- 2 -

CONTENTS

INTRODUCTION.......................................................................................................................................3

WARNING LABELS & SAFETY INSTRUCTIONS..............................................................................4

PRE-INSTALLATION PROCEDURES...................................................................................................5

Inspection For Shipping Damage.....................................................................................................5

GENERAL ELECTRICAL & GROUNDING.........................................................................................5

Permanent Connected ......................................................................................................................5

Cord Connected (Option).................................................................................................................5

INSTALLATION INSTRUCTIONS.........................................................................................................6

Locating The Display Case ..............................................................................................................6

Removing Case From Shipping Skid...............................................................................................6

Cleaning ...........................................................................................................................................6

Refrigeration Installation..................................................................................................................6

REFRIGERATION................................................................................................................................. 7-8

Self Contained Models.....................................................................................................................7

Self Contained Refrigeration Operation......................................................................................7

Remote Models ................................................................................................................................8

Remote Refrigeration Operation .................................................................................................8

Remote Refrigeration Instruction................................................................................................8

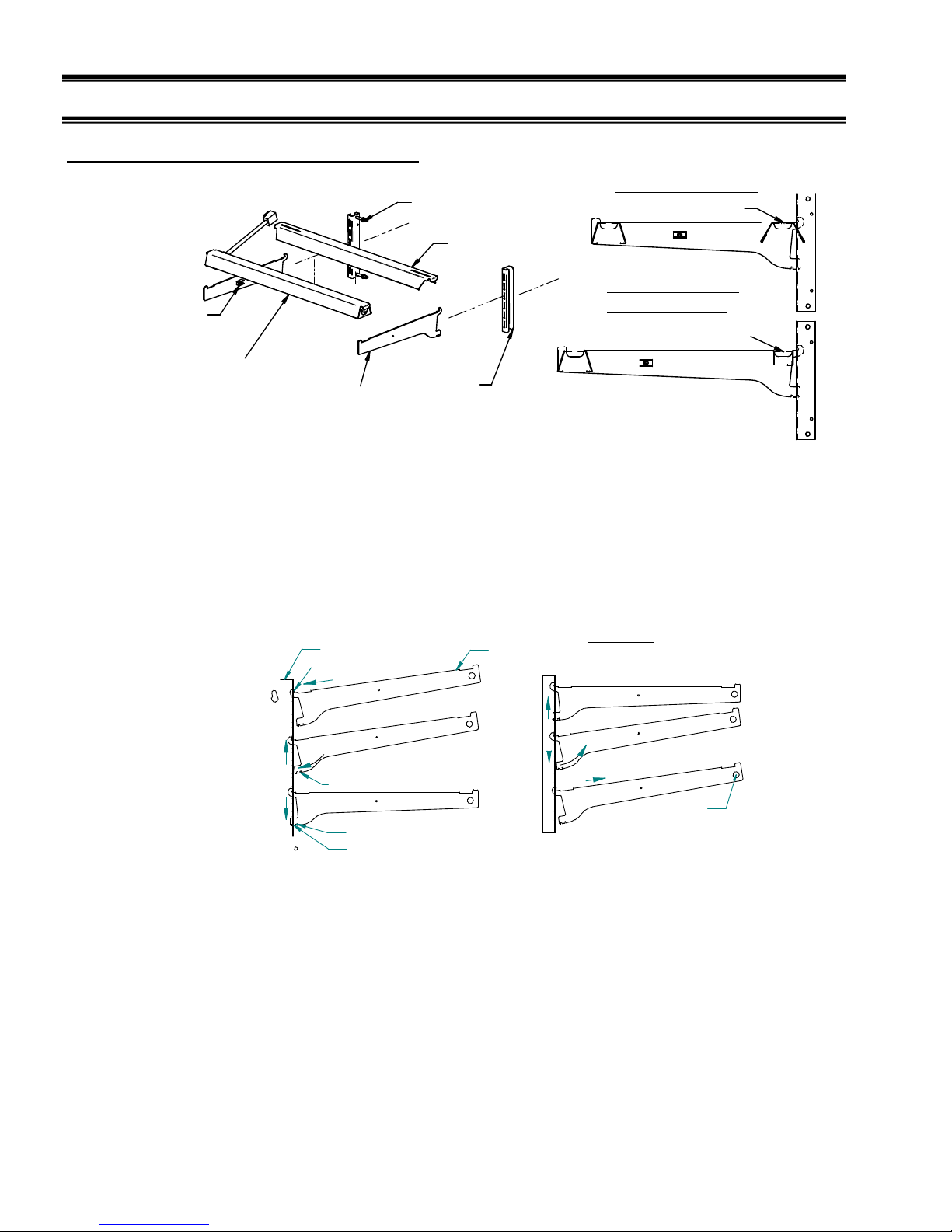

SHELVING INSTALLATION & REMOVAL.................................................................................. 9-11

Shelf Brackets & Supports......................................................................................................... 9-10

Wire Shelves ..................................................................................................................................10

Glass Shelves (Option)...................................................................................................................11

REAR DOORS ................................................................................................................................... 12-13

Top Section Rear Doors.................................................................................................................12

Bottom Section Rear Doors (Option).............................................................................................13

NIGHT CURTAIN (OPTION).................................................................................................................14

SECURITY NIGHT COVER (OPTION)...............................................................................................15

OPERATING INSTRUCTIONS ....................................................................................................... 16-17

Controls..........................................................................................................................................16

Top Section Refrigeration Louver Control.....................................................................................17

Placing Product In Case .................................................................................................................17

MAINTENANCE ......................................................................................................................................18

Top Light Bulb Replacement.........................................................................................................18

Shelf Light Bulb Replacement.......................................................................................................18

PERIODIC MAINTENANCE .................................................................................................................19

Cleaning Condenser Coil................................................................................................................19

CLEANING INSTRUCTIONS.......................................................................................................... 20-23

Daily Cleaning................................................................................................................................20

Weekly Cleaning............................................................................................................................21

Weekly Top Section Cleaning.................................................................................................. 21-22

Weekly Bottom Section Cleaning............................................................................................ 22-23

Weekly Exterior Cleaning..............................................................................................................23

SERVICE INFORMATION .............................................................................................................. 24-25

Special Service Situations..............................................................................................................24

Pre-Service Checklist.....................................................................................................................25

SALE & DISPOSAL.................................................................................................................................26

Owner Responsibility.....................................................................................................................26

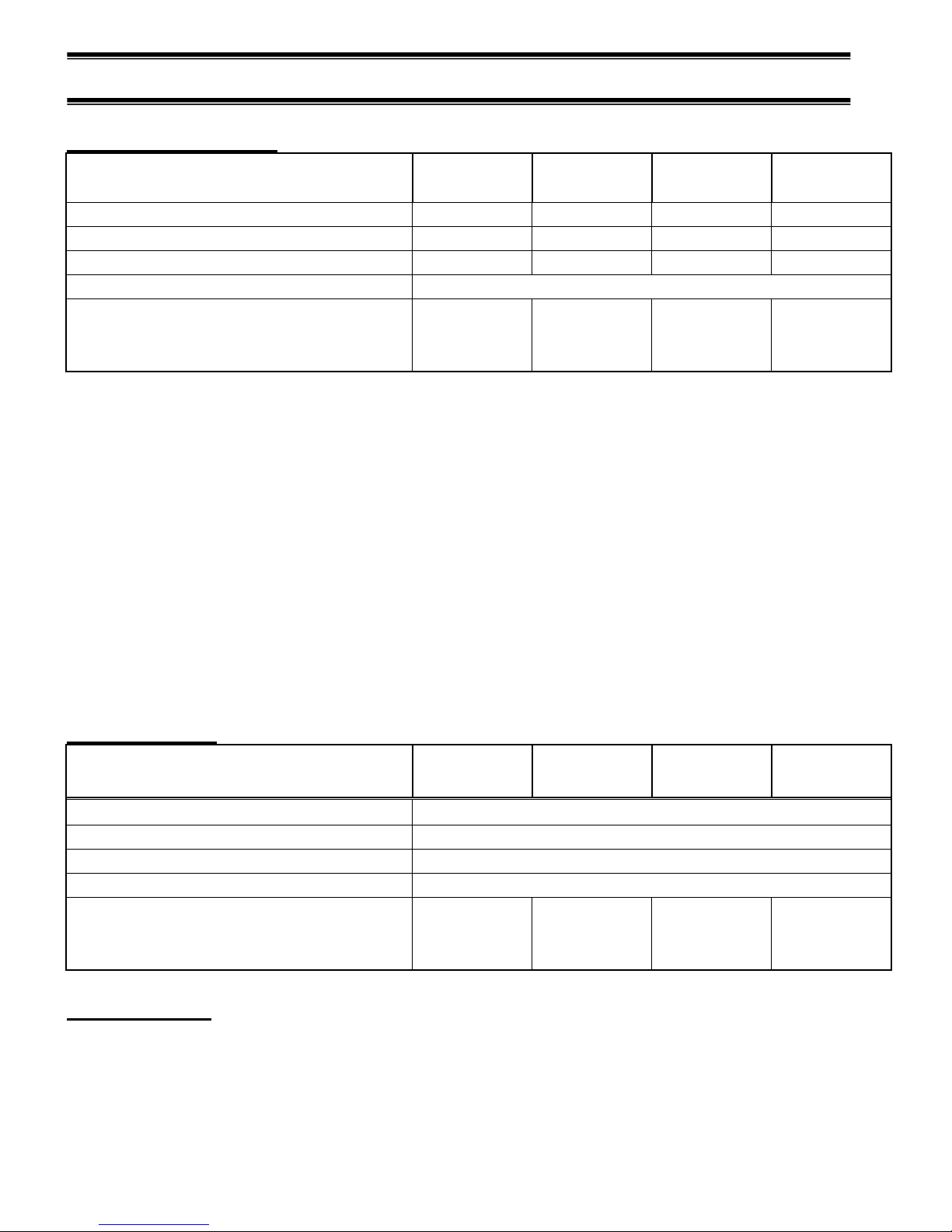

REFRIGERATION & ELECTRICAL DATA.......................................................................................26

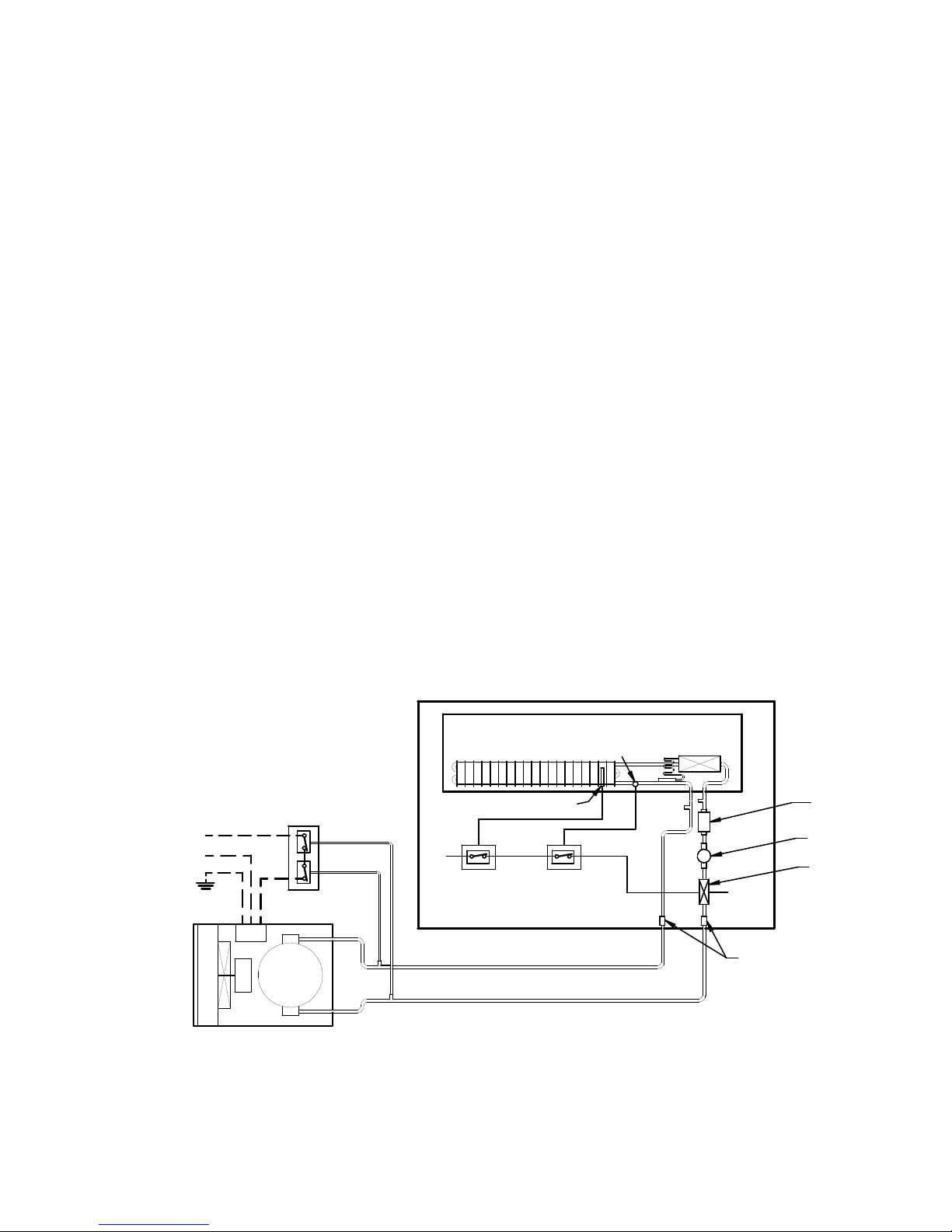

WIRING DIAGRAMS........................................................................................................................ 27-28

Self Contained................................................................................................................................27

Remote ...........................................................................................................................................28

REPLACEMENT PARTS.................................................................................................................. 29-31