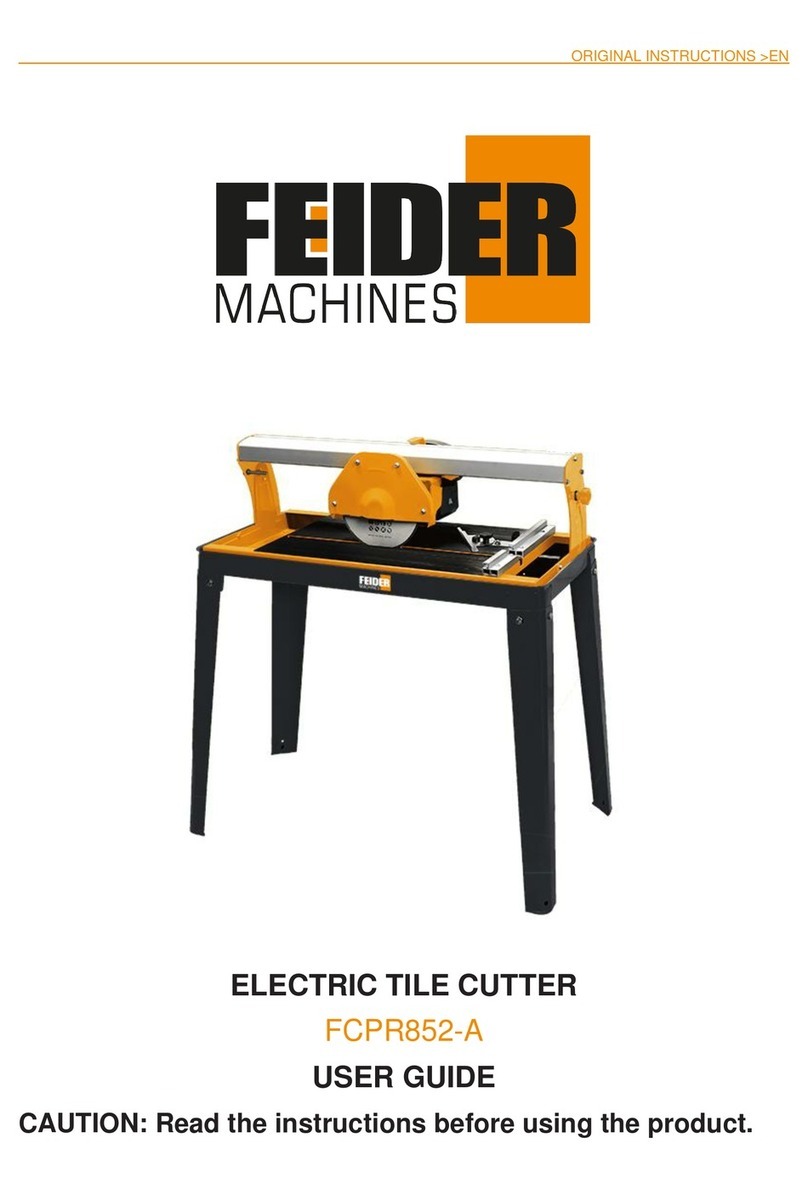

Feider Machines FCPR852 User manual

ORIGINAL INSTRUCTIONS

TILE CUTTER 200mm

FCPR852

Warning: Please read the manual carefully before using the unit!

Feider France

ZI – 32, rue Aristide Bergès, 31270 Cugnaux, France

MADE IN RPC 2021

DESCRIPTION OF THE SYMBOLS

The use of symbols in this manual is intended to draw your attention to possible risks. The

safety symbols and the explanations that accompany them must be perfectly understood. The

warnings in themselves do not remove the risks and cannot replace correct actions for

preventing accidents.

CAUTION!!! DANGER

RECOMMENDATION: USE HEARING PROTECTION

RECOMMENDATION: USE EYE PROTECTION

CAUTION – Risk of cutting

Confirms compliance with all safety standards

RECOMMENDATION READ THE MANUAL

RECOMMENDATION USE PROTECTIVE GLOVES

Do not dispose of old appliances with domestic rubbish .

External view

Fig. 1

Description (Fig. 1)

1. Angle scale

2. Locking knobs (x2) for the adjustment of bridge angle

3. Angle indicator

4. Handle

5. Adjustable bridge

6. Locking knob of the adjustable rail for the miter angle

7. Adjustable rail for the miter angle

8. Lock of the rail for the miter angle

9. Circular saw guard

10. Diamond cutting blade

11. Measuring guide

12. Locking transport nut of the cutting block

13. Stand

14. Water tank

Scope of supply

1. Rail for the miter angle 1 set

2. Wrench 2 pcs.

3. Stand with a rubber carpet 4 pcs.

4. Cap for the water tank 1 pcs.

5. Locking knobs for the stands 8 pcs.

6. blade 1 pcs.

Technical features of the model

Voltage/Frequency

No-load speed

Motor power

Cutting blade size

Table size

Max. cutting depth at 90°

Max. cutting depth at 45°

230 V~50 Hz

2950/min

800 W S2:20 min

Ø200 x 25.4mm

790 mm x 394 mm

32 mm

28 mm

Max. cutting length

Inclined cutting

IP class

Net weight

520 mm

0-45°

IP 54

28 kg

Only diamond blade can be used for this machine, blade size Ø200 x Ø25.4mm

Materials which can be cut-off by the machine: Tile and domolite

Remark

- The use of all other types of wheels or tool (such as for example circular saw blades) which

are not indicated in the list is not allowed.

- any modification which could lead to a change in the original characteristics of the

machine, for example, rotational speed or maximum diameter of the cutting-off wheel may

be carried out only by the manufacturer of the machine who shall confirm that the machine

is still in conformity with the safety regulations.

Noise and vibration level:

Sound pressure level LpA

82,8 (A)

Sound power level LWA

95.8 dB(A)

Uncertainty K

3 dB(A)

Vibration level hand/arm:

3.9 m/s2

Uncertainty K:

1.5m/s2

The declared total vibration value was measured using standard test method and can be used

for comparing tools. The declared total vibration value can also be used during initial exposure

estimation.

WARNING: Depending on the actual way of using the tool, vibration values can be completely

different from the declared values. The need of identifying personal protective equipment and

operator protection is based on exposure estimation in actual working conditions (taking into

consideration all parts of the work cycle, such as product downtime, idle work, and running

time).

Safety rules

Important!

Before each use (!) and regularly during work the user must:

- perform visual inspection of the tool,

- inspect the general condition of the tool,

- check the tool, the accessories and the safety equipment for integrity,

- check the security of fastening elements, units, attachments etc., bolts tightening etc.,

- check for other damages (incl. leaks) and other deviations from the norm.

If found, those defects must be eliminated before starting using the tool.

It is prohibited and dangerous (!) to use the tool which has damages or loosened fastening

elements because of potential for injury (!).

The manufacturer shall not be liable for the consequences and damages as a results of use of

the tool with the above-named defects.

WARNING! When using electric tools basic safety precautions should always be followed to

reduce the risk of fire, electric shock and personal injury.

Read all these instructions before attempting to operate this product and save these

instructions.

1. Keep work area clear

Cluttered areas and benches invite injuries.

2. Consider work area environment

Do not expose tools to rain.

Do not use tools in damp or wet locations.

Keep work area well lit.

Do not use tools in the presence of flammable liquids or gases.

3. Guard against electric shock

Avoid body contact with earthed or grounded surfaces (e.g. pipes, radiators, ranges,

refrigerators).

4. Keep other persons away

Do not let persons, especially children, not involved in the work touch the tool or the

extension cord and keep them away from the work area.

5. Store idle tools

When not in use, tools should be stored in a dry locked-up place, out of reach of

children.

6. Do not force the tool

It will do the job better and safer at the rate for which it was intended.

7. Use the right tool

Do not force small tools to do the job of a heavy duty tool.

Do not use tools for purposes not intended; for example do not use circular saws to cut

tree limbs or logs.

8. Dress properly

Do not wear loose clothing or jewellery; they can be caught in moving parts.

Non-skid footwear is recommended when working outdoors.

Wear protective hair covering to contain long hair.

9. Use protective equipment

Use safety glasses.

Use face or dust mask if working operations create dust.

10. Connect dust extraction equipment

If the tool is provided for the connection of dust extraction and collecting equipment,

ensure these are connected and properly used.

11. Do not abuse the cord

Never yank the cord to disconnect it from the socket. Keep the cord away from heat,

oil and sharp edges.

12. Secure work

Where possible use clamps or a vice to hold the work. It is safer than using your hand.

13. Do not overreach

Keep proper footing and balance at all times.

14. Maintain tools with care

Keep cutting tools sharp and clean for better and safer performance.

Follow instruction for lubricating and changing accessories.

Inspect tool cords periodically and if damaged have them repaired by an authorized

service facility.

Inspect extension cords periodically and replace if damaged.

Keep handles dry, clean and free from oil and grease.

15. Disconnect tools

When not in use, before servicing and when changing accessories such as blades, bits

and cutters, disconnect tools from the power supply.

16. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and adjusting wrenches are removed from

the tool before turning it on.

17. Avoid unintentional starting

Ensure switch is in "off" position when plugging in.

18. Use outdoor extension leads

When the tool is used outdoors, use only extension cords intended for outdoor use

and so marked.

19. Stay alert

Watch what you are doing, use common sense and do not operate the tool when you

are tired.

20. Check damaged parts

Before further use of tool, it should be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting and any other conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or replaced by an

authorized service centre unless otherwise indicated in this instruction manual.

Have defective switches replaced by an authorized service centre.

Do not use the tool if the switch does not turn it on and off.

21. Warning

The use of any accessory or attachment other than one recommended in this

instruction manual may present a risk of personal injury.

22. Have your tool repaired by a qualified person

This electric tool complies with the relevant safety rules. Repairs should only be carried

out by qualified persons using original spare parts, otherwise this may result in

considerable danger to the user.

Additional safety rules for tile cutter

• Before maintenance, lubrication, adjustment and change of attachments, such as cutting

blades, tips and knives, make sure that electrically driven tools are turned off.

• Do not stop the cutting blade by forcing the machine or using side pressure.

• Do not use bent cutting blades or cutting blades with damages of any type. The use of bent or

damaged cutting blades is extremely dangerous and can lead to serious personal injury of the

cutter, of the persons standing nearby, and it can result in the machine breakdown.

• Do not use cutting blades with a larger size than indicated. Use only cutting blades which are

designed for this machine. The speed of rotation (min-1) indicated on the cutting blade must be

HIGHER than the speed of rotation (min-1) of the tile cutter.

• Make sure that the rotation arrow on the cutting blade corresponds to the rotation of the

electric motor.

• Disconnect the machine from the power source and make sure that there are no hindrances

by manually turning the cutting blade.

• Make sure that the removable guard works properly (no hindrances).

• The guard must be installed and it must be in good working order. While the machine is

disconnected from the power source, check the operation of the guard and make sure it works

properly.

• When changing the cutting blades make sure that the surface of cutting blades and flanges is

clean. Make sure that the securing nut is fastened securely. Make sure that the nut is not

overtightened.

• Do not start the machine if the cutting blade contacts the processed part.

• Do not cut when holding the tile with your hand, make sure that the tile is securely fastened

in the guide bar.

• Make sure that there is enough space for taking the smaller piece of the tile being cut to the

side. Failure to meet this condition can result in the cut fragment being jammed by the cutting

blade.

• Do not cut more than one tile at a time.

• Do not cut fragments which are too small and which do not enable fastening them securely

on the guide bar and keeping hands at a safe distance from the cutting blade.

• Make sure that there are no foreign objects on the machine bench.

• In case of binding of any objects in the machine disconnect it from the power source to

remove the jammed objects.

• Do not remove the jammed object while the machine is still working.

• Do not allow the machine to work without water. The absence of water in the tank results in

cutting blade overheating which leads to the breakdown thereof and incorrect tile cutting.

• Do not try to modify the machine or its auxiliaries.

• Do not overload the machine – it must perform its job; absence of overload reduces the wear

of the machine and of the cutting blade, it increases its work efficiency and service life.

• When working on the machine use ear and eye protection.

• Work on the tile cutter in waterproof protective clothing.

• Decorative surfaces should be cut with the tile cutter using the dust shield and a plastic

waterproof shield.

Rules for the installation of parts of the equipment

CAUTION! Do not connect the plug to the power source before the machine is completely

assembled and adjusted, before reading and understanding the safety and operating

instructions.

Installation of supports. (Fig. 2)

• Turn the tank (14) upside down and place it

on a level and stable surface.

• Insert the four supports in the openings in

the water tank.

• Tighten the screws by hand.

• Turn the tank with supports around and

place it on a level and stable surface.

Fig. 2

Installation of the pump. (Fig. 3)

• Place the pump on the water tank

(stationary position of the pump) on the tilt.

• Lay the hose and the cord around the

pump.

• Press on the pump case with your thumbs

till you hear a click. The click indicates that

the pump is installed in place.

Installation of the rail for the miter angle

(Fig. 4)

• Using the plate (20) (two threaded holes)

connect two locking knobs (6) with the guide

bar; do not tighten the knobs.

• Install the rail for the miter angle complete

with (not tightened) knobs on the bench;

• Loosen the knob (8) of the adjustable rail

for the miter angle.

• Set the desired distance and angle.

• Tighten all the knobs by turning them

clockwise.

Filling water in the water tank

• Before turning the machine on and starting the cutting, fill the water tank completely.

• Before cutting the tile turn the machine on and make sure the water is fed on the cutting

blade to cool it down.

• Regularly check the water level in the tank; the water level must be higher than the pump

level and the lower point of the cutting blade.

Connecting power supply

Before connecting the machine to the power source make sure that the nominal voltage

indicated on the nameplate corresponds to the mains voltage.

CAUTION! This machine must be grounded.

Incorrect grounding of the machine may result in electric shock. Make sure that the power

source is grounded. In case of doubt have it checked by a qualified electrician.

CAUTION! When connecting (disconnecting) the plug of the tile cutter to (from) the power

source avoid contact with plug outlets. Contact with outlets may result in electric shock.

Fig. 3

Fig. 4

Equipment operating rules:

The cutting blade may be tilted to any angle within the range from 0° to 45°. Adjustable rail for

the miter angle on the bench can be rotated to any angle. During the cutting process the pump

can feed water to the cutting blade extending the service life of the cutting blade and reducing

the level of dust.

The movement of the cutting blade along the guide in a straight line ensures the straight

cutting.

Turning on and off (Fig. 5.)

The machine is equipped with a no-voltage

release switch. In case of power supply

interruption or when disconnecting the

plug from the outlet before turning the

machine off, the machine does not turn on

without warning by restoration of power

supply or when the plug is inserted in the

outlet before the portable shutoff

protection device returns to the initial

state, the machine is also turned on with a

switch installed on the machine.

To start the machine press the GREEN button marked with “I”.

To stop the machine press the RED button marked with “O”.

CAUTION! When the machine is started, the cooling water pump is also started.

Before starting work on the machine, carefully read and study the following section.

• Install the tool in the desired position, then

tighten all the adjusting knobs.

• Loosen the fastening nut (12, Fig. 8).

• Remove the supporting screw (21, Fig. 6).

Fig. 6

Fig. 5

Cutting (Fig. 7)

• Make sure that all the adjusting knobs are

tightened correctly (2) and that there is

enough water in the tank for the flow on the

cutting blade.

• Mark the cutting position (11) on the

processed part, place the processed part on

the bench by pressing it firmly against the

supporting guard and rail for the miter

angle/transverse guard.

• Adjust the position on the rail for the miter

angle/transverse guard and make sure that

the cut is correct.

• Turn the machine on, wait until the cutting

blade reaches its maximum speed, hold the

handle for moving the electric motor firmly,

perform the cut by moving the electric

engine and the cutting blade unit smoothly.

Note: Do not push on the cutting blade, the blade must cut the material with permanent speed.

Depending on tile thickness and type the cutting can take a different amount of time for

different materials. Do not try to push the cutting blade through the tile, it can result in electric

motor stop, slower cutting and uneven edges.

Bevelled cut (Fig. 8)

• The procedure is the same as during the

straight cutting, but the cutting block is tilted

by loosening two locks which are used to

adjust the bridge angle (2).

• After that the bridge can be tilted to the

desired angle according to the angle scale (1)

and the locks are tightened again.

• Before cutting make sure that the tile is

securely fastened.

Fig. 8

Fig. 7

Miter cutting (Fig. 9)

• The procedure is the same as during the

straight cutting, the rail for the miter

angle/transverse guard is set to the desired

angle. Before cutting make sure that the tile

is securely fastened.

CAUTION! Do not lift or remove the cutting waste before the cutting blade fully stops.

Changing the cutting blade

CAUTION! Before changing the cutting

blade, in order to avoid injuries as a result of

accidental starting turn the switch off to “0”

and disconnect the plug from the power

source.

• Remove the cutting blade guard cover (23, Fig.

10) by loosening the three screws (11, Fig. 10)

• Use two wrenches (supplied) to loosen (left-

hand thread) the nut (24, Fig. 11)

• Remove the outer flange (25, Fig. 11), then the

cutting blade (26)

• Inspect the new cutting blade for visible

damages. If any, use another blade.

• When installing the new cutting blade, mark the

correct direction of rotation, the arrows on the

cutting blade and on the cutting blade guard (9,

Fig. 1) must show in the same direction.

• Place the outer flange back, tighten the nut

using the supplied wrenches.

• CAUTION. Do not operate the machine without

the guard installed.

Fig. 10

Fig. 9

Fig. 11

DEFECTS

In case of defects of the tool due to wear and tear of the parts, contact the point of sale where

you acquired this tool or the service centre.

WARNING! Before carrying out maintenance or adjustments, the machine

must be unplugged from power.

Cleaning

Empty the water reservoir and remove from the reservoir and the table any dust deposits

remaining after cutting. Clean the tile cutter using clean, dry cloth. From time to time,

depending on the degree of dust deposit accumulation, clean the water pump, making sure

that filters are clean and not clogged.

Repair

This product does not contain any parts that could be repaired by the customer. For service

and repairs turn to a qualified professional at SWAP, https://swap-europe.com

Power supply

If the power cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified person, which will allow to avoid any risks.

Transportation

1. Before transporting and moving the product to any other location, turn it off and unplug

the power.

2. Install transport covers, if applicable.

3. Protect the product from strong impacts or strong vibrations that can occur during vehicle

transport.

4. Protect the product from slipping and falling over.

Storage

1. Clean the product as described above.

2. Store the product and its accessories in a dry, frost-free place.

3. Always store the product in a place out of reach of children. The perfect storage

temperature is between 10 and 30°C.

4. We recommend using the original packaging for storing the product or covering it with an

appropriate cloth, to protect it from dust.

Troubleshooting

It is suspected, that faults are often caused by reasons that users can remove by themselves.

That is why the product should be checked using this section. In most cases the problem can

be quickly resolved.

Problem

Possible cause

Solution

1. Product does not start

1.1. Power not connected

1.2. Damaged power cord

or plug

1.3. Other electrical fault

of the product

1.1. Connect the power

1.2. Check by a qualified

electrician

1.3. Check by a qualified

electrician

2. Product does not reach

full power

2.1. Extension cord not

suitable for the product

2.2. Power supply (eg.

generator) voltage too low

2.3. Vents are blocked

2.1. Use a suitable

extension cord

2.2. Connect to another

power supply

2.3. Clear the vents

3. Unsatisfactory work

results

3. Accessory not suitable

for the material

3. Use a suitable accessory

DISPOSAL

Electrical products should not be discarded with household products. According to the

European Directive 2012/19/EU on waste electrical and electronic equipment and its

implementation into national law, electrical products used must be collected separately

and disposed of at collection points provided for this purpose. Talk with your local

authorities or dealer for advice on recycling.

ROHS Directive (EU)2015/863 amending 2011/65/EU

Also complies with European standards, with national standards and the following technical

provisions:

EN55014-1:2017

EN61000-3-2:2014

EN61000-3-3:2013

Philippe MARIE / PDG

Declaration of conformity

FEIDER FRANCE

ZI, 32 RUE ARISTIDE BERGES – 312070 CUGNAUX – FRANCE

Declares that the machinery designated below:

Tile Cutter

Model: FCPR852

Serial number: 20210165906-20210166305

Complies with the provisions of the Directive « Machinery » 2006/42/EC and national laws

transposing it:

Also complies with the following European directives:

EMC Directive 2014/30/EU

Cugnaux, 01/01/2021

WARRANTY

The manufacturer guarantees the product against defects in material and workmanship for a period of 2

years from the date of the original purchase. The warranty only applies if the product is for household use.

The warranty does not cover breakdowns due to normal wear and tear.

The manufacturer agrees to replace parts identied as defective by the designated distributor. The

manufacturer does not accept responsibility for the replacement of the machine, in whole or in part , and/or

ensuing damage.

The warranty does not cover breakdowns due to:

• insucient maintenance.

• abnormal assembly, adjustment or operations of the product.

• parts subject to normal wear and tear.

The warranty does not extend to:

• shipping and packaging costs.

• using the tool for a purpose other than that for which it was designed.

• the use and maintenance of the machine done in a manner not described in the user manual.

Due to our policy of continuous product improvement, we reserve the right to alter or change specications

without notice. Consequently, the product may be dierent from the information contained therein, but a

modication will be undertaken without notice if it is recognized as an improvement of the preceding

characteristic.

READ THE MANUAL CAREFULLY BEFORE USING THE MACHINE.

When ordering spare parts, please indicate the part number or code, you can nd this in the spare parts list

in this manual. Keep the purchase receipt; without it, the warranty is invalid. To help you with your product,

we invite you to contact us by phone or via our website:

• +33 (0)9.70.75.30.30

• https://services.swap-europe.com/contact

You must create a "ticket" via the web platform.

• Register or create your account.

• Indicate the reference of the tool.

• Choose the subject of your request.

• Describe your problem.

• Attach these les: invoice or sales receipt, photo

of the identication plate (serial number), photo

of the part you need (for example: pins on the

transformer plug which are broken).

WARRANTY

WHAT TO DO IF MY MACHINE BREAKS DOWN?

If you bought your product in a store:

a) Empty the fuel tank.

b) Make sure that your machine is complete with all accessories supplied, and clean! If this is not the case,

the repairer will refuse the machine.

Go to the store with the complete machine and with the receipt or invoice.

If you bought your product on a website:

a) Empty the fuel tank.

b) Make sure that your machine is complete with all accessories supplied, and clean! If this is not the case,

the repairer will refuse the machine.

c) Create a SWAP-Europe service ticket on the site: https://services.swap-europe.com When making the

request on SWAP-Europe, you must attach the invoice and the photo of the nameplate (serial number).

d) Contact the repair station to make sure it is available before dropping o the machine.

Go to the repair station with the complete machine packed, accompanied by the purchase invoice and the

station support sheet downloadable after the service request is completed on the SWAP-Europe site

For machines with engine failure from manufacturers BRIGGS & STRATTON, HONDA and RATO, please

refer to the following instructions.

Repairs will be done by approved engine manufacturers of these manufacturers, see their site:

• http://www.briggsandstratton.com/eu/fr

• http://www.honda-engines-eu.com/fr/service-network-page;jsessionid=5EE8456CF39CD572AA2AEEDFD

290CDAE

• https://www.rato-europe.com/it/service-network

Please keep your original packaging to allow for after-sales service returns or pack your machine

with a similar cardboard box of the same dimensions.

For any question concerning our after-sales service you can make a request on our website https://

services.swap-europe.com

Our hotline remains available at +33 (9) 70 75 30 30.

PRODUCT FAILURE

THE WARRANTY DOES NOT COVER:

• Start-up and setting up of the product.

• Damage resulting from normal wear and tear of the product.

• Damage resulting from improper use of the product.

• Damage resulting from assembly or start-up not in accordance with the user manual.

• Breakdowns related to carburetion beyond 90 days and fouling of carburetors.

• Periodic and standard maintenance events.

• Actions of modication and dismantling that directly void the warranty.

• Products whose original authentication marking (brand, serial number) has been degraded, altered or

withdrawn.

• Replacement of consumables.

• The use of non-original parts.

• Breakage of parts following impacts or projections.

• Accessories breakdowns.

• Defects and their consequences linked to any external cause.

• Loss of components and loss due to insucient screwing.

• Cutting components and any damage related to the loosening of parts.

• Overload or overheating.

• Poor power supply quality: faulty voltage, voltage error, etc.

• Damages resulting from the deprivation of enjoyment of the product during the time necessary for repairs

and more generally the costs related to the immobilization of the product.

• The costs of a second opinion established by a third party following an estimate by a SWAP-Europe repair

station

• The use of a product which would show a defect or a breakage which was not the subject of an immediate

report and/or repair with the services of SWAP-Europe.

• Deterioration linked to transport and storage*.

• Launchers beyond 90 days.

• Oil, petrol, grease.

• Damages related to the use of non-compliant fuels or lubricants.

* In accordance with transport legislation, damage related to transport must be declared to carriers within 48

hours maximum after observation by registered letter with acknowledgement of receipt.

This document is a supplement to your notice, a non-exhaustive list.

Attention: all orders must be checked in the presence of the delivery person. In case of refusal by the

delivery person, it you must simply refuse the delivery and notify your refusal.

Reminder: the reserves do not exclude the notication by registered letter with acknowledgement within 72

hours.

Information:

Thermal devices must be wintered each season (service available on the SWAP-Europe site). Batteries must

be charged before being stored.

WARRANTY EXCLUSIONS

Table of contents

Other Feider Machines Cutter manuals