Exlar Tritex User manual

Tritex 1 Installation and Setup 109/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

LINEAR & ROTARY ACTUATOR

INSTALLATION, OPERATION AND SERVICE

MANUAL

Information furnished by EXLAR Corporation is believed to be accurate and reliable. However, no responsibility is assumed by

EXLAR Corporation for its use. EXLAR reserves the right to change the design and operation of the equipment described herein

and any associated motion products that may appear in this document. Information in this document pertaining to equipment not

furnished by EXLAR should be confirmed by that equipment manufacturer. EXLAR assumes no responsibility for changes to

information by other manufacturers or errors in that information or the description of that information. Information in this document is

subject to change without notice.

Tritex 1 Installation and Setup 209/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

Warranty and Limitation of Liability

Products are warranted for two years from date of manufacture as determined by the

serial number on the product label. Labels are generated and applied to the product at the

time of shipment. The first and second digits are the year and the third and fourth digits

represent the manufacturing week. Product repairs are warranted for 90 days from the

date of the repair. The date of repair is recorded within Exlar Corporation’s database

tracked by individual product serial number.

Exlar warrants its product(s) to the original purchaser and in the case of original

equipment manufacturers, to their original customer to be free from defects in material

and workmanship and to be made only in accordance with Exlar's standard published

catalog specifications for the product(s) as published at the time of purchase. Warranty or

performance to any other specifications is not covered by this warranty unless otherwise

agreed to in writing by Exlar and documented as part of any and all contracts, including

but not limited to purchase orders, sales orders, order confirmations, purchase contracts

and purchase agreements. In no event shall Exlar be liable or have any responsibility

under such warranty if the product(s) has been improperly stored, installed, used or

maintained, or if Buyer has permitted any unauthorized modifications, adjustments and/or

repairs to such product(s). Seller's obligation hereunder is limited solely to repairing or

replacing (at its opinion), at the factory any product(s), or parts thereof, which prove to

Seller's satisfaction to be defective as a result of defective materials, or workmanship and

within the period of time, in accordance with the Seller's stated product warranty (see

Terms and Conditions above), provided, however, that written notice of claimed defects

shall have been given to Exlar within thirty (30) days from the date of any such defect is

first discovered. The product(s) claimed to be defective must be returned to Exlar,

transportation prepaid by Buyer, with written specification of the claimed defect. Evidence

acceptable to Exlar must be furnished that the claimed defects were not caused by

misuse, abuse, or neglect by anyone other than Exlar.

Components such as seals, wipers, bearings, brakes, bushings, gears, splines, and

roller screw parts are considered wear parts and must be inspected and serviced on a

regular basis. Any damage caused by failure to properly lubricate Exlar products and/or to

replace wear parts at appropriate times, is not covered by this warranty. Any damage due

to excessive loading is not covered by this warranty.

The use of products or components under load such that they reach the end of their

expected life is a normal characteristic of the application of mechanical products.

Reaching the end of a product’s expected life does not indicate any defect in material or

workmanship and is not covered by this warranty.

Costs for shipment of units returned to the factory for warranty repairs are the

responsibility of the owner of the product. Exlar will return ship all warranty repairs or

replacements via UPS Ground at no cost to the customer.

For international customers, Exlar will return ship warranty repairs or replacements via

UPS Expedited Service and cover the associated shipping costs. Any VAT or local

country taxes are the responsibility of the owner of the product.

Tritex 1 Installation and Setup 309/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

The foregoing warranty is in lieu of all other warranties (except as Title), whether

expressed or implied, including without limitation, any warranty of merchantability, or of

fitness for any particular purpose, other than as expressly set forth and to the extent

specified herein, and is in lieu of all other obligations or liabilities on the part of Exlar.

Seller's maximum liability with respect to these terms and conditions and any resulting

sale, arising from any cause whatsoever, including without limitation, breach of contract or

negligence, shall not exceed the price specified herein of the product(s) giving rise to the

claim, and in no event shall Exlar be liable under this warranty otherwise for special,

incidental or consequential damages, whether similar or dissimilar, of any nature arising or

resulting from the purchase, installation, removal, repair, operation, use or breakdown of

the product(s) or any other cause whatsoever, including negligence.

The foregoing warranty shall also apply to products or parts which have been repaired

or replaced pursuant to such warranty, and within the period of time, in accordance with

Seller's stated warranty.

NO PERSON, INCLUDING ANY AGENT OR REPRESENTATIVE OF EXLAR, IS

AUTHORIZED TO MAKE ANY REPRESENTATION OR WARRANTY ON BEHALF OF

EXLAR CONCERNING ANY PRODUCTS MANUFACTURED BY EXLAR, EXCEPT TO

REFER PURCHASERS TO THIS WARRANTY.

Tritex 1 Installation and Setup 409/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

Safety Considerations

As with any electro-mechanical device, safety must be considered during the installation and

operation of your Tritex Series actuator. Throughout this manual you will see paragraphs

marked with CAUTION and WARNING signs as shown below

“Warning” indicates the information following is essential to avoiding a safety hazard.

“Caution” indicates the information following is necessary for avoiding a risk of damage

to the product or other equipment.

General

Failure to follow safe installation guidelines can cause death or serious injury. The voltages

used in the product can cause severe electric shock and/or burns and could be lethal.

Extreme care is necessary at all times when working with or adjacent to the product. The

installation must comply with all relevant safety legislation in the country of use. The forces

created by actuator could be lethal or cause severe injury if proper protection is not provided to

keep personnel away from moving components.

System Design and safety for personnel

The actuator is intended as a component for professional incorporation into complete

equipment or a system. If installed incorrectly, the actuator may present a safety hazard.

The actuator uses high voltages and currents, carries a high level of stored electrical energy,

and is used to control equipment which can cause injury. Close attention is required to the

electrical installation and the system design to avoid hazards either in normal operation or in the

event of equipment malfunction. System design, installation, commissioning and maintenance

must be carried out by personnel who have the necessary training and experience. They must

read this safety information and this manual carefully. None of the functions or features of

the Tritex actuator may be used to ensure safety of personnel, i.e. they must not be used

for safety-related functions. Careful consideration must be given to the functions of the

actuator which might result in a hazard, either through their intended behavior or through

incorrect operation due to a fault. In any application where a malfunction of the actuator or its

control system could lead to or allow damage, loss or injury, a risk analysis must be carried out,

and where necessary, further measures taken to reduce the risk- for example a failsafe brake in

case of loss of actuator braking power.

Never attempt to connect or disconnect the actuator with power applied. Dangerous

voltages are present. Damage to equipment and injury to personnel can result. Many

amplifiers have voltage present for a considerable time period after incoming power

is removed. Take care to insure that the amplifier has discharged all power.

In a domestic environment this product may cause radio interference, in which case

supplementary mitigation measures may be required.

WARNING

CAUTION

WARNING

WARNING

WARNING

WARNING

Tritex 1 Installation and Setup 509/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

Table of Contents

TRITEX™ PRODUCT OVERVIEW.................................................................................9

General Specifications........................................................................................................................11

Drive specifications for TRA500 remote option.......................................................................................11

Specifications: Size 20 Linear Actuators............................................................................................12

TLM20...............................................................................................................................................12

TSM20...............................................................................................................................................13

Specifications: Size 30 Linear Actuators............................................................................................14

TLM30...............................................................................................................................................14

TSM30...............................................................................................................................................15

Specifications: Size 60 Motors and Gear motors...............................................................................16

RTM060 ............................................................................................................................................16

RSM060 and RSG060.......................................................................................................................16

Specifications: Size 90 motors and Gear Motors...............................................................................18

RTM090 ............................................................................................................................................18

RSM090 and RSG090.......................................................................................................................18

Model Mask and Ordering Information...............................................................................................20

INSTALLATION............................................................................................................24

Mechanical Installation........................................................................................................................24

Lubrication.........................................................................................................................................24

Mounting Configurations....................................................................................................................24

Mounting and Operating Considerations............................................................................................24

General Operation.............................................................................................................................25

TLM & TSM Series Linear Actuator Anti-rotation Option.....................................................................25

TLM/TSM Anti-Rotate ..........................................................................................................................26

TLM20 Dimensions..............................................................................................................................27

TSM20 Dimensions..............................................................................................................................28

TLM30 Dimensions..............................................................................................................................29

TSM30 Dimensions..............................................................................................................................30

RTM060 and RTG060 Dimensions......................................................................................................31

RSM060 and RSG060 Dimensions......................................................................................................32

RTM090 & RTG090 Dimensions..........................................................................................................33

RSM090 & RSG090 Dimensions..........................................................................................................34

Tritex 1 Installation and Setup 609/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

Tritex Configurations ..........................................................................................................................37

Electrical Installation...........................................................................................................................39

Introduction........................................................................................................................................39

Power Supply Selection.....................................................................................................................39

Regulated vs Unregulated Power Supplies ........................................................................................40

Grounding .........................................................................................................................................41

Power Supply Wiring Diagrams..........................................................................................................42

Power Supply Wiring and Fusing.......................................................................................................43

Power Supply Connections................................................................................................................44

Tritex Input and Output Wiring ...........................................................................................................45

I/O Power Supply...............................................................................................................................47

Two Power Supply Configuration.......................................................................................................47

Single Power Supply Configuration....................................................................................................47

Digital Inputs......................................................................................................................................48

Digital Outputs...................................................................................................................................49

Analog Input......................................................................................................................................50

Analog Output....................................................................................................................................51

Communications................................................................................................................................52

PC Communications..........................................................................................................................53

EMC Considerations..........................................................................................................................54

EXPERT SOFTWARE ..................................................................................................56

Installation...........................................................................................................................................56

Overview..............................................................................................................................................56

Opening the Expert Software..............................................................................................................57

Welcome Screen...............................................................................................................................57

Quick Connect...................................................................................................................................58

Open a Recent Application ................................................................................................................58

Create an Application from a Standard Template...............................................................................58

Create a New User Application..........................................................................................................59

Other Welcome Screen Controls........................................................................................................60

Operation with an Open Application...................................................................................................61

Opening More Pages / Tabs..............................................................................................................61

Viewing Pages in the Application.......................................................................................................61

Viewing Pages not in the Application..................................................................................................62

Basic Steps for Offline Operation.......................................................................................................63

User Units..........................................................................................................................................63

Key Application Pages.......................................................................................................................66

Communication between PC and Tritex.............................................................................................67

Device Drivers...................................................................................................................................67

Port Settings......................................................................................................................................68

Online Operation .................................................................................................................................69

Open an Application ..........................................................................................................................69

Connect to the Drive..........................................................................................................................69

Initializing Remote Drive and Actuator combinations..........................................................................71

Online Status & Control .....................................................................................................................73

Tritex 1 Installation and Setup 709/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

SYSTEM SETUP...........................................................................................................74

System Setup.......................................................................................................................................74

Startup Tab........................................................................................................................................74

Limits Tab..........................................................................................................................................75

Fault Enables ....................................................................................................................................76

Operating Modes...............................................................................................................................77

Dedicated Move.................................................................................................................................78

In Position Window............................................................................................................................79

Position Limits...................................................................................................................................80

Analog Input Calibration.....................................................................................................................81

Motion Control.....................................................................................................................................83

Motion Control Overview....................................................................................................................83

Default & Alternate Mode...................................................................................................................83

Host Mode.........................................................................................................................................84

Special Condition Motion...................................................................................................................84

Home Operation................................................................................................................................85

Jog....................................................................................................................................................87

Move.................................................................................................................................................88

Analog Motion Control .......................................................................................................................89

Analog Input......................................................................................................................................89

Analog Position Control .....................................................................................................................89

Analog Positioning.............................................................................................................................89

Analog Velocity Control......................................................................................................................90

Analog Velocity Page.........................................................................................................................90

Analog Input Scaling..........................................................................................................................92

INPUTS AND OUTPUTS..............................................................................................93

Digital I/O .............................................................................................................................................93

Input / Output Assignments................................................................................................................93

Monitoring Input / Output Status.........................................................................................................94

Input Function Definitions...................................................................................................................94

Output Function Definitions................................................................................................................96

Analog I/O............................................................................................................................................98

Analog Input......................................................................................................................................98

Analog Output....................................................................................................................................98

Mapping & Scaling.............................................................................................................................98

Analog Output Calibration..................................................................................................................99

ONLINE DIAGNOSTICS.............................................................................................101

Tuning................................................................................................................................................101

Additional Tuning Parameters..........................................................................................................102

Status, Faults & Warnings.................................................................................................................103

Status Display..................................................................................................................................103

Faults, Possible Causes and Solutions............................................................................................104

Tritex 1 Installation and Setup 809/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

VALVE CONFIGURATION.........................................................................................105

Opening the Expert Software............................................................................................................105

Welcome Screen.............................................................................................................................105

Basic Steps for Configuration...........................................................................................................106

User Units........................................................................................................................................107

Valve Configuration...........................................................................................................................108

Home Operation.................................................................................................................................110

Jog Operation....................................................................................................................................111

Control Page......................................................................................................................................112

Monitor Page......................................................................................................................................113

MAINTENANCE AND TROUBLESHOOTING............................................................114

Maintenance Procedures ..................................................................................................................114

Disassembly....................................................................................................................................114

Lubrication Maintenance..................................................................................................................115

Grease Renewal..............................................................................................................................115

Reassembly.....................................................................................................................................116

Troubleshooting Procedures............................................................................................................117

ACCESSORIES..........................................................................................................118

Cables................................................................................................................................................119

TTIOC-xxx I/O Cable.......................................................................................................................119

TTIPC-xxx Power Cable ..................................................................................................................120

TTICO-xxx Communications Cable..................................................................................................120

Power Supply.....................................................................................................................................121

TTPS1048 Power Supply Introduction..............................................................................................121

Communication Converters..............................................................................................................123

Model TT232485 RS232 to 485 Introduction....................................................................................123

Model TTUSB485 USN to 485 Introduction......................................................................................126

Shunt Regulator.................................................................................................................................129

TTSR1 Shunt Regulator Option .......................................................................................................129

EFT/B & Surge Filter..........................................................................................................................133

Declaration of Conformity.................................................................................................................134

Tritex 1 Installation and Setup 909/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

Tritex™ Product Overview

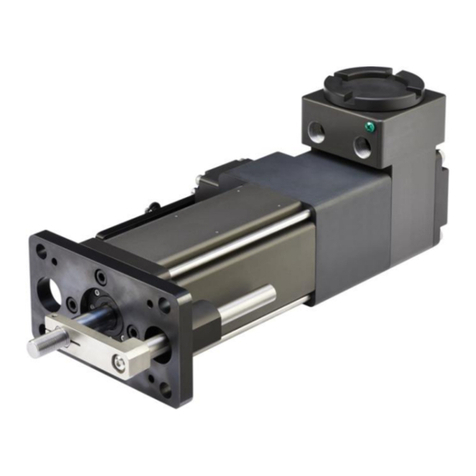

The Exlar Tritex Series of electric actuators combines an integrated brushless servo motor,

amplifier and motion controller. Optionally the system can be configured for remote mounting of

the amplifier and motion control

Integrated actuator, servo motor, amplifier and motion control

Integrated actuator and servo motor with remote drive amplifier and motion control

I/O

8 inputs

4 outputs

1 analog input

(0-10v or 4-20ma)

1 analog output

(0- 20 ma)

RS 485

Communication

port

24 – 48V

DC power

supply

TRA

-

500

TSM, RSM or RSG

24 – 48V

DC power

supply

I/O

8 inputs

4 outputs

1 analog input

(0-10v or 4-20ma)

1 analog output

(0- 20 ma)

RS 485

Communication

port

Tritex 1 Installation and Setup 10 09/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

The Tritex actuators are available in linear and rotary versions with integrated or remote

amplifier and motion control. The Remote amplifier and motion control models would typically

be used in application where space at the actuator is limited or in applications with high ambient

temperatures.

Actuator

Models

N

umbers

With Integrated amplifier

& motion control

Remote mount amplifier

and motion control

TRA500-x

Size and type

TLM20-(see model mask) TSM-20-(see model mask) 2 inch linear actuator

TLM30-(see model mask) TSM-30-(see model mask) 3 inch linear actuator

RTM60-(see model mask) RSM-60-(see model mask) 60 mm motor

RTG60-(see model mask) RSG-60-(see model mask) 60 mm gear motor

RTM90-(see model mask) RSM-90-(see model mask) 90 mm motor

RTG90-(see model mask) RSG-90-(see model mask) 90 mm gear motor

All of the required power components and motion processor are contained in the actuator or

remote housing.

Input 8

Input 7

Input 6

Input 5

Input 4

Input 3

Input 2

Input 1

Output 4

Output 3

Output 2

Output 1

RS-485

Logic

Power

BUS +

BUS -

BUS Power

Common

Logic Power

GND

24 – 48 V

Power Supply

Analog Input

Analog Output

24V I/O

Supply

Tritex 1 Installation and Setup 11 09/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

General Specifications

Drive Specification for all Tritex Models with embedded drives

Embedded

Drive Specifications

Input Voltage, Bus

and Logic 24-48 Volts DC nominal, 20 -60 Volts continuous operating range.

Under voltage trip 19V, Over voltage trip 85V

I/O Power Supply

24V nominal, 30V max, 12V min

Digital Inputs

8 – opto- isolated, 24V nominal 30V max, programmable functions

Digital Outputs

4 – opto- isolated 50 mA continuous, short circuit protected,

programmable functions

Analog Input

0-10 Volts or 0-20 mA, differential input 12 bit resolution, programmable

as position, velocity or torque command

Analog Output

0-20 mA, 11 bit resolution, programmable functions

Serial Interface

RS-485, Modbus RTU protocol, max baud rate 38.4k

Commutation

Sinusoidal, 15kHz PWM

Resolution

0.001 revolution

Accuracy

+ / - 0.005 revolution

Output Current

Continuous and peak output current is dependent on actuator

Environmental

Ambient Temperature for rated output: 25° C

Maximum Operating temperature range 0° – 55° C

Power De-rating of 2.5% per degree C between 25° C and 55° C

Humidity: 10 to 95% non-condensing

EMC

IEC/EN 61800-3:2004-08 with use of shielded cables and EFT/B &

Surge Filter 37263 (see Accessories section) or similar

Drive specifications for TRA500 remote option

TRA500 Remote

Drive Specifications

Input Voltage, Bus

and Logic 24-48 Volts DC nominal, 20 -60 Volts continuous operating range.

Under voltage trip 19V, Over voltage trip 85V

I/O Power Supply

24V nominal, 30V max, 12V min

Digital Inputs

8 – opto- isolated, 24V nominal 30V max, programmable functions

Digital Outputs

4 – opto- isolated 50 mA continuous, 24V nominal 30V max, short

circuit protected, programmable functions

Analog Input

0-10 Volts or 0-20 mA, differential input 12 bit resolution, programmable

as position, velocity or torque command

Analog Output

0-20 mA, 11 bit resolution, programmable functions

Serial Interface

RS-485, Modbus RTU protocol, max baud rate 38.4k

Commutation

Sinusoidal, 15kHz PWM

Feedback

Analog Hall

Continuous Output

Current (Peak of sine

Amps)*

25° C Ambient 40° C Ambient 55° C Ambient

Stall Rated Stall Rated Stall Rated

15 15 14 12 12 8.5

Peak Output Current

(Peak of sine Amps) 20

Environmental

IP65, Humidity: 10 to 95%, non-condensing

*Actual output current may be reduced if the motor/actuator continuous and peak current ratings

are lower

Tritex 1 Installation and Setup 12 09/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

Specifications: Size 20 Linear Actuators

TLM20

TLM series includes embedded drive and motion controller.

TLM 20 LINEAR ACTUATOR PERFORMANCE SPECIFICATIONS

Backlash in (mm) .008 (.20)

Lead Accuracy in/ft (mm/300 mm) .001 (.025)

Maximum Radial Load lb (N) 15 (67)

Environmental Rating IP54

Stator 1 Stack 1B8-50 2 Stack 2B8-34 3 Stack 3B8-25

Lead RPM at 48 VDC* 5000 3400 2500

0.1 Stall Force lbf (N) 239 (1063) 377 (1677) 503 (2237)

Max Speed in/sec (mm/sec) 8.33 (212) 5.66 (144) 4.17 (2237)

0.2 Stall Force lbf (N) 119 (529) 188 (836) 251 (1117)

Max Speed in/sec (mm/sec) 16.66 (424) 11.33 (288) 8.33 (212)

0.4 Stall Force lbf (N) 60 (267) 94 (418) 126 (560)

Max Speed in/sec (mm/sec) 33.33 (848) 22.66 (575) 16.66 (424)

Power Supply Current

Draw at Rated Power

(48V) Amps 10 10 10

Resolution 0.001 revolutions x lead

Accuracy (not including

backlash) +/- 0.005 revolutions x lead

Stroke Length in (mm) 3 (75) 6 (150) 10 (254) 12 (300)

Approximate Weight lb

(kg) 7 (3.2) 8.5 (3.9) 10 (4.5) 11.5 (5.2)

Tritex 1 Installation and Setup 13 09/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

TSM20

TSM series requires a TRA500 remote drive and motion controller.

TSM 20 LINEAR ACTUATOR PERFORMANCE SPECIFICATIONS

Backlash in (mm) .008 (.20)

Lead Accuracy in/ft (mm/300

mm) .001 (.025)

Maximum Radial Load lb (N) 15 (67)

Environmental Rating IP54

Stator 1 Stack 1B8-50 2 Stack 2B8-34 3 Stack 3B8-25

RPM at 48

VDC 5000 3400 2500

Lead

Ambient

Temp Deg C 25° 40° 55° 25° 40° 55° 25° 40° 55°

0.1

Stall Force lbf

(N) 295

(1312) 262

(1165) 227

(1010) 460

(2046) 411

(1828) 355

(1579) 575

(2558) 514

(2286) 445

(1979)

Max Speed in/sec

(mm/sec) 8.33 (212) 5.66 (144) 4.17 (106)

0.2

Stall Force lbf

(N) 148

(658) 131

(583) 113

(503) 230

(1023) 205

(912) 177

(787) 288

(1281) 257

(1143) 223

(992)

Max Speed in/sec

(mm/sec) 16.66(424) 11.33(288) 8.33(212)

0.4

Stall Force lbf

(N) 74

(329) 66

(294) 57

(254) 92

(409) 82

(365) 71

(316) 115

(512) 103

(458) 89

(396)

Max Speed in/sec

(mm/sec) 33.33 (848) 22.66 (575) 16.66 (424)

Power Supply Current

Draw at Rated Power

(48V) Amps

10

10

10

Resolution 0.001 revolutions x lead

Accuracy (not including

backlash) +/- 0.005 revolutions x lead

Stroke Length in

(mm)

3

(75)

6

(150)

10

(254)

12

(300)

Approximate Weight lb

(kg) 6.5 (2.9) 7.0 (3.2) 7.5 (3.4) 8.0 (3.6)

Tritex 1 Installation and Setup 14 09/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

Specifications: Size 30 Linear Actuators

TLM30

TLM series includes embedded drive and motion controller.

TLM 30 LINEAR ACTUATOR PERFORMANCE SPECIFICATIONS

Backlash in (mm) .008 (.20)

Lead Accuracy in/ft (mm/300 mm) .001 (.025)

Maximum Radial Load lb (N) 15 (67)

Environmental Rating IP54

Stator 1 Stack 1B8-20 2 Stack 2B8-13 3 Stack 3B8-10

Lead RPM at 48 VDC* 2000 1300 1000

0.1 Stall Force lbf (N) 585 (2606) 935 (4159) 1250 (5560)

Max Speed in/sec (mm/sec) 3.33 (84.6) 2.17 (55.1) 1.67 (42.4)

0.2 Stall Force lbf (N) 293 (1303) 468 (2082) 625 (2780)

Max Speed in/sec (mm/sec) 6.67 (169.4) 4.33 (109.9) 3.33 (84.6)

0.5 Stall Force lbf (N) 117 (520) 187 (832) 250 (1112)

Max Speed in/sec (mm/sec) 16.67 (423.4) 10.83 (275.1) 8.33 (211.6)

Power Supply Current Draw

at Rated Power (48V) Amps 10

10

10

Resolution 0.001 revolutions x lead

Accuracy (not including

backlash) +/- 0.005 revolutions x lead

Stroke Length in (mm) 3 (75) 6 (150) 10 (254) 12 (300) 18 (450)

Approximate Weight lb (kg) 10 (4.5) 12 (5.4) 19.5 (8.8) 21 (9.5) 25.5 (11.6)

Tritex 1 Installation and Setup 15 09/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

TSM30

TSM series requires a TRA500 remote drive and motion controller.

TSM 30 LINEAR ACTUATOR PERFORMANCE SPECIFICATIONS

Backlash in (mm) .008 (.20)

Lead Accuracy in/ft

(mm/300 mm) .001 (.025)

Maximum Radial Load lb (N) 15 (67)

Environmental Rating IP54

Stator 1 Stack 1B8-20 2 Stack 2B8-13 3 Stack 3B8-10

RPM at 48 VDC* 2000 1300 1000

Lead Amb. Temp Deg C 25° 40° 55° 25° 40° 55° 25° 40° 55°

0.1 Stall Force lbf

(N) 756

(3362) 686

(3051) 608

(2704) 1201

(5342) 1091

(4853) 968

(4306) 1545

(6872) 1404

(6245) 1247

(5547)

Max Speed in/sec (mm/sec) 3.33 (84.6) 2.17 (55.1) 1.67 (42.4)

0.2 Stall Force lbf

(N) 378

(1681) 343

(1526) 304

(1352) 600

(2669) 545

(2425) 484

(2153) 772

(3434) 702

(3123) 623

(2771)

Max Speed in/sec (mm/sec) 6.67 (169.4) 4.33 (109.9) 3.33 (84.6)

0.5 Stall Force lbf

(N) 151

(672) 137

(609) 122

(543) 240

(1068) 218

(970) 194

(862) 309

(1375) 281

(1250) 249

(1108)

Max Speed in/sec (mm/sec) 16.67 (423.4) 10.83 (275.1) 8.33 (211.6)

Power Sup

ply Current

at Rated Power (48V) Amps 15

12

10

15

12

10

15

12

10

Resolution 0.001 revolutions x lead

Accuracy (not

including backlash) +/- 0.005 revolutions x lead

Stroke Length in

(mm)

3

(75)

6

(150)

10

(254)

12

(300)

18 (450)

Approximate Weight lb

(kg) 9.5 (4.3) 11.5 (5.2) 19 (8.6) 22 (10) 25 (11.3)

Tritex 1 Installation and Setup 16 09/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

Specifications: Size 60 Motors and Gear motors

RTM060

RTM060 series includes embedded drive and motion controller.

RTM060 ROTARY MOTOR TORQUE AND SPEED RATINGS

For output torque of RTG Gearmotors, multiply by ratio and efficiency. Please note maximum allowable

output torques in the Gearmotor Mechanical Ratings table page 16.

Stator 1 Stack 1B8-50 2 Stack 2B8-34 3 Stack 3B8-25

RPM at 48 VDC 5000 3400 2500

Cont. Stall Torque lbf-in (Nm) 4.7 (.53) 7.5 (.85) 10 (1.13)

Peak Torque lbf-in (Nm) 9.4 (1.06) 15 (1.69) 20 (2.26)

Power Supply

Current Draw at

Rated Power (48V) Amps

10

10

10

Resolution 0.001 revolutions / ratio

Accuracy (not

including backlash)

+/- 0.005 revolution / ratio

RSM060 and RSG060

RSM& RSG060 series requires a TRA500 remote drive and motion controller

RSM060 ROTARY MOTOR TORQUE AND SPEED RATINGS

For output torque of RSG gearmotors, multiply by ratio and efficiency. Please note maximum allowable output

torques in the Gearmotor Mechanical Ratings table page 16.

Stator 1 Stack 1B8-50 2 Stack 2B8-34 3 Stack 3B8-25

RPM at 48

VDC 5000 3400 2500

Ambient Temp Deg C 25° 40° 55° 25° 40° 55° 25° 40° 55°

Cont. Stall Torque lbf-in

(Nm) 5.9

(.53) 5.2

(.53)

4.5

(.53)

9.2

(.85) 8.2

(.53)

7.1

(.53)

11.4

(1.13) 10.2

(.53)

8.9

(.53)

Peak Torque lbf-in (Nm) 9.4 (1.06) 15 (1.69)

20 (2.26)

Power Supply

Current Draw at

Rated Power (48V) Amps

10

10

10

Resolution 0.001 revolutions / ratio

Accuracy (not

including backlash)

+/- 0.005 revolution / ratio

RTM/RTG and RSM/RSG060 INERTIA

Stator 1 Stack 2 Stack 3 Stack

Motor Armature Inertia (+/-5%) lb-in-sec2 (kg-cm2)0.000237 (0.268) 0.000413 (0.466) 0.000589 (0.665)

Gearmotor Armature Inertia* lb-in-sec2 (kg-cm2)0.000226 (0.255) 0.000401 (0.453) 0.000576 (0.651)

*Add armature inertia to gearing inertia for total inertia.

Tritex 1 Installation and Setup 17 09/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

S

IZE 6

0 RADIAL LOAD

AND BEARING LIFE

S

IZE 6

0

GEARMOTOR MECHANICAL RATINGS

S

IZE 6

0

BACKLASH AND EFFICIENCY

SIZE 60 GEARING REFLECTED INERTIA

Single Reduction Double Reduction

Gear Stages Lbf-in-sec

2

(kg-cm

2

) Gear Stages Lbf-in-sec

2

(kg-cm

2

)

4:1 0.0000132 (0.0149) 16:1 0.0000121 (0.0137)

5:1 0.0000087 (0.00984) 20:1, 25:1 0.0000080 (0.00906)

10:1 0.0000023 (0.00261) 40:1, 50:1, 100:1 0.0000021 (0.00242)

Tritex 1 Installation and Setup 18 09/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

Specifications: Size 90 motors and Gear Motors

RTM090

RTM090 series includes embedded drive and motion controller

RTM090 ROTARY MOTOR TORQUE AND SPEED RATINGS

For output torque of RTG Gearmotors, multiply by ratio and efficiency. Please note maximum allowable

output torques in the Gearmotor Mechanical Ratings page 18.

Stator 1 Stack 1B8-17 2 Stack 2B8-10 3 Stack 3B8-07

RPM at 48 VDC 1700 1000 700

Cont. Stall Torque lbf-in (Nm) 19 (2.1) 29 (3.3) 45 (5.0)

Peak Torque lbf-in (Nm) 30 (3.4) 50 (5.6) 70 (7.9)

Power Supply

Current Draw at

Rated Power (48V) Amps

10

10

10

Resolution 0.001 revolutions / ratio

Accuracy (not

including backlash)

+/- 0.005 revolution / ratio

RSM090 and RSG090

RSM& RSG090 series requires a TRA500 remote drive and motion controller

RSM090 ROTARY MOTOR TORQUE AND SPEED RATINGS

For output torque of RSG gearmotors, multiply by ratio and efficiency. Please note maximum allowable

output torques in the Gearmotor Mechanical Ratings able page 18.

Stator 1 Stack 1B8-17 2 Stack 2B8-10 3 Stack 3B8-07

RPM at

48 VDC 1700 1000 700

Ambient Temp Deg C 25° 40° 55° 25° 40° 55° 25° 40° 55°

Cont. Stall Torque lbf-in

(Nm) 22

(2.5) 20

(2.3)

17.5

(2.0)

37

(4.2) 34

(3.8)

30

(3.4)

51

(5.7) 46

(5.2)

42

(4.7)

Peak Torque lbf-in

(Nm) 30 (3.4) 15 (5.6)

70 (7.9)

Power Supply

Current Draw at

Rated Power (48V) Amps

15 12 10 15 12 10 15 12 10

Resolution 0.001 revolutions / ratio

Accuracy (not

including

backlash)

+/- 0.005 revolution / ratio

RTM/RTG and RSM/RSG090 INERTIA

Stator 1 Stack 2 Stack 3 Stack

Motor Armature Inertia (+/-5%) lb-in-sec2 (kg-cm2)0.00054 (0.609) 0.00097 (1.09) 0.00140 (1.58)

Gearmotor Armature Inertia* lb-in-sec2 (kg-cm2)0.00114 (1.29) 0.00157 (1.77) 0.00200 (2.26)

*Add armature inertia to gearing inertia for total inertia.

Tritex 1 Installation and Setup 19 09/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

S

IZE

90 RADIAL LOAD AND BEARING LIFE

S

IZE

90

GEARING REFLECTED INERTIA

S

IZE

90

BACKLASH AND EFFICIENCY

S

IZE

90

MECHANICAL RATINGS

Tritex 1 Installation and Setup 20 09/27/12

PN: 27666 Exlar Corporation

Rev. M 952-500-6200M

Model Mask and Ordering Information

TLM Series TRITEX TLM SERIES ORDERING GUIDE

AAABB-CCDD-EFG-HHH-HH - (XX…XX - #####)

AAA = Actuator Type G = Rod End

TLM = Tritex Linear Actuator M = Male US Std Thread A = Male Metric

BB = Actuator Frame Size F = Female US Std Thread B = Female Metric

20 = 2 inch nominal frame actuator X = Special (please specify)

30 = 3 inch nominal frame actuator HHH-HH - Motor Stator

CC = Stroke Length TLM20

03 = 3 inch (75 mm) 1B8-50 = 1 Stack, 5000 rpm at 48 VDC, 2500rpm at 24

VDC

06 = 6 inch (150 mm) 2B8-34 = 2 Stack, 3400 rpm at 48 VDC, 1700 rpm at 24

VDC

10 = 10 inch (254 mm) 3B8-25 = 3 Stack, 2500 rpm at 48 VDC, 1250 rpm at 24

VDC

12 = 12 inch (305 mm) TLM30

18 = 18 inch (457 mm) (TLM30 only) 1B8-20 = 1 Stack, 2000 rpm at 48 VDC, 1000 rpm at 24

VDC

DD = Lead (linear motion per screw revolution) 2B8-13 = 2 Stack, 1300 rpm at 48 VDC, 750 rpm at 24

VDC

01 = 0.1 inch (2.54 mm) 3B8-10 = 3 Stack, 1000 rpm at 48 VDC, 500 rpm at 24

VDC (not available in 3 inch stroke)02 = 0.2 inch (5.08 mm)

04 = 0.4 inch (10.16 mm) (TLM20 only)

XX..XX = Travel and Housing Options (Multiples

Possible)

05 = 0.5 inch (12.7 mm) (TLM30 only) Travel Options

E = Connections AR = External Anti-rotate L1/2/3 = External Limit

Switches

I = Exlar std M23 style connector PF = Preloaded Follower* RB = Rear Brake

(future option)

Bxx = Embedded leads, 3 ft. XT = Special Travel Options

Pxx = Embedded leads w/plug, std M23 style connector,

3 ft. Housing Options

X = Special (please specify) P5 = IP65 sealed housing

F = Mounting Special Motor Options

C = Rear Clevis D = Double Side Mount XL = Special Lubrication

E = Extended Tie Rod F - Front Flange XM = Special Motor Option

S = Side Mount T = Side Trunnion

##### = 5 digit PN assigned to designate special

model

number

M = Metric Extended Tie Rod X = Special Optional 5 digit assigned PN to designate unique model

numbers

* The dynamic load rating of zero backlash, preloaded screws is 63% of the dynamic load rating of the std non-

preloaded screws. The calculated travel life of a preloaded screw will be 25% of the calculated travel life of the same

size and lead of a non-preloaded screw.

Table of contents

Other Exlar Controllers manuals

Popular Controllers manuals by other brands

Titan Controls

Titan Controls SPARTAN Series instruction manual

Soyal

Soyal AR727HV3 quick guide

Telecom Behnke

Telecom Behnke BEHNKE-STATION Technical manual

Phoenix Contact

Phoenix Contact ILC 130 ETH user manual

Matsunaga

Matsunaga TSA-1030-CJ operating instructions

Vortice

Vortice Vort Delta T WIFI Instruction booklet

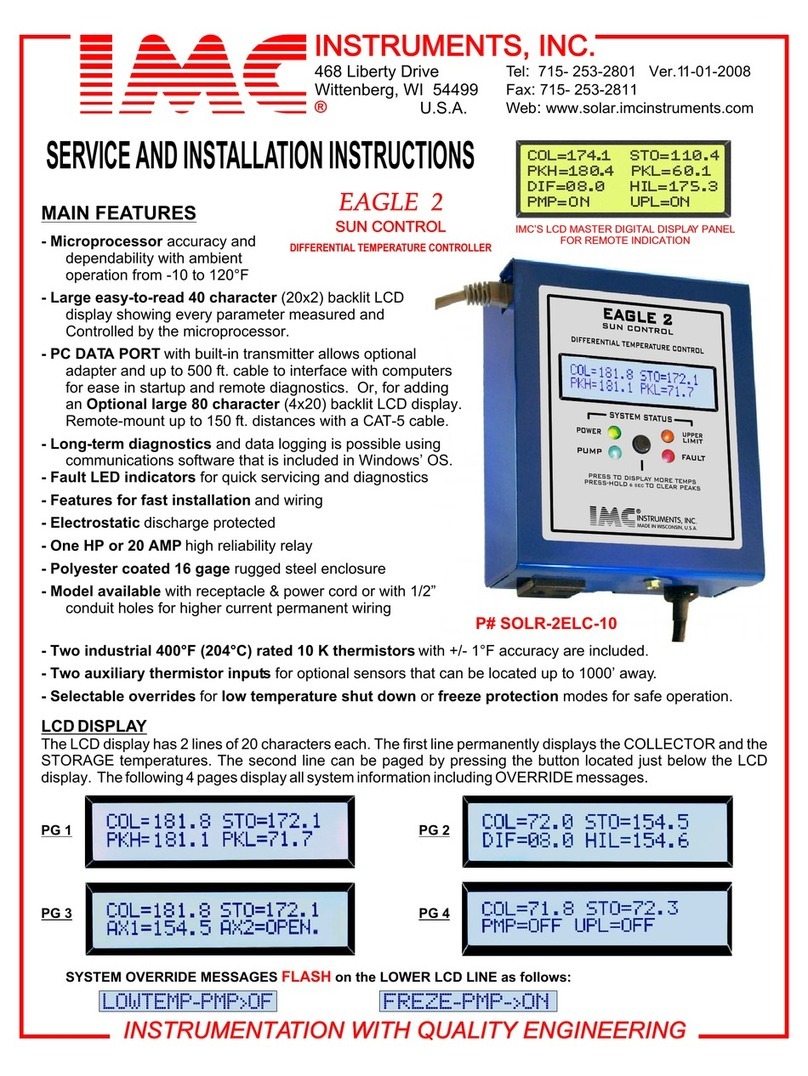

IMC

IMC EAGLE 2 SOLR-2ELC-10 Service and parts manual supplement

LIXiSE

LIXiSE LXC701 Series user manual

Honeywell

Honeywell CentraLine LYNX BACnet CLLYUB1012S Product data

WAREMA

WAREMA BACnet 4M230.8I AP installation instructions

Sinovo

Sinovo SD300-2S-0.7G user manual

Pacific Power Source

Pacific Power Source UPC-3 Operation manual