Feltest AirSpeed/2 User manual

Instruction manual

Feltest AirSpeed/2

2

3

1. Table of contents 3

2. Safety instructions 4

2.1 Intended use 4

2.2 Safety precautions 4

3. About the instrument 6

3.1 Names of parts 6

3.2 Working principle 7

4. The measurement 7

4.1 Measuring procedure 7

4.2 Interpretation of the results 9

5. Technical data 10

6. Declaration of conformity 11

4

2. Safety instructions

2.1 Intended use

The Feltest AirSpeed/2 is intended to measure the airflow through a

press felt over an Uhle box on running paper machines. The instrument

may not to be used on any other object, like for example dryer screens

or conveyor belts.

2.2 Safety precautions

Running paper machines can be very dangerous! Therefore it is very

important to read this manual and its safety instructions before

operating the Feltest AirSpeed/2.

• Before using the instrument, read this

manual carefully, it contains important saf-

ety information. If you not fully understand

this manual, please contact Feltest

Equipment bv for more information.

Keep this manual where the operator can

easily find it.

• Use the instrument as intended and

according to this manual. Do not measure

the airflow through forming fabrics or dryer

fabrics on running paper machines.

• Be aware of the danger of rotating machi-

ne parts. Do not make measurements

close to in-going nips. You or the instru-

ment could be grabbed into the machine,

which can result in severe life threatening

injuries and very costly damages.

• Do not measure press felts with holes

or damaged edges. Before starting your

measurements, check with the staff of the

paper machine if holes or damaged edges

are known. At the machine, first look very

carefully for any defects or signs indicating

defects, before starting the measurement.

If you have any doubt, do not measure.

5

• Before starting a measurement, make

sure you find a stabile position with two

feet on a solid base. Do not bend over

into the machine. If you must lean

against a safety fence (or something

similar), first check its stability.

• Always follow the safety instructions that

apply for the location where the

measurements are done. Do not ignore

or remove safety constructions from the

paper machine.

Please note:

Doing measurements (of any kind) on running paper

machines is dangerous and requires alertness, concen-

tration and common sense. The Feltest instruments are

designed and constructed to be as save as possible for

their intended use. Nevertheless it is the user's responsibility to

actually use the instrument in a safe way. Feltest Equipment bv can

not be held responsible or liable in any way for suffered injuries or

damages that occurred while using their instruments.

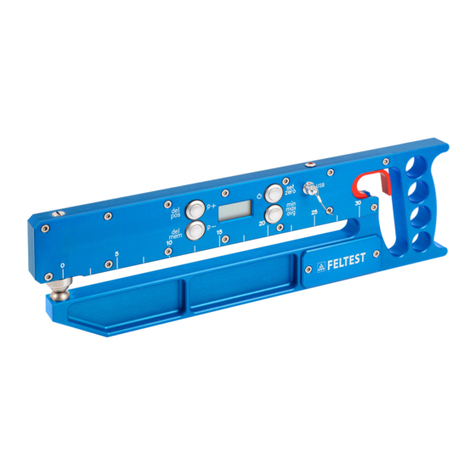

0 5 10 15 20 25 30

0.00

BAT

6

3. About the instrument

With this air speed meter (or anemometer) you have acquired a preci-

sion instrument of exceptional quality. You also obtain the benefit of

our many years’ experience in measuring physical data on running

paper machine clothing.

All probes have been calibrated in a wind tunnel and are checked to

conform to the required tolerances.

3.1 Names of parts

The instrument is built up out of an electronic

read out unit, a probe with a small propeller that

is installed in a plastic measuring head and a

telescopic grip.

• The air flow is measured by a small, aerody-

namically optimised propeller which is extre-

mely accurate and reliable.

• The plastic measuring head is made from

HDPE which ensures low friction with the felt.

Contamination will not stick to the material,

therefore it can be cleaned easily.

Average, minimum and maximum values can be

called up at any time. As the calculation of

these values takes place simultaneously they

can be requested at any time, the test result is

not affected.

7

3.2 Working principle

The Feltest AirSpeed/2 works with a vane or propeller anemometer as

the propeller has proofed to be more accurate and durable than a ther-

mal anemometer in the harsh environment of a paper machine.

The propeller speed, directly corresponding to the flow rate, is sensed

electronically without inducing any reaction force and is transmitted to

the read out unit.

The read-out unit operates through a microprocessor with a minimum

current loading. This makes it possible to perform all functions and

measurements by using only a few keys and allows the data to be cal-

led up at any time. The measuring data are read on the LCD display.

The unit is battery operated.

4. The measurement

It is of utmost importance to work safely when

measuring the air speed through a press felt. Find

a safe and stable position close to the Uhle box,

expand the telescopic grip so it will not be

necessary to bend over into the machine but most

important is to stay away from any in-going nip!

4.1 Measuring procedure

Preparation

The connector and cable of the probe are led through the telescopic

grip. Then the measuring head and the telescopic grip can be mounted

together. The connector is clicked into the read out unit (watch the red

dots) and the instrument can be switched on with the On/Off key.

The instrument performs a functional test lasting about 2 seconds.

During this time the display shows the probe code 15.20. The first 2

digits indicate the propeller head diameter, the last 2 digits the full-

scale reading in m/s.

The instrument now measures continuously and shows the average

value of the last 2 seconds on the display. The display is refreshed

every 0,5 second. Changeover to 6 or 22 seconds average: press the

8

Fast or Slow key. To return to the 2-second average the instrument

must be switched off and on again.

Error indication

If the display shows E.xx when switching on or during operation, this

indicates a fault. The fault can be identified from the E-number details

under Technical Data in chapter 5.

Measurement

When it is safe to measure the air speed, the measuring head is held

against the felt, above the slit of the Uhle

box. The slit in the measuring head should

be in contact with the felt, the round hole

should be ‘on top’.

By rotating the measuring head a few deg-

rees clockwise and counter clockwise one

will see that the measured air flow will vary.

There is no rule of thumb for the right

angle; it depends on felt weight and water

content, felt speed, width of the slit and the

force with which the measuring head is pressed onto the felt. Generally

spoken the position which gives the highest test results is the best.

After switching on the instrument, averages are calculated over 2

seconds (every 0,5 second a value). Pressing the Min/Max key will

return the minimum and maximum test results measured. Pressing the

Flow key will return to the current test values.

Where greater accuracy is required and the flow is rather irregular the

test time can be extended, resulting in an average over 6 seconds

(press the Fast key) or 22 seconds (press the Slow key). During the

measurement the remaining test time up to the end is indicated in

seconds. The Mean or average value of the complete measuring cycle

will be calculated when the measuring time has ended. A new meas-

urement is started by pressing the Fast or Slow key again. To return to

the 2 second average, the instrument needs to be switched off and on

again.

When the display shows BATT the battery (9 Volt) has to be replaced.

9

4.2 Interpretation of the results

By measuring the air speed through a press felt it becomes possible to

quantify the felt’s permeability or openness. Generally the measured air

speed should be between roughly 2 and 10 m/s. If the test results are

too low, the Uhle box will hardly remove any water out of the press felt

and values over 10 m/s will only cost vacuum without increasing the

amount of removed water.

Still, only measuring the air speed is not enough to determine the felt’s

condition. The applied vacuum is very important and should be meas-

ured as well (for example with the Feltest RealVac) as manometers on

Uhle boxes are seldom reliable. To compare the permeability from

several measurements over time with different levels of vacuum, one

could calculate a relative “dynamic permeability”. This means to meas-

ure both vacuum and air speed and then calculating the air speed

towards a standard vacuum of 10kPa.

An example:

Measured Measured air speed Dynamic Perm

vacuum @ 10 kPa

20 kPa 4.0 m/s 2.0 m/s

30 kPa 4.0 m/s 1.3 m/s

35 kPa 4.0 m/s 1.1 m/s

This examples makes clear that, although the measured air speed is

always 4.0 m/s, the felt becomes more closed as the applied vacuum

is increasing.

If the air flow through a felt decreases, this can be the result of

contamination or compaction of the felt. Also a high water content in

the felt will reduce the air flow over the Uhle box. Only by also measu-

ring the caliper with a Feltest Caliper Gauge and the water content,

one gets the whole picture and is it possible to accurately determine

the felts condition.

10

5. Technical data

Probe

Medium: non-corrosive gases

Measuring range: 0,5 to 20 m/s

Start-up code: 15.20

Connector: Lemo FCG.0B.305.CLCD52Z

Accuracy: 2,0% full scale plus 5% reading

Operating temperature: 0 to +120° C

Storage temperature: 65 to +150° C

Read out unit

Medium: non-corrosive gases

Unit of meas.: flow in m/s

Display: LCD 4 characters

Measuring rate: 2 values/sec.

Supply: Battery (1 x 9 Volt, size PP3)

Current consumption: approx. 15 mA

Battery life: approx. 12 hours

Case dimensions: 80x145x39 mm (ABS plastic)

Case protection: IP64 (splash water proof)

Weight: 230 g

Operating temperature: 0 to + 50° C

Storage temperature: -30 to + 80° C

Air humidity: 0 to 90% rh, non condensing

Standard: laser controlled wind tunnel

(Certificate in accordance with EN 45001)

Error diagnosis

E.01 = probe type not recognised

E.03 = over velocity measuring range

11

6. Declaration of conformity

Instrument: MiniAir Junior

Instrument type: Vane anemometer

Type designation: V7

The signing legal authorities state, that the above mentioned equipment meets the

requirements of the electromagnetic compatibility (EMC) according to the

Guideline of Counsel 89/336/EEC of 03.05.1989

The evaluation procedure of conformity was assured according to the following

standards:

a) Emission : EN 55022 : 1994

b) Immunity : EN 50082-1 : 1992

This EC – Declaration of conformity is based on the test report No. 95.1 10951 of the

EMC-Testcenter of SEV/ASE, CH-8320 Fehraltorf.

Signed on January 1st 1996,

M.F. Lensvelt

Managing Director

Postal address: Visiting address:

Feltest Equipment BV Feltest Equipment BV

Postbus 205 Bijenkorf 55

NL-6960 AE Eerbeek NL-6961 PA Eerbeek

The Netherlands The Netherlands

P.O. Box 205

NL – 6960 AE Eerbeek

The Netherlands

T: +31 313 652 215

F: +31 313 654 068

W: www.feltest.com

Table of contents

Other Feltest Test Equipment manuals

Popular Test Equipment manuals by other brands

ChemInstruments

ChemInstruments COF-1000 operating instructions

Tektronix

Tektronix 2445 instruction manual

Keysight Technologies

Keysight Technologies U3022AE10 User's and service guide

Anritsu

Anritsu MP1801A Service manual

Sonel

Sonel S-36 VLF user manual

Macmesin

Macmesin MultiTest-xt Assembly and installation