or 2" buffs or

inside ring buffs than slower single or double speed equipment.

4. The maximum speed of 10,000 RPM is also fast enough to permit the use of small mounted abrasive points, brushes,

cutters or other accessories in a collet holder.

Wheel Dia. Speed RPM SFPM

1" Full - 7,000 1,750

1" Med - 4,000 1,000

2" Full - 7,000 3,500

2" Med - 4,000 2,000

3" Full - 7,000 5,250

3" Med - 4,000 3,000

4" Full - 7,000 7,000

4" Med - 4,000 4,000

6" Low - 1,725 2,600

6" Low - 3,450 5,200

Please note: Cotton, chamois or felt buffs over 4" in diameter should not be used with the Bench Polisher.

Maintenance

Lubrication: This Bench Polisher has pre-lubricated ball bearings and a dustproof motor housing and does not require any

lubrication. The motor is designed to operate at about 40-50° F above room temperature which will be warm to the touch but will

not harm the motor.

Brush Wear: Disconnect power cord before checking for brush wear. Check for brush wear periodically (about every 100 hours of

continuous operation). The brush tubes are located under the two protective caps on the right hand side of the motor (as you face

it). Remove them with a standard screw driver blade, unscrew the brush tube caps, check the brush length, and install new

brushes if the old ones are less then 1/4" in overall length. Be sure that the radius in the end of the brush is in line and conforms

to the commutator surface.

Limited Warranty

The Bench Polisher is guaranteed to be free of defects in material or workmanship for a period of 1 year after purchase. During

the warranty period, the defective product will be repaired or replaced without charge or, at our option, the purchase price will be

refunded. This warranty does not cover damage caused in transit or by accident, misuse, or ordinary wear.

ALL IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO WARRANTIES OF FITNESS AND MERCHANTABILITY ARE

HEREBY LIMITED IN DURATION TO A PERIOD ENDING ONE YEAR FROM DATE OF PURCHASE, AND WE WILL NOT BE

LIABLE OR RESPONSIBLE FOR ANY SPECIAL OR CONSEQUENTIAL DAMAGES.

FDJ On Time presents the manufacturer’s instructions in a useful, organized form. Original instructions are available with the product.

Table of contents

Popular Other manuals by other brands

Toshiba

Toshiba SD-V593SU owner's manual

BFT

BFT MOOVI 30-50 ALPHA BOM Installation and user manual

GRASS VALLEY

GRASS VALLEY AURORA 7 - ARCHIVE AND RESTORE WORKFLOW Application note

Pondline

Pondline 260 owner's manual

AMX

AMX AXC-232 Specifications

HydraMaster

HydraMaster TITAN 425 Owner’s Guide and Maintenance Schedule