Felker FRS-30 Use and care manual

1

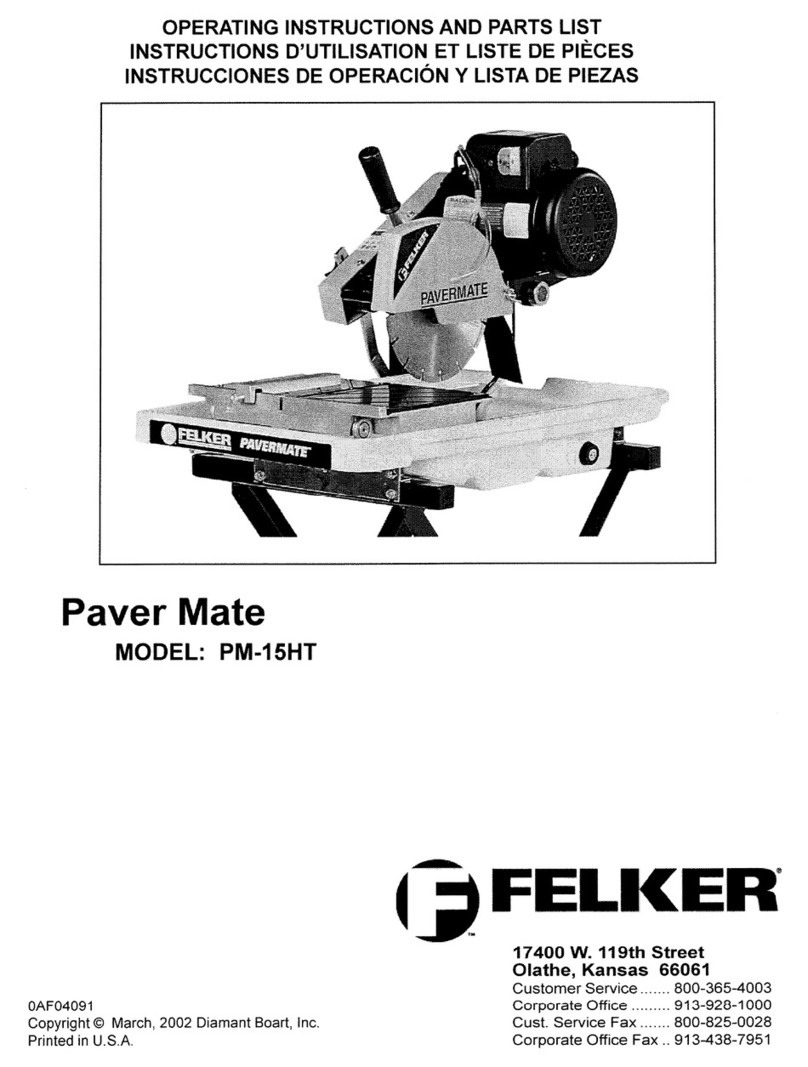

OPERATING INSTRUCTIONS AND PARTS LIST

INSTRUCTIONS D’UTILISATION ET LISTE DE PIÈCES

INSTRUCCIONES DE OPERACIÓN Y LISTA DE PIEZAS

0AF04109

Copyrig t © May, 2002 Diamant Boart, Inc.

Printed in U.S.A.

17400 W. 119t Street

Olat e, Kansas 66061

Customer Service ....... 800-365-4003

Corporate Office ......... 913-928-1000

Cust. Service Fax ....... 800-825-0028

Corporate Office Fax .. 913-438-7951

FELKER RAIL SAWS

FRS-30 FRS-38

FRS-51

2

TABLE DES MATIÈRES

1.0 NORMES POUR LA SECURITE ET LA SANTE

1.1 Symboles ........................................................ 4-6

1.2 Autocollants-descriptions et emplacements .......7

1.3 Normes de sécurité:-Faire Ne faire pas .... 26-27

2.0 INTRODUCTION

2.1 Descriptions de la machine ..............................28

2.2 Plaquettes de sécurité sur la machine .............28

2.3 Systèmes de sécurité .......................................28

2.4 Accessoires standard et optionnels..................29

3.0 CARACTERISTIQUES TECHNIQUES

3.1 Données techniques .........................................29

3.2 Niveau sonore ..................................................29

4.0 INSTALLATION

4.1 Levage et transport...........................................30

4.2 Montage et démontage .............................. 30-31

4.3 Branchement électrique ...................................32

5.0 OPERATIONS POUR LA MISE EN EXERCICE

5.1 Déplacement ....................................................32

5.2 Montage du disque et de la roue à profiler -

utilisée seulement sur le FRS 51......................33

5.3 Marche et arrêt .................................................34

5.4 Modalités d’utilisation ................................. 34-35

6.0 ENTRETIEN

6.1 Conseils et instructions pour l’entretien ...........36

6.2 Entretien ordinaire ............................................36

7.0 RECHERCHE DES PANNES

7.1 Inconvénients causes et remèdes ...................37

DIAGRAMMES e pièces de Rechange

FRS-30 and FRS-38.......................................... 38-39

FRS-51.............................................................. 40-41

GARANTIE .............................................................43

CONTENTS

1.0 SYMBOLS, DECALS & SAFETY WARNINGS

1.1 Symbol Definitions ........................................ 4-6

1.2 Decal Descriptions and Locations .....................7

1.3 Safety Warnings: - DOs & DO NOTs ............ 8-9

2.0 INTRODUCTION

2.1 Description of machine ....................................10

2.2 Safety warnings on the machine .....................10

2.3 Safety systems ................................................10

2.4 Standard equipment and option accessories ..11

3.0 TECHNICAL FEATURES

3.1 Technical data..................................................11

3.2 Noise level .......................................................11

4.0 INSTALLATION

4.1 Lifting system and transport ............................12

4.2 Mounting and Disassembling .................... 12-13

4.3 Electrical connection .......................................14

5.0 STARTING UP

5.1 Moving / placing the machine ..........................14

5.2 Installation of Blade or Profile Wheel -

used only on FRS 51 .......................................15

5.3 Start / Stop operations.....................................16

5.4 How to use the machine ............................ 16-17

6.0 MAINTENANCE

6.1 Advice and maintenance warnings..................18

6.2 Typical maintenance ........................................18

7.0 TROUBLE-SHOOTING

7.1 Problems causes and solutions ......................19

DIAGRAMS and SPARE PARTS

FRS-30 and FRS-38.......................................... 20-21

FRS-51.............................................................. 22-23

WARRANTY ...........................................................25

3

CONTENIDO

1.0 NORMAS PARA LA SEGURIDAD Y LA SALUD

1.1 Definición de los simbolos ................................... 4-6

1.2 Descripción de calcamonias y ubicaciones............ 7

1.3 Advertencias de seguridad: Hacer No Hacer . 44-45

2.0 INTRODUCCION

2.1 Descripción de la máquina ................................... 46

2.2 Placas de seguridad en la máquina ..................... 46

2.3 Sistemas de seguridad ......................................... 46

2.4 Accesorios estándar y opcionales ........................ 47

3.0 CARACTERISTICAS TECNICAS

3.1 Datos técnicos ...................................................... 47

3.2 Nivel de ruido........................................................ 47

4.0 INSTALACION

4.1 Elevación y transporte .......................................... 48

4.2 Montaje y desmontaje ..................................... 48-49

4.3 Conexión eléctrica ................................................ 50

5.0 OPERACIONES PARA LA PUESTA EN SERVICIO

5.1 Desplazamiento .................................................... 50

5.2 Montaje del disco y de la rueda perfiladora -

utilizada solamente en FRS 51 ............................ 51

5.3 Arranque y parada ................................................ 52

5.4 Modo de empleo .............................................. 52-53

6.0 MANTENIMIENTO

6.1 Consejos y advertencias para el

mantenimiento ...................................................... 54

6.2 Mantenimiento ordinario ....................................... 54

7.0 LOCALIZACION DESPERFECTOS

7.1 Inconvenientes causas y soluciones ................... 55

DIAGRAME Y PIEZAS DE REPUESTO

FRS-30 and FRS-38 ....................................................... 56-57

FRS-51............................................................................. 58-59

GARANTIA DE LA MAQUINA . ........................................... 61

4

Symbol Defini ions

Symboles

Definición De Los Simbolos

• Please read the instructions for use prior to operating the machine for the first time.

• Avant toute mise en service lire attentivement la notice et se familiariser avec la machine.

• Antes de la puesta en marcha lea detenidamente las instrucciones y familiaricese con la máquina.

• Mandatory

• Obligatoire

• Obligatorio

• Indication

• Indicazione

• Indicación

• Prohibition

• Interdiction

• Prohibición

• Warning Triangle

• Triangle d’advertissement

• Triángwulo De Advertencia

• Wear Eye Protection

• Port obligatoire des lunettes de protection

• Usar Gafas De Protección

• Wear Head Protection

• Port Obligatoire Du Casque Et Des Écouteurs

• Usar Casco De Protección

• Wear Breathing Protection

• Port obligatoire d’un masque respiratoire protecteur

• Usar Máscara De Protección

• The Use Of Ear Protection Is Mandatory

• Port obligatoire da casque antibruit

• Es Obligatorio El Uso De Protección Auditiva

• Wear a Hard Hat

• Port Obligatoire Da Casque Antibruit

• Usar Casco Duro

• Wear Safety Shoes

• Port obligatoire des chaussures de sécurité

• Usar Zapatos De Seguridad

• Wear Appropriate Clothing

• Port obligatoire de la tenue appropriée

• Usar Ropa Adecuada

• Remove The Blade Prior To Hoisting Loading Unloading And Transporting The Machine On Jobsite.

• Démontage Obligatoire Du Disque En Cas D’élingage De Chargement De Déchargement Et DeTransport

Sur Le Chantier.

• Desmontar El Disco Antes De Desplazar Cargar Descargar O Transportar La Máquina En La Obra.

5

• Motor Off

• Arrêt Du Moteur

• Parar El Motor

• Use In Well Ventilated Area

• A Utiliser Dans Un Endroit Bien Ventilé

• Usar En Una Área Bien Ventilada

• Do Not Use In Flammable Areas

• Ne Pas Utiliser Dans Des Ambiances Comportant Un Risque D’incendie

• No Usar In Áreas Inflamables

• Machinery Hazard Keep Hands And Feet Clear.

• Danger! Rester À Distance De La Machine

• Máquina Peligrosa - Mantenga Manos Y Pies Alejados De La Máquina

• No Non-working Personnel In Area

• Zone Interdite Au Personnel Non-Ouvrier

• Prohibido Para Personas Ajenas A La Obra

• No Smoking

• Défense De Fumer

• No Fumar

• Do Not Operate Without All Guards In Place

• Ne Pas Utiliser Avant D’avoir Installé Toutes Les Protections

• No Operar Sin Todas Las Protecciones In Su Sitio

• Always Keep the Blade Guards In Place

• Toujours Vérifier Que Les Protections De Disque Sont Bien En Place

• Mantenga Siempre Las Protecciones De La Hoja En Su Sitio

• Keep Work Area Clean/Well Lit Remove All Safety Hazards

• La Zone De Travail Doit Toujours Être Propre Bien Éclairée Et Ne Présenter Aucun Risque

• Mantenga Limpio El Sitio De Trabajo/Bien Iluminado Elimine Todos Los Riesgos De Seguridad

• Dangerously High Noise Level

• Niveau De Bruit Dangereux

• Nivel De Ruido Elevadamente Peligroso

• Pay Extreme Attention To The Care And Protection Of The Machine Before Starting Up

• Accorder Une Très Grande Attention Á La Sécurité Et À La Préparation De La Machine Avant

De Commencer À Travailler

• Ponga Extrema Atención Al Cuidado Y Preparación De La Máquina Antes De Ponerla En Marcha

• Remove Tools From Area and Machine

• Enlever Les Outils De La Zone De Travail Et De La Machine

• Elimine Las Herramientas Del Área Y De La Máquina

• Electrical Switch - OFF

• Interrupteur électrique-arrêt

• Conmutador De Apagado Eléctrico

• Electrical Switch - ON

• Interrupteur électrique-marche

• Conmutador De Encendido Eléctrico

• Electrical Switch - Start

• Interrupteur électrique-démarrage

• Conmutador De Arranque Eléctrico

6

• Diamond Blade

• Disque diamanté

• Sierra Diamantada

• Blade Diameter

• Diamètre De Disque

• Diámetro De La Hoja

• Pulley Diameter

• Diamètre De Poulie

• Diámetro De La Correa

• Number of Revolutions Per Minute Rotational Speed

• Nombre De Tours/Minutes Vitesse De Rotation

• N° De Revoluciones Por Minuto Velocidad De Rotación

• Blade Flange Diameter

• Diamètre Du Flasque De Disque

• Diámetro De La Brida De La Hoja

• Blade Cutting Depth

• Profondeur De Coupe Du Disque

• Profundidad De Corte De La Hoja

• Machine Mass (lbs)

• Poids De La Machine (en lbs)

• Masa De La Máquina (lbs)

• Electric Motor

• Moteur Électrique

• Motor eléctrico

WARNING

HEARING HAZARD

DURING NORMAL USE OF THIS MACHINE OPERATOR MAY BE EXPOSED TO A NOISE

LEVEL EQUAL OR SUPERIOR TO 85 dB (A)

ATTENTION!!!

RISQUE DE LÉSION POUR L’OUÏE.

DANS DES CONDITIONS NORMALES D’UTILISATION CETTE MACHINE PEUT COM-

PORTER UNE EXPOSITION ACOUSTIQUE D’UN NIVEAU ÉGAL OU SUPÉRIEUR À

85 DB (A) POUR L’OPÉRATEUR PRÉPOSÉ.

ATENCION

RIESGO DE DAÑO AUDITIVO

EN CONDICIONES NORMALES DE UTILIZACIÓN EL OPERADOR DE ESTA MÁQUINA PUEDE

ESTAR EXPUESTO A UN NIVEL DE RUIDO IGUAL O SUPERIOR A 85 dB (A)

• Repairs Are To Be Done By An Authorized Dealer Only

• Les réparations ne peuvent être exécutées que par un distributeur agréé

• Las Reparaciones Deben Ser Efectuadas Únicamente Por Un Distribuidor Autorizado

7

DECAL DESCRIPTIONS & LOCATION

SYMBOLES

DESCRIPCIÓN DE CALCAMONIAS Y UBICACIONES

187043 (1) Decal Locations:

FRS-30 Control Box

FRS-38 Control Box

FRS-51 Cutting Head

193022 (1) Decal Location:

Corner of Blade Guard

193020 (3) FRS-38 Decal Locations:

Both Sides of Water Tank

Operator End of Water Tank

193019 (3) FRS-30 Decal Locations:

Both Sides of Water Tank

Operator End of Water Tank

193021 (3) FRS-51 Decal Locations:

Both Sides of Water Tank

Operator End of Water Tank

8

DO read this entire operator’s manual before operating this machine. Understand all warnings instructions and controls.

DO keep all guards in place and in good condition.

DO wear safety approved hearing eye head and respiratory protection.

DO read and understand all warnings and instructions on the machine.

DO read and understand the symbol definitions contained in this manual.

DO keep all parts of your body away from the blade and all other moving parts.

DO know how to stop the machine quickly in case of emergency.

DO turn the “ON/OFF” switch to the “OFF” position prior to connecting the machine to the power source.

DO inspect the blade flanges and shafts for damage before installing the blade.

DO use the blade flange size shown for each blade size.

DO use only the blade flanges supplied with the saw. Never use damaged or worn blade flanges.

DO use only blades marked with a maximum operating speed greater than the blade shaft speed. Verify speed by checking

blade shaft rpm and pulley diameters and blade flange diameters.

DO verify saw drive configuration by checking blade shaft RPM pulley diameters and blade flange diameter.

DO read all safety materials and instructions that accompany any blade used with this machine.

DO inspect each blade carefully before using it. If there are any signs of damage or unusual wear DO NOT USE THE

BLADE.

DO mount the blade solidly and firmly. Wrench tighten the arbor nut.

DO make sure the blade and flanges are clean and free of dirt and debris before mounting the blade on the saw.

DO use the correct blade for the type of work being done. Check with blade manufacturer if you do not know if blade is

correct.

DO use caution and follow the instructions when loading and unloading the machine.

DO operate this machine only in well ventilated areas.

DO instruct bystanders on where to stand while the machine is in operation.

DO establish a training program for all operators of this machine.

DO clear the work area of unnecessary people. Never allow anyone to stand in front of or behind the blade while the motor

is running.

DO make sure the blade is not contacting anything before starting the motor.

DO use caution when lifting and transporting this machine.

DO always tie down the machine when transporting.

DO use caution and follow instructions when setting up or transporting the machine.

DO have all service performed by competent service personnel.

DO make sure electric powered machines are plugged into a properly grounded circuit.

DO make sure power cords are the proper size and in good condition.

DO maintain a secure grip on the material being cut.

DO clean the water tray frequently.

DO verify the blade arbor hole matches the machine spindle before mounting the blade.

DO clean the machine after each day’s use.

DO follow all electrical codes in your area.

DO consider work area environment. Don’t expose power tools to rain. Don’t use power tools in wet locations.

DO use caution to guard against electric shock. Prevent body contact with grounded surfaces (i.e. pipes radiators ranges

refrigerators).

DO use correct voltage and proper extension cords. Never carry tool by cord or yank it to disconnect it from receptacle. Keep

cord away from heat oil and sharp edges.

DO always carry the machine with the motor stopped.

DO disconnect tools from power source when not in use before servicing and when changing accessories.

DO carefully maintain and clean for better and safer performance. Follow instructions for changing accessories. Inspect tool

cords periodically and if damaged have repaired by authorized service facility.

DO only cut in a straight line.

DO only saw as deep as the job specifications require.

DO always give a copy of this manual to the equipment user. If you need extra copies call TOLL FREE 1-800-365-4003.

SAFETY FIRST!

WARNINGS

DO’s AND DO NOT’s

WARNING: FAILURE TO COMPLY WITH THESE WARNINGS AND OPERATING

INSTRUCTIONS COULD RESULT IN DEATH OR SERIOUS BODILY INJURY.

DO

9

DO NOT operate this machine unless you have read and understood this operator’s manual.

DO NOT operate this machine without the blade guard or other protective guards in place.

DO NOT stand behind or in front of the blade path while the motor is running.

DO NOT leave this machine unattended while the motor is running.

DO NOT operate this machine when you are tired or fatigued.

DO NOT use a wet blade without adequate water supply to the blade.

DO NOT exceed maximum blade speed shown for each blade size. Excessive speed could result in blade breakage.

DO NOT operate the machine if you are uncertain of how to run the machine.

DO NOT use damaged equipment or blades.

DO NOT touch or try to stop a moving blade with your hand.

DO NOT cock jam wedge or twist the blade in a cut.

DO NOT transport a cutting machine with the blade mounted on the machine.

DO NOT use a blade that has been dropped or damaged.

DO NOT use carbide tipped blades.

DO NOT use abrasive blades.

DO NOT use conventional abrasive blades with water.

DO NOT touch a dry cutting diamond blade immediately after use. These blades require several minutes to cool after

each cut.

DO NOT use damaged or worn blade flanges.

DO NOT allow other persons to be near the machine when starting or when the machine is in operation.

DO NOT operate this machine in an enclosed area unless it is properly vented.

DO NOT operate this machine in the vicinity of anything that is flammable. Sparks could cause a fire or an explosion.

DO NOT allow blade exposure from the guard to be more than 180 degrees.

DO NOT operate this machine with the belt guard or blade guard removed.

DO NOT operate this machine unless you are specifically trained to do so.

DO NOT use a blade that has been over heated (Core has a bluish color).

DO NOT jam material into the blade.

DO NOT grind on the side of the blade.

DO NOT lay power cords in or near the water.

DO NOT replace the motor with any motor that does not have a special grounding connection.

DO NOT cut deeper than 1" per pass with a dry blade. Step out to achieve deeper cuts.

DO NOT start cutting with a saw until you have a clear work area and secure footing.

DO NOT operate this machine while using drugs or alcohol.

*****************

This saw was designed for cer ain applica ions only. DO NOT modify his saw or use for any applica ion o her han

for which is i was designed. If you have any ques ions rela ive o i s applica ion, DO NOT use he saw un il you

have wri en Diaman Boar , Inc. and we have advised you.

Diaman Boar , Inc.

17400 Wes 119 h S ree

Ola he, Kansas 66061

In USA 1-800-365-4003

SAFETY FIRST!

WARNINGS

DO’s AND DO NOT’s

WARNING: FAILURE TO COMPLY WITH THESE WARNINGS AND OPERATING

INSTRUCTIONS COULD RESULT IN DEATH OR SERIOUS BODILY INJURY.

DO NOT

10

2.0 INTRODUCTION

2.1 DESCRIPTION OF MACHINE

Thank you for choosing one of our machines.

The manufacturer designs and produces duarble and

reliable machines to solve all cutting processes.

FELKER RAIL SAWS are available in a range of mod-

els to cut material upto 51” in . They can be placed in-

side factories or used directly on building yards.

These rail saws are designed to use diamond blades to

cut marble or granite pieces with dimension size and

weight allowed by machines’ structure.

Location and name of principal components (Fig.1)

1) Blade Guard

2) Guide Bars

3) Control Switch Box

4) Water Tank

5) Water Pump

6) Handwheel to adjust cutting depth - FRS-51

7) Table Legs

8) Tilting Bridge 0°- 45°

2.2 SECURITY WARNINGS ON THE MACHINE

The decals on the machine must always be kept clean

and in a readable condition.

The safety warning decals are fixed on the blade guard

as shown on page 7.

2.3 SAFETY SYSTEMS

-Blade Guard: a protection device that avoids acci-

dental contacts with the blade.

It is obligatory to have this device securely mounted

before the machine is turned on.

-Overload pro ec ion: the overload protection stops

the motor in case of overload. Wait a few minutes

before turning the motor on again.

-Con rol Swi ch: easy access to the Start- Stop but-

tons. In case of interruption of electrical power saw

will remains OFF until Start button is again engaged.

This prevents the saw from turning on accidentally

when electrical power is restored.

Fig. 1

1

23

4

5

6

7

8

11

MODEL FRS 30 FRS 38 FRS 51

Power - HP 1.5 1.5 2

Supply voltage - Vac 115 115 230

Supply frequency - Hz 60 60 60

Phase 1 1 1

Full load amps - A 14.4 14.4 8.3

Blade motor - rpm 3400 3400 1700

Blade capacity - in. (mm) 10 (250) 10 (250) 14 (350)

Arbor size - in. (mm) 5/8 (15.9) 5/8 (15.9) 1 (25.4)

Length of Cut - in. (mm) 30 (750) 38 (950) 51 (130)

Depth of Cut at 90° - in. (mm) 2.6 (65) 2.6 (65) 4.1 (105)

Depth of Cut at 45° - in. (mm) 1.2 (30) 1.2 (30) 2.4 (60)

Cutting table 36.5 x 17.3 44.5 x 17.3 60 x 22.5

L x W - in. (mm) (930 x 440) (1130 x 440) (1520x 570)

Side extension 12.1 x 11 12.1 x 11 15.7 x 13.8

L x W - in. (mm) (310 x 280) (310 x 280) (400 x 350)

Saw dimension w/Leg & extension 48.4 x 30.7 x 47.2 56.3 x 30.7 x 47.2 66.9 x 39.4 x 50.8

L x W x H - in. (mm) (1230x780x1200) (1380x780x1200) (1750x1000x1290)

Saw Weight uncrated - lb (kg) 145.5 (66) 154.3 ( 70) 317.2 (144)

Crated weight - lb (kg) 170 (77) 181 (82) 350.5 (159)

3.0 TECHNICAL FEATURES

3.1 TECHNICAL DATA

2.4 STANDARD EQUIPMENT AND

OPTION ACCESSORIES

S andard Equipmen :

• Open End 30mm Wrench to change the blade

• Rip Fence

• Side Extension Table

Documen equipmen :

• Instruction manual

3.2 NOISE LEVEL

Noise produced from the machine on its own is less

than 70dB (A).

General noise level could INCREASE when:

• multiple saws are in the surroundings

• saw is inside of a building

• materials are being cut; some material types produce

more noise than others

• with use of improper acoustic safety devices.

Noise level could DECREASE by:

• reducing the speed rate of cut

• always using blades that are in good condition

• using silent core or StealthTM Blades.

NOTE:

Acoustic pressure over 85 dB (A) could be dangerous

for your hearing health it is recommended to always

use an approved hearing safety device while operating

the saw.

12

4.0 INSTALLATION

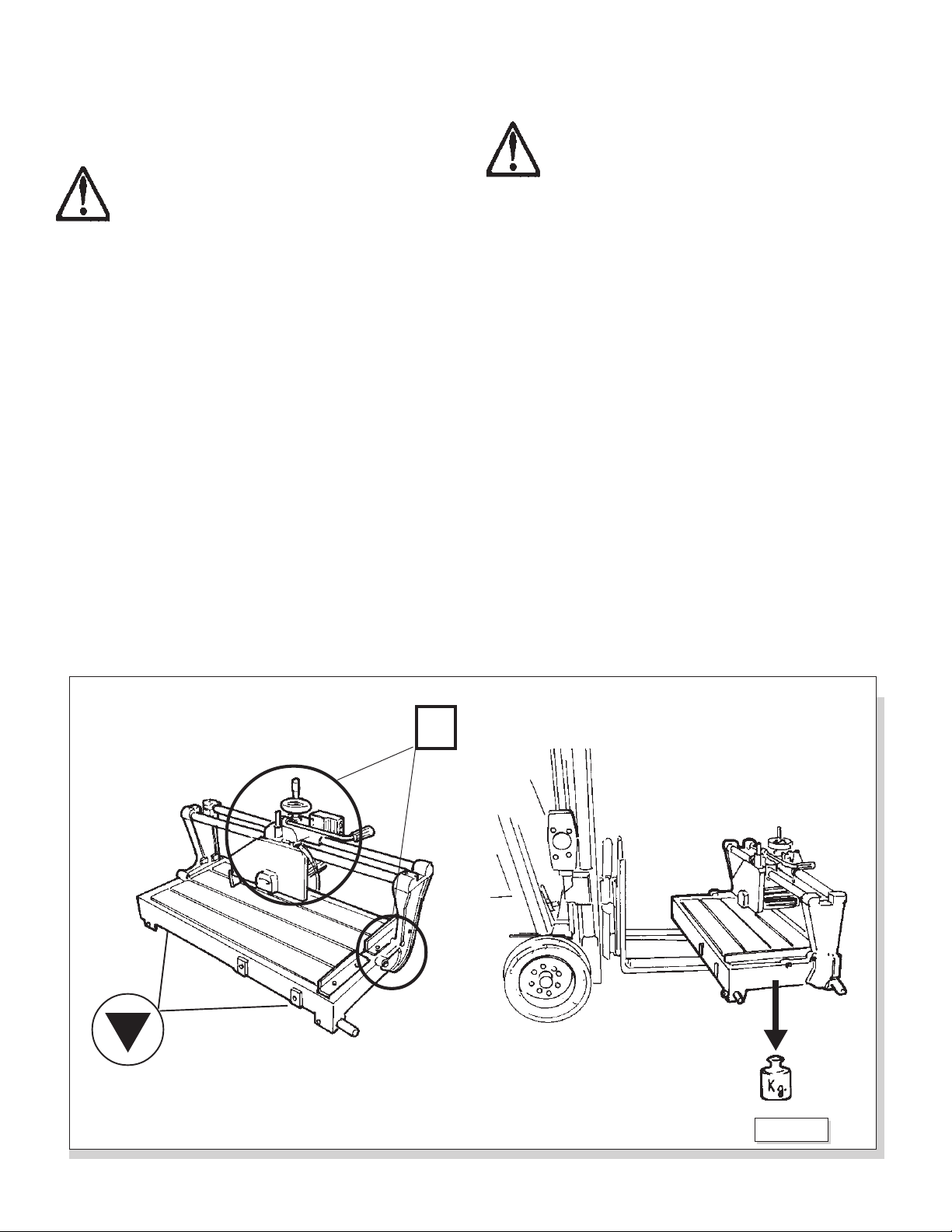

4.1 LIFTING SYSTEM AND TRANSPORT

Unpack he machine and check ha no par s

are missing or damaged. In case par s are

damaged during shipping, immedia ely con-

ac he carrier and manufac urer.

• Check ha lif ing device used is adequa e o carry

he weigh of he machine. See char in 3.1

Techinical Da a.

• Avoid lif ing he machine over persons or hings

ha could ge seriously hur or damaged in case

of i em falling.

• Before any lif ing opera ions always announce i

o hose around.

• Before lif ing he machine, always be sure ha

head is blocked in he cen er of he Guide Bars

using he Limi Rings, I (Ref. 4.2, Fig. 4).

To reduce volume and make transport/lifting operations

easier dismount all four legs.

The machine is packed inside a carton box.

The machine is to be lifted by a forklift placing it as

shown on Fig. 2.

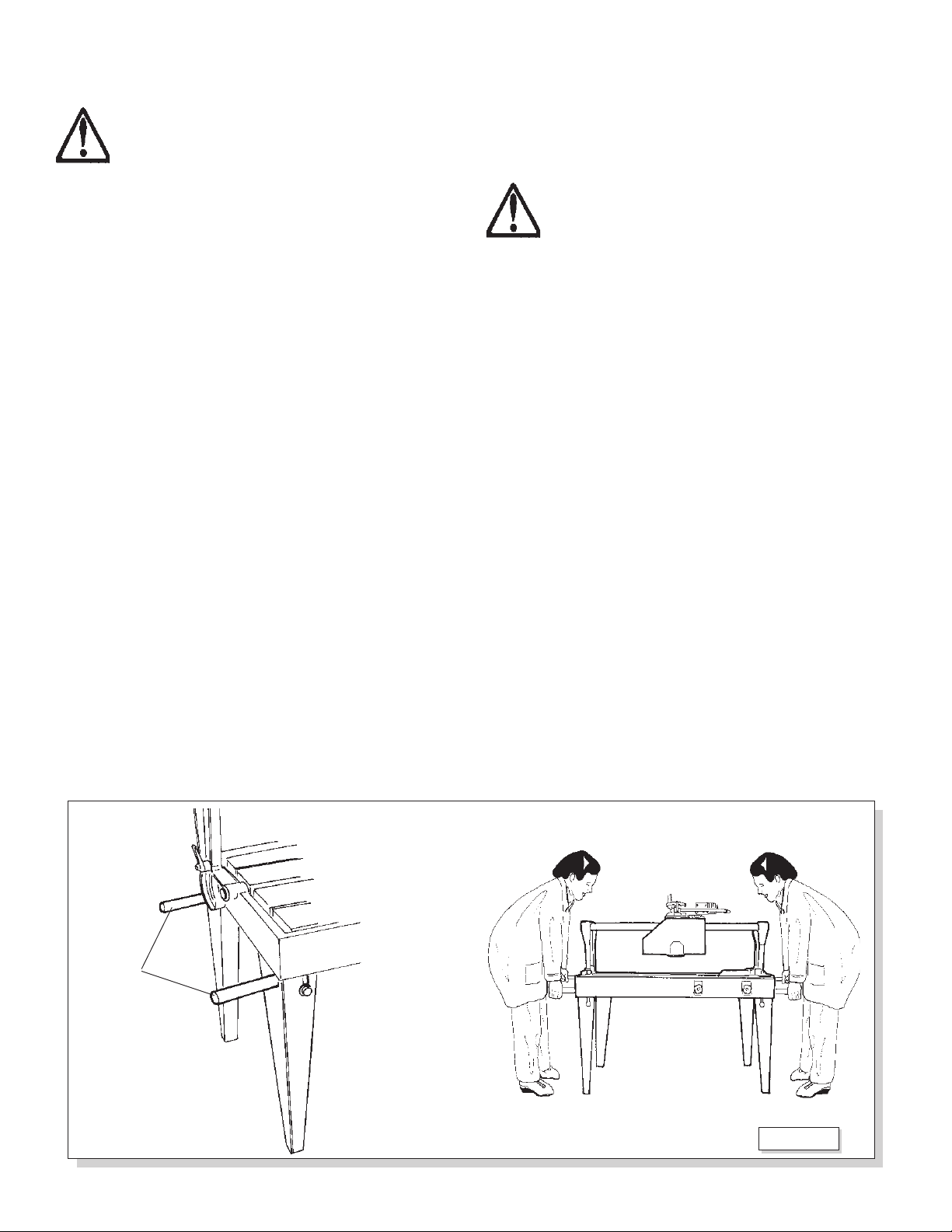

4.2 MOUNTING AND DISASSEMBLING

All moun ing and disassembling opera ions

mus be done wi h machine “OFF” and un-

plugged.

• Proceed wi h moun ing and disassembling opera-

ions very carefully wearing safe y gloves and

proper foo wear.

• Before placing the machine on the floor keep it on

the forklift and screw on the legs with its

proper key A+B (Fig. 3).

• Lower the arms of the forklift and set the machine

carefully on the floor.

• Install the side table extension C (Fig. 3) and tighten

the knobs D (Fig. 3).

• Mount the fence on side part F+E (Fig. 3) and hold it

with proper Lever Knob G (Fig. 3).

Fig. 2

Locked

Lift points

13

• Unblock the head by loosening the knobs I (Fig. 4)

and sliding the two limit rings L (Fig. 4) to the end of

the Guide bars.

• Replace the screws M (Fig. 5) of the tilting bridge N

(Fig. 5) with the M10 lever knobs O (Fig. 5) supplied

loose with the machine.

Fig. 4

L

L

II

Fig. 3

A

B

B

E

D

F

G

Fig. 5

ON

M

C

14

4.3 ELECTRICAL CONNECTION

• ONLY a qualified elec rician should con-

nec he machine o he fac ory elec ric

power supply per local elec rical codes.

• All ground wires mus be properly con-

nec ed.

• Machine MUST be connec ed o elec rical

supply of he same power as he require-

men s indica ed on mo or ID pla e or see 3.1

Technical Da a.

The machine is equipped with a 3 meter long Power

Cord and Plug.

In case the machine is placed inside a factory install a

properly sized magnetic circuit breaker and protect for

the wiring as required by local codes.

When the the machine is used on temporary job sights

connect the machine to power source outlets with the

plug installed on the machine respecting local safety

regulations.

5.0 STARTING UP

5.1 MOVING – PLACING THE MACHINE

• Before moving he machine, disconnec i

from he elec rical power supply.

• Always use cau ion when moving he ma-

chine o preven damage or personal injury.

Before moving the machine manually:

- Slide the head to the center of Guide Bars so the

weight is balanced

- Secure the head by tightening the knobs of the 2

limit rings

- Make sure that lever knobs locking the tilting bridge

of the machine are tight.

- Empty the water tank.

- Pull out the lift handles A (Fig. 6) from under the

table and carefully lift to a minimum height to move

the machine.

Two or four men can move the machine (Fig. 6) (de-

pending on the weight).

Fig. 6

A

15

Fig. 7

A

B

C

DE

F

5.2 INSTALLATION OF THE BLADE

OR PROFILE WHEEL- USED ONLY ON FRS 51

• ALWAYS urn off he machine and discon-

nec he power source before ins alling or

replacing he blade.

• ONLY use correc size ools for ins alling

Blade.

• ONLY use good quali y diamond blades

according o machines fea ures and for he

ma erial o be cu .

• Always use he required blade diame er

because i affec s he maximum cu ing

dep h and he useful cu ing leng h.

• Be sure he diamond blade is correc ly

balanced and ensioned and is properly

igh ened on arbor.

• Avoid cu ing pieces of ma erial ha are

oo big, oo small, or difficul o se prop-

erly on working able.

• The blade life depends on its daily use type and thick-

ness of piece to cut and proper water flow to keep it

cool.

• The blade should be replaced whenever the cutting

quality is not optimal because it could be worn out or

deformed. Operating with a worn out or defective

blade could be dangerous.

• Replace the blade or install the profile wheel by stand-

ing in front of the machine as follows.

1. Tilt the blade 45° and loosen the 2 screws A (Fig. 7)

behind the blade guard with a 10mm wrench and re-

move the guard B (Fig. 7).

2. Hold the motor spindle C (Fig. 7) and unscrew the blade

shaft nut (CW) clockwise using the 30mm wrench D

(Fig. 7) supplied (only on FRS 51). For the FS-30 &

38 hold the motor shaft from turning with a 6mm hex

key inserted into the back side of the motor and loosen

the nut (CW) with a 19mm wrench.

3. Once the blade is removed check the outer flange E

(Fig. 7) and inner flange interior surfaces and if needed

replace or clean them to remove any debris that might

prevent the blade from properly seating inside the

flanges.

No e: When using the thick-cored profile wheel on the

FRS 51 do not use the outer flange E (Fig. 7).

4. Mount the new blade in the direction of the rotation

arrow marked on the blade F (Fig. 7). It must be the

same direction as the arrow on the blade guard. (clock-

wise from the front).

5. After installing the new blade or profile wheel be sure

to securely tighten the nut counter-clockwise with the

correct wrench while holding the motor spindle.

6. Before using he machine be sure he blade guard

is securely in place. Re-install the blade guard B (Fig.

7) and securely tighten the 2 screws A (Fig. 7) using an

M10 wrench.

16

5.3 START / STOP OPERATIONS

Your machine is equipped with an electrical control box

complete with a magnetic ON-OFF switch composed

of 2 buttons with the following functions (Fig. 8):

(A) RED button: STOP

(B) GREEN button: START

NOTE:

If the electrical power is interrupted the machine will

remain “OFF” when power is restored until operator

again pushes the START button.

5.4 HOW TO USE THE MACHINE

• Before s ar ing he machine, be sure ha

blade and blade guard are securely igh -

ened.

• Se he machine where no hing danger-

ous is around i ha can in erfer wi h cu -

ing opera ions.

• Connect the machine to a properly protected and

grounded power outlet.

• Before starting the machine install the drain plug into

the hole located in the bottom ot he water tank. Fill

the tank with clean water until it fully covers the water

pump. Also flush tank and hoses with clean water to

remove debris after cutting each day.

• Place the material to cut against the fence and in line

with cutting plane of the blade.

• Lower/raise the handwheel C (Fig. 9) to adjust cut-

ting height (FRS-51 only).

• Never place hands along cu ing line of blade

opera ion.

• To turn on the blade motor and water pump push

the “green” start button D (Fig. 9). Both the blade

motor and water pump will start.

• Before s ar ing he cu ing opera ions, check for

adequa e wa er flow o he blade. Make adjus men

o flow valve E (Fig. 9) as needed.

The pump MUST ALWAYS work wi h sufficien wa er

in he ank (Pump should be fully submerged.) Wa er

is used o cool he pump and he cu ing blade.

Wi hou wa er, bo h could fail and be permanen ly

damaged.

• Pull handle F (Fig. 9) carefully to advance the cutting

blade to and through the material.

Fig. 9

CD

F

E

Fig. 8

B

A

17

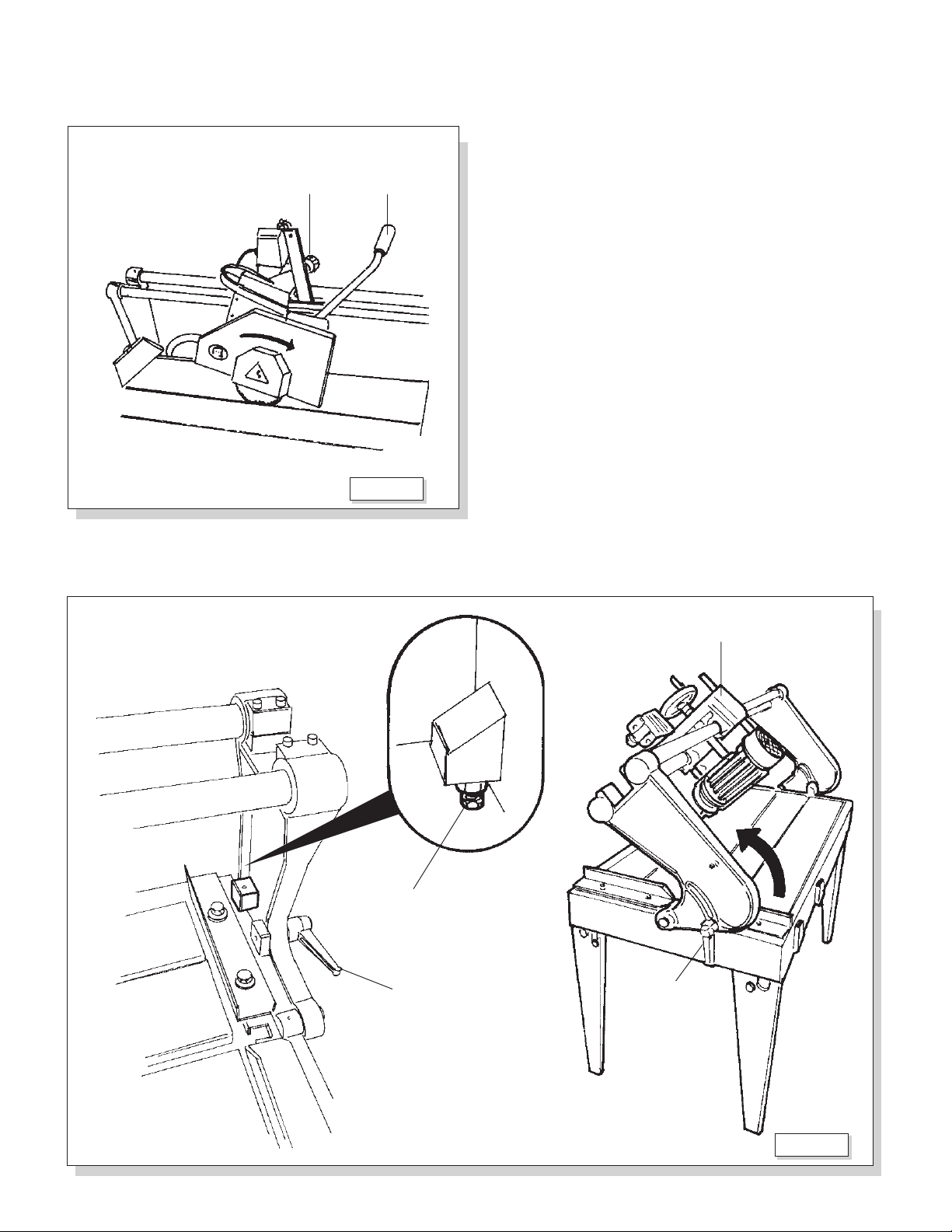

• On Models FRS-30 and FRS-38 you must pull the

handle G (Fig. 10) downwards to set depth of cut and

lock in position by tightening Knob H (Fig. 10).

• Carefully pull handle F (Fig. 10) & G (Fig. 10) to ad-

vance the cutting blade through the material.

• Make the cuts from left to right with the material with

the material up against the backstop on the far right

of the table.

• To tilt the head J (Fig.11) 0°- 45° loosen the two

side lever handles K (Fig. 11). Adjust to the angle

needed and tighten the lever handles again.

NOTE:

To accurately set 0° tilt adjust the micrometric screws

L (Fig. 11).

Fig.10

G

H

Fig.11

J

K

L

K

18

6.0 MAINTENANCE

6.1 ADVICE AND MAINTENANCE WARNINGS

• Before any service on he machine AL-

WAYS disconnec i from he elec rical

source.

• Never use flammable produc s o clean

he machine.

• All services no described in his manual

mus be effec ed ONLY by qualified person-

nel.

• ALWAYS use proper safe y equipmen .

6.2 TYPICAL MAINTENANCE

DAILY:

• To keep the machine in good conditions clean follow-

ing:

- floor surrounding

- machines’ components

- water tank

- water pump E (Fig. 12) inlet.

• Grease sliding guides at grease fittings A (Fig. 12)

using a manual grease gun B (Fig. 12)

Recommended Grease: General purpose #2 Lithum

based grease without molybedenum disulfide.

EVERY 2 WEEKS:

• Put grease on the vertical screw C (Fig. 12) using a

small brush D (Fig. 12)

Recommended Grease: General purpose #2 Lithum

based grease without molybedenum disulfide.

Fig.12

C

B

A

ED

19

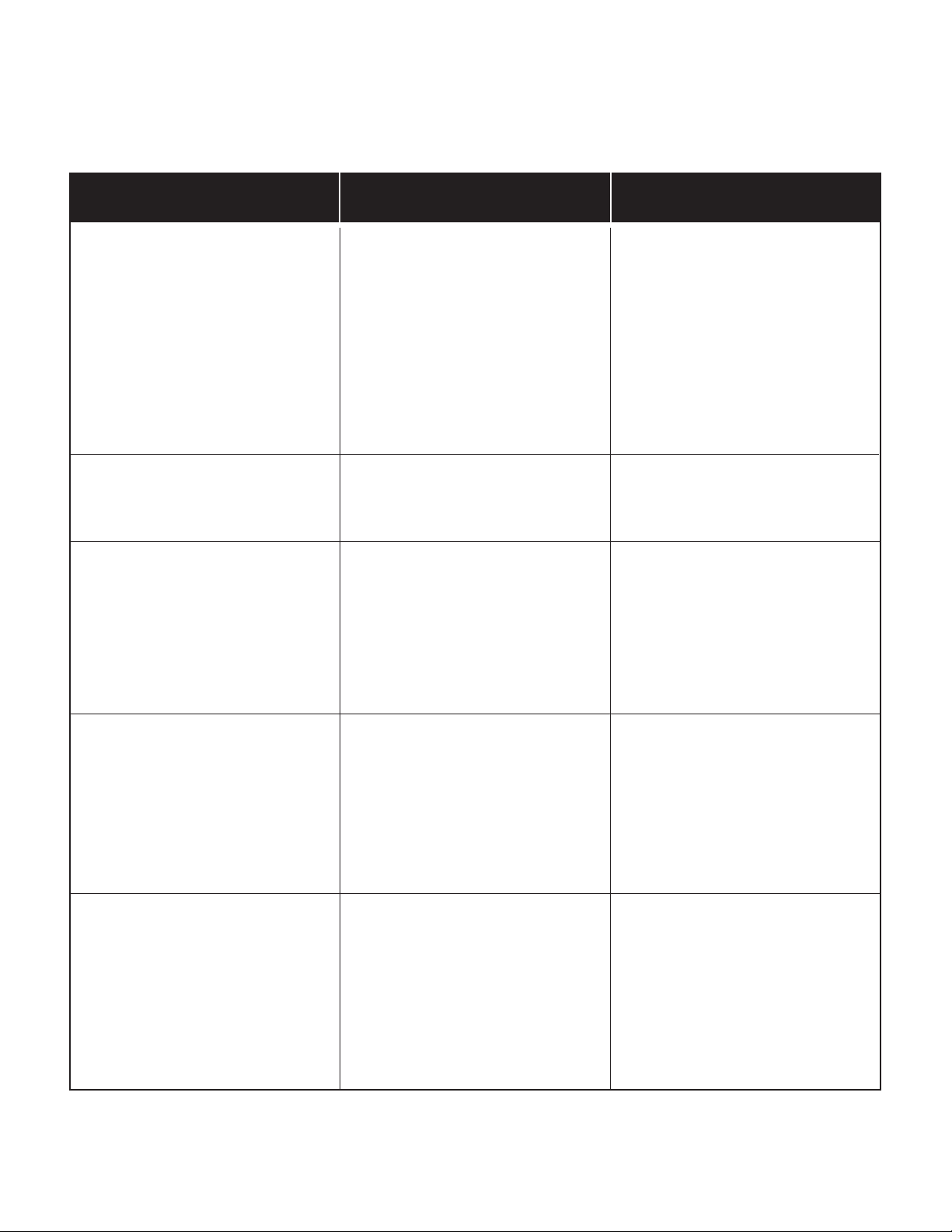

7.0 TROUBLE-SHOOTING

7.1 PROBLEMS, CAUSES AND SOLUTIONS

After pushing the START button the

machine remains off.

The saw motor doesn’t rotate.

The saw motor loses power or stalls

while cutting.

The blade motor works but insufficient

or no water flows over the blade.

Material cut is chipped when finished

cutting.

A)No electricity.

B)Electric wire or switch damaged

C)Fuses on electric line are burnt

D)Machine not connected to correct

voltage required.

A)Wrong voltage

B) Bad Motor capacitor.

A)Cutting feed rate is too fast

B)Blade is dull or worn out.

C)Voltage is too low.

A)Water hoses and connections are

dirty.

B)Water hose has kink.

C)Insufficient water level for the

pump.

D)Filter of water pump is dirty

A)Diamond blade out of tension bent

or using incorrect blade for the ma-

terial.

B)Feed rate too fast at end of cut.

C)Blade not fully penetrating through

the material.

A)Check: electrical connections cir-

cuit protection device magnetic

switch inside control box.

B)Repair or replace by qualifiied

electricain

C)Check fuses inside electric box

D)Require assistance.

A)Check electrical connection.

B)Replace by qualified electrician.

A)Reduce cutting speed.

B)Open blade to expose diamonds

or replace blade.

C)Extension cord may be too long.

Or have electric power checked by

qualified electrician.

A)Flush hoses and connection parts

with clear water to clean

B)Straighten or replace hose.

C)Add water to correct level.

D)Clean filter of water pump

A)Replace with new correct blade

B)Slow the feed rate near end of cut.

C)Increase depth of cut. Blade

should extend about 1/4” beneath

table surface.

PROBLEMS CAUSES SOLUTIONS

20

1 193737 1 ead Adj. ousing

2 193735 1 Spring

3 193740 1 Pivot Bracket

4 193697 1 Bearing Mtg Plate

5 193698 2 Bearing ousing

6 193689 1 Clevis Pin, 6x30

7 193690 1 Clevis Pin, 6x40

8 193693 2 Pivot Stud

9 193738 1 Cap Plug

10 193739 1 ead Adj. Rod

11 193732 4 Washer, Plastic

12 193723 1 Motor Plate

13 193662 1 andle Grip

14 193657 1 Knob, M8x25

15 193653 1 Kit, Linear Bearing (Set/4)

16 193663 1 Kit, Oil Seal (Set/4)

17 193699 1 Blade Guard, 10”

18 193672 1 Blade Flange - Inner

19 193678 1 “Y” Tube Fitting

20 193677 1 Water Valve

21 193679 1 ose Barb Fitting

22 193682 1 Water Tubing, Braided 20x16

23 193651 1 Splash Flap

24 193665 2 Limit Ring

25 193655 2 Knob, Limit Ring M6F

26 193669 1 Motor Assy: 1.5 P 115V-60 z

-- 193797 1 Capacitor, Motor: 110 mFd/400Vac

27 193741 1 Switch Control Assy

28 193713 2 Shoulder (Left & Right)

29 193714 2 Stop Block, Adj,

30 193660 2 Knob, Lever M10x35

31 193661 2 Knob, Lever M8x20

32 193692 2 Pivot, Shoulder

33 193683 1 Fence, Sq. Rail

DIAG PART QTY DIAG PART QTY

LOC NO REQ DESCRIPTION LOC NO REQ DESCRIPTION

34 193717 1 Angle Guide

35 193656 1 Knob, M6x20

36 193688 1 Screw - Special

37 193695 1 Nut, Square M6

38 193733 1 Scale, Dual

39 193736 1 Nut, Square

40 193696 1 Mounting Bar

41 193716 1 Backstop Angle

42 193734 1 Splash Shield

43 193707 1 Side Table Extension

44 193659 2 Knob, Lever M8x30

45 193676 1 Water Pump 115V-60 z

46 193680 1 Set, Table Legs

46a 193702 2 Table Leg, Left

46b 193747 2 Table Leg, Right

47 193681 4 Table Leg Pad

48 193727 4 Table Lift andle

49 193667 1 Drain Plug

50 178048 1 Wrench, 19mm Open-end

51 193674 1 ex Key, 6mm

52 193703 1 Water Tank - FRS-30

-- 193704 1 Water Tank - FRS-38

53 193710 2 Table Slat, Front - FRS-30

-- 193711 2 Table Slat, Front - FRS-38

54 193708 1 Table Slat, Rear - FRS-30

-- 193709 1 Table Slat, Rear - FRS-38

55 193686 1 Set, Guide Bars - FRS-30

-- 193687 1 Set, Guide Bars - FRS-38

56 193673 1 Blade Flange, Outer

57 193745 1 ex Nut, 12mm L. .

58 193743 2 Water Tube, Black 10x6,5x380

59 193744 1 Wrench, 10mm Open-end

60 185233 1 ex Key, 5mm

NS 030129 1 Plug, 5-15P 125V-15A

SPART PARTS LIST for FRS-30 & FRS-38

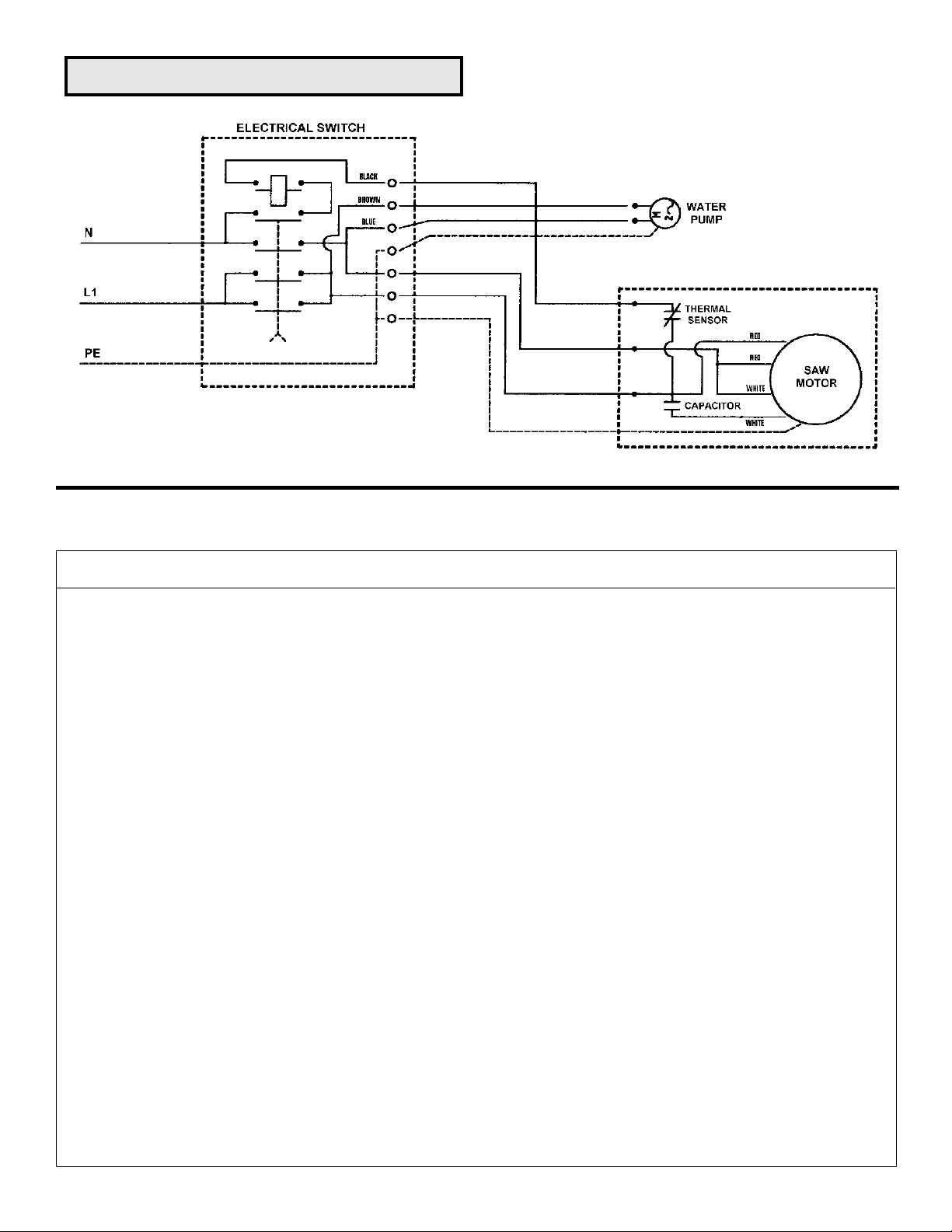

ELECTRICAL DIAGRAM: FRS 30 & 38

This manual suits for next models

5

Table of contents

Languages:

Other Felker Saw manuals

Felker

Felker tr-850 Use and care manual

Felker

Felker Super Tile Master STM-1000 Use and care manual

Felker

Felker PaverMatePM-15HT User manual

Felker

Felker Mason Mate II Use and care manual

Felker

Felker TKM-123 Use and care manual

Felker

Felker TM-1HT User manual

Felker

Felker TM-75 User manual

Felker

Felker TM-75 Use and care manual

Felker

Felker TILE MAGIC TMG-851 Use and care manual

Felker

Felker FTS-150 Use and care manual