Trace2O HydroTest HTCOD-TR User manual

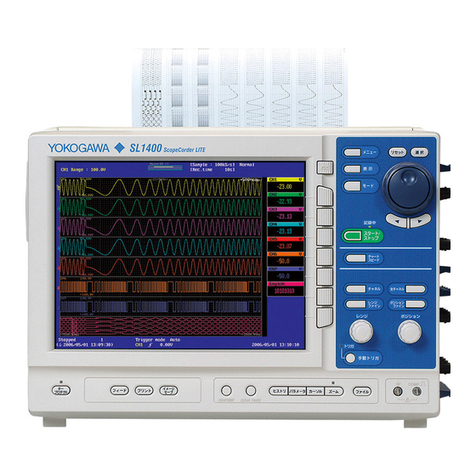

HTCOD-TR

HydroTest®

COD Thermoreactor

Instruction Manual

Content

1. HTCOD-TR ..................................................................................................... 3

1.1

Introduction ..................................................................................................... 3

1.1.1

Preface ............................................................................................................. 3

1.1.2

Guide to symbols............................................................................................. 3

1.2

Important information.................................................................................... 4

1.3

Unpacking ................................................................................................. 4

1.4

Connecting ................................................................................................ 4

1.5

Buttons............................................................................................................. 6

1.6

Function of buttons......................................................................................... 6

2.

Work session .............................................................................................. 19

3.

Beeper

.......................................................................................................... 19

4.

Function schematics................................................................................. 20

5.

Maintenance

............................................................................................... 21

6.

Cleaning

...................................................................................................... 21

7.

Technical data............................................................................................. 21

8.

Wiring diagramm........................................................................................ 22

9.

Error code (LED indication)..................................................................... 23

1.

HTCOD-TR

3

1.1 Introduction

Please read the manual before using the unit in particular taking note of the warning

symbols listed below.

The manufacture does not take responsibility for any issues caused by use of the unit

not in accordance with the instructions laid out in this manual.

1.1.1 Preface

The reactor is only suitable for 16 mm Ø test tubes, closed with a lid.

The unit has a transparent cover, which has to be closed during the heating process.

The required temperatures and the corresponding time periods are specific for the

different test tube types and specified in the corresponding method descriptions.

Don’t exceed temperatures or time spans in any case.

All warning labels must NOT be removed and should be replaced if they become

damaged or faded.

1.1.2 Guidetosymbols

The symbols below are used in this manual to indicate where there is risk of injury or

damaging devices or to indicate especially useful information:

DANGER!

Indicates risk of injury.

When not following instructions, severe injury or death may result.

ATTENTION!

Indicates possible damage to devices.

When not following instructions, devices may be heavily damaged.

IMPORTANT!

Indicates hints on operation and other useful information.

ATTENTION!

Hot surfaces! Do not touch, risk to be badly burned!

Read all instructions before using the instrument.

4

1. HTCOD-TR

1.2 Important information

Note on reactor placement

The setup location must not be extremely hot, cold, humid or dusty. Heat and cold

can impair the functionality of the reactor. Humidity and dust can cause the reactor

to fail.

Do not place the reactor near heaters such as radiators or the like. Do not expose the

reactor to mechanical vibrations or jarring.

Do not block or cover the ventilation openings.

Notes on power connection

Only use the power cord designated for use in your country.

The wall outlet should be within easy reach.

Pulling the power plug is the only way to disconnect the reactor from the power

source

Safety instructions for operation

The power cord must not be damaged. Do not place any objects on the power cord

and make sure it does not have any knots. To unplug the cord, always pull on the

plug and not on the cable itself.

Avoid covering the ventilation slots. Air circulation is necessary to prevent the reactor

from overheating. If the air circulation is restricted it could cause fire or damage the

reactor.

Never open the reactor housing yourself. There is a danger of electric shock

and other hazards. The reactor may only be opened and serviced by qualified

professionals.

Safetyrules

The heating block if programmed, may reach a temperature of 150 °C, this hap-

pens during the heating phase when the red LED is lighted. Please note the unit will

remain hot during the cooling phase even though the LED-light may be off.

During this phase the base of the instrument may be very hot!

Do not touch, risk to be badly burned!

The materials used during the work must be compatible with the temperatures

reached by the unit.

Cleaning

The heating plate must be allowed to cool before cleaning.

Use a damp cloth with a non flammable, non corrosive detergent .

Personal Protection Equipment

The equipment used for personal protection must be compatible with the reached

temperature and the dangers due to the working materials.

1.

HTCOD-TR

5

1.3 Unpacking

Carefully inspect all items to ensure that every part on the list below is present

and no visible damage has occurred during transportation.

Store the packing material to return the unit for repair or other kinds of transport.

The table below shows the parts included in the packing.

Partlist

Part

Quantity

1

Thermoreactor HTCOD-TR

1

2

Power cord (European version)

1

3

Instruction manual

1

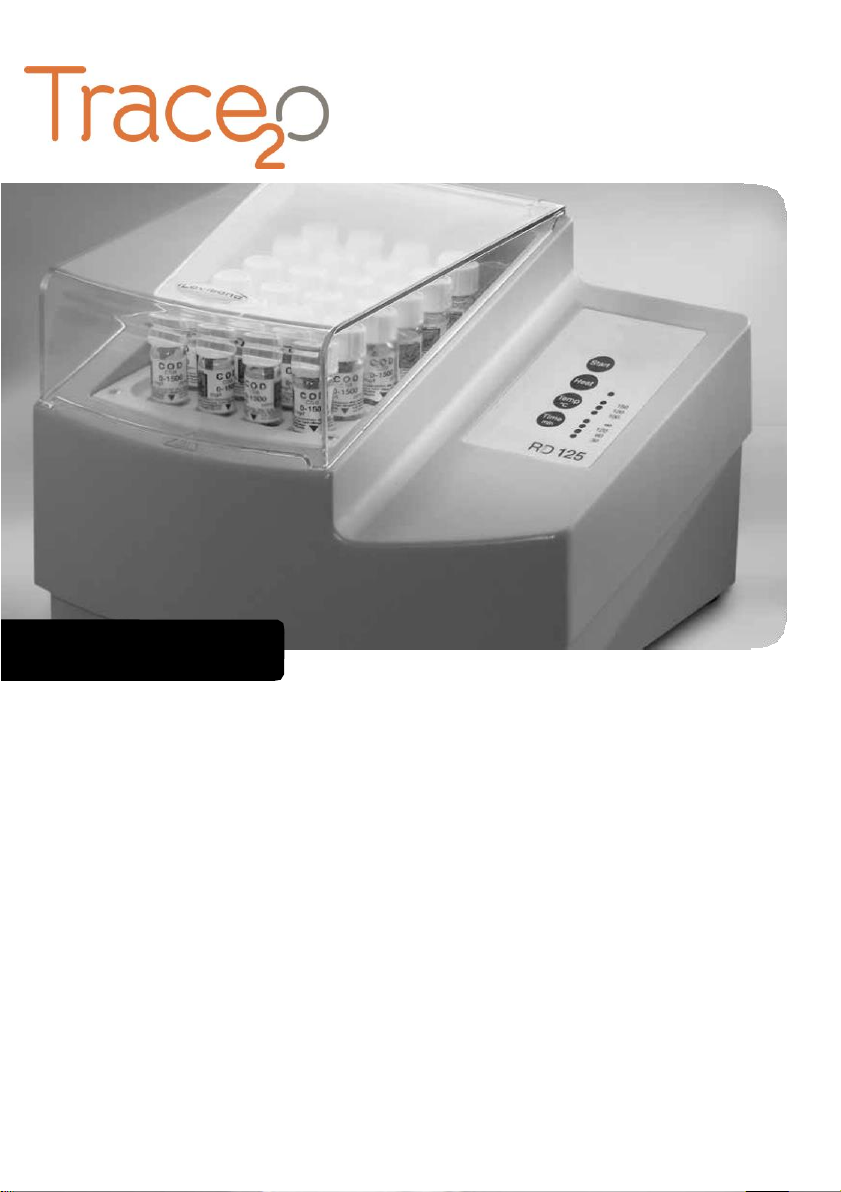

1.4 Connecting

On the reverse side of the reactor:

•Selector for voltage 115 V / 230 V

•

Plug for power cord

•

Fuse 4 AT

•ON/OFF Switch (0/I)

Before connecting to power supply check that the ON/OFF switch is turned to “0”

and check that the voltage selector (115 V/230 V) corresponds to the voltage

supplied by the electric socket.

Cover

Fuse

Plug for power cord

Selector

for voltage

ON/OFF Switch

6

R

125

1.5 Buttons

Start key / Timer

Heat key

Temperature key

Time (interval) key

Heat LED

TemperatureLEDs

Time LEDs

1.6 Function of buttons

Start key (for timer): By pressing this key the work cycle will start with the

pre-selected values for temperature and time. At the end of the work cycle the

beeper will sound (Beeper, see p. 7) and the heater automatically switches off.

Heat key: By pressing this key (after switching the instrument on using the main on/

off switch see page 17) the reactor will heat up to the pre-selected temperature.

Temp key: By pressing this key the temperature is selected (scrolling). It is possible

to select between 100/120 and 150 °C. When a temperature is selected the

corresponding LED will light.

Time key: By pressing this key the time is selected (scrolling). It is possible to select

between: 30/60/120 min or

(infinite). When a time is selected the corresponding

LED will light.

7

2.

Work session

This section describes the use of the reactor for a standard application.

For further applications please refer to “Function schematics” (page 20).

After the unit is switched on (main switch, reverse side, position I) the keypad

automatically shows the last selected temperature and time span.

The corresponding LEDs are lighted.

After switching on the block heating does not commence automatically.

For heating up the unit press the “Heat” key.

After pressing this key the Heat LED is lighted.

Before and after pressing the “Heat” key temperature and time span still can be

changed.

During heating up the Temperature LED will light intermediately, when the selected

temperature is reached the Temperature LED is lighted permanently.

By pressing the “Start” key the timer starts the work cycles corresponding to the cho-

sen time span (indication by Time LED). Starting the work cycle the Time LED changes

from lighted to flashing.

When the work cycle ends Time LED and Temperature LED are lighted while the Heat

LED is off.

At the end of the work cycle the heater is switched off.

3.

Beeper

Select temperature or time:

short double beep

(two frequencies)

Switch heater on:

long beep (one frequency)

Switch heater off:

long beep (one frequency)

Temperature reaches the selected value:

8 x short beep

(two frequencies)

Start of countdown:

long beep (one frequency)

End of countdown:

16 x short beep

(two frequencies)

Pressing a key which is inactive

(at the moment):

short beep

(one frequency)

Malfunction:

Continuous beep (2 frequencies)

until the instruments is switched

off with the main switch (position “O”).

In this case the LED combination

according pages 12/13 allows a

failure defi

4.

Function

schematics

8

After switching on the instrument with the main on/off switch, the heater is not active. Press the HEAT-key for heating up (status 1).

After heating up to the selected temperature the timer starts after pressing START-key (status 3).

Status

Heat-LED

Temp.-LED

Time-LED

Heat-key

Start-key

Temp-/Time-

key

Heater

next possible

status

1. Waiting for

pressing HEAT-key

Off

last selected

temperature

last selected

time-span

Press: =>

Status 2

Ignore

Selection

possible

Off

After pressing

HEAT-key:

Status 2

2. Heating up

On

Flashing

On

Press =>

Status 1

Ignore

Selection

possible

Heating up

or Cooling

down

If selected

temperature is

reached:

Status 3

3. Waiting for

pressing START-key

On

On

On

Press =>

Status 1

Press for t =

30, 60, 120

Selection

possible

Temperature-

controlled for

stability of

the selected

temperature

After pressing

Start-key:

Status 4

(t

)

Ignore for

t=

If selected

temperature will

be changed:

Status 2

If temperature

to different to

selected one:

Status 2

4. Time: Count

down

On

On

Flashing

Press =>

Status 1

Ignore

Ignore

Stable

Temperature

End of count

down:

Status 1

Heat-LED

On:

Heating up or stabilizing selected temperature.

Temp.-LED

Off:

Flashing:

Heater is off

Selected temperature is not reached (heating up or cooling down)

Together with HEAT-LED On: Selected temperature is reached

Together with HEAT-LED Off: Indicates selected temperature without indication of the real temperature of the reactor

Time-LED

Flashing:

Count down function

On:

indication of selected time-span without count down function.

9

5. Maintenance

The unit is protected by a 4AT fuse. The position of the fuse holder is on the reverse

side of the unit under the main switch.

Should the fuse need changing, disconnect the unit from the power supply and open

the cover with a suitable tool to access the fuse.

6. Cleaning

No special maintenance is necessary apart from periodic cleaning of the unit.

Disconnect the unit from power supply and use a dust-free cloth with a

non flammable, non aggressive detergent to clean the unit.

ATTENTION:

If the reactor is contaminated by spillage of the tube contents or breakage of the

test tube, the disposal of waste (both glass and liquid) must be done according to the

instructions set out in the Material Safety Data Sheet (MSDS) (Chapter 6 and/or 13).

A contaminated aluminium block must be replaced prior to further use of the reactor.

The reactor should be sent to the manufacturer or an authorised service centre.

7.

Technical data

Powersupply

V/Hz

230 / 50-60 or

115 / 50-60 selectable

Power

W

550

Size

mm

248 x 219 x 171

Weight

kg

3.9

Construction materials

Housing: ABS

Protection grid: PPS

Lid:

PC

Block insert: PBT

Heating block: Aluminium

Holes in the

aluminium block

24 holes, ø 16.2 mm ± 0.2 mm

Selectable temperatures

°C

100 / 120 /150

Probe type

Pt100 A class

Temperature stability

°C

± 1

at the Pt100

Selectedtime

Heating up from

min

30 / 60 / 120 / continuous ()

(20°C --> 150°C)

min

12

Thermoregulation

Microprocessor

Protection

°C

at the Alublock for 190

against overheating

Beeper

dB

max. 88

Environmentalconditions(operation)

Temperature

°C

10 –40

Humidity

%

max. 85

10

8. Wiring diagramm

9.

Err

or

Code

(LED

indication)

11

No.

Error type

Possible reason(s)

Temp LED

LED30min

LED60min

LED120min

LED

Continuous beep

1

Power supply frequency

Frequency higher/lower

50Hz / 60Hz;

Mainboard faulty

on

off

off

off

on

yes

2

Safety feature reaction

Mainboard faulty

on

off

off

on

off

yes

3

ADC error

Mainboard faulty

on

off

off

on

on

yes

4

Wiring problem

internal connection

incomplete

on

off

on

off

off

yes

5

Heating problem

-

no power;

-

reactor power

-

probe problem

on

off

on

off

on

yes

6

T value underrange

Mainboard faulty

on

off

on

on

off

yes

7

T value overrange

Mainboard faulty

on

off

on

on

on

yes

8

Temperature too high

Probe connection faulty

Mainboard faulty

on

on

off

off

off

yes

9

Microprocessor failure

EMC-interference

100° on

120° off

150° on

on

off

on

off

no

10

Temperature on

mainboard too high

Unit overheated

on

on

on

off

off

yes

Table of contents

Other Trace2O Test Equipment manuals

Popular Test Equipment manuals by other brands

Kikusui

Kikusui HP01A-TOS Operation manual

Rubarth Apparate

Rubarth Apparate RUMED 4001 Operating and maintenance instructions

Greenlee

Greenlee 6700 instruction manual

Kemot

Kemot MIE2125 owner's manual

Gossen MetraWatt

Gossen MetraWatt SECUTEST ST BASE operating instructions

Wingmate

Wingmate BREATHALYSER user manual

Tinsley

Tinsley 58-FMC instruction manual

DH Instruments

DH Instruments E-DWT-10000-AF Operation and maintenance manual

Van Der Stahl

Van Der Stahl PTT-100 V operating instructions

Forch

Forch BT 12 V operating instructions

ATD Tools

ATD Tools ATD-5614 owner's manual

Hisense

Hisense HKF-D1EC Instructions for installation, use and maintenance manual