Federal APD PosiDRIVE User manual

PosiDRIVE Security Gate

Installation, Operation, and

Maintenance Manual

Safety Notice

People’s lives and property depend on your safe installation and maintenance of equipment. Listed below are

some important safety instructions and precautions which you should follow when working on any Federal

APD equipment. Failure to follow all safety precautions and instructions can result in serious injury or property

damage. Refer to the specific operational manual for a particular piece of equipment before beginning any

service work.

❑Frequently inspect the equipment to ensure that it is operating properly.

❑Ensure that maintenance is performed by the factory or an authorized distributor at least twice a year.

Safety Hints

❑Use vibrant colors on parking equipment at entrance lanes and exit lanes.

❑Always provide proper signage, both on the roadway and on other equipment.

❑Maintain the manufacturer’s warning stickers on gate arms and on other equipment.

❑Encourage the use of safety devices such as buzzers or flashing lights.

❑Always recommend that sidewalks be parallel to entrance lanes and exit lanes.

Safety Notice

To prevent injury to pedestrians, maintenance personnel, persons on bicycles or motorcycles, monitor all activity

in relation to entrance and exit lanes to ensure barrier gates are not accidentally lowered or raised. Take special

care when commanding any equipment action from a centralized computer system, especially when the control

equipment is not in your line of vision.

Use Pictograms

Federal APD, Inc. recommends using universally identifiable icons, or pictograms, in all entrance and exit lanes,

roadways, posts and walls. Paint “No Pedestrian” pictogram on the roadway adjacent to the parking barrier gate.

Pictograms depicting “No Motorcycles,” “No Wheelchairs,” “No Bicycles,” and “No Trucks” are also

recommended.

Safety Is Good Business

As an institution, municipality, or private operator, it is important to be aware of the potential liabilities which

may arise in normal parking operations. Adapting a “Safety First” attitude provides your business and your

patrons with a safer environment. After all, safety is good business!

To reduce the risk of severe personal injury or damage to equipment, turn off

the power to the equipment before performing any maintenance or repairs.

Failure to heed this warning could result in injury or even death of those who

come in contact with the product.

COPYRIGHT

PosiDRIVE Security Gate

Version 6

ZMA-330

© 2008-2009 Federal APD, Inc. All rights reserved. No part of this publication may be reproduced, transmit-

ted, transcribed, stored in a retrieval system, or translated into any language in any form by any means with-

out the written permission of Federal APD, Incorporated.

Printing Date

First Version ..............................................July 2000

Second Version..........................................December 2000

Third Version.............................................February 2001

Fourth Version...........................................July 2001

Fifth Version..............................................December 2003

Sixth Version .............................................June 2009

Warranty Information

Federal APD, Inc. warrants that the Products will be free from any defects in material and work-

manship under normal use and service, wear and tear excepted, for a period of two years from the

date of shipment from Federal APD. Exceptions to this warranty may include any products and/or

accessories that are used with Federal APD equipment but are not manufactured by Federal APD

Inc. In those instances where Federal APD is not the manufacturer of goods sold hereunder, Fed-

eral APD's warranty shall be the lesser of such manufacturers' warranty, or Federal APD's standard

warranty.

This warranty shall not apply to Products which have not been properly maintained or have been

subjected to misuse, neglect, accident or damage, or which have been modified, changed, or

reworked in any way, without prior written approval of Federal APD. Federal APD's sole obliga-

tion shall be to repair or replace, at Federal APD's option, any defective part or parts within such

two year period. Upon Federal APD's written instructions, allegedly defective goods shall be

returned to Federal APD for inspection. This warranty extends only to the original purchaser from

Distributor/Dealer and shall not cover repair, labor, or replacement of parts that are by nature

expendable. Distributor/Dealer agrees to deliver the Federal APD Limited Warranty then in effect

to each of its customers at the time of the sale. Distributor/Dealer shall have no authority to bind

Federal APD to any warranty beyond that extended therein. All Products are subject to design and/

or appearance modifications which are production standards at the time of shipment. Federal APD

may, but shall not be required to, modify or update Products shipped prior to a current production

standard.

THERE ARE NO OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT

NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL FEDERAL APD BE LIABLE FOR

ANY LOSS OF PROFITS OR ANY INDIRECT OR CONSEQUENTIAL DAMAGES ARISING

OUT OF FEDERAL APD'S BREACH OF THIS WARRANTY OR ANY OTHER TERM OR

CONDITION OF THIS AGREEMENT.

PosiDRIVE Security Gate ZMA-330, Ver. 6 Table of Contents • i

Table of Contents

CHAPTER 1

Introduction .................................................................................................................................... 1

PosiDRIVE Security Gate Operational Overview ..................................................................... 2

Manual Operation................................................................................................................2

Automatic Operation ........................................................................................................... 2

Free Mode ..................................................................................................................... 3

Pay Mode ...................................................................................................................... 4

Pay/Free Mode .............................................................................................................. 5

Power Failure Detection ...................................................................................................... 6

PosiDRIVE Structural Overview............................................................................................... 6

Gate Enclosure (Cabinet) .................................................................................................... 6

Mechanical Components ..................................................................................................... 7

Drive Mechanism .............................................................................................................. 10

Electrical Components....................................................................................................... 10

Gate Arm ........................................................................................................................... 13

PosiDRIVE Controller....................................................................................................... 14

DIP Switches............................................................................................................... 15

Inputs........................................................................................................................... 15

Outputs........................................................................................................................ 16

Opening the Enclosure Door.................................................................................................... 16

Removing the Enclosure Cap................................................................................................... 16

CHAPTER 2

Installation..................................................................................................................................... 19

Installation Overview............................................................................................................... 20

Installing the Enclosure............................................................................................................ 20

Wiring the Gate........................................................................................................................ 23

Installing the Gate Arm............................................................................................................ 25

Install a Standard Gate Arm .............................................................................................. 26

Install a Folding Gate Arm ................................................................................................ 27

Change the Gate Arm Configuration................................................................................. 34

Setting the Mainsprings ........................................................................................................... 38

Disabling the Locked-Down Feature (Optional) ..................................................................... 40

Setting the DIP Switches.......................................................................................................... 42

CHAPTER 3

Maintenance and Repair.............................................................................................................. 45

Maintenance and Repair Overview.......................................................................................... 46

Performing Preventive Maintenance........................................................................................ 46

Grease Mainshaft Bearings................................................................................................ 47

Grease the Connection Rod Bearings................................................................................ 47

Troubleshooting a Problem...................................................................................................... 48

Locking, Unlocking, and Advancing the Gate Arm ................................................................ 49

Adding, Removing, or Replacing the Mainsprings.................................................................. 52

Aligning the Drive Mechanism................................................................................................ 54

ii • Table of Contents ZMA-330, Ver.6 PosiDRIVE Security Gate

APPENDIX A

Product Support............................................................................................................................57

Getting Help .............................................................................................................................58

Accessing the Distributor Resource Center..............................................................................59

APPENDIX B

Order and Repair Procedures .....................................................................................................61

Placing an Order.......................................................................................................................62

Requesting a Repair..................................................................................................................62

Locate a Part Number ........................................................................................................63

Mainsprings.................................................................................................................64

Enclosure.....................................................................................................................65

Electrical Components ................................................................................................68

Standard Gate Arm......................................................................................................70

Folding Gate Arm........................................................................................................73

Drive Mechanism ........................................................................................................78

Index ..............................................................................................................................................83

PosiDRIVE Security Gate ZMA-330, Ver. 6 List of Figures • iii

List of Figures

Figure 1.1 Free Gate with Opening Loop...................................................................................... 3

Figure 1.2 Pay Gate ....................................................................................................................... 4

Figure 1.3 Pay/Free Gate ............................................................................................................... 5

Figure 1.4 Enclosure Components................................................................................................. 7

Figure 1.5 Mechanical Components .............................................................................................. 8

Figure 1.6 Electrical Components ............................................................................................... 11

Figure 1.7 Standard Gate Arm..................................................................................................... 13

Figure 1.8 Folding Gate Arm....................................................................................................... 14

Figure 1.9 PosiDRIVE Controller ............................................................................................... 14

Figure 1.10 Draw Latch............................................................................................................... 17

Figure 2.1 PosiDRIVE Security Gate Footprint Dimensions...................................................... 21

Figure 2.2 Gate Cabinet Warning Label (Part # 20-3469) .......................................................... 22

Figure 2.3 Wiring with the Federal APD Detector Harness........................................................ 24

Figure 2.4 Wiring with a Non-Federal APD Detector Harness................................................... 25

Figure 2.5 Standard Gate Arm Installation.................................................................................. 26

Figure 2.6 Gate Arm Warning Label (Part # 20-4343) ............................................................... 27

Figure 2.7 Dimensions for Folding Gate Arm Mounting Hole ................................................... 28

Figure 2.8 Installing the Cable Tower ......................................................................................... 29

Figure 2.9 Attaching the Fixed Section of the Folding Gate Arm to the Gate Flange ................ 30

Figure 2.10 Attaching the Folding Section to the Gate Arm Stabilizer....................................... 31

Figure 2.11 Attaching the Stabilized Folding Section to the Gate Arm Fixed Secton................ 32

Figure 2.12 Attaching the Cable Turnbuckle to the Gate Arm.................................................... 33

Figure 2.13 Gate Arm Configuration Components ..................................................................... 34

Figure 2.14 Pivot Bar................................................................................................................... 35

Figure 2.15 Set Screws ................................................................................................................ 36

Figure 2.16 Mainshaft Removal .................................................................................................. 36

Figure 2.17 Spring Adjustment Bolts .......................................................................................... 39

Figure 2.18 Down Bump Stop ..................................................................................................... 41

Figure 2.19 DIP switches in the Open Position........................................................................... 42

Figure 3.1 Motor Crank Position when the Gate Arm is Down .................................................. 51

Figure 3.2 Motor Crank Position when the Gate Arm is Up ....................................................... 51

Figure 3.3 Mainspring Connection Bar ....................................................................................... 53

Figure 3.4 Mainspring Attachment Points................................................................................... 53

Figure 3.5 Drive Mechanism Alignment ..................................................................................... 55

Figure B.1 Mainspring Parts........................................................................................................ 64

iv • List of Figures ZMA-330, Ver.6 PosiDRIVE Security Gate

Figure B.2 Enclosure Cap Parts ................................................................................................... 65

Figure B.3 Enclosure Door Parts ................................................................................................. 66

Figure B.4 Enclosure Cabinet Parts ............................................................................................. 67

Figure B.5 Electrical Sub-Panel Parts.......................................................................................... 68

Figure B.6 Detector Bracket and Backup Battery Assembly Parts.............................................. 70

Figure B.7 Standard Gate Arm Parts ........................................................................................... 71

Figure B.8 Folding Gate Arm and Stabilizer Parts ...................................................................... 73

Figure B.9 Folding Gate Arm Cable Tower Parts ....................................................................... 75

Figure B.10 Folding Gate Arm Adapter and Fixed Section Parts ............................................... 76

Figure B.11 Folding Gate Arm Packages .................................................................................... 77

Figure B.12 Drive Mechanism Installation Parts......................................................................... 78

Figure B.13 Drive Mechanism Frame Parts (View 1) ................................................................. 79

Figure B.14 Drive Mechanism Parts (View 2) ............................................................................ 80

PosiDRIVE Security Gate ZMA-330, Ver. 6 Introduction • 1

CHAPTER 1

Introduction

This chapter contains the following topics:

PosiDRIVE Security Gate Operational Overview ..............................................2

Manual Operation .........................................................................................2

Automatic Operation.....................................................................................2

Free Mode ..............................................................................................3

Pay Mode................................................................................................4

Pay/Free Mode .......................................................................................5

Power Failure Detection ...............................................................................6

PosiDRIVE Structural Overview ........................................................................6

Gate Enclosure (Cabinet)..............................................................................6

Mechanical Components...............................................................................7

Drive Mechanism........................................................................................10

Electrical Components................................................................................10

Gate Arm.....................................................................................................13

PosiDRIVE Controller................................................................................14

DIP Switches........................................................................................15

Inputs....................................................................................................15

Outputs .................................................................................................16

Opening the Enclosure Door .............................................................................16

Removing the Enclosure Cap ............................................................................16

2 • PosiDRIVE Security Gate Operational Overview ZMA-330, Ver.6 PosiDRIVE Security Gate

PosiDRIVE Security Gate Operational Overview

The PosiDRIVE Security Gate is a low-maintenance security gate, with a

microprocessor-based controller that protects roadways up to 20 feet (6 m). The

PosiDRIVE gate has a variable operating time, from 1.5 to 6 seconds, depending on the

length of the gate arm. The gate is capable of operating in an ambient temperature of

-30°F (-34°C) to 140°F (60°C) without any adjustments. It can be configured as a right-

hand or left-hand flange gate without any additional hardware.

The PosiDRIVE Security Gate works with several types of vend devices, such as vehicle

detection loops, card reading devices, or ticket issuing devices. The gate controller

inputs support both manual and automatic operation.

Manual Operation

For manual operation a toggle switch is wired into the Raise/Lower input on the gate

controller (Figure 2.3, on page 24). When the toggle switch is placed in the “raise”

position (i.e., the circuit is completed), the gate arm raises and remains in the up position

until the toggle switch is moved to the “lower” position.

Automatic Operation

For automatic operation, one or more vend devices are wired into the Vend input on the

gate controller (Figure 2.3, on page 24). Depending on the vend device(s), the lane runs

in one of the following modes:

■“Free Mode” on page 3

■“Pay Mode” on page 4

■“Pay/Free Mode” on page 5

For all automatic operation modes, a vehicle detection loop that resides under the gate

arm (loop B) is wired into the B Presence input on the gate controller. The gate

automatically lowers when the patron pulls off of the loop B.

PosiDRIVE Security Gate ZMA-330, Ver. 6 PosiDRIVE Security Gate Operational Overview • 3

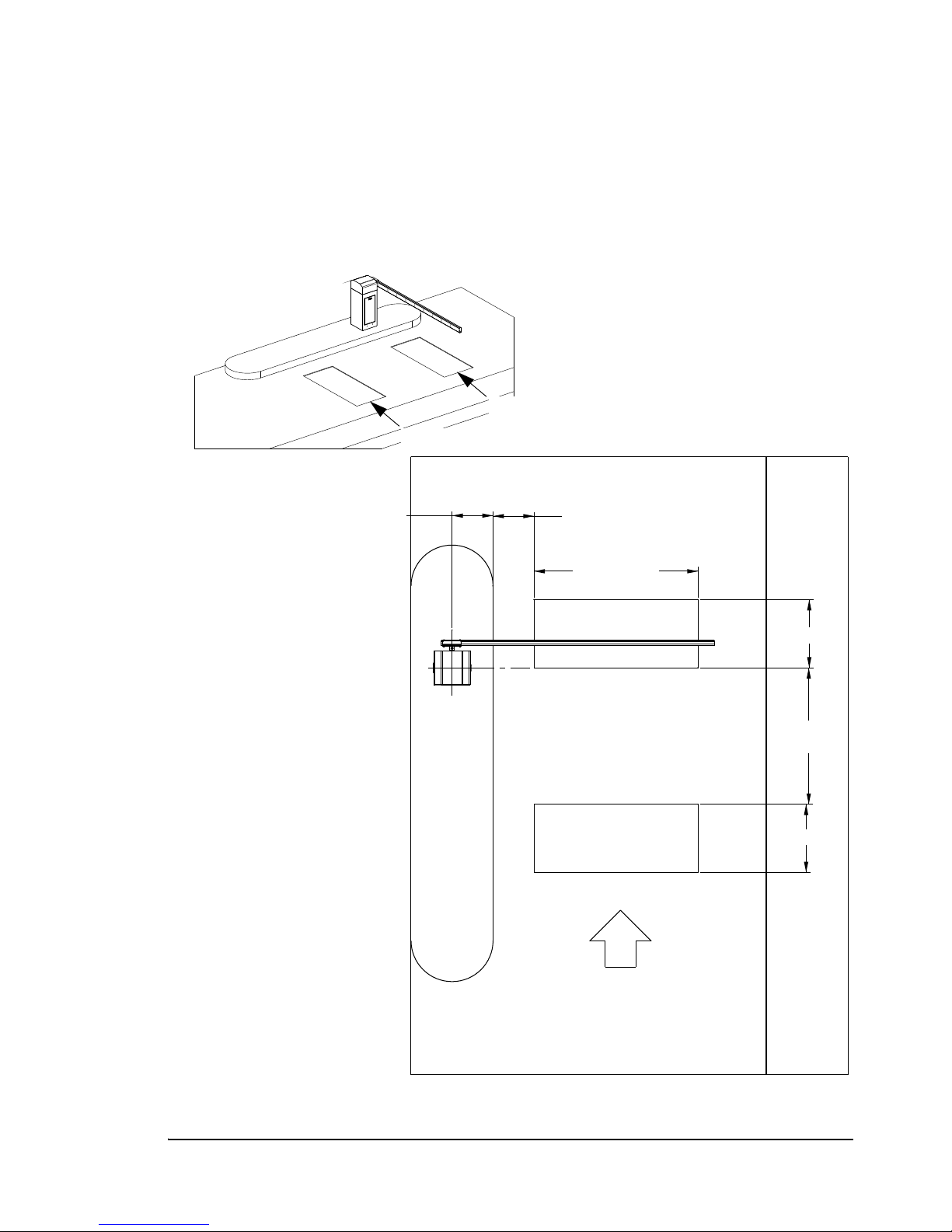

Free Mode

Free mode is used in a single-direction lane through which a patron enters or exits the

facility free of charge. This mode requires two vehicle detector loop inputs: loop A and

loop B. When a vehicle pulls onto the loop A, the gate arm raises. The gate arm lowers

after the vehicle clears loop B.

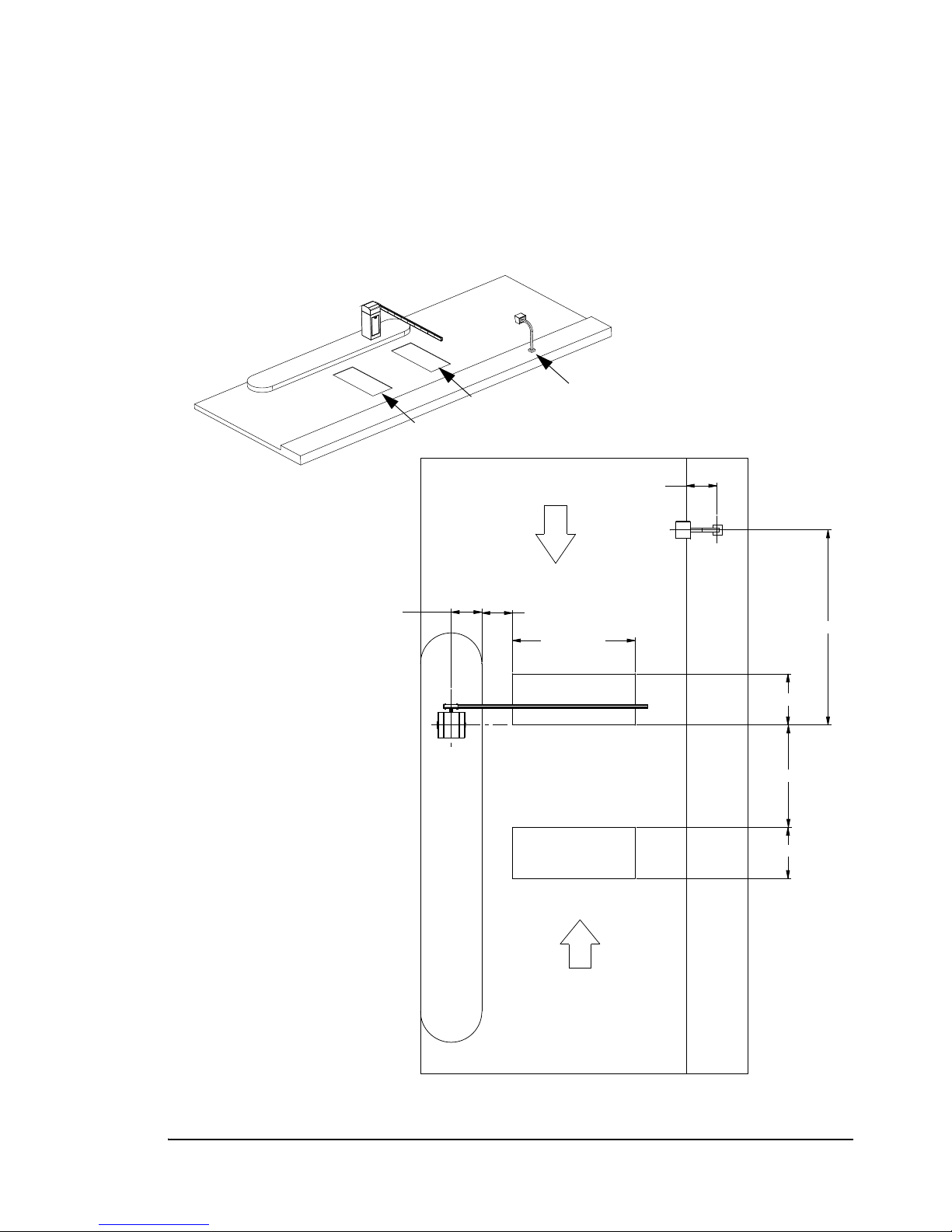

Figure 1.1 Free Gate with Opening Loop

TRAFFIC FLOW

2'-6" (.76 m)

5' (1.5 m)

MAX.

2'-6" (.76 m)

1'-6" (.46 m)

6' (1.8 m)

1'-6" (.46 m)

A

B

Loop A

Loop B

4 • PosiDRIVE Security Gate Operational Overview ZMA-330, Ver.6 PosiDRIVE Security Gate

Pay Mode

Pay mode is used in a single-direction lane in which controlled access is required to

enter or exit the facility. This mode requires a vehicle detection loop (loop B) and a

vend-device such as a card reader or a switch that a booth attendant uses to raise the

gate. The gate arm lowers after the vehicle clears loop B.

Note: An additional loop (loop A) may be used to enable the vend device, for

example, the lane may contain a ticket issuing device that is activated when the

patron pulls onto loop A.

Figure 1.2 Pay Gate

TRAFFIC FLOW

2'-6" (.76 m)

8'-3" (2.5 m)

2'-6" (7.6 m)

1'-6" (.46 m)

6' (1.8 m)

9'-6" (2.9 m)

1'-6" (.46 m)

A

B

Loop B

Loop A (optional)

Vend Device

PosiDRIVE Security Gate ZMA-330, Ver. 6 PosiDRIVE Security Gate Operational Overview • 5

Pay/Free Mode

Pay/free mode is used in a dual-direction lane. It requires two vehicle detection loops

(loop A and loop B) and a vend-device such as a card reader. In the free direction,

vehicle presence on loop A vends the gate. In the pay direction, the vend-device vends

the gate. In either direction, the gate arm lowers after the vehicle clears the loop B.

Figure 1.3 Pay/Free Gate

TRAFFIC FLOW INTRAFFIC FLOW IN

TRAFFIC FLOW OUTTRAFFIC FLOW OUT

2'-6"2'-6" (.76 m)(.76 m)

5'5' (1.5 m)(1.5 m)

2'-6"2'-6" (.76 m)(.76 m)

1'-6"1'-6" (.46 m)(.46 m)

6'6' (1.8 m)(1.8 m) 9'-6" (2.9 m)9'-6" (2.9 m)

1'-6"1'-6" (.46 m)(.46 m)

1'-6"1'-6" (.46 m)(.46 m)

A

B

Loop A

Loop B Vend Device

6 • PosiDRIVE Structural Overview ZMA-330, Ver.6 PosiDRIVE Security Gate

Power Failure Detection

The PosiDRIVE controller is able to sense when there is a power failure. If the

controller is programmed to raise the gate arm during a power failure, the controller uses

the power from backup battery assembly to raise the gate arm automatically. The gate

arm stays in the up position until the power is restored.

Note: If the controller is not programmed to automatically raise the gate, the gate must

be raised manually. See “Locking, Unlocking, and Advancing the Gate Arm” on

page 49.

PosiDRIVE Structural Overview

This section describes the following PosiDRIVE components:

■“Gate Enclosure (Cabinet)” on page 6

■“Mechanical Components” on page 7

■“Drive Mechanism” on page 10

■“Electrical Components” on page 10

■“Gate Arm” on page 13

■“PosiDRIVE Controller” on page 14

Gate Enclosure (Cabinet)

Federal APD, Inc. builds the PosiDRIVE gate enclosure using 0.090 inch galvanized

steel. The enclosure is weather resistant and allows proper operation in all weather

conditions and temperatures ranging from -30°F (-34°C) to 140°F (60°C). Louvres on

the back and cutouts on the four bottom corners of the enclosure provide air circulation,

thus preventing excessive moisture buildup.

The enclosure is 15 inches W x 16 inches D x 42 inches H (38 cm W x 41 cm D x 107

cm H), finished in yellow or white powder coat paint. The enclosure consists of two

pieces, a base and a removable cap. The base houses the power supply and electronics

package as well as provides the main structure of the enclosure. In addition, the base

provides reinforced flanges for installation, hookup points for the mainsprings, and

mounting provisions for the drive mechanism. Figure 1.4 illustrates the main

components of the gate enclosure.

The enclosure cap is a removable piece that provides easy access to the drive

mechanism without disrupting the operation of the gate. Inspection and maintenance can

be performed easily by removing the enclosure cap. It is secured by four draw latches to

the base, requiring no tools to remove or install. See “Removing the Enclosure Cap” on

page 16.

PosiDRIVE Security Gate ZMA-330, Ver. 6 PosiDRIVE Structural Overview • 7

Figure 1.4 Enclosure Components

Mechanical Components

The PosiDRIVE gate is powered by a 150 watt, 24 VDC brushless DC gear motor.

The motor is connected directly to a fully sinusoidal four-bar drive mechanism. A

sinusoidal mechanism has the distinct advantage of providing smooth, progressive

acceleration and a mechanical advantage at the limits of travel, where it is needed most.

This arrangement eliminates the need for Vee-belts and their associated maintenance.

One advantage of a brushless DC motor is that the gate can adjust the speed of the entire

system depending on the size of the arm installed. Therefore, the same motor and

gearbox can be used in all situations, allowing the flexibility of using any size gate arm.

Another advantage to the brushless DC motor is the ability of the gate to know where

the gate arm is at all times. The motor provides an output that is monitored by the

controller. The controller interprets the signals to determine arm position and speed.

Using this information, the PosiDRIVE gate operates like a full servo system, providing

benefits such as not requiring mechanical contact to limit its travel, no limit switches,

and an extremely sensitive collision detect system.

The PosiDRIVE gate uses as many as four internal extension mainsprings to

counterbalance the weight of the gate arm. The number of mainsprings and their

adjustment must be properly set at the time of installation in order for the gate to

function properly. When correctly set, these mainsprings offset the torque on the

mechanism created by the weight of the arm, providing a safe, balanced system which

greatly reduces the power required by the motor and increases the efficiency of the gate.

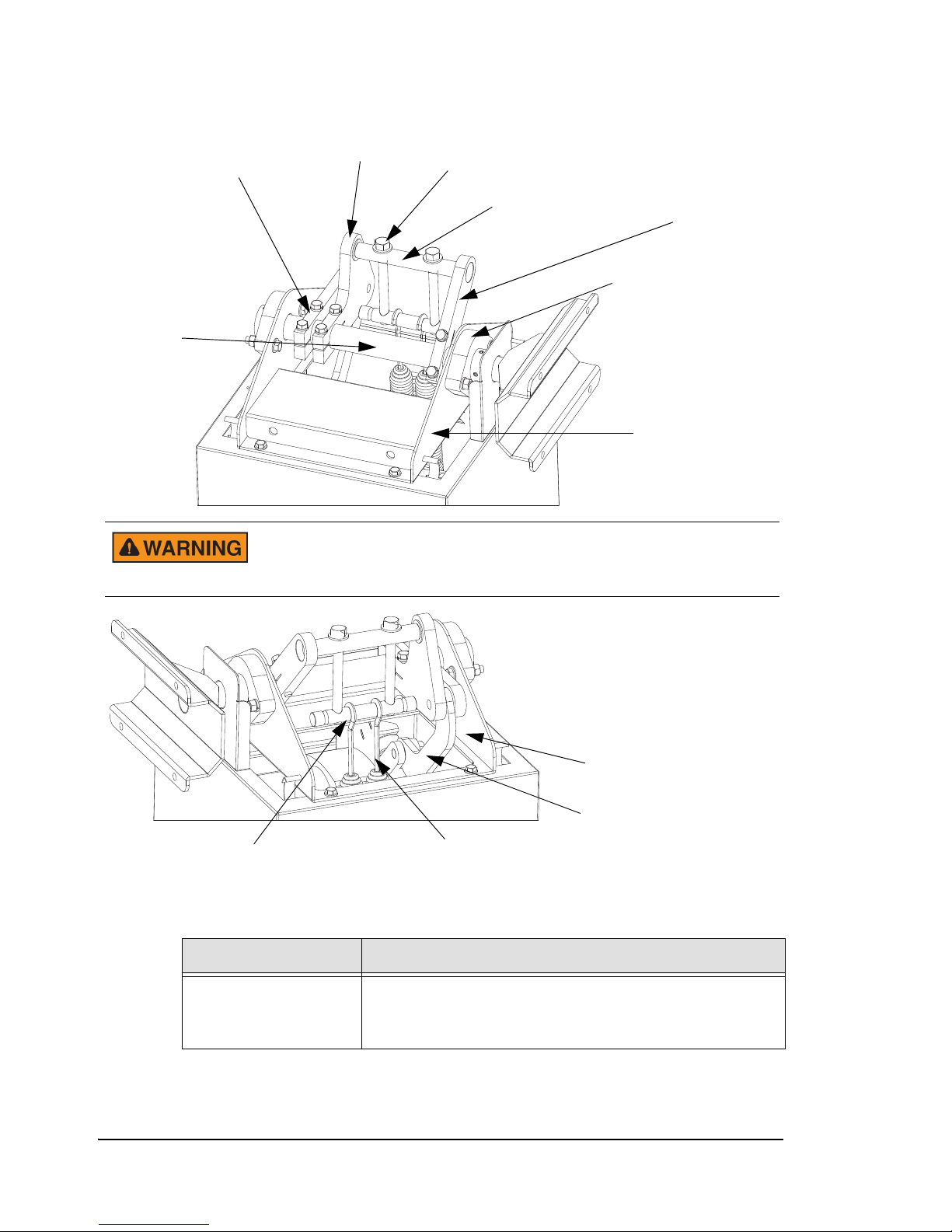

Figure 1.5, on page 8 shows the PosiDRIVE mechanical components. Component

descriptions follow the illustration.

Enclosure Cap

Enclosure Base

Enclosure Door

Gate Arm

8 • PosiDRIVE Structural Overview ZMA-330, Ver.6 PosiDRIVE Security Gate

Figure 1.5 Mechanical Components

Table 1.1 Mechanical Component Descriptions

Component Description

Mechanism Frame Steel frame that forms the foundation for the PosiDRIVE

mechanism. All of the drive components, including the

motor and mainshaft are attached to the mechanism frame.

Mainshaft Crank

Part 1

Mainspring Adjustment Bolt

Mainspring Pivot Bar Mainspring Crank

Mainshaft Bearing

Mainshaft

Mechanism Frame

Mainshaft Crank

Part 2

Connecting Rod

Motor Crank

Mainspring

Mainspring Connection Bar

To prevent a serious pinching injury including dismemberment, use

care when working with the drive mechanism and alway terminate

power prior to performing maintenance or repairs.

PosiDRIVE Security Gate ZMA-330, Ver. 6 PosiDRIVE Structural Overview • 9

Motor 24 VDC gear motor that powers the PosiDRIVE gate. The

motor and gear box are contained in a single sealed

housing for simplicity and maintenance-free operation.

Motor Crank Link that is attached to the output shaft of the motor. This

link is attached to the motor shaft by means of a friction

clamp but also includes a keyed shaft to prevent slipping

under all conditions.

Connecting Rod Intermediate link in the PosiDRIVE system. The connecting

rod incorporates two high quality spherical bearings for

maximum life and excellent tolerance to misalignment.

Mainshaft Crank Part 1 One of two combined pieces that attach to the mainshaft

and provide the driving force to the mainshaft.

Mainshaft Crank Part 2 The second of the main driving links. This piece is also

designed to serve as an attachment point for the spring

system. It incorporates a single high quality deep groove

ball bearing that one end of the mainspring pivot bar rests

in.

Mainspring Crank Other link attached to the mainshaft that serves as the

second attachment point for the spring system.

Mainspring Pivot Bar Bar that rides in the pair of ball bearings in the mainshaft. It

links and supports the mainspring adjustment bolts.

Mainspring

Connection Bar

Bar to which the mainsprings are attached. The connection

bar incorporates four shallow grooves to keep the

mainsprings properly positioned.

Mainspring

Adjustment Bolts

The two long bolts that connect the mainspring connection

bar to the mainspring pivot bar. They provide the means to

fine-tune the spring tension to a given arm.

Mainshaft Shaft that carries the gate arm at one end and to which the

driving links are attached.

Mainshaft Bearings Large bearings mounted to the sides of the mechanism

frame that carry the mainshaft.

Gate Arm Flange Arm carrier that is attached to the end of the mainshaft.

Table 1.1 Mechanical Component Descriptions (Continued)

Component Description

10 • PosiDRIVE Structural Overview ZMA-330, Ver.6 PosiDRIVE Security Gate

Drive Mechanism

The drive mechanism in the PosiDRIVE gate is a direct drive, sinusoidal mechanism.

This system provides a substantial mechanical advantage for the motor at the beginning

and ending of a cycle when it is most needed. The result of this is that when the gate is at

the extreme limits of travel, in the “full down” or “full up” position, the mechanism is

“locked” and cannot be manually advanced by pushing the gate arm. In other words, at

the full up and full down positions, the mechanism cannot be driven or advanced by any

torque applied to the mainshaft. When servicing the PosiDRIVE gate, you must be

aware of this.

There are times, such as when setting the mainsprings, when you must operate the

mechanism by hand, using the gate arm. It is also necessary at times during this

procedure and others to ensure that the linkage is in the fully locked up position for

safety. Raising the gate arm by hand will NOT bring the linkage into this position. It will

bring it closed, but it will not be fully locked.

In order to lock the mechanism, you must always advance the mechanism by hand for

the last few degrees of travel. That is, if you raise or lower the arm by hand to what feels

like the limits of its travel, the mechanism still must be manually advanced a small

amount to ensure that it is in the locked position. If the mechanism is already locked,

either up or down, then it becomes impossible to get it out of this position by moving the

gate arm. The mechanism must be manually advanced out of the locked position before

moving the gate arm. This is a side effect of the sinusoidal linkage and the variable

mechanical advantage the system provides.

For instructions on manually advancing the mechanism into and out of the locked

positions, see “Locking, Unlocking, and Advancing the Gate Arm” on page 49.

Electrical Components

The use of a 24 VDC motor in the PosiDRIVE gate provides several electrical benefits.

First, by using a low (non-hazardous) voltage throughout the system, the risk of shock to

service personnel is greatly reduced. The PosiDRIVE gate utilizes a universal input 24

volt power supply. This supply can accept input voltages anywhere from 85 VAC to 264

VAC at 50 or 60 Hz. This allows the PosiDRIVE gate to be installed into virtually any

voltage environment without modification, providing maximum flexibility. The

nameplate rating for power consumption is 2 amps for 115 VAC and 1 amp for 220

VA C .

The PosiDRIVE gate is also equipped with a backup battery assembly, which provides

power to the controller and motor in the event of a power failure to allow the

PosiDRIVE gate to raise the arm. It is not intended to operate the gate in a power failure

mode, but just to provide the option of raising the gate to allow patrons to exit. It also

does not power any loop circuits. Automatically raising the gate during a power failure

is a configurable option. See “Setting the DIP Switches” on page 42.

PosiDRIVE Security Gate ZMA-330, Ver. 6 PosiDRIVE Structural Overview • 11

The PosiDRIVE gate can detect a line power failure and will wait (operating on battery

power) for a period of 10 seconds before raising the arm. This eliminates false responses

to transient (short term) power glitches. On detection of the return of line power, again a

delay of 10 seconds is provided before normal operation is resumed. The backup battery

assembly has ample power to provide this feature for several years before replacement.

Figure 1.6, on page 11 shows the PosiDRIVE gate electrical components. Component

descriptions follow the illustration.

Figure 1.6 Electrical Components

The door safety switch disconnects power to the motor under ALL

circumstances. If the door safety switch is bypassed (not normally

recommended) and the circuit breaker switch is turned off for any

reason, after 10 seconds, the gate activates under battery power and

raises the arm. The powerful drive mechanism can cause serious

bodily injury. Do not bypass the door safety switch unless absolutely

necessary.

Table 1.2 PosiDRIVE Electrical Component Descriptions

Component Description

Junction Box A junction is located on the electrical sub-panel below the

circuit breaker, where an installer can mount a convenience

outlet.

Safety Switch

PosiDRIVE Controller

Power Supply

Motor Driver

Board Manual/Auto Switch

Circuit Breaker/Master

Power Switch

Junction Box

Electical Subpanel

12 • PosiDRIVE Structural Overview ZMA-330, Ver.6 PosiDRIVE Security Gate

Circuit Breaker Switch This is the main overload protection mechanism for the

entire gate. It is also the master power switch. CAUTION:

The door safety switch disconnects power to the motor

under ALL circumstances. If the door safety switch is

bypassed (not normally recommended) and the breaker

switch is turned off for any reason, the system will respond

to this as a line power failure. After 10 seconds, the gate will

activate under battery power and raise the arm. Use

extreme caution when servicing the gate and be aware of

this condition. This is why the door safety switch should not

be bypassed unless absolutely necessary.

Electrical Sub-Panel Steel panel mounted inside the enclosure, which holds all of

the electrical components.

PosiDRIVE Controller “Brain” behind the PosiDRIVE gate and its operation. It is a

plug-in, microprocessor-based controller that monitors and

directs all operations of the gate. It is capable of operating

on input voltages ranging from 18 VDC to 32 VDC.

Motor Driver Board “Brain” behind the brushless DC motor. It controls the

proper operation of the motor as well as regulates the power

delivered to the motor.

Safety Switch A plunger-style switch that automatically terminates power

to the motor when the enclosure door is open. To bypass

the switch, pull out the plunger. To reactivate the switch,

depress the plunger. The plunger springs back to the safe

position.

Manual/Auto Switch Setting the switch to the Manual position raises the arm to

the up position indefinitely. Setting the switch to the

Automatic position causes the gate to resume normal

operation.

Table 1.2 PosiDRIVE Electrical Component Descriptions (Continued)

Component Description

To avoid serious injury, use

extreme caution when

bypassing the safety switch.

Make sure all technicians are

clear of the drive mechanism

and the gate arm path before

bypassing the switch.

Table of contents

Popular Gate Opener manuals by other brands

AGS

AGS 104 installation guide

Genius

Genius FALCON 14 MC Instructions for use

SEA

SEA ALPHA 200 STANDARD installation manual

Nice

Nice hyke HK7224 Instructions and warnings for installation and use

LIFE home integration

LIFE home integration ERGO ER4 Instructions for installation, use and maintenance

RIB

RIB SUPER 3600 L1 CRX Installation

cedamatic

cedamatic GLISS 1300 Operating instructions and spare parts catalogue

Erreka

Erreka JEDI JES100E manual

CAME

CAME FROG A installation manual

Chamberlain

Chamberlain SLY500E-120 manual

Comunello Automation

Comunello Automation SWIFT Installation and user manual

RIB

RIB IDRO 27 Operating and installation instructions