FEDERAL INDUSTRIES RSSL378 Installation instructions

E3745

REV L 05/24/23

RSSL378, RSSL478, RSSL578, RSSL678

RSSL360, RSSL460, RSSL560, RSSL660

Self-Contained & Remote Models

NSSL378, NSSL478, NSSL578, NSSL678

Non-Refrigerated

INSTALLATION & OPERATION

INSTRUCTIONS

KEEP THIS MANUAL FOR FUTURE REFERENCE

Engineering and technical data are subject to change without notice.

FEDERAL INDUSTRIES 215 FEDERAL AVE Belleville, WI 53508

Toll Free 1(800) 356-4206 WI Phone (608) 424-3331 Fax: (608) 424-3234

Refrigerated Self-Serve Merchandiser (High Profile) Page 2

CONTENTS

INTRODUCTION .............................................................................................................4

WARNING LABELS & SAFETY INSTRUCTIONS..........................................................5

PRE-INSTALLATION PROCEDURES............................................................................6

Inspection For Shipping Damage......................................................................6

INSTALLATION INSTRUCTIONS...................................................................................6

Locating The Display Case.........................................................................................6

Grill Removal..............................................................................................................6

Removing Case From Shipping Skid..........................................................................7

Removing Packaging Material....................................................................................7

Leveling The Case......................................................................................................7

Condensate Evaporator..............................................................................................7

Lights..........................................................................................................................8

ELECTRICAL CONNECTION & GROUNDING INSTRUCTIONS...................................9

Electrical Supply Wiring ....................................................................................9

Grounding Requirements............................................................................9

Optional permanent connection ..................................................................9

OPERATING INSTRUCTIONS......................................................................................10

Initial Start-Up................................................................................................................10

Light Switch & Lights......................................................................................................10

LED Light Replacement.................................................................................................10

Digital Display.........................................................................................................................10

Placing Product in Case.................................................................................................10

Energy Saving Night Curtain..........................................................................................10

Electronic Temperature Control ....................................................................................11

Powering On Control......................................................................................................11

Adjusting Set Point.........................................................................................................12

Error Codes....................................................................................................................13

Optional Electronic Temperature Control ......................................................................14

Powering On Control......................................................................................................14

Adjusting Set Point.........................................................................................................15

Error Codes....................................................................................................................15

Temp Probe Common Resistance Chart.......................................................................16

ELECTRONIC CONTROL FUNCTIONALITY...............................................................17

Electronic Control............................................................................................17

Operation...................................................................................................17

Defrost Cycle..............................................................................................18

Control Factory Setting ..............................................................................18

Control Display................................................................................................19

Minimum Run Timer Feature ..........................................................................19

Maximum Run Timer Feature .........................................................................19

Refrigerated Self-Serve Merchandiser (High Profile) Page 3

REFRIGERATION OPERATION...................................................................................19

Self-Contained Refrigeration Operation..........................................................19

Dual Pressure Control ( Self-Contained Models Only )...................................19

Remote Refrigeration .....................................................................................20

Electronic Expansion Valve (EEV).............................................................20

Remote Refrigeration Operation .....................................................................21

CLEANING INSTRUCTIONS ........................................................................................22

Cleaning The Condenser Coil.........................................................................22

Cleaning The Condensate Pump....................................................................22

Cleaning The Acrylic Air Deflector...................................................................23

Daily Cleaning.................................................................................................23

Weekly Cleaning.............................................................................................24

SHELVES......................................................................................................................25

Installation & Removal.....................................................................................25

SERVICE INFORMATION.............................................................................................26

Pre-Service Checklist ...............................................................................................27

Special Service Situations ........................................................................................28

SALE & DISPOSAL ......................................................................................................28

Owner Responsibility................................................................................................28

REFRIGERATION & ELECTRICAL DATA .............................................................................29

RSSL378/360 ............................................................................................................29

RSSL478/460 ....................................................................................................30 & 31

RSSL578...........................................................................................................32 & 33

RSSL678...........................................................................................................34 & 35

NSSL378, NSSL478, NSSL578, NSSL678................................................................36

REPLACEMENT PARTS............................................................................................ 37 thru 44

RSSL DISPLAY AREA & VOLUME.........................................................................................45

WIRING DIAGRAMS................................................................................................... 46 thru 53

Refrigerated Self-Serve Merchandiser (High Profile) Page 4

INTRODUCTION

Thank you for purchasing a Federal Industries Merchandiser. This manual contains important instructions for

installing and servicing the RSSM, Refrigerated Self-Service Merchandisers. A repair parts list is also included in

the manual. Read all of these documents carefully before installing or servicing your case.

NOTICE

Read this manual before installing your case. Keep this manual and refer to it before doing any service

on the equipment. Failure to do so could result in personal injury or damage to the case.

NOTICE

Installation and service of the electrical components in the case must be performed by a licensed

electrician.

The portions of this manual covering components contain technical instructions intended only for persons

qualified to perform electrical work.

DANGER

Improper or faulty hookup of electrical components in the case can result in severe injury or death.

All electrical wiring hookups must be done in accordance with all applicable local, regional, or national

standards.

NOTE: UNIT MUST BE GROUNDED

REGISTRATION & SERIAL NUMBER

It’s important to keep a record of the model and serial number of your merchandiser for warranty and part

identification. Please write them here for your quick reference.

Register your product online! Visit our website at www.federalindustries.com and register your product

today.

Case Model__________________________ Serial Number______________________

We’re here to provide you with the best possible experience with your new product, however, we cannot cover

everything about your merchandiser in this manual, so if you have any additional questions or issues, please see

the SERVICE INFORMATION PAGE to find who you should contact.

Refrigerated Self-Serve Merchandiser (High Profile) Page 5

WARNING LABELS AND SAFETY

INSTRUCTIONS

This is the safety-alert symbol. When you see this symbol on your case or in the

manual, be alert to the potential for personal injury or damage to your equipment.

Be sure you understand all safety messages and always follow recommended precautions and safe

operating procedures.

NOTICE TO EMPLOYERS

You must make sure that everyone who installs, uses, or services your case is thoroughly

familiar with all safety information and procedures.

Important safety information is presented in this section and throughout the manual. The

Following signal words are used in the warning and safety messages:

DANGER: Severe injury or death will occur if you ignore the message.

WARNING: Severe injury or death can occur if you ignore the message.

CAUTION: Minor injury or damage to your case can occur if you ignore the message.

NOTICE: This is important installation, operation, or service information. If you ignore the

message, you may damage your case.

The warning and safety labels shown throughout this manual are placed on your Federal

Industries case at the factory. Follow all warning label instructions. If any warning or safety labels

become lost or damaged, call our customer service department at 1(800) 356-4206 for replacements.

This label is located on the back of the display case This label is located below the display pan.

and on the front of the case behind the access panel.

CAUTION

POWER BEFORE

RISK OF ELECTRIC

SHOCK DISCONNECT

91-12340

SERVICING UNIT.

CAUTION

HAZARDOUS MOVING PARTS

DO NOT OPERATE UNIT WITH

DISPLAY PANS REMOVED.

Refrigerated Self-Serve Merchandiser (High Profile) Page 6

PRE-INSTALLATION PROCEDURES

Inspection For Shipping Damage

You are responsible for filing all freight claims with the delivering truck line.

Inspect all cartons and crates for damage upon arrival. If there is damage to

shipping crates, cartons, or if a shortage is found, note this on (all copies) of

the Bill Of Lading prior to signing.

If damage is discovered when the case is uncrated, immediately call the delivering

truck line and follow-up the call with a written report indicating concealed damage to

your shipment. Ask for an immediate inspection of your concealed damaged item.

Crating material must be retained and shown to the inspector from the truck line.

INSTALLATION INSTRUCTIONS

Locating the Display Case NOTE: This case is designed for indoor use only.

The case should be located where it is not subjected to the direct rays of the sun,

heating ducts, grills, radiators, or ceiling fans, nor should it be located near open doors or

main door entrances. Avoid locations where there is excessive air movement or air disturbances

and avoid high humidity locations such as near cases with water misting or fogging devices.

The condenser air inlet is located in the front of the case. Do not block this inlet and do not

locate the air inlet near a source of heat. Clearance of 6” minimum must be maintained at the

back of the case for condenser discharge air. Clearance at the top of

the case should also be at least 8”.

Do not build this unit into an alcove and do not locate where condenser discharge air

cannot escape or where warm condenser air is allowed to re-circulate.

Grill Removal

WARNING: Electrical shock hazard. Do not operate unit with panels removed.

Must remove front and rear base grills for merchandiser installation. The front base grill

is secured with fast lead captive screws, and the rear base grill is secured with self

threading screws.

Both base grills must be replaced after merchandiser installation. Base grills must be

in place for proper operation of the merchandiser.

Refrigerated Self-Serve Merchandiser (High Profile) Page 7

Removing Case From Shipping Skid

CAUTION: If a Johnson bar or pry bar is used to move the case, make certain that

the case is lifted under the welded steel frame, and not by the end panels of the case.

Damage to the ends will result from lifting under the end panels.

Move the case as near as possible to the final location before removing it from the

shipping skid. Having removed the front and rear compressor compartment grills. Remove

the (three or four sets of bolts, nuts, and washers depending on case size) that secure the case to the

shipping skid. Discard these bolts, nuts, and washers.

Removing Packaging Material

Remove bubble wrap and packing material for all shelves, etc. If it is

necessary to remove tape residue from various materials, use cleaning

compounds recommended in the cleaning section of this manual.

Leveling the Case

The case must be level for proper drainage of defrost water to the condensate evaporator or

condensate pump.

Check the level of the case along the front rail and along the top of the display pan. Shim

under the case frame as needed to level the case. It is recommended that the leveled case be

sealed to the floor with an NSF Listed Sealant.

Condensate Evaporator

NOTICE: Steam from the condensate evaporator may be visible around the

base of the merchandiser during normal operation.

This merchandiser may be furnished with an electric condensate evaporator, or a

electric condensate pump. Plumbing connections are not required, unless

merchandiser is specifically ordered without a condensate evaporator or pump.

The condensate evaporator can be removed from the merchandiser and the

condensate drain can be plumbed to a external drain to conserve energy. To remove

the condensate evaporator, disconnect the wires at the condensate evaporator. This

must be done by a qualified electrician.

This is an open merchandiser and can produce a large amount of condensate water.

To ensure that adequate evaporator capacity is available, a high wattage heater is

used.

Make sure that the condensate drain line has not been dislodged during shipment and

that the drain trap terminates properly over the water reservoir.

Refrigerated Self-Serve Merchandiser (High Profile) Page 8

Lights

Standard Top Light

The case comes with one standard top light which is internally wired to the power

source. The light switch is located on the left top ceiling behind the air discharge honey comb.

Optional Shelf Lights

If optional shelf lights are furnished, make certain that the shelf light cords are completely

inserted into the sockets in the back panel and end of led lights or lights will not work

The power supply used on this case allows for removal of one or more shelf lights

without affecting the remaining lights.

When plugging or unplugging light cords, turn the light switch to the “off” position.

Refrigerated Self-Serve Merchandiser (High Profile) Page 9

ELECTRICAL CONNECTION AND

GROUNDING INSTRUCTIONS

Electrical Supply Wiring

DANGER: Improper or faulty hookup of electrical components in the

display case can result in severe injury or death.

THIS CASE MUST BE GROUNDED

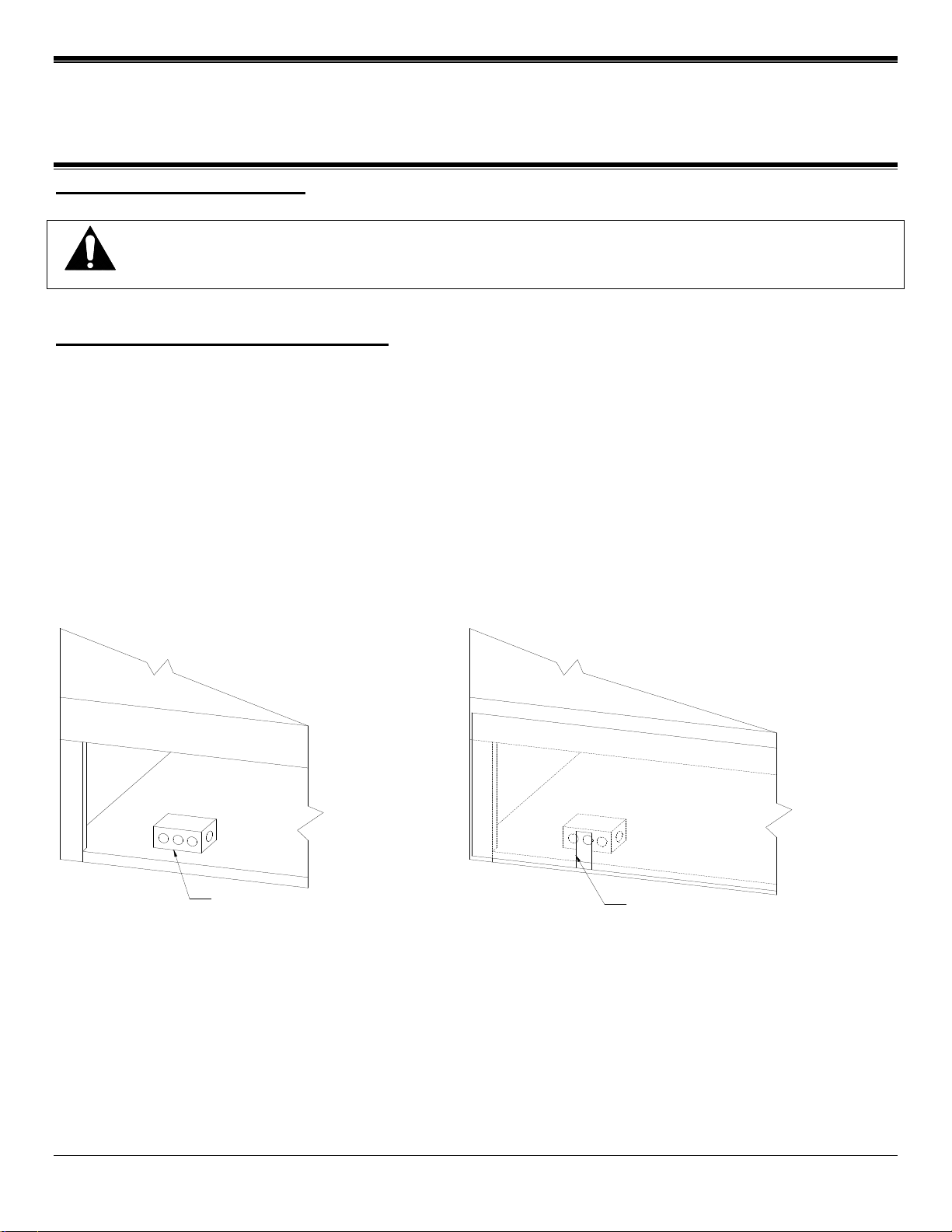

Optional Permanent Connection

-Only a licensed electrician must perform all case electrical connections.

-All electrical wiring hookups must be done in accordance with all applicable local, regional, or

national electrical standards.

-A separate circuit for each display case is required to prevent other appliances on the same circuit

from overloading the circuit and causing malfunction.

-The electrical service must be grounded upon installation.

-See the electrical data plate located at the rear of the case for circuit load and wire current capacity.

-Standard Base Electrical Connection: The electrical connection box is accessible from the rear of the

case. Power Supply Wiring can be routed through the floor of the base frame or through the access

hole in the rear of the unit. Remove electrical box cover to access electrical connections.

POWER IN BOX POWER IN ACCESS HOLE

Refrigerated Self-Serve Merchandiser (High Profile) Page 10

OPERATING INSTRUCTIONS

Initial Start-Up

-After completing the items in the installation section of this manual. The case is ready

to be put into service. On self-contained models, the service valves on the refrigeration

system are back-seated when the unit leaves the factory.

-RSSL cases are designed to operate at 40º to 41º F. under ambient conditions not to

exceed 75º F. and 55% relative humidity.

-Nearly all open refrigerated merchandisers operate better when loaded with product than

when empty. If a check is made of the case operating temperatures, perform this check with

product in the case.

-Open refrigerated merchandisers are not intended as storage refrigerators and will not “pull

down” room temperature products efficiently. Load case interior with pre-chilled product only.

Light Switch And Lights

The light switch is located in the ceiling. This switch operates the interior lights only. If optional

shelf lights are installed, they are also controlled by this switch.

Led Light Replacement

The light is attached to the shelf with plastic spring clips. To remove a light, un plug cord from

end of bulb and pull down.

When replacing lights, use direct equivalents to the original bulbs.

Digital Display

This unit is equipped with an electronic temperature control with Digital Display.

The Display show a number 1 thru 9 to indicate temperature level.

Placing Product In Case

Do not overload the case with product to a point where the top air discharge grill or the

bottom air intake grill are blocked, or where the air curtain created by the discharge air is

blocked.

LOAD CASE INTERIOR WITH PRE-CHILLED 38deg OR COLDER

PRODUCT ONLY.

Energy Saving Night Curtain

This unit is equipped with an energy saving night curtain.

The night curtain is located in the top inside front of the canopy.

To use the night-curtain pull down and latch on front panel just below the

clear acrylic air deflector when case is not in use.

NOTICE: This refrigerated display case is designed to operate

in a maximum environment of 75 DEG. F and 55% relative

humidity. Exceeding these limits will cause poor case

Refrigerated Self-Serve Merchandiser (High Profile) Page 11

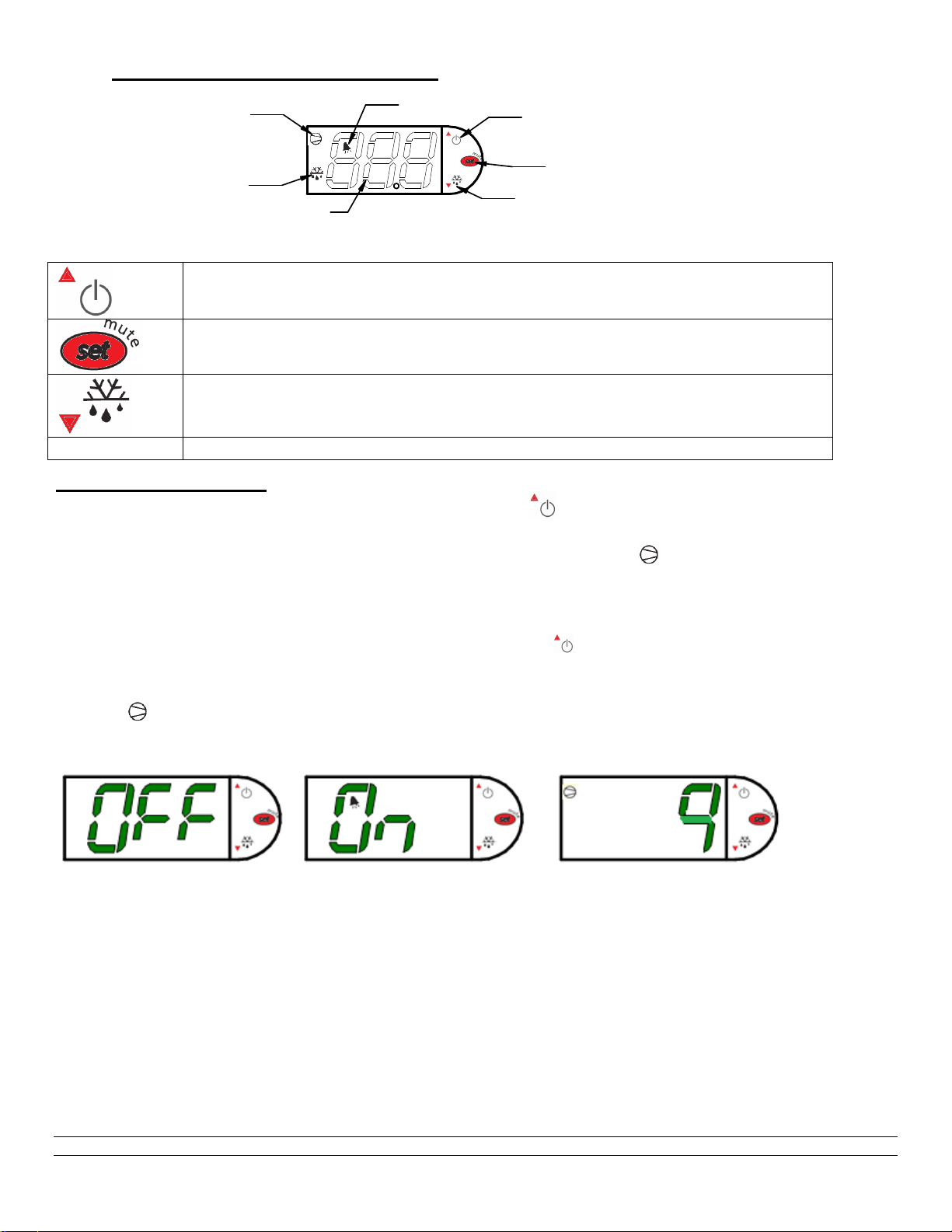

Electronic Temperature Control

DIGITAL DISPLAY

SET POINT ADJUST MODE

POWER TO CONTROL ON/OFF

AND SET POINT UP ADJUST

MANUAL DEFROST AND

SET POINT DOWN ADJUST

COMPRESSOR RUN

INDICATOR

DEFROST MODE INDICATOR

ALARM INDICATOR

Button Overview

Press and hold this button for three seconds to turn system on (if off) or off (if on).

Also used to adjust set point when in set point adjust mode

Press to enter set point adjust mode, confirm set point changes, and mute alarms.

Press and hold this button for three seconds to initiate a manual defrost (and cancel

defrost if initiated), also adjusts set point down when in set point adjust mode

Powering on control

To turn refrigeration control power on, press and hold for approx. three seconds. The display

will read “On” while the button is depressed. When the control powers on, the display will read the

current set point (a number “1” thru “9” ). The compressor run indicator will illuminate on the

display, meaning that the compressor is running. (Note: the control may already be in the on mode

when shipped from factory).

To turn refrigeration control power to off, press and hold for approx. three seconds. The

display will read “Off” while the button is depressed. When the control powers off the display will flash

back and forth between the relative current case temperature and “Off”. The compressor run

indicator will be off on the display. When refrigeration control is in the off-mode cabinet lights and

evaporator fans will still operate, but the compressor will not turn on causing the case to gradually

reach room temperature.

Refrigerated Self-Serve Merchandiser (High Profile) Page 12

Adjusting the set point

The set point is what determines how cold the display case will hold food and beverage. To adjust the

set point press and hold the button approx. three seconds until the display begins to flash a

number. Then press the use the button to scroll number up (colder) or press the button to

scroll number lower (warmer). There are nine (9) available set points numbers, the higher the number

of the set point, the colder the display case will run, with setting “9” being the coldest and setting “1”

being the warmest. Once you have chosen your desired setting press the button again to confirm

your choice.

Entering manual defrost mode

The control is programmed to automatically initiate a defrost by two different methods, involving time

and temperature, as outlined in the “Defrost Cycle” section (Pg. Error! Bookmark not defined.) of

“ELECTRONIC CONTROL PARAMETERS AND EXPLANATION OF OPERATION.” While it is

uncommon that the automatic defrost cycles would insufficiently defrost the case, a Manual Defrost

mode is available if this situation arises. Note: The control will not allow the initiation of a manual

defrost within 30 minutes of completion of another defrost cycle, manual or automatic.

To initiate a manual defrost press and hold the button approx. three seconds. The control will

read “dEF” while the button is being held. The defrost is initiated when the defrost mode indicator

illuminates on the display. The control display will then return to reading the case temperature. When

the defrost mode indicator turns off the defrost is complete and the compressor will turn back on

illuminating the compressor run indicator .

Refrigerated Self-Serve Merchandiser (High Profile) Page 13

Error codes

It is possible for error codes to be displayed on the control screen. In the event of a malfunction an alarm will

sound and the alarm indicator will be displayed on the display. An error code or codes will flash

intermittently on the display. If there are multiple codes, the display will continuously cycle through them. The

following photo shows error code “E0” as an example.

Mute: You may mute the alarm by pressing and releasing the wrench button. The red ringing bell and all error

codes will still be displayed. When the fault is remedied the control will return to normal operation and will

automatically clear the codes from the display.

Carel Control

EO = Air sensing probe - Open or shorted

E1 = Evap. coil probe - Open or shorted

Refrigerated Self-Serve Merchandiser (High Profile) Page 14

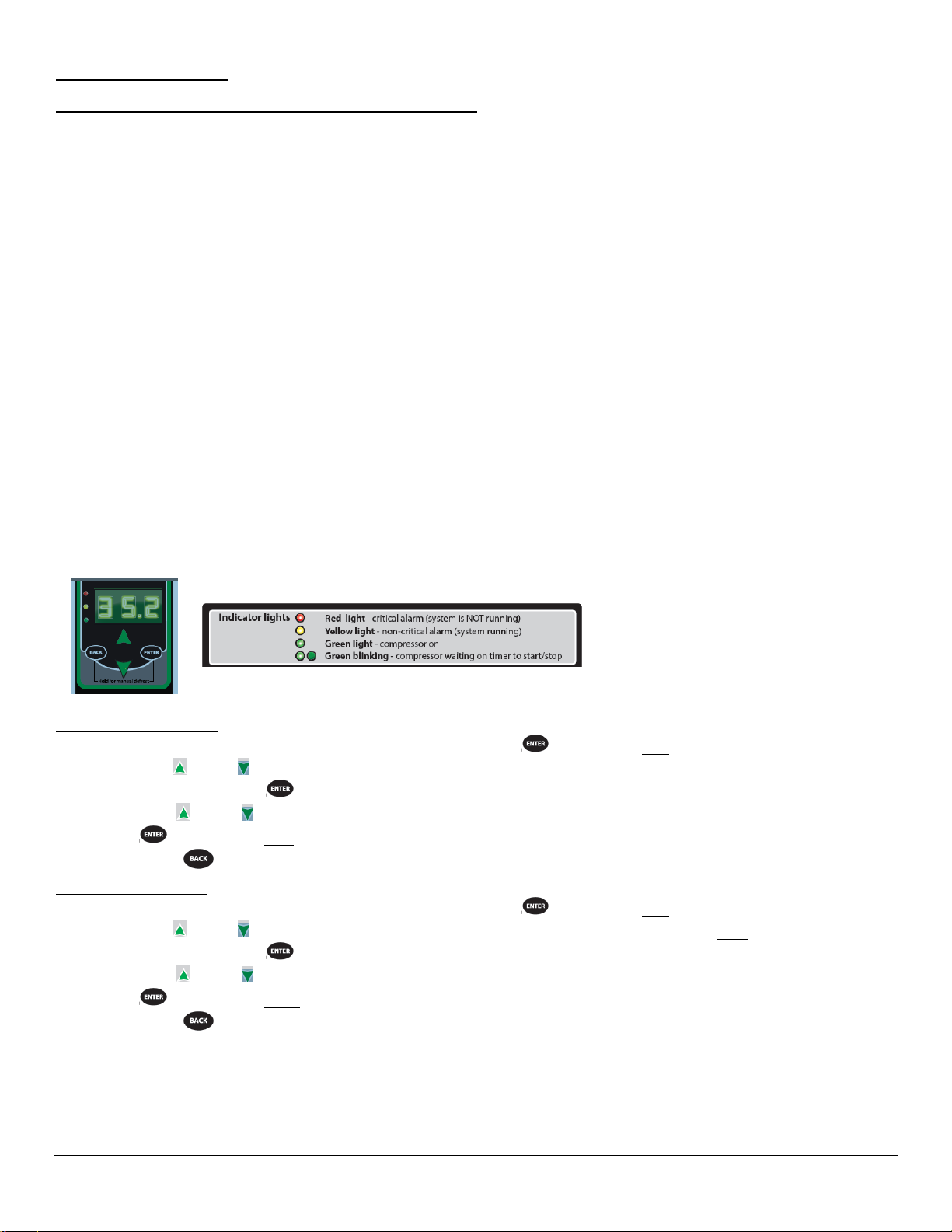

Alternate Electronic Temperature Control

Power on/off: Press and hold to turn system on or off.

Set: Press and hold to enter the set point adjustment menu.

Defrost: Press and hold to initiate a manual defrost.

Up: Change set points when in set point adjustment menu.

When not in set point menu, shows maximum temperature of

air discharge probe.

Down: Change set points when in set point adjustment menu.

When not in set point menu, shows minimum temperature of

air discharge probe.

Display indication symbols

On

Compressor on

Flashing

Minimum compressor off time in progress

On

Unit in defrost mode

Flashing

Defrost delay

On

Condenser fan running

Flashing

Minimum condenser fan off time in progress

On

Alarm occurring. See error code section below.

On

Indicates temperature unit of measure.

Powering on control

To turn refrigeration control power on, press and hold “ ” for approx. three seconds. The display

will read the probe temperature when on. When the control powers on, the display will read the

current probe temperature. The compressor and condenser fan run indicators ( & ) will illuminate

on the display, meaning that the compressor and condenser fan are running. (Note: the control may

already be in the on mode when shipped from factory).

To turn refrigeration control power to off, press and hold “ ” for approx. three seconds. When the

control powers off the display will read “OFF”. When refrigeration control is in the off-mode cabinet

lights and evaporator fans will still operate, but the compressor will not turn on causing the case to

gradually reach room temperature.

Refrigerated Self-Serve Merchandiser (High Profile) Page 15

Adjusting the set point

The set point is what determines how cold the display case will hold food and beverage. To adjust the

set point press the “ ” button. Then press “ ” button to increase the set point number (colder) or

press the “ ” button to decrease the set point number (warmer). There are nine (9) available set

points numbers, the higher the number of the set point, the colder the display case will run, with

setting “9” being the coldest and setting “1” being the warmest. Once you have chosen your desired

setting press the “ ” button again to confirm your choice. The control cutout temperature for the

selected setpoint will briefly be displayed if the setpoint was changed.

Entering manual defrost mode

The control is programmed to automatically initiate a defrost by two different methods, involving time

and temperature, as outlined in the “Defrost Cycle” section (Pg.15) of “ELECTRONIC CONTROL

FUNCTIONALITY.” While it is uncommon that the automatic defrost cycles would insufficiently

defrost the case, a Manual Defrost mode is available if this situation arises.

Note: The control will not allow the initiation of a manual defrost within 30 minutes of completion of

another defrost cycle, manual or automatic.

To initiate a manual defrost press and hold the “ ” button approx. three seconds. The defrost is

initiated when the defrost mode indicator illuminates on the display. The control display will then

return to reading the probe temperature. When the defrost mode indicator turns off the defrost is

complete and the compressor will turn back on automatically and the compressor and condenser fan

indicator will be shown ( & ).

Control Alarms

It is possible for error codes to be displayed on the control screen. In the event of a malfunction an alarm will

sound and the alarm indicator will be displayed. An error code or codes will flash intermittently on the

display. If there are multiple codes, the display will continuously cycle through them.

Mute: You may mute the alarm by pressing any button. The red alarm symbol and all error codes will still be

displayed. When the fault is remedied, the control will return to normal operation and will automatically clear

the codes from the display.

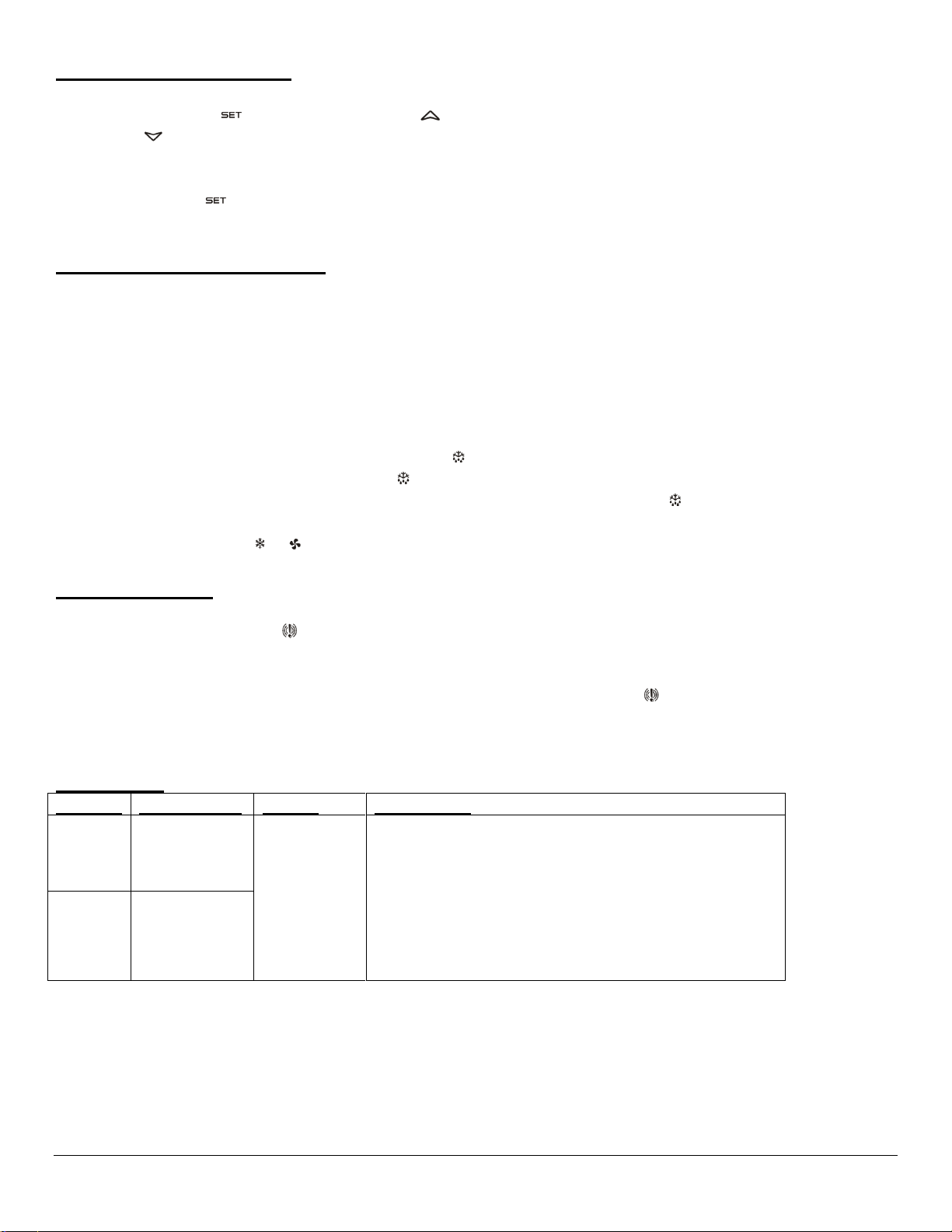

Error Codes

Display

Description

Cause

Resolution

“P1”

Air discharge

temperature

probe failure

Probe signal

is

interrupted

or short-

circuited

•Check to ensure probe wires and quick disconnect are secure

in control.

•Check probe resistance to table below. If 0 resistance is

present, check wiring insulation. If infinite resistance is

present, check for breaks in wiring (meter will likely read

overload or very high in the mega-ohm range).

•Ensure that probes are wired per the wiring diagram provided.

Replace probe if other remedies fail, or if probe resistance

deviates from “Table 3” below.

“P2”

Defrost

temperature

probe failure

Refrigerated Self-Serve Merchandiser (High Profile) Page 16

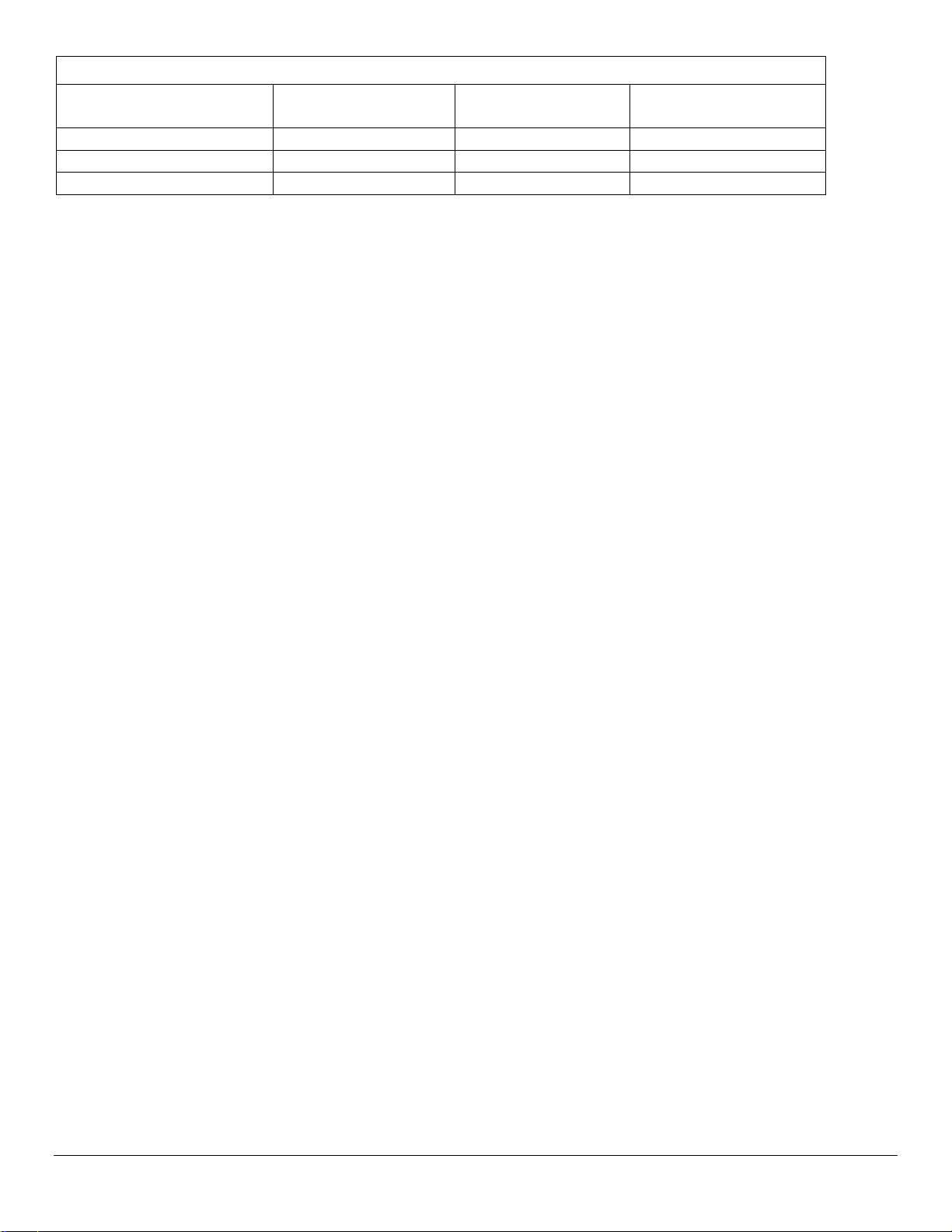

TEMPERATURE PROBE COMMON RESISTANCE CHART

Probe Temp

Maximum

Resistance [Ω]

Normal

Resistance [Ω]

Minimum

Resistance [Ω]

32°F(0°C)

27.83

27.28

26.74

77°F(25°C)

10.1

10

9.9

212°F(100°C)

1

0.97

0.94

Refrigerated Self-Serve Merchandiser (High Profile) Page 17

ELECTRONIC CONTROL FUNCTIONALITY

Electronic Control

This unit is equipped with an electronic temperature control. The control parameters are set at

the factory and cannot be manually changed in the field. Control parameter changes can only

be made by downloading a new set of parameters using a program chip supplied by Federal

Industries. The pre-set control parameters are listed on the chart in the Settings Chart below.

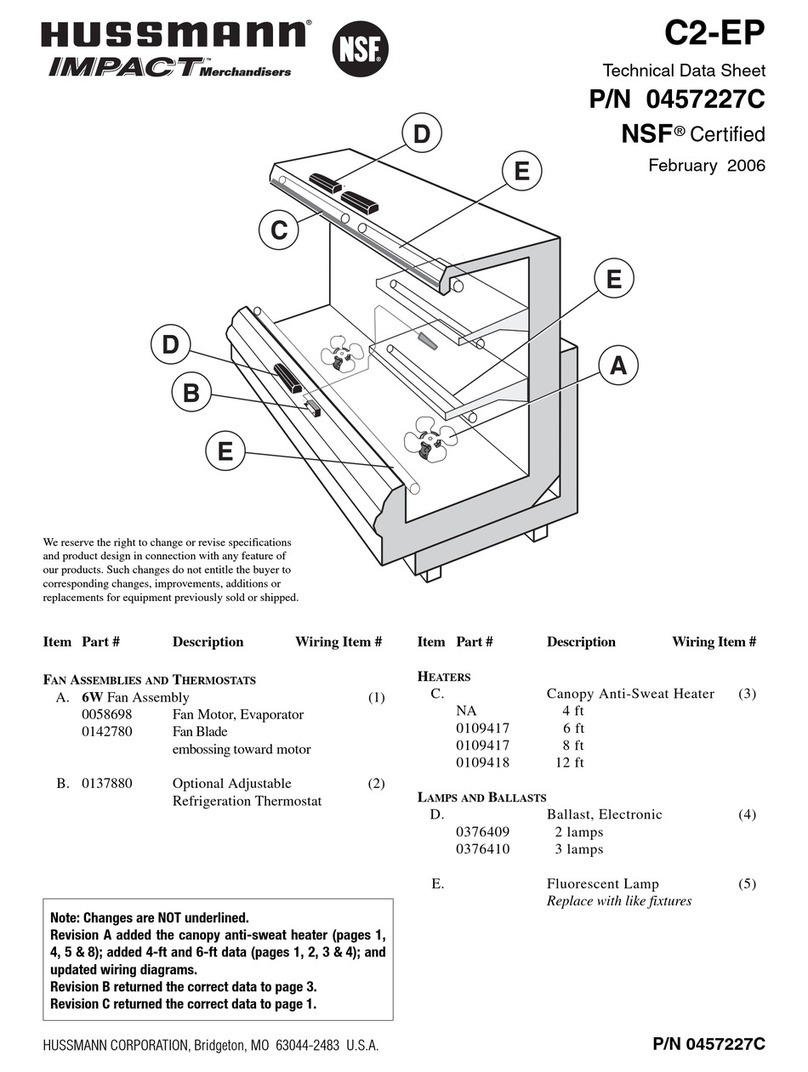

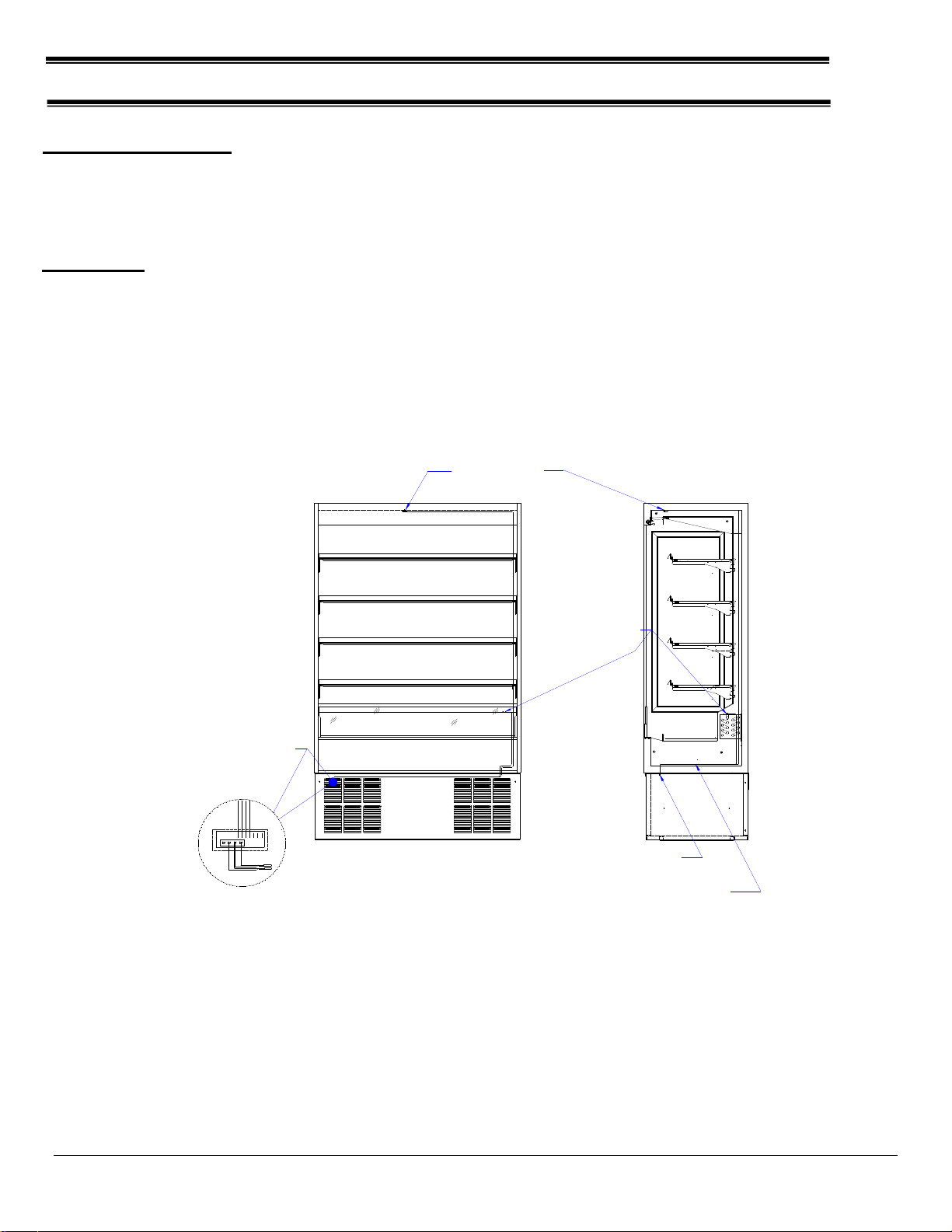

Operation

The control uses two sensors, one located in the air stream and one located on the evaporator coil.

The sensor located in the air stream is referred to as the temperature control sensor. The sensor

located on the evaporator coil is referred to as the coil sensor.

The temperature control sensor is located inside the top air duct behind the honeycomb material and

is labeled (TEMP). The sensor location is critical for proper operation on the unit. Do not move or

relocate this sensor.

The coil sensor is strapped to the evaporator coil and is labeled (DEFROST). This sensor location is

critical for proper operation of the unit. Do not move or relocate this sensor.

CONTROL LOCATED BEHIND

BASE FRONT PANEL

TEMP SENSOR BULB

LOCATED LEFT OF CENTER

IN AIR DISCHARGE DUCT

DETAIL OF TEMP CONTROL

W/SENSOR WIRES ATTACHED

PROBE WIRES ROUTED THRU

TUB FLOOR AND UP BACK OF CASE

PROBE WIRES MOUNTED TO INSIDE

FLANGE OF TOP FRONT BASE RAIL

W/CABLE HOLDERS

DEFROST SENSOR PROBE LOCATION

3" IN FROM COIL HEADER PLATE

MOUNTED TO CENTER COIL TUBE

WITH (2) CABLE TIES

14GA.

TEMP.PROBE PBI

DEFROS TPROBE PB2

14GA.

18GA.

18GA.

BLK

OR

RED

WW

R

BLK

Y

BLK

CAREL

CONTROLLER

11 109 8

76 54

OPTIONAL CONTROL

BLK

OR

RED

BLK

OR

RED

The temperature control is set to cut in at 39 degrees F. The Temp control cuts out at 24 degrees F at

the coldest setting’ COLD’ and 34 degrees F at the warmest setting, ‘1’ on the control readout.

Refrigerated Self-Serve Merchandiser (High Profile) Page 18

Defrost Cycle

The electronic control is programmed to initiate defrost by two different methods. There are (3) programmed

defrost cycles in the control which will initiate a defrost cycle every 8 hours. The unit does not have a time

clock so the defrost cycles cannot be set for any specific time of day.

The electronic controller uses time to initiate the defrost cycle, and temperature to terminate the defrost cycle.

The controller also has an ‘On demand’ defrost feature that will initiate a defrost cycle when the temperature

differential between the evaporator temperature and the air temperature is more than 15 degrees for 5 minutes

after 30 minutes into the refrigeration cycle.

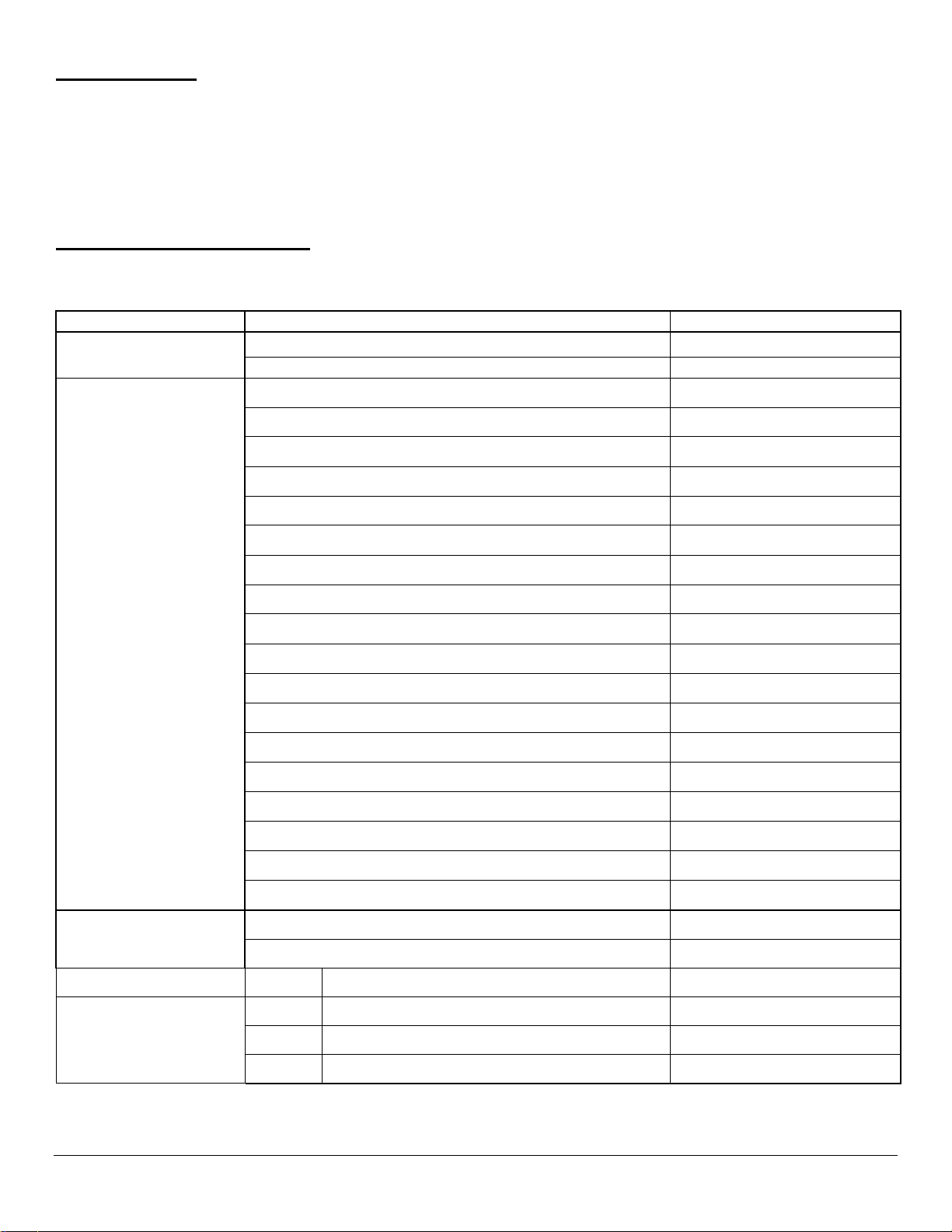

Control Factory Settings

The control parameters are set at the factory and cannot be manually changed in the field. Control parameter

changes can only be made by downloading a new set of parameters using a program chip supplied by Federal

Industries

TAB

PARAMETER DESCRIPTION

RSSM

CONFIGURATION

Controller Operation Temperature Units

Degrees Fahrenheit

Defrost Termination Method

Evaporator Sensor

SET-POINTS

Setting “1” Cut-In (Warmest Setting)

39ºF

Setting “1” Cut-Out (Warmest Setting)

34ºF

Setting “2” Cut-In

39ºF

Setting “2” Cut-Out

32ºF

Setting “3” Cut-In

39ºF

Setting “3” Cut-Out

31ºF

Setting “4” Cut-In

39ºF

Setting “4” Cut-Out

27ºF

Setting “5” Cut-In

39ºF

Setting “5” Cut-Out

25ºF

Setting “6” Cut-In

39ºF

Setting “6” Cut-Out

23ºF

Setting “7” Cut-In

39ºF

Setting “7”Cut-Out

22ºF

Setting “8” Cut-In

39ºF

Setting “8” Cut-Out

21ºF

Setting “9” Cut-In (Coldest Setting)

39ºF

Setting “9” Cut-Out (Coldest Setting)

20ºF

COMPRESSOR

Compressor Minimum On Time

5 minutes

Compressor Maximum On Time

60 minutes

DEFROST

Defrost Termination Temperature

45ºF

DEFROST

Time to First Defrost (hh:mm)

8 hr

Time to subsequent Defrost

8 hr

Defrost Max Duration

30 minutes

Refrigerated Self-Serve Merchandiser (High Profile) Page 19

Control Display

The control display is located in the unit base. It is programmed to display the current set point

associated with the control sensor located inside the air duct at the top of the case.

Minimum Run Timer Feature

The unit controller is programmed to have the condensing unit run a minimum of 5 minutes,

regardless of the control temp being satisfied. If the temperature control reaches the cut out set point

before 5 minutes, the minimum run time setting in the control will keep the unit in a run cycle mode

until the timer reaches 5 minutes. The refrigeration cycle will be off until the temperature control cut in

temperature is reached.

This timer typically comes into effect in low ambient conditions where the unit may cycle too

frequently to maintain proper product temperature.

Maximum Run Timer Feature

The unit controller is programmed to have the condensing unit run a maximum of 60 minutes.

If the unit has not reached cut out temperature setting in 60 minutes, the unit goes into on off cycle.

This typically comes into effect in high ambient temperature and relative humidity conditions.

REFRIGERATION OPERATION

Self-Contained Models

Refrigeration R404A Charge Prior To 01/01/2020

See Refrigeration

And Electrical Data

Pages

Refrigeration R449a Charge After 01/01/2020

See Refrigeration

And Electrical Data

Pages

The self-contained models are shipped from the factory with a completely operational 404A

refrigeration system and require no modifications or adjustments upon installation. Case must be

installed as per the installation section of this manual to provide proper condensing air cooling.

Self-Contained Refrigeration Operation

The unit temperature is controlled by the Electronic control outlined in the control section of this

manual.

Note: The condenser fan is factory wired to run continuously.

Dual Pressure Control (Self-Contained Models Only)

The dual pressure control is used as a safety device and is factory set. The pressure control

works on a differential. The low-pressure side is a safety to protect the compressor in the case

of refrigerant loss. The high-pressure side is a safety to protect from system failure causing too

high of system pressure.

The high side of the pressure control is factory set to 400psi and is not adjustable.

Low side setting for the R404a cases are set at 40psi differential for the cutout and 60psi for

the cut-in.

Refrigerated Self-Serve Merchandiser (High Profile) Page 20

Remote Operation

Electronic Expansion Valve (EEV) After 1/20

A traditional TXV uses springs and a temperature bulb to open and close a valve port that controls the flow of

refrigerant entering the evaporator coil. An electronic expansion valve (EEV) controls the refrigerant flow much

more precisely, increasing the performance and efficiency of the refrigeration system. The EEV controls the

flow of Refrigerant by opening and closing the valve port based on the response to signals sent to the EEV by

an electronic controller. The electronic Control bases these signals by processing information provided from a

temperature sensor and pressure transducer located on the discharge side of the evaporator coil.

These sensors monitor the evaporator superheat and protects the compressor from any liquid flood back under

low superheat conditions.

EEV Controller Settings

The electronic expansion valve controller also allows the use of different types of refrigerants without the need

to change the expansion valve.

The controller is set from the factory to run on R449a refrigerant and will not need any changes to the control

unless another refrigerant is used.

Note: Check your State and Local regulations for approved refrigerants for your install location. Federal

Industries is not liable for any alternate refrigerants used.

The control is located on the base floor on the left-hand side front view .

Note: Never change any of the other setting other than the refrigerant type. It may also be necessary to

change the superheat setting only when using a different refrigerant.

Changing Refrigerant

•Access the set point mode by pressing and holding the button until Ctl displays on the screen.

•Use the up or down arrows to advance through the available set points until rFG displays on the

screen and press the botton.

•Use the up or down arrows until the desired refrigeration displays on the screen and press and hold

the button until rFG once again displays on the screen.

•Press the to return to escape the settings menue.

Changing Superheat

•Access the set point mode by pressing and holding the button until Ctl displays on the screen.

•Use the up or down arrows to advance through the available set points until SSP displays on the

screen and press the botton.

•Use the up or down arrows to set the desired superheat displays on the screen and press and hold

the button until SSP once again displays on the screen.

•Press the to return to escape the settings menue.

This manual suits for next models

11

Table of contents

Other FEDERAL INDUSTRIES Merchandiser manuals