FE CC-M User manual

INP-TN512878-E

COMPACT CONTROLLER M

(CC-M)

TYPE: PDA3

Application Manual

Instruction Manual

INP-TN512878-E i

We thank you very much for purchasing Fuji Electric’s compact controller M (CC-M).

•Carefully read the instruction manual and sufficiently be familiar with its contents before installing,

operating and maintaining the compact controller M. Improper handling may cause accidents or

injuries.

•The specifications of compact controller M are subject to change without prior notice for improvement of

the product.

•It is strictly forbidden to remodel the compact controller M without permission. We will not be

responsible for any accident attributable to such remodeling without permission.

•The person in charge of operating the compact controller M is requested to keep the instruction manual.

•After reading the manual, it must be kept at a place always accessible by personnel in charge of its

operation.

•An arrangement must be taken so that the instruction manual will be handed over to the end user.

•The contents of this manual have been prepared carefully. However, it should be noted that Fuji is not

responsible for any loss caused indirectly from errors in wiring or missing of information.

Manufacturer : Fuji Electric Instrumentation Co., Ltd.

Type : Described in nameplate on main frame

Date of manufacture : Described in nameplate on main frame

Product nationality : Japan

INTRODUCTION

•It is forbidden to transfer a part or the whole of contents of

the manual without permission.

•Contents of the manual are subject to change without prior

notice.

Request

©Fuji Electric Systems Co., Ltd. 2004

Issued in February, 2004

ii INP-TN512878-E

Before use, carefully read the safety precautions for correct operation.

•The precautions concern important matters related to safety. Be sure to observe them. The safety

matters are ranked to “DANGER”, “CAUTION”.

Indications and meanings are as follows.

If the handling is wrong, dangerous situations might occur, causing death or

serious injury.

If the handling is wrong, dangerous situations might occur, causing medium or

slight degree of injury or physical damage only.

•If the fault or anomaly of the device may cause serious accident or troubles to other devices, externally

install appropriate emergency stop circuit and protective circuit to avoid accidents.

•The instrument has no power switch nor fuse. Install them if necessary. (Fuse rating 250 V, 2 A)

•For avoiding device breakage and fault, supply a power voltage matching the rating.

•For avoiding electric shock, maloperation and device troubles, do not turn on power until all installation

and wiring have ended.

•The instrument is not an intrinsically-safe explosion-proof type. Do not use it in atmosphere of

combustible or explosive gases.

•Never disassemble, retouch, remodel nor repair the instrument. Otherwise, abnormal operation,

electric shock or fire may occur.

•While turned on, do not touch the terminals. Otherwise, electric shock or maloperation may occur.

•Before engaging or disengaging the module or unit, turn off power. Otherwise, electric shock,

maloperation or troubles may occur.

•Periodic maintenance is recommended so that the instrument can be used continuously and safely.

Some parts installed on the device have limited service life or are subjected to secular change.

•Do not block the ventilation opening located on the top and bottom of the main unit. Otherwise, fault,

abnormal operation, shortened service life or fire may occur.

SAFETY PRECAUTIONS

INP-TN512878-E iii

•Over-temperature Protection

Any control system should be designed with prior consideration that any part of the system has

potential to fail.

In case of temperature controlling, a continuance of heating on should be regarded as the most

dangerous state.

The followings are the most probable causes of inducing continuance of heating on:

1) The failure of the controller with heating output constantly on

2) The disengagement of the temperature sensor out from the system

3) The short circuit in the thermocouple wiring

4) Valve or switch contact point outside the system is locked to keep heating on

In any application in which it is apprehended that physical injury or destruction of equipment might

occur, we recommend to install an independent safeguard equipment to prevent over-temperature which

shut down the heating circuit and for additional safety, we also recommend this equipment to have its

own temperature sensor.

The alarm output signal of the controller is not designed to work as protective measures when the

controller is in failure condition.

iv INP-TN512878-E

•Do not use any instrument which is found damaged or deformed when unpacked. Otherwise, fire,

maloperation or fault may occur.

•Make sure the product is as specified before use. Otherwise, the product may break or be troubled.

•Do not drop, tip over nor give a shock to the product. Otherwise, the product may break or suffer

from a fault.

•Install the device so that dust, wire chip, iron powder or other foreign matters will not enter it.

Otherwise, maloperation or fault may occur.

•Periodically make sure terminal screws and setscrews are securely tightened. Use at a loosened status

may cause fire or maloperation.

•Before changing the setting while operating, forced output, startup, shutdown or other actions,

sufficiently check the safety. Wrong operation may break or trouble the machine.

•During the running, the furnished terminal cover must be put on the terminal block. Otherwise,

electric shock or fire may occur.

•For mounting the device, avoid the following place.

Ambient temperature is beyond 0 to 50ºC (0 to 40ºC at close mounting sidewise).

Ambient humidity is beyond 5 to 90% RH.

A condensation occurs.

Exposed to corrosive gases (particularly, sulfuric gas, ammonia or the like) or combustible gases.

Vibration or impact is exerted to the main unit.

Splashed with water, oil, chemical, steam or vapor

Exposed to dust, salt or iron excessively.

Inductive disturbance is so excessive as to easily produce electrostatic charge, magnetic field

or noise.

A heat accumulation occurs by radiation heat, etc.

•Install this controller on the panel so as not to apply stress to the case, otherwise it may result in damage

to the case.

•If dipped in water, do not use the instrument. Otherwise, there may be a fear of electric leakage,

electric shock or fire.

•For connecting a thermocouple input, do not use wires other than specified compensating wires.

Otherwise, reading error or abnormal operation may occur.

•For connecting a resistance bulb input, use wires of a resistance which is low enough and uniform

between 3 wires. Otherwise, reading error or abnormal operation may occur.

•If noise from the source is excessive, add an insulating transformer and use a noise filter.

•For cleaning the main unit, clean the front panel to use dry cloth, and do not use alcohol, benzine or

other organic solvents. Do not directly splash water to the main unit. Otherwise, deterioration, fault,

electric leakage, electric shock or fire may occur.

•When discarding the product, handle it as an industrial waste.

•Be sure to carry out grounding. Otherwise, electric shock or maloperation may occur.

•Wiring must be carried out by qualified specialists. Wrong wiring may cause fire, fault or electric

shock.

INP-TN512878-E v

INTRODUCTION·····················································································································i

SAFETY PRECAUTIONS·······································································································ii

CONTENTS····························································································································· v

FOREWORD ·························································································································vii

1. GENERAL PRECAUTIONS ON COMPACT CONTROLLER (CC-M)·························· 1

1.1 Precautions for use of wafers ·································································································1

1.2 Correspondence of external signals and internal signals························································1

1.3 Contents of internal arithmetic operations ·············································································2

1.4 Modes and output signals of controller ··················································································3

1.5 Control output bumpless changeover ·····················································································4

2. BALANCELESS, BUMPLESS CIRCUIT AT THE TIME OF MODE CHANGE

OF CONTROLLER MODE (CASE OF FROM A-MODE TO R-MODE) ······················· 5

2.1 Case where R-SV is an external signal (manual bumpless changeover)·····························5

2.2 Case where R-SV is an internal signal (caser where primary PID control and

secondary PID control are used) ····························································································5

2.2.1 Bumpless changeover circuit of ordinary cascade control·······································5

2.2.2 Bumpless changeover circuit with inverse arithmetic operation function ···············6

2.2.3 Bumpless changeover circuit using primary integration circuit·······························7

2.2.4 Bumpless changeover circuit using pulse width integration wafer (06) ··················8

3. HOW TO HOLD OUTPUT VALUE (MV) ······································································· 9

3.1 Method to input external signal (forced manual SMAN)·······················································9

3.2 Method to input external signal (EX-MV) ·············································································9

3.3 Method to stop addition of ∆MV value··················································································9

4. METHOD FOR MATERIALIZATION OF VARIOUS FUNCTIONS USING

WAFERS OF VARIOUS TYPES ···················································································· 10

4.1 How to use changeover wafer (67)·······················································································10

4.1.1 Analog signal hold circuit······················································································10

4.1.2 Sample hold circuit using pulse generation wafer ·················································10

4.1.3 R · S flip-flop circuit (RESET priority) ·································································11

4.1.4 Changeover of digital signal ··················································································11

4.2 Creation of one-shot multiple circuits (method to use basic period)·································12

4.2.1 Method to seize rise of input··················································································12

4.2.2 Method to seize fall of input ··················································································12

4.2.3 Method using timer and logical wafer ···································································13

CONTENTS

vi INP-TN512878-E

4.3 How to use ramp output wafer····························································································· 14

4.3.1 Ramp output circuit (case of normal way of use)·················································· 14

4.3.2 Method to use ramp wafer as a change ratelimiter················································ 14

4.4 How to use dead time wafer ································································································ 15

4.4.1 Series connection of dead time wafers ·································································· 15

4.5 Method to convert analog signal to integration pulse·························································· 16

4.6 Method to create time function circuit using analog integration wafer and N wafer ·········· 17

4.7 Method to create 32-segmented-line approximation circuit ················································ 18

4.8 Sequence circuit of program setting wafer ·········································································· 19

4.9 Bulb compensation circuit ··································································································· 20

5. METHOD FOR MATERIALIZATION OF VARIOUS ADVANCE CONTROLS ··········21

5.1 Selective control (auto selector) ·························································································· 21

5.1.1 Method to make selection by outputs of primary integration wafer and

secondary integration wafer ·················································································· 22

5.1.2 Method to make selection by velocity control type outputs of primary PID

wafer and secondary PID wafer ············································································ 23

5.2 Variable gain control············································································································ 24

5.2.1 Variable gain by LIN wafer ··················································································· 25

5.2.2 Variable gain by primary PID block and secondary PID block····························· 26

5.2.3 Deviation square type PID control ········································································ 26

5.3 Feed forward control ··········································································································· 27

5.3.1 Static feed forward ································································································ 28

5.3.2 Dynamic feed forward··························································································· 28

5.4 Dead time control ················································································································ 29

5.4.1 Sampling control ··································································································· 29

5.4.2 Intermittent PID control (sample value type PID control) ···································· 30

5.4.3 Smith’s dead time compensation control······························································· 31

INP-TN512878-E vii

This Application Manual mainly describes methods for use of wafers contained in Compact Controller M

(hereinafter abbreviated as "CC-M"), for materializing a sophisticated measurement control system using

CC-M. It also describes general precautions and typical applications that constitute a system.

Make best use of this Application Manual for materializing more sophisticated functions using CC-M.

FOREWORD

INP-TN512878-E 1

1.1 Precautions for use of wafers

(1) Nothing is executed if “0000” is entered in a wafer mounting position in the wafer wire

connection chart. Enter a wafer number for execution of a wafer instruction.

(2) If “0000” is used as the code of the wafer input destination, it means same as input of 0% in case

of analog input or same as input of 0 (OFF) in case of digital input.

(3) If a signal is brought from a place where a wafer is not mounted (place where “0000” is entered

or where non-defined wafer is located), the content of this signal is not guaranteed. (It is not

0%.)

(4) Each one of wafers of primary and secondary control blocks (wafer No. 21 to 27, 41 to 46) or

each one of wafers of dead time is executed only once.

(5) If a signal is brought from a wafer that is located after oneself, the content of this signal becomes

a value that is earlier by one sampling period (0.2 second, for example). Normally, therefore, it

is necessary to determine the wafer execution sequence so as to use the output of a wafer that is

mounted before oneself. On the contrary, by making use of this fact, it is possible to use data

that is earlier by one sampling period (0.2 second, for example).

1.2 Correspondence of external signals and internal signals

(1) Voltage of 1 to 5V or current of 4 to 20mA corresponds to wafer of 0.00% to 100.0%.

Arithmetic operation by the internal control block is executed in the range of - 327.67% to

327.67% and the minimum unit is 0.01%.

Furthermore, internal general-purpose arithmetic operation is executed in the range of

- 21474836.47% to 21474836.47 and the minimum unit is 0.01%. See each wafer description

for details.

(2) Analog input signals (AI signals) can be input in the range of - 12.50% to 112.50% (0.5 to 5.5V).

(When AI check is not specified)

(3) When analog input check is specified (input signal to be checked is specified in AI CHECK SET

screen), the subject analog input is checked by values of - 12.5% to 112.5%, and an alarm

(FAULT) signal is issued if the input is outside of this range.

(4) Analog output signals are produced in the range of - 12.50% to 112.50%.

Note: Description in (2) and (3) assumes that the analogue input range is from 1 to 5V DC.

1. General precautions on Compact Controller (CC-M)

2INP-TN512878-E

1.3 Contents of internal arithmetic operations

+

–

×

%300=%100÷%300

÷

50% + 50% = 100%

50% + (-100%) = -50%(Addition)

50% - 30% = 20%

(- 200%) - (- 50%) = - 150%(Subtraction)

(Multiplication)

%100=%100×%100

%01.0=%1×%1

%06.74=%66.66×%11.111

()

%60=%30×%200

- -

%100=%100

%20=%300÷%60

(Division)

(Square root)

()

%50=%20÷%10 --

%100=%200÷%200

%42.141=%200

%20.173=%300

%10=%1

%0=%5

-

INP-TN512878-E 3

1.4 Modes and output signals of controller

Figure 1-1

What requires balance operation for bumpless changeover out of these changeovers is :

•Changeover from a mode other than EX-M mode to EX-M mode (See section.1.5)

Important

4INP-TN512878-E

1.5 Control output bumpless changeover

Bumpless circuit at the time of changeover of operation output to EX-M

1) Method to gradually bring close by ramp output wafer

Figure 1-2

When an EX-M (external output setup) command enters, the output (MV) varies by inclination CONT

determined by the ramp wafer. Bump (impact) is prevented as a result.

INP-TN512878-E 5

Bumpless changeover can always be performed for changeover from remote (R) to auto (A).

Bumpless changeover from auto (A) to remote (R) can be performed by the following methods.

Note: Remode (R) indicates cascade mode (C) in front button “C”

2.1 Case where R-SV is an external signal

(manual bumpless changeover)

When R-SV is an external signal (case where input is made to X2 terminal of wafer (41)), the value of

R-SV can be confirmed by pressing the RSV button of chameleon keys on the front face, in the state

where the 1Loop screen is displayed, in the A-mode.

In this case, bumpless changeover can be accomplished by matching the value of local SV (secondary

SV) with R-SV.

2.2 Case where R-SV is an internal signal (caser where primary PID

control and secondary PID control are used)

2.2.1 Bumpless changeover circuit of ordinary cascade control

Wafer wire connection is performed as shown below in case of ordinary cascade control.

In this case, when auto (A) mode is selected, 2ND LS signal is “0.01” (= ON), and the input of

primary integration wafer (23) has been changed to the value of EX-MV. As the value of EX-MV

is input from the SV value of secondary PID, the output of primary integration wafer (23) agrees

with the SV value of secondary PID. When changeover from A to C is attempted, bumpless

changeover is accomplished.

Figure 2-1

(Bumpless changeover can be accomplished in the auto (A) mode, by feedback of the secondary SV

value to primary integration.)

2. Balanceless, bumpless circuit at the time of mode change

of controller mode

(

case of from A-mode to R-mode

)

6INP-TN512878-E

2.2.2 Bumpless changeover circuit with inverse arithmetic operation function

In case where an arithmetic operation circuit is located between primary PID and secondary PID , if

its arithmetic operation is simple,

Figure 2-2

bumpless changeover can be accomplished by feedback to the primary integration circuit by way of

the inverse arithmetic operation circuit.

INP-TN512878-E 7

2.2.3 Bumpless changeover circuit using primary integration circuit

Figure 2-3

(Integrate R·SV-PV value (Y4) of secondary input processing wafer (41) by way of primary PID

wafer.)

When the arithmetic operation between primary PID and secondary PID becomes complicated, many

wafers are required for inverse arithmetic operation for tracking. In such a case, compensation can

be made by using R · SV-PV appearing in output (Y4) of the secondary input processing wafer.

When constant value control is good in the A-mode and steady-state is produced, secondary PV and

secondary SV are almost matched. When the deviation between this PV and 41 wafer output Y4 (R

· SV-PV) is made small, the R · SV value and the secondary SV value are almost matched.

For this purpose, the R · SV value is controlled by using the output of R · SV-PV in integration (I)

term of primary PID arithmetic operation in the A-mode. Provided, however, that when the primary

side is of positive action, it is necessary to input an input value with inversed sign to primary

integration (I) term.

Furthermore, attention is needed if the primary PID and secondary PID are of extreme non-linear

type or of large gain.

8INP-TN512878-E

2.2.4 Bumpless changeover circuit using pulse width integration wafer (06)

Figure 2-4

When complicated arithmetic operation enters between primary PID and secondary PID, many

wafers are required for inverse arithmetic operation as described in section 2.2.3. Furthermore, if

the method using integration described in section 2.2.3 is used, the tracking time is determined by the

integration time of primary PID, and there are cases where bumpless changeover cannot be

accomplished within a short length of time. In such a case, bumpless changeover can be

accomplished within a short length of time, if the difference between R · SV and 2ND · SV is

integrated by pulse width integration wafer (06) and if feedback of the result is made to primary

integration wafer (23).

The multiplication wafer (64) in the feedback is what is used for adjusting the gain of feedback, and

normally if it is set at 20 to 30% , changeover can be implemented without hunting.

INP-TN512878-E 9

When it is wanted to hold the output value (MV), it can be accomplished by the following methods.

3.1 Method to input external signal (forced manual SMAN)

Forcibly produce the M-mode by inputting a DI signal of “SMV” from outside.

(The mode lamp on the front face changes to “M”, and the MV operation button becomes valid.)

In this case, call the ALARM CONNECT screen out of the OUT CONNECT screen, and register DI

terminal mode in “SMAN-REQ”.

3.2 Method to input external signal (EX-MV)

Input a DI signal of “EX-MV” specified opening mode from outside.

Figure 3-1

(When an output signal is input through the input terminal of EX-MV, the then output value is held.)

3.3 Method to stop addition of ∆MV value

Figure 3-2

(When integration value ∆M integration of speed type of 2ND • PID wafer (42) Y1is stopped, MV of

the then value is held.)

3. How to hold output value (MV)

10 INP-TN512878-E

4.1 How to use changeover wafer (67)

4.1.1 Analog signal hold circuit

It is possible to hold the analog signal by returning the output (Y1) of the changeover wafer (67) to

the input (X1).

Figure 4-1

4.1.2 Sample hold circuit using pulse generation wafer

Figure 4-2

The value is held at the time when the pulse generator wafer (88) is ON.

Note: Sample hold wafer (DO) is also available.

4. Method for materialization of various functions using

wafers of various types

INP-TN512878-E 11

4.1.3 R ·S flip-flop circuit (RESET priority)

Figure 4-3

When set signal (S) is changed from “0” to “1”, output Q changes from “0” to “1”. When reset

signal (R) is changed from “0” to “1”, output Q changes from “1” to “0”.

When two flip-flop wafers (67) are used, they can be used as R-S flip-flop.

4.1.4 Changeover of digital signal

A changeover wafer can also handle changeover of digital signal. When it is wanted to set the

digital signal by a constant, use 0.00 instead of 0 (OFF), and use 0.01 instead of 1 (ON).

A changeover wafer is capable of changing both analog and digital signals.

Note: Flip-flop wafer (A5) is

also available.

Table of contents

Other FE Controllers manuals

Popular Controllers manuals by other brands

Aalborg

Aalborg DPC operating manual

Remote Solutions

Remote Solutions SAFE-T-RACK SR-U Operation manual

Mitsubishi Electric

Mitsubishi Electric Ecodan PAR-WT50R-E Operation manuals

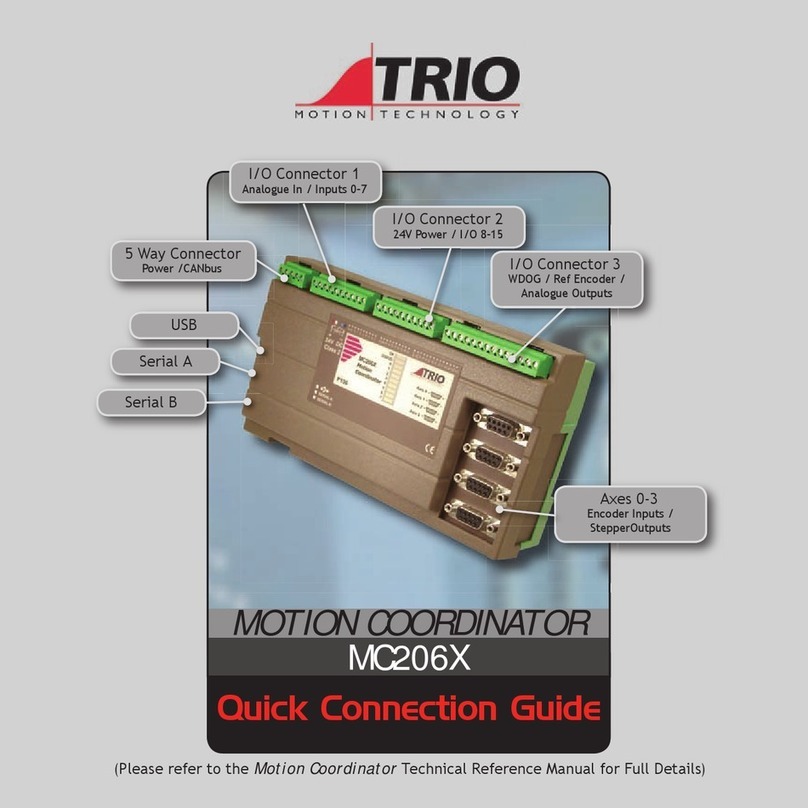

Trio

Trio MC206X Quick connection guide

Vaillant

Vaillant VRT 350f installation instructions

Exlar

Exlar Tritex installation manual