i-3

METAL DOT MATRIX REV. 04.2002

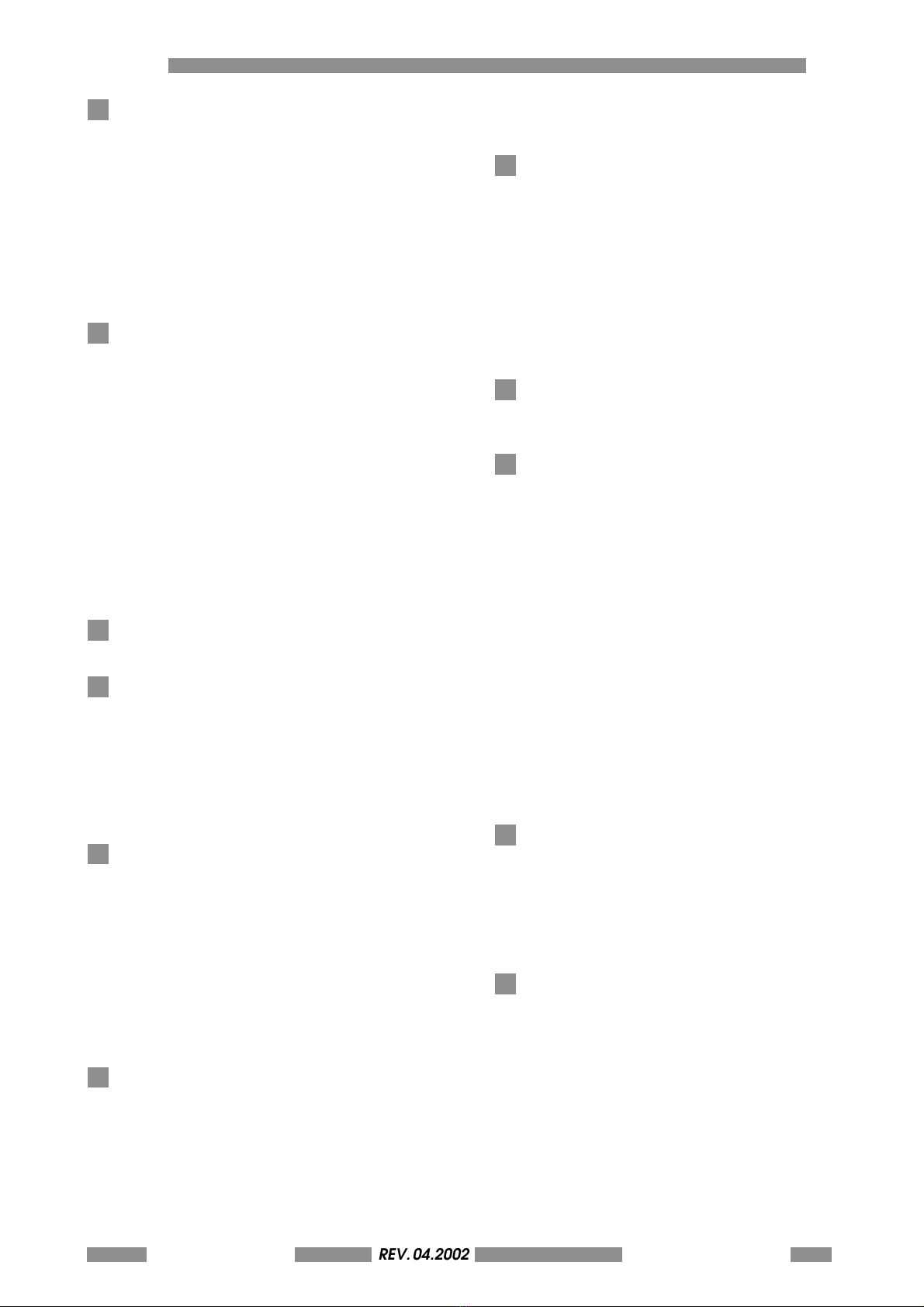

INDEX I

OPERATORS MANUAL

FOREWORD.................................................... 0.5

0.1USING THE WORKSHOP MANUAL............. 0.7

0.1.1 Importance of the manual ....... 0.7

0.1.2 Conservin the manual............. 0.7

0.1.3 Consultation the manual .......... 0.7

0.1.4 Symbols used in the manual ..... 0.7

0.2 PROCEDURE FOR UPDATING MANUAL IN

CASE OF MODIFICATIONS TO

MACHINE ................................................ 0.8

0.3 ORDERING ORIGINAL REPLACEMENT

PARTS ..................................................... 0.8

GENERAL INFORMATION .............................. 1.9

1.0 GENERAL INFORMATION ..................... 1.10

1.1 ELECTRICAL SPECIFICATION ............... 1.11

1.2 EQUIPMENT CLASSIFICATION AND

STANDARD REFERENCE ....................... 1.11

1.3 PHYSICAL ENVIRONMENT AND

OPERATING CONDITIONS ................... 1.11

1.4 DIMENSIONS AND WEIGHT .................. 1.11

1.5 STAMPING CAPACITY AND TECHNICAL

FEATURES ............................................... 1.12

1.6 CAUTIONS............................................. 1.13

1.7 ENVIRONMENTAL

RECOMMENDATIONS .......................... 1.14

1.8 SAFETY INSTRUCTIONS ......................... 1.15

1.9 DECLARATIONS OF CONFORMITY ...... 1.17

UNPACKING .................................................2.19

2.0 UNPACKING ......................................... 2.20

INSTALLATION ...............................................3.21

3.1 CHECKING THE ACCESSORIES ............ 3.22

3.2 ELECTRICAL CONNECTIONS ............... 3.23

3.3 CHOOSING THE WORKING PLACE ..... 3.23

3.4 ADVISE AND CARE DURING THE

INSTALLATION ....................................... 3.24

3.5 SWITCHING ON AND CONTROLLING THE

DISPLAY ................................................. 3.25

OVERALL DESCRIPTION................................4.27

4.1 OVERALL PARTS DESCRIPTIONS .......... 4.28

4.1.1 The top door............................. 4.28

4.1.2 Safety mushroom pushbutton

(emer ency stop) .................... 4.28

4.1.3 The console............................... 4.29

4.1.4 The indicator lamps ................. 4.29

4.2 DIFFERENCES BETWEEN MANUAL (1000)

AND AUTOMATIC (2000) MODELS...... 4.30

4.3 STORED CONFIGURATION AND

REPLACING LITHIUM BATTERY ............. 4.31

HOW TO PRODUCE ONE CARD ...................5.33

5.0 HOW TO PRODUCE ONE CARD ......... 5.34

5.1 SETTING THE MACHINE ........................ 5.34

5.1.1 Automatic (2000) version ........ 5.35

5.1.2 Manual (1000) version ............. 5.36

5.1.3 Stylus adjustment ...................... 5.37

5.2 SWICHING ON THE MACHINE ............. 5.38

5.3 INSTALL THE SOFTWARE "SWORD" ........ 5.39

5.4 RUN THE PROGRAM AND PRODUCE ONE

CARD ................................................... 5.40

MAINTENANCE.............................................6.43

6.1 SCHEDULED LUBRICATION .................. 6.44

6.2 RECOMMENDED LUBRICANTS ............ 6.44

6.3 GENERAL MAINTENANCE BY THE

OPERATOR ............................................ 6.45

6.3.1 Trolley-Truck Oilin ................... 6.45

6.3.2 Plate loader oilin ................... 6.45

6.3.3 Stampin unit............................ 6.46

6.4 UNLOADER LIFTER ................................ 6.46

6.5 SAFETY INTERLOCK SWITCH

FUNCTIONAL TEST ................................ 6.46

TROUBLE SHOOTING.....................................7.47

7.1 ERROR MESSAGES AND PROBLEM

SOLVING................................................ 7.48

THE MACHINE'S SETUP.................................A.51

A.0 SETUP PROCEDURE ............................. A.52

A.1 KEYBOARD DESCRIPTION ................... A.52

A.2 DESCRIPTION AND MODIFY OF

SETTING ................................................ A.54

A.3 GENERAL PROGRAMMING OF THE

MACHINE ............................................. A.56

A.4 CONFIGURATION PARAMETERS ......... A.58

A.5 SERIAL PORT PROGRAMMING ........... A.59

A.6 MECHANICAL PARAMETERS

ADJUSTMENT ....................................... A.60

A.7 PROTOCOLS SETTINGS ........................ A.61

A.8 PASSWORD .......................................... A.65

A.9 STAMPING CONFIGURATION ............. A.66

A.10KEYPAD LCD SETTING ......................... A.68

A.11RESET OF PARAMETERS ....................... A.70

A.12DISPLAYING THE COUNTERS ............... A.71

A.13CARD TEST LIST .................................... A.72

A.14RESET OF THE MACHINE ..................... A.72

HOW TO UPDATE THE FW ............................. B.73

B.1 INTRODUCTION .................................... B.74

B.2 CONNECTION PROCEDURE ............... B.74

B.3 SOFTWARE ............................................. B.75

B.4 FIRMWARE UPDATING PROCEDURE ... B.76

B.5 CHANGE RESIDENT LOGOS AND FONT

PROCEDURE ......................................... B.76

LCD EDIT ..................................................C.78

C.1 LCD EDIT AVAILABILITY ........................ C.78

C.2 ENABLING THE OFF-LINE MODE ......... C.78

C.3 FORMAT MENU .................................... C.79

C.4 FORMAT CHANGE .............................. C.79

C.5 STAMP DATA ENTRY ............................ C.80

C.6 EDIT STAMPED CARDS ........................ C.82

C.7 FORMATS - GENERAL .......................... C.83

C.8 SETTING UP A FORMAT ....................... C.87

C.9 DESIGNING INDIVIDUAL FIELDS .......... C.92

C.10STORING THE FORMAT ........................ C.97

0

1

2

3

4

5

6

7

A

B

CC

1.10DIRECTIVEWEEE...................................1.18