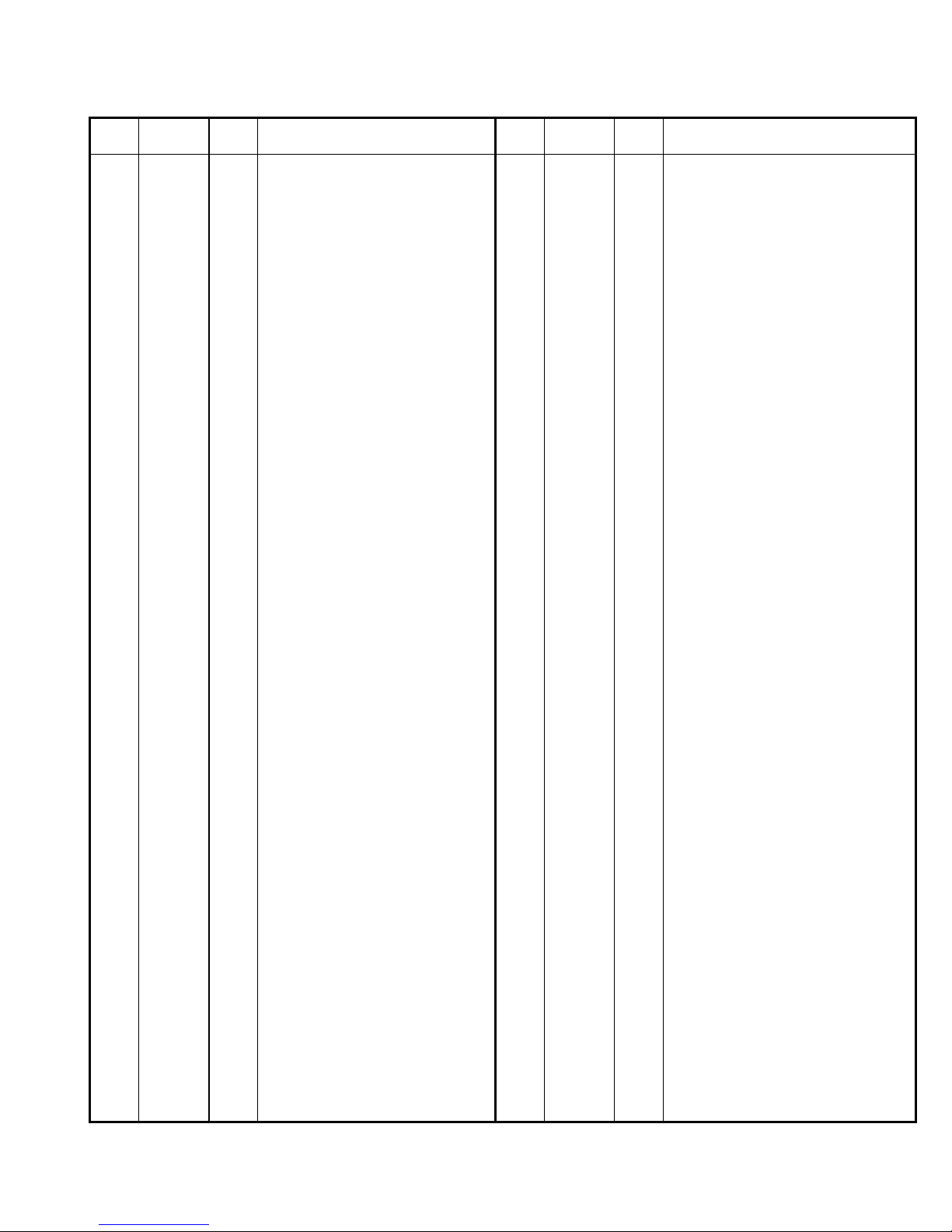

7

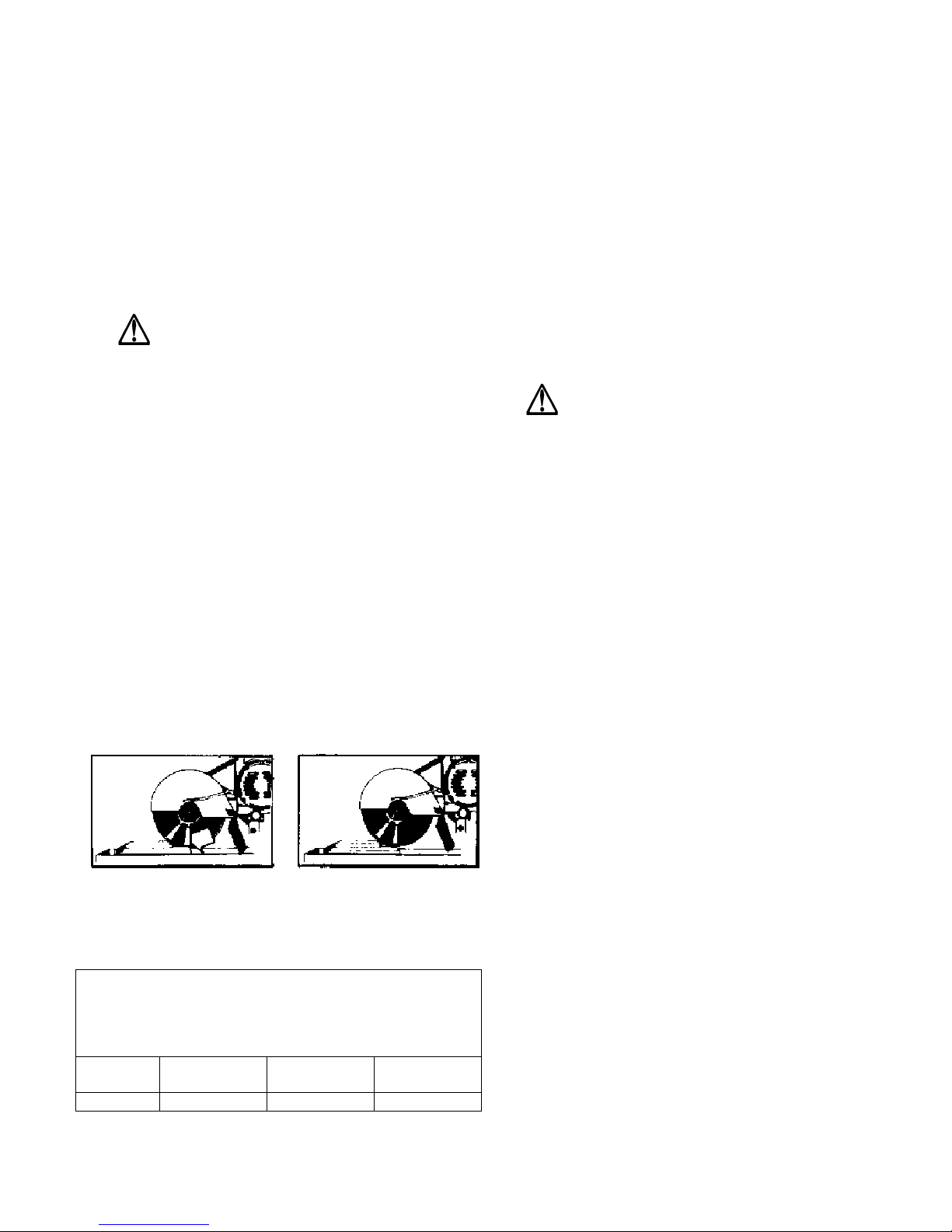

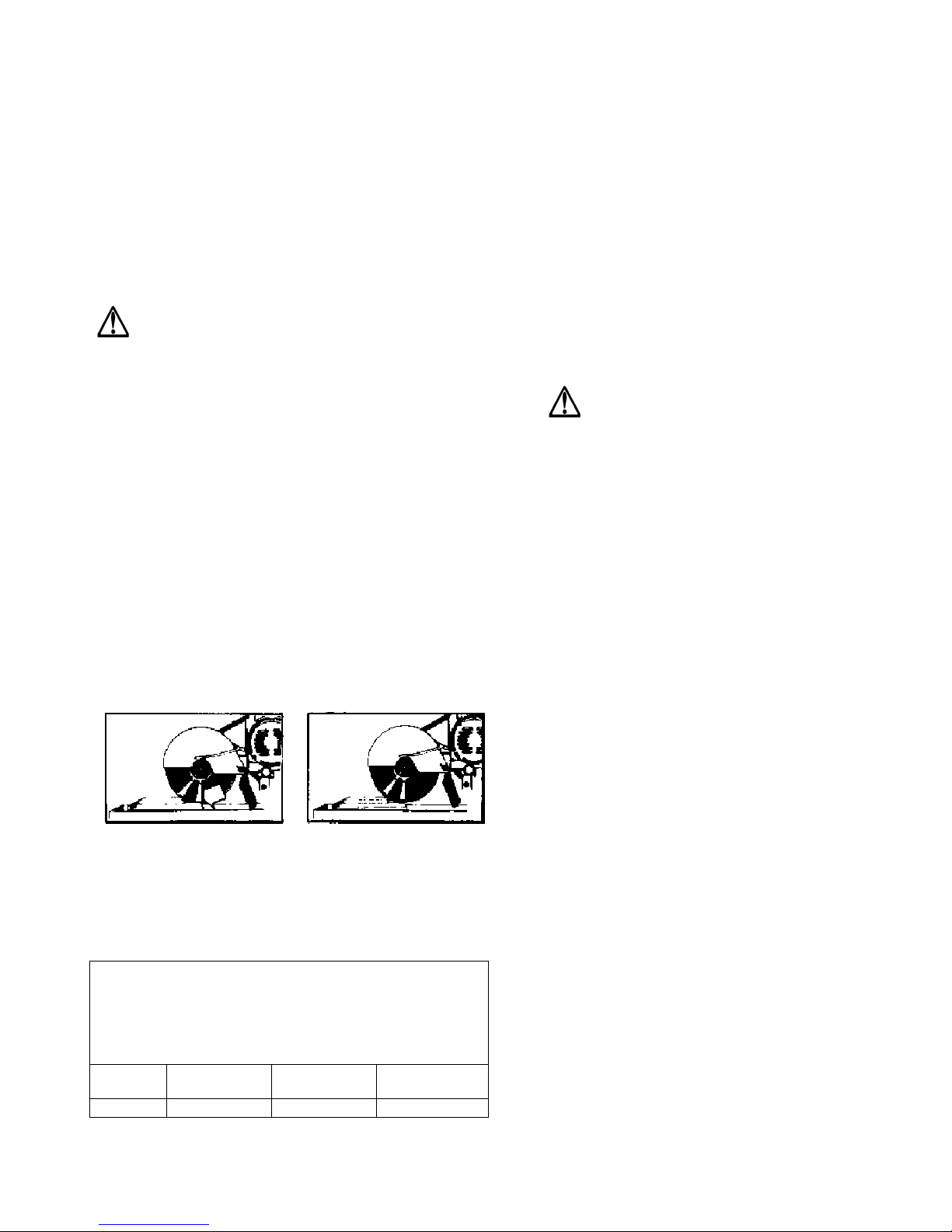

DIAGRAM 1 - PARTS LIST (9/17/03)

DIAG.

LOC. PART

NO. QTY.

REQ. DESCRIPTION DIAG.

LOC. PART

NO. QTY.

REQ. DESCRIPTION

1 161634 1 Stand Weldment 59 161693 1

Rip Guide Assembly

2 161671 2 Rigid Castor 60 020323 1 Capscrew, Hex Hd. 3/8"-16 x 1"

3 161670 2 Swivel Castor 61 169332 1

Blade Guard Assy 10" (Incl. 23-31, 82)

4 021416 16 Capscrew, Hex Hd, 5/16"-18 x 1" 62 169365 1 Guard, Splash

5 020197 16 Locknut, Fiber, 5/16"-18 63 169366 1 Screw, Pan Hd, Self-Tapping, #8 x 3/8"

6 161687 4 Floor Lock 64 020739 1 Washer, Flat #10

7 048740 4 Capscrew, Hex Hd, 3/8"-16x1-1/4" 65 020126 1 Bolt, Carriage, 5/16"-18 x 1-3/4"

8 020199 4 Locknut, Fiber, 3/8"-16 66 020245 1 Locknut, Wing, 5/16"-18

9 161600 1 Frame Weldment 67 169548 1 Blade Guard, 10"

10 161658 2 Pan Stop Assy (Incl.11-12) 68 163248 1 Rubber Strip, Sponge

11 051065 4 Plastic Tabs 69 - - - - - - - - - -

12 197044 4 Latch 70 169564 1

Water Tube Assy, 1/4"Y x 72"

13 020489 2 Screw, Hex Hd, Self-Tapping 1/4"-20x3/4" 71 171032 1 Motor Base

14 161632 1 Lock Bar 72 189661 2 Bearing Cap

15 020373 1 Capscrew, Hex Hd, 5/16"-18 x 1-1/2" 73 020785 4 Lockwasher, Split, 5/16”

16 020197 1 Locknut, Fiber, 5/16"-18 74 020441 4 Capscrew, 5/16"-18 x 1-3/4”

17 161641 1 Wrench, Blade Shaft 15/16" x 9/16" Box 75 052004 1 Blade Shaft Assy (Incl. 58-63)

18 169486 1 Hand Knob, 5/16"-18 x 1" 76 052006 1 Shaft, Blade

19 020763 1 Washer, Flat, SAE 5/16" 77 071110 1 Washer, Spring

20 043260 2 Set Collar 78 071081 2 Bearing, Blade Shaft

21 161661 1 Pan 79 169522 1 Flange, Inner

22 030386 1 Drain Plug 80 169523 1 Flange, Outer

23 161624 2 Rail, Large Outer 81 020176 1 Nut, Thin Hex, 5/8"-18

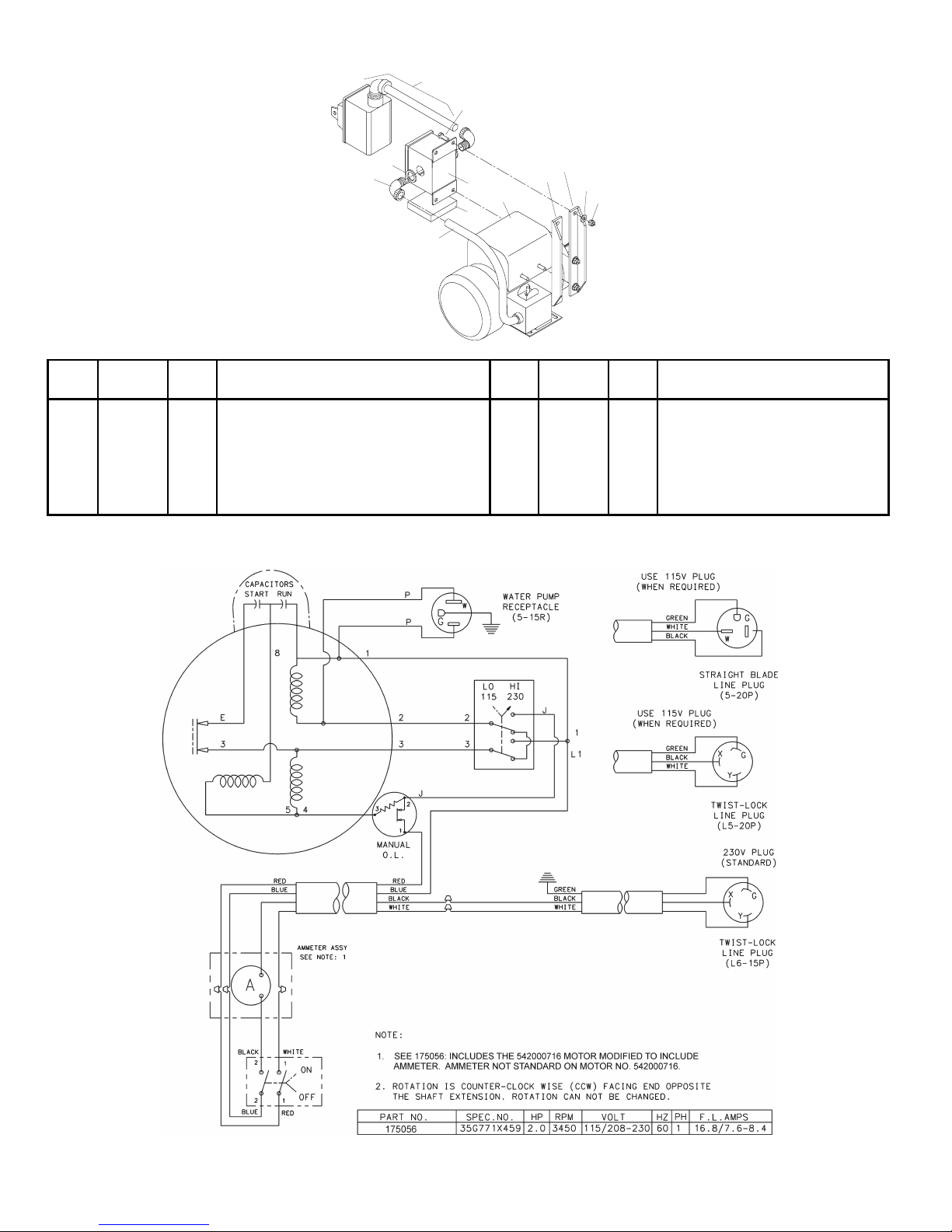

24 161626 2 Rail, Small Inner (Optional) 82 542000605 1 Motor & Switch Assy, 1.5 HP, 115V-230/60/1

25 020301 16 Capscrew, Hex Hd, .25-20 x 5/8” - - 175056 1 Motor & Switch Assy, 2 HP, 115-230V/60/1

26 020195 16 Locknut, Fiber 1/4"-20 (542000716 Modified w/ Ammeter Assy)

27 169635 2 Support, Inner Rail (Optional) - - 161706 1 Motor & Switch Assy, 2 HP

28 161316 1 Water Pump Assembly, 115V/60/1 240/50/1 (542000607 w/ Decals)

- - 050216 1 Water Pump Assembly, 230V/50/1 83 020741 4 Washer, Flat, 1/4"

29 197237 1 Hose Barb 1/4" NPT x 1/4" OD 84 020489 2 Screw, Hex Washer Hd, 1/4"-20 x 3/4"

30 161134 1 Valve, Flow Control 85 021416 4 Capscrew, Hex Hd, 5/16"-18 x 1"

31 - - - - - - - - - - - - - 86 020742 4 Washer, Flat, 5/16"

32 161663 1 Conveyor Cart Assy (Incl. 33-43) 87 020197 4 Locknut, Fiber, 5/16"-18

33 161751 1 Back Stop 88 020060 2 Key, 3/16" Sq. x 1"

34 048740 2 Capscrew, Hex Hd, 3/8"-16x1-1/4" 89 030906 1 Pulley, 2G3V2.25 - .875 w/SS

35 020743 2 Washer, Flat, 3/8" (For 1-1/2HP & 2HP)

36 161662 1 Cart Weldment 90 161696 1

Pulley, Blade Shaft 2G3V2.00 - .625 w/SS

37 030822 4 Wheel, Cart

(For 1-1/2 HP & 2 HP)

38 020763 4 Washer, Flat, SAE 5/16" 91 058020 2 V-Belt, 3VX280

39 032366 4 Nut, KEPS, 5/16"-18 92 169499 1 Mounting Bracket, Belt Guard

40 161622 2 Cutting Board, Cart 93 020370 4 Capscrew, 1/4”-20 x 3/4”

41 020411 12

Machine Screw, Hex Hd, #10-24 x 3/4" 94 020262 4 Washer, Flat, 1/4”

42 020739 12 Washer, Flat #10 95 020195 4 Locknut, Fiber, 1/4”-20

43 020194 12 Locknut, Fiber, #10-24 - - 1 Belt Guard Assy (Incl. 96-102)

44 161666 1 Extension Cart Assembly 96 171013 1 Belt Guard

45 161667 1 Extension Cart Weldment 97 169343 1 Decal: Warning/Caution

46 161623 1 Cutting Board, Ext. 98 021416 1 Capscrew, Hex Hd, 5/16"-18 x 1"

47 020411 4 Machine Screw, Hex Hd, #10-24 x 3/4" 99 020763 1 Washer, Flat, SAE, 5/16"

48 020739 4 Washer, Flat #10 100 020197 1 Locknut, Fiber, 5/16"-18

49 020194 4 Locknut, Fiber, #10-24 101 021423 2 Capscrew, Hex Hd, 1/4"-20 x 1/2"

50 020323 2 Capscrew, Hex Hd, 3/8"-16 x 1" 102 020762 2 Washer, Flat, 1/4"

51 020743 2 Washer, Flat, 3/8" 103 169573 1 Cart Assy, Conveyor (Incl104-108)

52 161707 1 Miter Guide Assy. (Incl. 53-58) in Optional Deluxe Package

53 161650 1 Miter Guide Weldment 104 169576 1 Cart, Conveyor w/ V-Top

54 161655 1 Locking Bolt - - 030049 1 Wheels-Set of 4 (Incl. Items 105 & 106)

55 050106 1 Spring 105 032366 4 Nut, KEPS, 5/16"-18

56 050105 1 Stop 106 030822 4 Wheel, Cart

57 050103 1 Knob, Metal

58 161043 2 Knob