Metkon MICRACUT 152 Administrator Guide

1

metkon.com

OPERATION & INSTRUCTION MANUAL

PRECISION CUTTER

2

EC Declaration of Conformity

Manufacturer : Metkon Instruments Inc.

Address : Demirtas Dumlupinar Organize Sanayi Bolgesi

Ali Osman Sonmez Cd. No: 14 Bursa / TURKEY

Model No : MICRACUT 152

Herewith declares that;

Precision Cutter

is in conformity with the provisions of the Machinery Directive (directive 2006/42/EEC), as amended, and with national

implementing legislation;

is in conformity with the provisions of the Low Voltage Directive (directive 2014/35/EU), as amended, and with national

implementing legislation;

is in conformity with the provisions of the EMC Directive (directive 2014/30/EU), as amended, and with national

implementing legislation;

And furthermore declares that

the following (parts/clauses of) standards have been applied

EN ISO 12100:2010, TS EN 60204-1, TS EN IEC 61000-6-2, TS EN 61000-6-4

Authorized Person: ERCIN SENAY

Position: Manager of Research and Development Department

Year: 2019

Bursa / Turkey

3

Index

DESCRIPTION ............................................................................................................................ 4

Design .....................................................................................................................................................................................4

Technical Data ........................................................................................................................................................................5

Warranty .................................................................................................................................................................................6

Safety Precautions ..................................................................................................................................................................6

INSTALLATION & SET UP........................................................................................................... 7

Unpacking & Checking Contents of Package ...........................................................................................................................7

Step by Step Unpacking...........................................................................................................................................................7

Installation and Set-Up ...........................................................................................................................................................9

CONTROL PANEL......................................................................................................................14

Control Button Functions ...................................................................................................................................................... 14

Operation Parameter Ranges ................................................................................................................................................ 14

OPERATION ..............................................................................................................................14

Mounting of Cutting Wheel ................................................................................................................................................... 14

Blade Dressing ...................................................................................................................................................................... 15

Cutting Operation.................................................................................................................................................................. 15

SERVICE AND MAINTENANCE ..................................................................................................16

Maintenance ......................................................................................................................................................................... 16

Troubleshooting.................................................................................................................................................................... 17

ACCESSORIES AND CONSUMABLES.........................................................................................18

Clamping Devices and Accessories ....................................................................................................................................... 18

Consumables......................................................................................................................................................................... 19

TECHNICAL DOCUMENTATION ................................................................................................21

Customer Service .................................................................................................................................................................. 21

4

DESCRIPTION

Design

MICRACUT 152 precision cutters are used for precise and

deformation-free cutting of “Metals, Ceramics, Electronic

Components, Crystals, Composites, Biomaterials, Sintered

Carbides, Minerals, etc.” MICRACUT 152 has its place in

virtually any metallurgical, geological, electronics, research,

biomedical or industrial laboratory. The applications are

endless.

•Modern and sturdy design

•Easy to use control panel with ergonomic turn-knob

•Precise micrometer with digital readout

•Gravity feed system

•Automatic stop at the end of cut

•Transparent protection hood with magnetic safety

switch

•Inbuilt recirculation coolant tank

MICRACUT 152 accommodates diamond and abrasive wheels

up to 175 mm (7”) diameter and the speed range is between

50 and 1500 rpm. Modern-looking touch pad controls with

ergonomic turn knob allows fast and easy setting of wheel

speed and increases productivity. The gravity feed loading

design minimizes sample deformation. The sliding weight arm

with counterweight allows precise force application. The

digital micrometer enables the operator to set the cutting

width with a resolution of 1 micron. The digital micrometer is

interchangeable and the customer can mount other types of

micrometers if and whenever required. The coolant tray is

removable from the instrument for easy cleaning. MICRACUT

152’ s cutting chamber is fully enclosed by a transparent

hood. Blade dresser is optionally available. At the end of the

cut, the motor automatically stops and an audible signal

notifies the operator.

Optional Cutting Table Attachment is available for manual

cutting of extra flat large specimens and PCB’s.

MICRACUT 152 precision cutters are capable of cutting most

materials such as, brittle or ductile metals, hard or soft

metals, composites, ceramics, rocks, biomaterials, laminates,

etc. They are designed for cutting all types of materials with

minimal structural deformation.

The structural integrity of the sample is maintained through

MICRACUT 152's design and operation. Additionally, low kerf-

loss and sample holding versatility makes the MICRACUT 152

an essential part of the modern day laboratory. The cut

surface is ready for microscopic examination with minimal

polishing.

Safety

MICRACUT 152 precision cutters has the highest safety

standards. The magnetic safety switch does not allow the

motor to be started unless transparent hood is closed. If

transparent hood is opened during cutting, the motor

immediately stops automatically. Easily accessed and

operated emergency stop button ensures immediate shut

down. Soft closing feature of transparent hood protects

fingers from risk of injury.

5

Technical Data

Model

Order No

MICRACUT 152

16 05

Disc Diameter, mm

Ø175 mm

Cutting Capacity, mm

Ø50 mm

Cutting Motor Power, W

100 W

Disc Speed, RPM

50 RPM - 1500 RPM

Cutting Method

Chop

Parallel Cutting in X-Axis

Yes

X-Axis Positioning, mm

25 mm

Cooling Unit, lt

850 ml (integrated)

Dimensions, WxDxH, mm

510 x 430 x 340h mm

Weight, kgs

28 kgs

6

Warranty

The MICRACUT 152 is guaranteed against defective material or

workmanship for a period of 12 months from the date of receipt

by the customer or latest 18 months after the shipping date.

THE WARRANTY IS NOT VALID IF INSPECTION SHOWS

EVIDENCE OF MISUSE OR UNAUTHORIZED REPAIR. Warranty

covers only replacement of defective materials. Should this unit

need to be returned to our factory for service contact your

distributor for authorization and include the following details:

Serial Number of the unit, Invoice number and date. Transport

costs belong to the customer.

NOTE

Disabling Magnetic Safety switch on the MICRACUT 152 will

void warranty.

Using any other brand consumables

apart from METKON brand (cut-off

wheels, cooling fluids) this warranty

will not cover:

Painting deformation and rusting on the components

Deformation and corrosion occurred on Motor, Bearings,

Clamping Devices, bearing housings, etc.

Safety Precautions

Read the below instructions carefully before use.

Place the machine on a sturdy and safe table.

The equipment must be installed in compliance with

local safety regulations.

Only use approved METKON accessories and

consumables to achieve max. safety and lifetime.

The equipment is not for use with saw-blade type cut

off wheels.

Follow the instructions and safety regulations when

lifting and carrying the equipment.

Be sure that the sample is securely fixed in the

clamping devices. Handle the large and sharp

samples in a safe way.

The equipment emits only moderate noise. But

during the cutting process the emitted noise may be

higher. Wearing hearing protection is recommended.

Disconnect the electrical connection before servicing

the equipment.

After cutting operation heat and sharp edges may

occur. Using protection gloves are recommended.

Do not bypass the safety switch.

Follow the periodically maintenance and keep the

hood open when not working.

NOTE

METKON Instruments Inc. can make any changes

without notice on the equipment, accessories,

consumables and miscellaneous products.

Consequently; visual or written information on

the instruction manuals, technical materials, catalogues,

website, product videos and other marketing materials may

show inconsistencies and may be different from the product.

7

INSTALLATION & SET UP

Unpacking & Checking Contents of Package

Carefully unpack and check contents of the package. If any

components are missing or damaged, save the packing list

and materials and advise your distributor and the carrier of

the discrepancy.

Power Cable, 1.8 mt, 1 piece

Combination Wrench, 17mm, 2 pieces

Brush, 1 piece

Screwdriver, 6.5 x 25, 1 piece

Dressing Stone, 10 x 10 x 100 mm, 1 piece

Hex Key, 4 mm, 1 piece

Hex Key, 2.5 mm, 1 piece

WARNING

The MICRACUT 152 weighs 28 kgs and be sure

that there are enough people to safely lift the

unit from the shipping carton. It is

recommended to wear safety shoes during

transportation

The MICRACUT 152 is shipped completely assembled except

its digital micrometer for safely shipment.

MICRACUT 152 is only available as bench top.

MICRACUT 152 should be placed on a sturdy and safe

platform. Please be sure that the platform is large enough

and can stand it’s weight.

You can see the dimensions and weight of MICRACUT 152

as below:

Dimensions

W

D

H

510 mm

430 mm

340 mm

Weight

Approx. 28 kgs

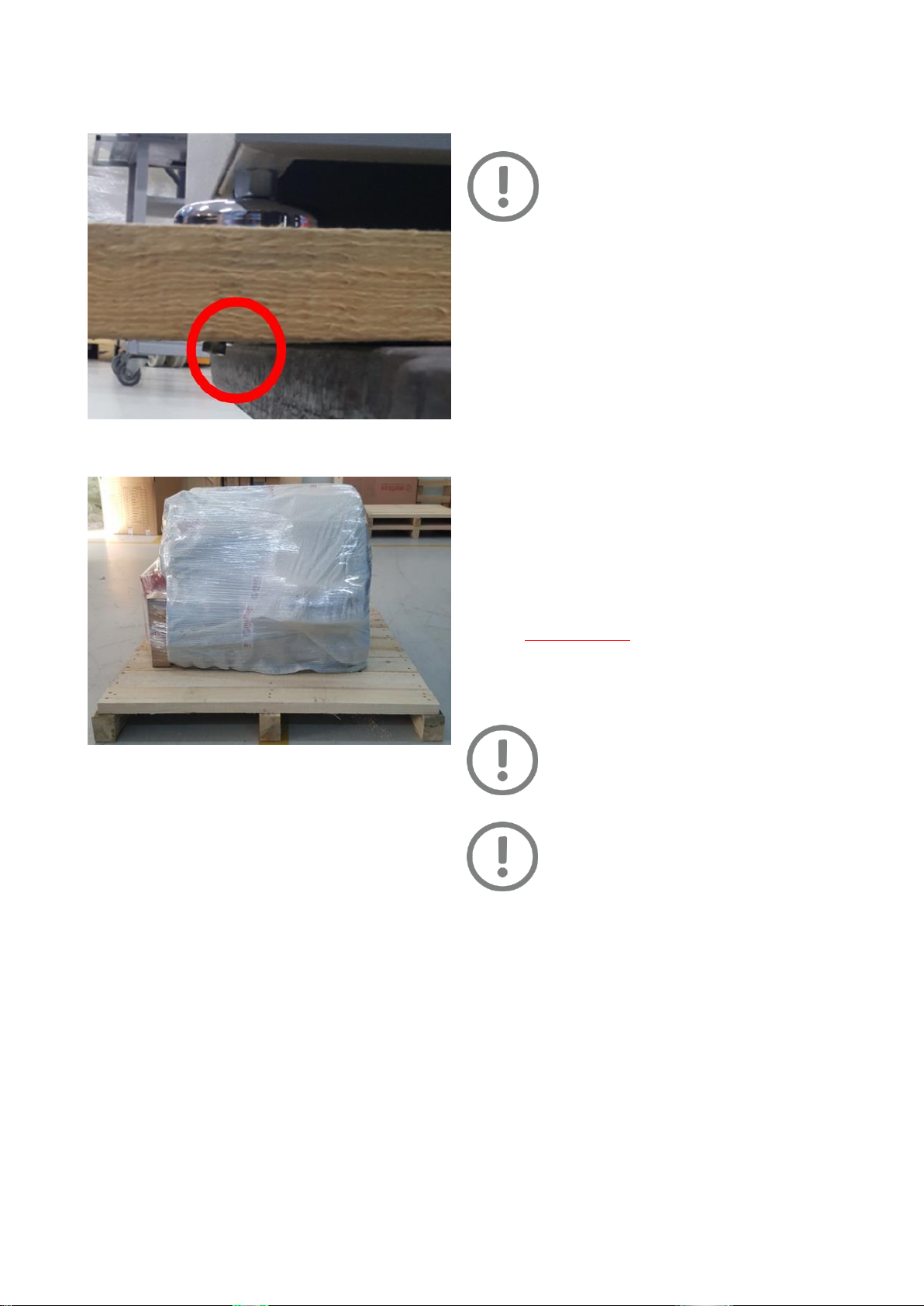

Step by Step Unpacking

If Sent in a Carton Box

Carefully remove the outer stretch wrap, cut the strips

and remove the cover.

Open the box and remove filling materials inside the box.

Remove the equipment from the box by holding wooden

base at the bottom. Please consider weight of equipment

when lifting it. Lift the equipment by considering the

center of gravity.

8

Equipment is fixed on the wooden base with bolts.

Carefully remove these bolts.

Carefully remove the protective bubble wrap. Be carefull

not to damage equipment while using a knife.

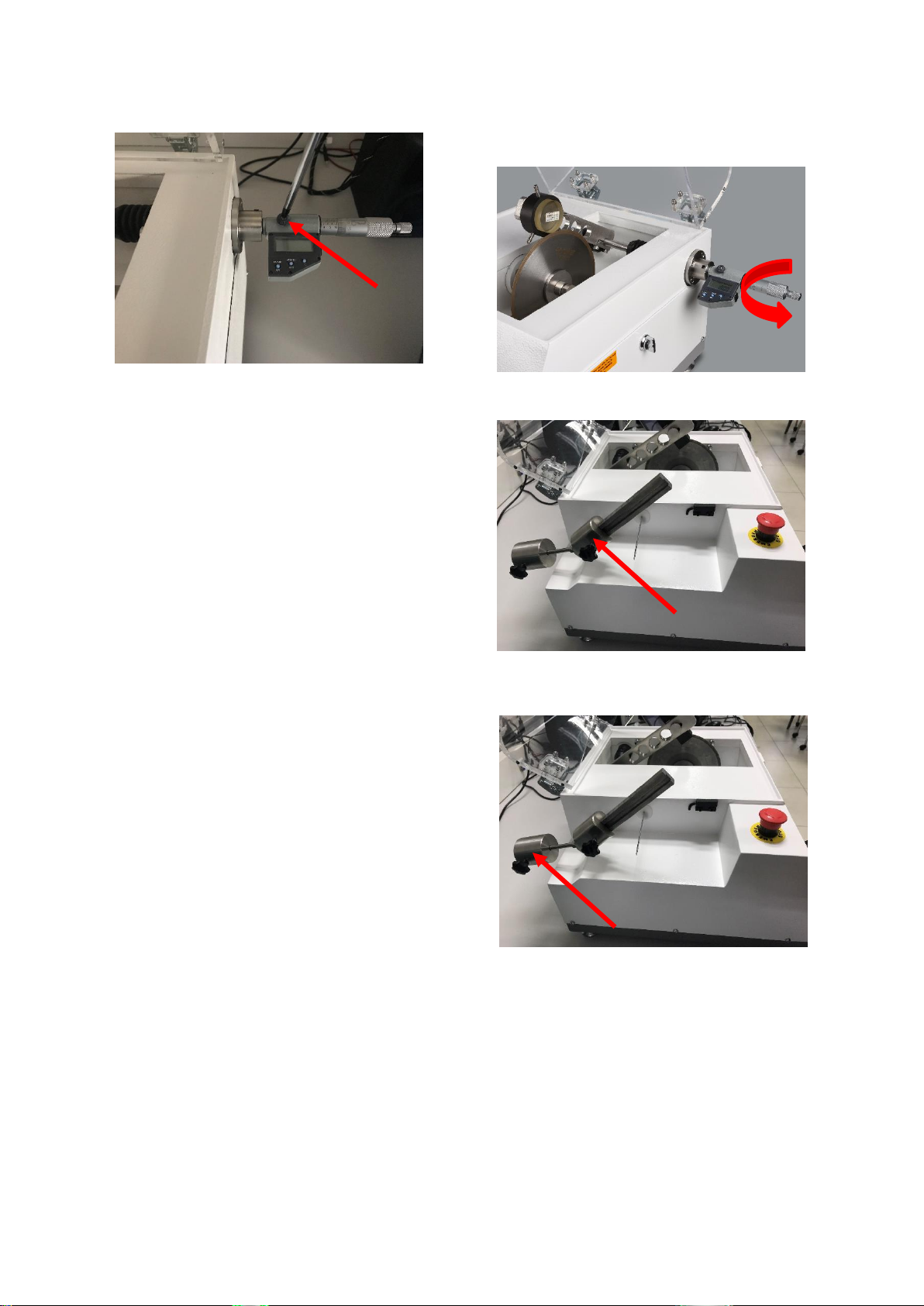

If Sent in a Wooden Case

Carefully remove the outer stretch wrap.

Open the top cover of wooden case by removing screws.

Open the back, front and side covers in the same way

and remove filling materials inside the case.

9

Equipment is fixed on the wooden base with bolts.

Carefully remove these bolts.

Carefully remove the protective bubble wrap. Be carefull

not to damage equipment while using a knife.

Installation and Set-Up

CAUTION

Follow approved procedures and take all

necessary preventive safety measures when

lifting and installing this equipment. Improper

lifting can result equipment damage.

The MICRACUT 152 is shipped completely assembled except

its digital micrometer for safely shipment. It is designed for

table-top placement. After unpacking select a smooth

location to place the MICRACUT 152. Then, adjust the leveling

feet to make the equipment parallel (set-square). Locate the

MICRACUT 152 with convenient access to a grounded type

electrical receptacle.

Electrical Installation

Before making electrical connections, check that the voltage

and frequency stated on the specification plate correspond to

the local voltage and frequency. Check that the values for

one-phase grounded voltage, is compatible with the intended

electrical supply before installation.

Connect the mains cable of the MICRACUT 152 to an

appropriate electrical outlet.

Close the door. Turn the instrument on from the main

switch, which is on the backside of the instrument.

See Cutting Operation section for operation.

Press “START” and “STOP” buttons and observe from the

window that the cutting wheel shaft rotates clockwise

when looked at from the left.

ATTENTION

Connect the unit to the grounded mains

voltage. The MICRACUT 152 requires a 1-phase

electrical supply.

WARNING

Electrical Shock Hazard. A qualified electrical

technician should perform all hard wiring and

electrical maintenance

10

Disconnect the power supply before making any

electrical adjustments.

Make sure that the supply voltage and frequency is

correct. Check the values from the machine identification

plate located at the rear of the machine

Voltage / Frequency

Operational

Power Range

Fuse Rating

115 V, 50/60 Hz. 1 ph.

100 - 125 V

6 A (C Type)

230 V, 50/60 Hz. 1 ph.

200 - 250 V

6 A (C Type)

Identification Plate

Connect the equipment to the grounded mains voltage.

Power cord will be supplied with the equipment.

Length of the power cable is 1.8 meters

Power Cable

You can see suitable power sockets as below. If you have

not suitable power socket, in this case you should supply

a suitable power cord.

Cooling Unit

The MICRACUT 152 uses the “drag” principle of lubrication

with the lubricant carried to the sample on the periphery of

the wheel. METCOOL Cutting Fluid reduces cutting time and

produces superior quality cuts. Its use promotes effective

lubrication which allows the diamond particles to cut cleanly.

Coolant is lost during the cutting process because of

evaporation or left in the cutting chamber or components. For

the best cutting performance and corrosion protection,

replace the coolant regularly (max. 1 month)

IMPORTANT

ONLY water-based cooling fluids has to be

used. Use of alcohol or oil based flammable

cooling fluids are strictly FORBIDDEN because;

the vapor is potentially EXPLOSIVE when

ignited.

CAUTION

Do not run the pump dry for more than 30

seconds.

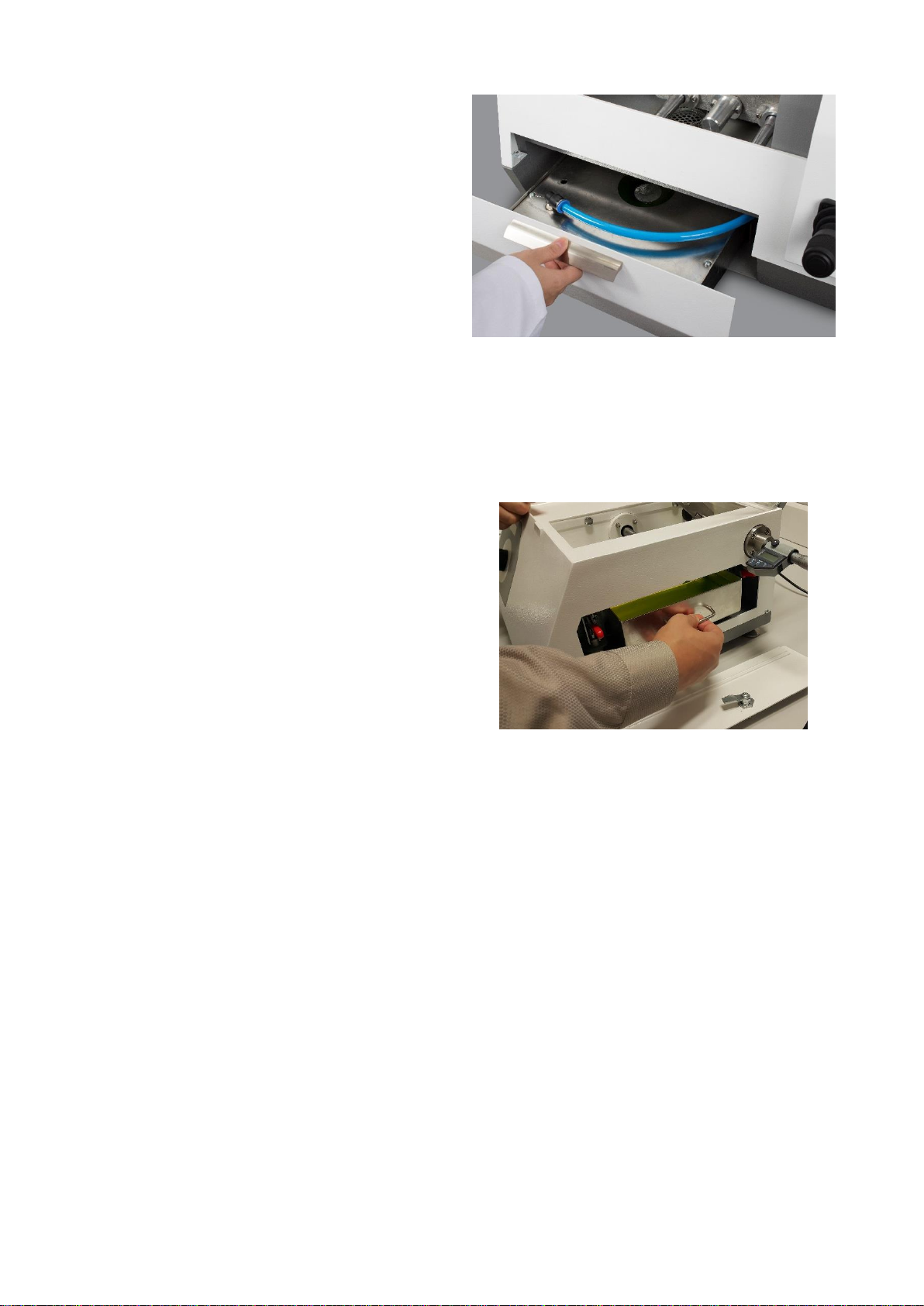

For removing the water tank, please follow the below steps:

Remove the cutting-wheel.

Open the covers which are under the wheel

11

Open the side cover.

Open the RED fixers of the coolant tank to release the

tank.

Pull out the coolant tank for re-filling the cutting fluid.

Fill the Lubricant Pan with Fluid to a level that will

immerse wheel approximately 6-7 mm.

Fill the tank with a mixture at a ratio of 95% clean water

+ 5% METCOOL cutting fluid until the mixture level

comes to 5 mm below the top. Water hardness should be

5-20 °dH in German Hardness and should not contain

bacteria and chemical salts. METCOOL ratio should not

less than 3% and should not more than 6%. If

concentration is below 3%, corrosion may occur inside

the cutting chamber. If concentration is more than 6%,

foaming effect may occur.

Push the recirculation tank into place again and follow

the steps backwards.

The recirculation unit should be checked for cooling

water every day.

Mounting of Micrometer

MICRACUT 152 is shipped completely assembled except its

digital micrometer for shipment safety. Please follow the

following steps to install the digital micrometer:

Insert the battery to the micrometer.

Micrometer

Insert the micrometer to its flange on the equipment and

push towards to the body of the equipment.

When you completely push the micrometer tighten the

screw for completing the installation. Do not tighten too

much as the micrometer will not be able to push the

cutting arm.

12

To arrange the sensitivity of the micrometer, tighten or

loosen the screw indicated on the below photo.

Mounting Clamping Devices

Metkon offers a wide range of specimen holders for the

MICRACUT 152.

Loosen the Set screw and slip the Counter Balance Weight

to the rear of the Shaft to hold the Support arm in an

upright position.

Select the proper Chuck for the particular application and

clamp the Specimen in place.

Attach the loaded Chuck to the Support arm with the

Chuck Mounting Thumb Screw.

After the Chuck is secured, move the holding arm to the

far left by adjusting the Micrometer Head.

Slide the Counter-Balance Weight toward the front of the

unit until balance is achieved and tighten the Set Screw.

Fasten the Sample properly: the samples must never

move around in the specimen holder during cutting.

Movements may lead to damage of the cut-off wheel and

sample will invariably cause a bad cutting quality.

Cut-Off Switch Mechanism

When the specimen is cut completely, the support arm drops

to the lowest position due to the effect of gravity. The support

arm falls on the wire switch, allowing the motor to stop

automatically.

Micrometer Adjustment and Weight Selection

Adjust the Micrometer to position the specimen for

cutting.

Weight can be applied to the work in increments of 100

grams by movement of sliding weight.

Intermediate Weights can be applied through careful

adjustment of the Counter-Balance Weight at the rear of

the Support Arm.

Counter-Balance Weight

Heavy Loads cause surface damage to the Specimen,

therefore light weights are recommended.

13

Mounting PCB Cutting Table

Disassemble the screws of the cover and remove the

cover of the MICRACUT 152. If your sample has small size,

you do not have to remove the cover.

Place the table on the equipment. Be sure that the

magnetic switch is securely closed.

You can easily and safely cut flat specimens with this

table.

Safety

The MICRACUT 152 machines conform to the highest

standards of safety regulations. The cutting motor cannot be

started unless the hood is closed. In case of opening the hood

during cutting operation, the cutting motor immediately stops.

Safety Switch

Noise Level

Approximately 62 dBa is measured at idle running at a

distance of 1 meter from the machine.

14

CONTROL PANEL

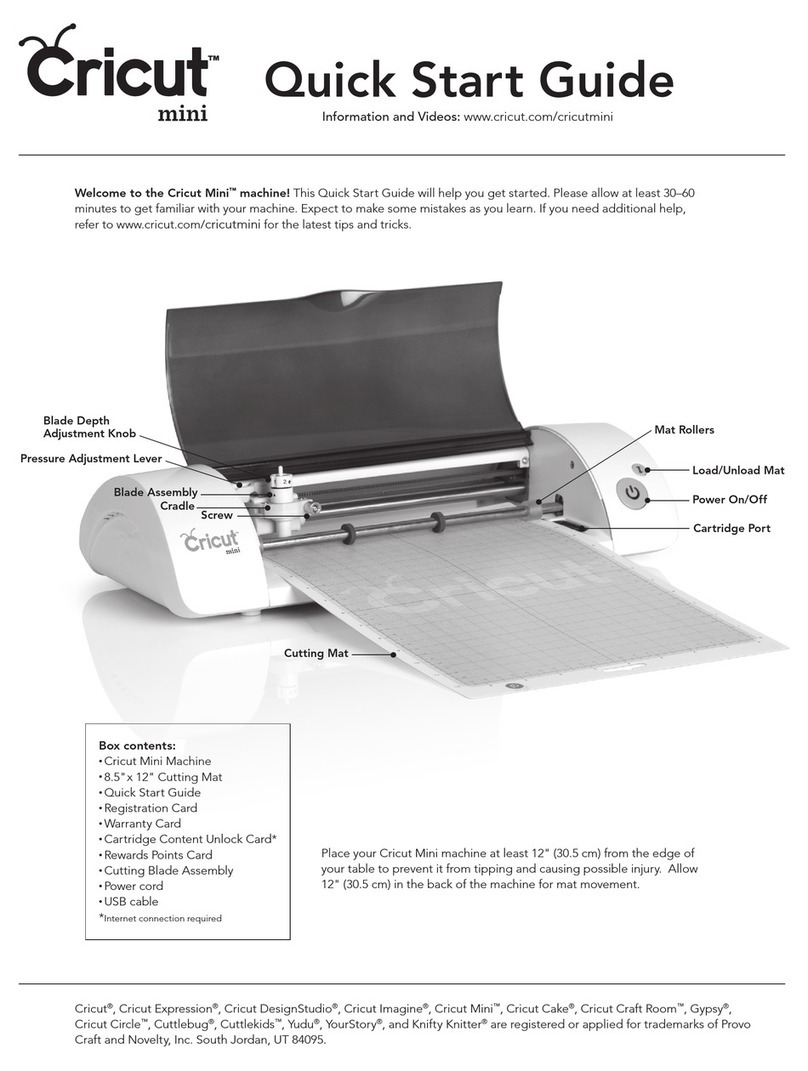

MICRACUT 152 has a modern looking and easy to use operator

panel with buttons and knob. It has specially designed to

increase operator comfort and maximize productivity.

MICRACUT 152 Control Panel

Control Button Functions

Start

Stop

Operation Parameter Ranges

Cutting Wheel Speed (RPM) : 50 –1500 RPM

OPERATION

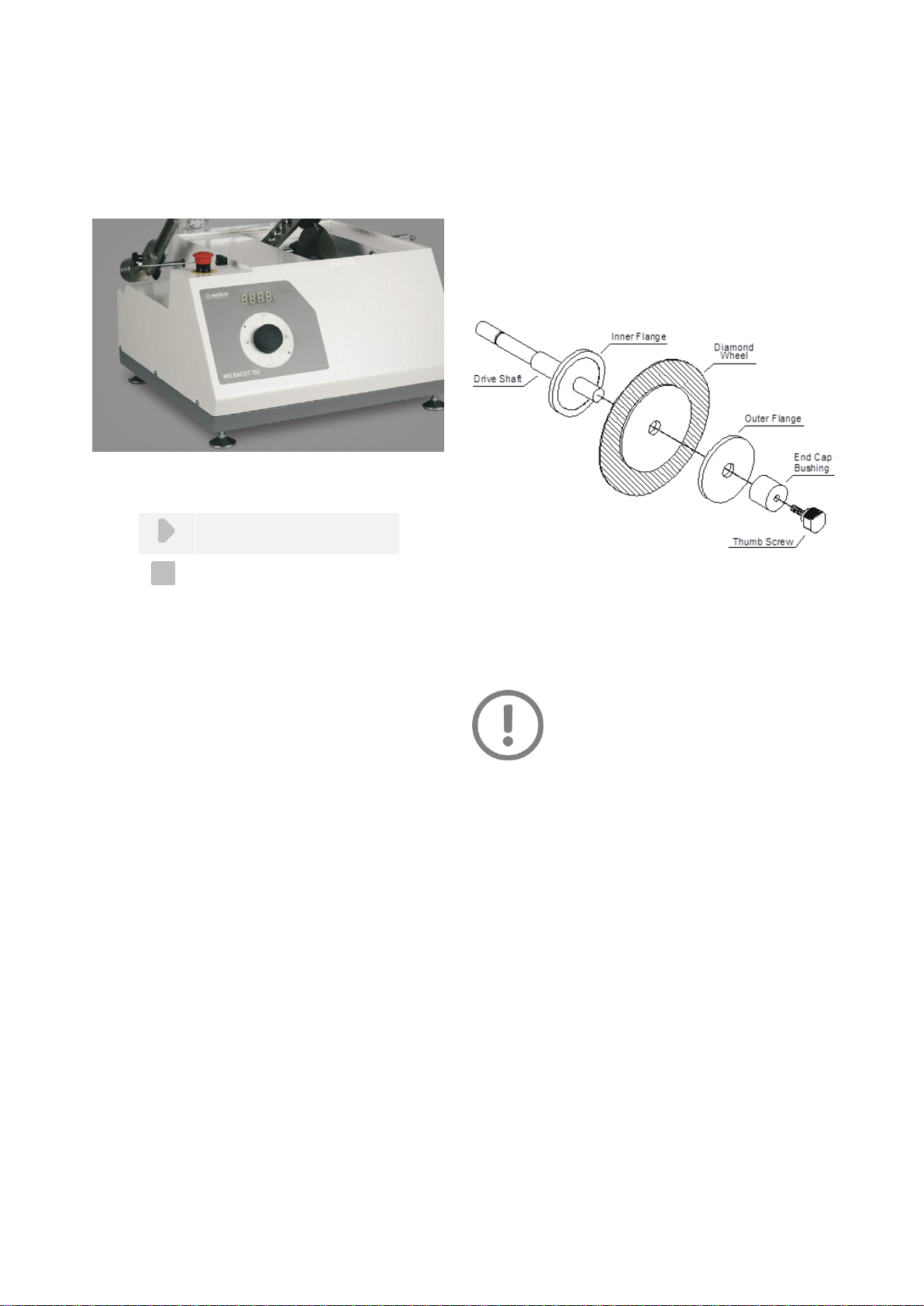

Mounting of Cutting Wheel

Remove Thumb Screw, End Bushing and Outer Flange

from Drive Shaft.

Install wheel on Drive Shaft against Inner Flange relieved

surface.

Slip on Outer Flange and End cap Bushing, then hand

tighten Thumb Screw to complete installation.

Mounting of Abrasive/Diamond/CBN Wheel

Flanges provide support for the wafering blades. Failure to

provide adequate flange support may result in curved cuts

and damaged blades.

NOTE

Before reinstallation of a wheel, the Cap

Bushing, Screw and Flanges should be

cleaned in a mild detergent solution to

remove adherent particles from previous

sawing. This will help prevent misalignment

of wheel, which might cause poor-quality

cuts.

15

Blade Dressing

New wheels must be dressed before making sample cuts.

Dressing removes normal smeared matrix metal and exposes

the abrasive grain to assure free cutting. Blade dressing

exposes the abrasive grain to ensure free cutting. New

wafering blades should be dressed several times and older

blades dressed as required based on the specimen material

properties. When cutting metal samples, it may be necessary

to dress after each cut.

Regular dressing of diamond and CBN cut-off wheels is

important to keep a consistent quality of the cuts. A badly

maintained and poorly dressed cut-off wheel requires a higher

cutting pressure and will, therefore, generate more frictional

heat. It may also bend, causing deformed cuts.

Please fasten the dressing stick to the special sample holder

and mount this sample holder to the equipment as shown in

below picture. Tighten the special sample holder to the main

body of the instrument with the set screws. Start the machine

in low speed. You can do the dressing within the same time

you are doing a cutting operation.

Dressing Unit

Cutting Operation

Turn on the equipment from the main power switch at

the backside of the machine.

Main Power Switch

The display of the front panel will be lighten up.

Set the disc speed by turning the knob from the front

panel to the desired speed in RPM.

Press the turn-knob to save the disc speed.

Fast speeds tend to damage the specimen surface.

Settings between 500-800 RPM are recommended for

general use.

After the disc speed is set, press the “Start”button and

carefully lower the Specimen Arm onto the wheel to start

cutting.

For safety reasons, shut the transparent cover on top of

the cutting chamber.

Adjust the position of the sample by the help of the

micrometer located at the right side of the equipment.

When the cut is completed, the Cut-Off Switch Arm is

automatically depressed which stops the MICRACUT 152.

16

SERVICE AND MAINTENANCE

Maintenance

The MICRACUT 152 Precision Cutter should be cleaned

periodically to prevent build-up of cutting residue and cutting

fluids. Exterior painted surfaces including the cutting chamber

may be cleaned with non-abrasive household cleaners.

The protective hood and touch screen control panel should

be cleaned with a soft cloth.

Use only “METCOOL II” cutting fluids to obtain maximum

corrosion protection and cooling properties.

Use only “METCOOL-NF” cutting fluid if you continuously cut

reactive metals like copper, brass, cobalt, aluminum, tungsten

carbide, etc… METCOOL-NF has perfect corrosion protection

for the machine when cutting these parts.

The precision of diamond and CBN cut-off wheels and thus

the cut depends on how carefully the following instructions

are observed:

Never expose the cut-off wheel to overload, such as

heavy mechanical load, or heat.

Store the cut-off wheel in a dry place, horizontally on a

plane support, preferably under light pressure.

A clean and dry cut-off wheel does not corrode.

Therefore, clean and dry the cut-off wheel before

storing. If possible, use ordinary detergents for the

cleaning.

When the cutter is not in use for a long time, keep the hood

raised so that the unit dries.

Daily Maintenance

At the end of the working day, please clean the cutting

chamber. After cleaning it is recommended to dry the

clamping devices and the cutting chamber.

Leave the hood open when you are finished with

cleaning.

If the cooling fluid level is low, please add fluid.

After cutting operation please control diamond cutting

wheel and dress the surface of the wheel if necessary.

Recirculation Cooling Tank

Weekly Maintenance

Remove the cooling fluid tank. Drain the cutting fluid

completely and clean all the swarf and particles. Prepare

the new cutting fluid suspension and fill.

Prepare the new cutting fluid suspension in a ratio of 97

% water + 3 % METCOOL II cutting fluid.

Do not add only water, because concentration become

low which may cause corrosion. Add mixture at a ratio of

97% water + 3% METCOOL II cutting fluid. Water

hardness should be 5-20 °dH in German Hardness and

do not contain bacteria and chemical salts.

Monthly Maintenance

The clamping vises need monthly lubrication with a,

water-resistant automotive grease. (Never use grease

containing Molybdenum Disulphide or graphite, which

can impair the clamping ability of the Vise.)

Remove the cooling fluid tank. Drain the cutting fluid

completely, and clean out all the swarf and fine particles.

Prepare anew cutting fluid suspension.

17

Troubleshooting

ERROR

DESCRIPTION

ACTION

The cut-off wheel is not rotating

The hood is left open

Close the hood properly.

Burning remarks on the cutting surface

The cut-off wheel is not compatible

with the cut piece

Use proper cut-off wheel.

See consumables section for the

correct cut-off wheel selection.

High cutting force

Lower the force applied

Insufficient cooling

Check that there is enough cooling

fluid in the tank.

Unwanted burrs on the sample

The cut-off wheel is not compatible

with the cut piece

Use proper cut-off wheel.

See consumables section for the

correct cut-off wheel selection.

High cutting force at the end of cycle

Reduce the cutting force before the

end of the operation

Improper clamping of the sample

Support the sample from both sides.

Cut-off wheel breaks

Incorrect mounting of the cut-off wheel

Check the mounting of the cut-off

wheel and be sure that the nut and

the flange is set properly

The cut-off wheel is not compatible

with the cut piece

Use proper cut-off wheel.

See consumables section for the

correct cut-off wheel selection.

High cutting force

Lower the force applied.

Insufficient cooling

Check that there is enough cooling

fluid in the tank.

The Lexan window is blurred

Insufficient cleaning

Clean the Lexan window with a mild

soapy water (Do not use the cooling

fluid)

18

ACCESSORIES AND CONSUMABLES

Clamping Devices and Accessories

METKON offers a number of special clamping devices and specimen vices for use with our MICRACUT precision cutters. Please

see below, the clamping devices and accessories table, as well as clamping device drawings.

Order No

Specimen Vises for MICRACUT 152

GR 0213

Cutting Table Attachment for manual cutting of extra flat specimens and PCB 's.

GR 0409

Dressing Unit for MICRACUT 152

YM 1590-00

Dressing Stone

GR 0400

Universal Specimen Vise

GR 0401

Specimen vise with double parallel vice for long specimens

GR 0402

Specimen vise for round and mounted specimens, ø 32mm

GR 0403

Specimen vise for irregular shaped specimen

GR 0404

Specimen vise for adhering specimens

GR 0405

Specimen vise for biomedical samples

GR 0406

Swivel arm unit for angular cutting

GR 0430

Specimen vise (teardrop shape) for specimens 18-40mm

GR 0431

Specimen vise (teardrop shape) for specimens 5-20mm

GR 0434

Specimen vise for round cylindrical specimens (up to 40 mm diameter)

GR 0453

Fastener vise for longitudinal sectioning of screws, fasteners, tubes, etc.

from 12 to 45 mm. in length

GR 0410

Set of Flanges, Ø75 mm, suitable for 12.7 and 25.4 mm arbor diameters.

Order No

Spare Part Kit for MICRACUT 152

GR 1960

Recommended Set of Spare Parts, MICRACUT 152

*SWITCH, 1 pc.

*DIGITAL MICROMETER, 0-25, 0.001 mm, 1 pc.

*BELT, 10 mm, 1 pc.

*PULLEY GEAR, Ø12, 1 pc.

*BEARING, 6001, 1 pc.

*SPRING, MICROMETER MOTION, 1 pc.

19

Consumables

Abrasive cut-off wheels

The most commonly used abrasives for the cutting of different materials are SiC and Al2 O3. Silicon carbide is suitable for non-

ferrous metals, whereas Aluminum oxide is preferred for ferrous metals. Hard wheels are used for cutting soft materials while

soft wheels are recommended for cutting harder materials.

Diamond and CBN Cut-off Wheels

Metal bonded wheels are used for cutting brittle materials, such as ceramics or minerals, while resin bonded wheels are used

for ductile materials, such as sintered carbides or composites that contain predominantly hard phases. Several factors are

important for choosing the appropriate wafering blade.

These include:

“High & low concentration metal bonded diamond wheels”, “Diamond size (fine or medium)”, “blade diameter”and “blade

thickness”. The diamond concentration is important because it directly affects the load, which is applied during cutting. For

example, brittle materials such as ceramics require higher effective loads to section, whereas ductile materials such as metals

require more cutting points. The result is that low concentration blades are recommended for sectioning hard brittle materials

such as ceramics and high concentration blades are recommended for ductile materials containing a large fraction of metal or

plastic.

CBN wheels are usually used for cutting very hard metals.

Order No

CODE

DESCRIPTION

18-150

TRENO-HP

Ø150 mm, for Non-Ferrous Metals, Stainless Steels, 10 pcs/pack

18-151

TRENO-MP

Ø150 mm, for Medium and Hardened Steels, 10 pcs/pack

Order No

CODE

DESCRIPTION

19-100

DIMOS

Ø100 mm, Diamond Cut-off wheels (Metal Bonded, high conc.)

19-125

DIMOS

Ø125 mm, Diamond Cut-off wheels (Metal Bonded, high conc.)

19-130

DIMOS

Ø125 mm, Diamond Cut-off wheels (Metal Bonded, low conc.)

19-126

DIMOS

Ø125 mm, Diamond Cut-off wheels (Resin Bonded, high conc.)

19-150

DIMOS

Ø150 mm, Diamond Cut-off wheel (Metal Bonded, High Concentration)

19-157

DIMOS

Ø150 mm, Diamond Cut-off wheel (Metal Bonded, Low Concentration)

19-151

DIMOS

Ø150 mm, Diamond Cut-off wheel (Resin Bonded, High Concentration)

19-127

CBN

Ø125 mm, CBN Cut-off wheels (Metal Bonded, high conc.)

19-152

CBN

Ø150 mm, CBN Cut-off wheels (Metal Bonded, high conc.)

20

Cutting Fluid

Cutting fluid is one of the most important thing to protect sample surface and the machine. Its function is to reduce heat

generation between cut-off wheel and specimen surface during cutting operation. Second function is to prevent corrosion from

specimen surface and the machine parts. METCOOL II has special anti-corrosion additives as well as perfect cooling properties.

It is nature friendly, boron-free and anti-bacterial. METCOOL-NF provides perfect corrosion protection when cutting reactive

metals like copper, brass, cobalt, aluminum, tungsten carbide, etc... Mixing ratio is 95% water + 5% METCOOL II.

Order No

CODE

DESCRIPTION

19-902

METCOOL

Nature Friendly Soluble Oil, 5 lt.

19-905

METCOOL II

Nature Friendly Soluble Oil, 1 lt.

19-906

METCOOL-NF

Nature Friendly Soluble Oil, 5 lt.

Perfect corrosion protection for reactive metals like copper, brass, cobalt, aluminum,

tungsten carbide, etc.

Table of contents

Other Metkon Cutter manuals