Ecom CP 400 User manual

CP 400/420

Bedienungsanleitung

Operating Instructions

Notice d‘utilisation

33

Contents

1. Introduction 34

1.1 Standard Equipment 34

1.2 Safety Information 34

2. Calibrator Interface 35

2.1 Calibrator Display 36

2.2 Using the Backlight 39

2.3 Using the Zero Function 39

2.4 Other Menu Controlled Functions 39

3. Measuring Pressure 42

3.1 Media Compatibility 42

3.2 Measuring Pressure with External Modules 42

4. Measuring Current 43

5. Measuring Voltage 44

6. Measuring Temperature with and RTD 44

7. Performing a Pressure Switch Test 45

8. Calibrating Transmitters 47

8.1 Using the mA Input Function 47

8.2 Calibrating a Pressure-to-Current Transmitter 47

8.3 Percent Error Function 48

9. Factory Setups 51

10. Custody Transfer / Flow Calibration 52

11. Remote Operation 52

11.1 Remote Interface 52

11.2 Setting up the RS-232 Port for Remote Control 53

11.3 Changing Between Remote and Local Operation 53

11.4 Using Commands 53

11.5 Remote Commands and Error Codes 55

11.6 Entering Commands 58

12. Specifications 62

13. Warranty 63

14. Maintenance 63

14.1 Replacing Batteries 63

14.2 Cleaning the Unit 63

15. Menu Map 64

34

1. Introduction

The CP 400/420 is designed to be a simple to use yet very versatile pressure calibrator. Its

two internal pressure sensors combined with inputs for mA, voltage, switch contacts and

an RTD probe allow the 400/420 to calibrate virtually any pressure device. An external

pressure module option allows an even wider range of pressure calibration options

including absolute and differential.

1.1 Standard Equipment

Check to see if your calibrator is complete. It should include: CP 400 or CP 420 calibrator,

instruction manual, test leads, carrying case, calibration certificate.

1.2 Safety Information

Use the calibrator only as specified in this manual, otherwise injury and damage to

the calibrator may occur.

Warning

To avoid possible electric shock or personal injury:

- Do not apply more than the rated voltage. See specifications for supported ranges.

- Follow all equipment safety procedures.

- Never touch the probe to a voltage source when the test leads are plugged into the

current terminals.

- Do not use the calibrator if it is damaged. Before you use the calibrator, inspect the

case. Look for cracks or missing plastic. Pay particular attention to the insulation

surrounding the connectors.

- Select the proper function and range for your measurement.

- Make sure the battery cover is closed and latched before you operate the calibrator.

- Remove test leads from the calibrator before you open the battery door.

- Inspect the test leads for damaged insulation or exposed metal. Check test leads

continuity. Replace damaged test leads before you use the calibrator.

- When using the probes, keep your fingers away from the probe contacts.

Keep your fingers behind the finger guards on the probes.

- Connect the common test lead before you connect the live test lead.

When you disconnect test leads, disconnect the live test lead first.

- Do not use the calibrator if it operates abnormally. Protection may be impaired.

When in doubt, have the calibrator serviced.

- Do not operate the calibrator around explosive gas, vapor, or dust.

- When measuring pressure, make sure the process pressure line is shut off and

depressurized before you connect it or disconnect it from the pressure module.

- Disconnect test leads before changing to another measure or source function.

When servicing the calibrator, use only specified replacement parts.

- To avoid false readings, which could lead to possible electric shock or personal injury,

replace the battery as soon as the battery indicator appears.

Caution

To avoid possible damage to calibrator or to equipment under test:

- Use the proper jacks, function, and range for your measurement or sourcing application.

35

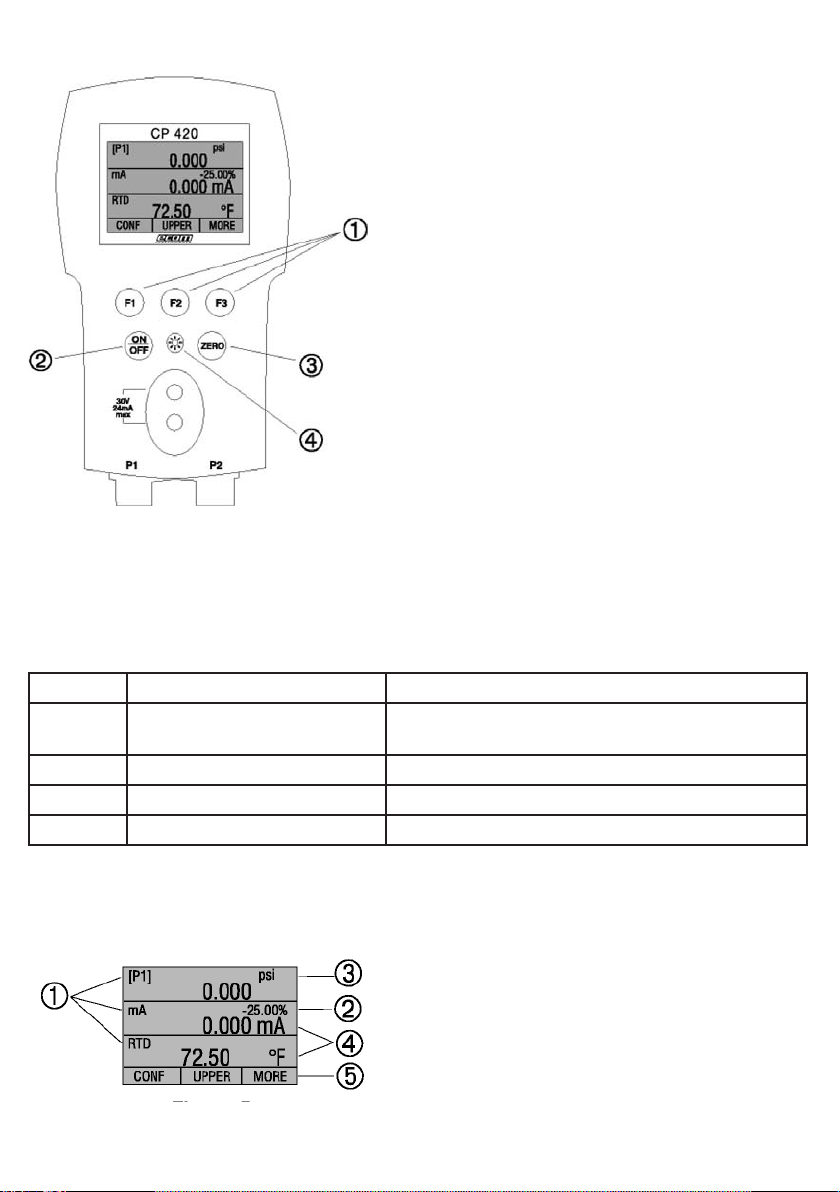

2. Calibrator Interface

Figure 1 shows the location of the process measurement inputs, while table 1 describes their use.

Figure 1: Pressure Measurement Inputs Side View

Table 1: Process Measurement Inputs

No. Name Description

1, 2 Input Terminals These terminal are used to measure current, voltage and

a contact closure for switch test.

3 P1 Pressure Port This is the connection for the internal sensor P1

4 P2 Pressure Port This is the connection for the internal sensor P2

5 RTD Probe Connector This connector is where the RTD probe is plugged in.

6 Serial Interface This is used to interface to optional external modules.

36

Figure 2 shows the location of the keys. Table 2 describes the function of each key.

Figure 2: Keypad

Table 2: Key Functions

No. Name Description

1 Function Keys These keys are used in various ways, primarily

to configure the calibrator

2 ON/OFF Key This key is used to turn the calibrator on and off

3 ZERO Key This key is used to zero pressure measurements

4 Backlight Key This key is used to turn the backlight on and off

2.1 Calibrator Display

The Calibrator Display consists of two regions: The menu bar (located along the bottom

of the screen) is used to access a menu system. The main display (the rest) consists of

up to three process measurement sub-regions.

These sub-regions will henceforth be referred to as the

UPPER, MIDDLE and LOWER displays. Figure 3 shows

the location of the different display fields while table 3

describes them.

Figure 3: Display

37

Table 3: Display Functions

No. Name Description

1 Primary Parameters Indicates what is being measured

2 Span Indicator Indicates the percent of the 4 to 20 mA span.

(For mA and mA Loop functions only)

3 Pressure Units Indicates one of 17 pressure units available for display

4 Units ndicates the unit of measure for the display

2.1.1 Main Menu Functionality

There are three options on the Main Menu, CONFIG, {current display} and MORE. The

Main Menu is home for the menu display.

2.1.1.1 Setting the Current Display

The current display is indicated by the center option on the Main Menu, pressing the F2

key will toggle the current display.

2.1.1.2 Setting Current Display Parameters

To set the parameters of the current display use the CONFIG option to get to the Display

Configuration Menu.

Here the SELECT option will toggle through the choices for each parameter. The first

parameter is MODE. Since voltage, current and switch test modes all use the same

jacks, two of these functions cannot be used concurrently. The ability to select certain

functions is limited based on what is already selected in another active display. The

NEXT option is used to change to the second parameter. Only RTD and Pressure modes

have a second parameter, RTDs can be read in Celsius or Fahrenheit and Pressures can

be read in 13 engineering units.

With a single display the following modes are available:

P[1] = Pressure on left side sensor.

P[2] = Pressure on right side sensor.

[EXT] = Pressure with external pressure module.

P[1] ST = Switch Test with left side sensor.

P[2] ST = Switch Test with right side sensor.

[EXT] ST = Switch Test with external pressure module.

mA = Milliamps measure without loop power.

mA LOOP = Milliamps measure with loop power.

VOLTS = Voltage Measure.

RTD = RTD Temperature Measurement (if a probe is connected).

The following table shows which functions are available concurrently.

An X in a column indicates that the mode in the current display will not be available for

selection if the mode in that row is in use in any other active display.

38

Table 4: Mode Concurrency

CURRENT DISPLAY

OTHER DISPLAY

P(1) P(2) (EXIT) P(1)

ST

P(2)

ST

(EXIT) mA mA

Loop

Volt RTD

P(1)

P(2)

(EXIT)

P(1)

P(1)ST XXXXXX

P(2)ST XXXXXX

(EXIT) XXXXXX

mA XXX XX

mALoop XXXX X

Volt XXXXX

RTD

2.1.1.3 Accessing Other Menus

Use the MORE option on the Main Menu to access the other menu functions.

(See page 64, Menu Map)

39

2.2 Using the Backlight

The backlight is controlled by the dedicated backlight key. It toggles on and off when the

key is pressed; this is one of the few functions that cannot be controlled by the serial

interface.

2.3 Using the Zero Function

When the ZERO_KEY is pressed, the calibrator will zero the current display if a pressure

mode is selected, and the pressure is within the zero limit.

2.3.1 Internal Sensor and Pressure Module (non-absolute)

When a sensor or module is selected on the current display and the ZERO_KEY is

pressed the calibrator subtracts the current reading from the output.

2.3.2 Absolute Pressure Module

When an absolute pressure module is selected on the current display and the ZERO_KEY

is pressed the calibrator prompts the user to enter the barometric reference pressure.

This is done using the arrow keys (F2 and F3 Keys).

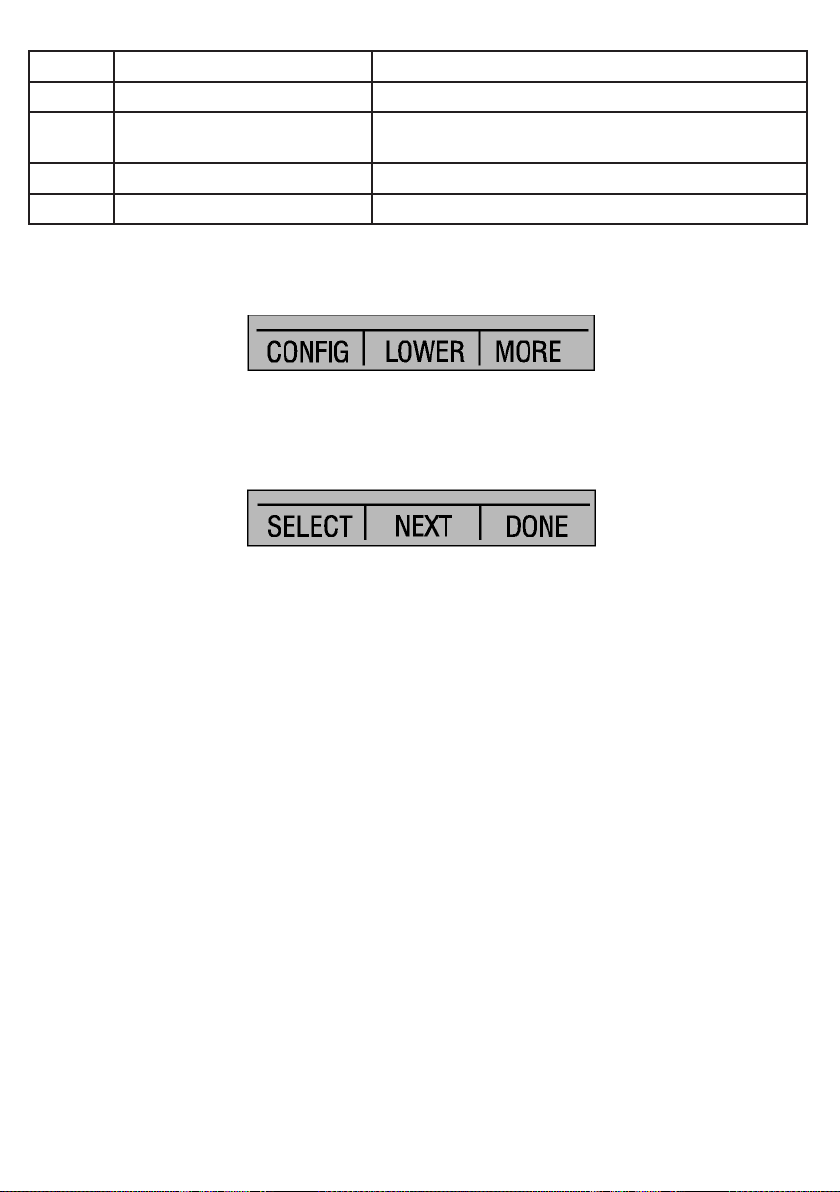

2.4 Other Menu Controlled Functions

There are eight ‘sub-main’ menus that can be accessed through the MORE option of the

Main Menu. A ‘sub-main’ menu contains three options. The first option is unique to the

function. The second and third options of a ‘sub-main’ menu are always the same. The

NEXT option leads to the next ‘sub-main’ menu and the DONE option returns home . For

the last ‘sub-main’ menu the NEXT option wraps around to home. See Page 64 for a

detailed mapping of the menu structure.

A note on naming convention:

If a ‘sub-main’ menu has subordinate menus, it will henceforth be referred to as

{function} Main Menu. E.g. the display contrast sub-main menu will be called the

Contrast Main Menu. If not it will be called the {function} menu.

2.4.1 Setting the Contrast

From the Contrast Main Menu choose the CONTRAST option to access the Contrast

Adjustment Menu.

Use the arrow keys to adjust the display contrast to the desired level and then use the

CONTRAST DONE option to return home.

40

2.4.2 Locking and Unlocking Configurations

Use the LOCK CFG or UNLOCK CFG option of the Configuration Lock Menu to lock or

unlock the display configuration.

When the LOCK CFG option is chosen the menu display returns home and the CONFIG

option on the Main Menu indicates that it is locked. Also all menus are locked out with

the exception of the Contrast Adjustment menus and the Configuration Lock Menu.

When the UNLOCK CFG option is chosen the configuration is unlocked and the menu

display continues to the next sub-main menu.

2.4.3 Saving and Recalling Setups

The calibrator will automatically save the current set-up for recall at power-up.

Additionally 5 set-ups can be accessed through the SETUPS menu.

Select the SETUPS option from the Setups Main Menu.

Choose SAVE to save a set-up , RECALL to recall the set-up, or DONE to do nothing and

return home.

If SAVE or RECALL is selected use the arrow keys to select the set-up location. Then use

the save option to store the current set-up into the selected location or the recall option to

recall the set-up stored in the selected location. The display menu will automatically go

home.

2.4.4 Setting AutoShut-off Parameters

The calibrator can be set to automatically shut-off after a selected number of minutes; this

function can also be disabled. To set the auto shut off parameters select the AUTO OFF

option on the Auto Shut Off Main Menu.

41

Use the arrow keys to select the number of minutes before the calibrator turns off or

disable auto shut-off by scrolling all the way down.

Use the AUTO OFF DONE option to set the parameters and return home. The auto shut

off time is reset whenever a key is pressed.

2.4.5 Activating and Deactivating a Display

Use the DISPLAY option on the Display Selection Main Menu to access the Display

Activation Menu.

The {function} option can be used to select which display to act upon. The ON/OFF

option turns the selected display on or off. The selected display and current on/off state

are displayed in the lower display.

Use the DONE option to save the changes and return home. When a display is

deactivated its configuration is retained. When the display is activated its configuration is

checked against the configurations of the other currently active displays, if the

configurations are in conflict the recalled display’s configuration is modified to avoid the

conflict. If all three displays are deactivated the LOWER display will come on

automatically

2.4.6 Setting the RTD probe type

Use the PROBE TYPE option of the RTD Probe Type main menu to access the RTD

Probe selection menu.

There are four probe types to select from P100-385, P100-392, P100-JIS and CUSTOM.

Use the SELECT option to select the desired probe type and the DONE option to store

the change and return home.

Note: The default probe type is PT100-385.

42

3. Measuring Pressure

To measure pressure, connect the calibrator using an appropriate fitting. Choose a

pressure setting for the display being used. The calibrator is equipped with two internal

sensors and many optional external sensors (EPMs) are available. Be sure to choose the

sensor based on working pressures and accuracy.

Figure 5

Use the (ZERO) key to zero the pressure sensor when vented to atmospheric pressure.

Important NOTE: To ensure accuracy of the calibrator it is critical to zero the calibrator

before a device is calibrated.

3.1 Media Compatibility

The calibrator utilizes a media isolated sensor to prevent sensor contamination.

Whenever possible clean, dry air is the media of choice. If that is not always possible,

make sure that the media is compatible with Nickel Plated Brass and 316 Stainless Steel.

3.2 Measuring Pressure with External Modules

The calibrator provides a digital interface to External Pressure Modules. These modules

are available in various ranges and types including gauge, vacuum, differential and

absolute. The modules work seamlessly with the calibrator. Simply plug them into the

interface and select [EXT] (external sensor). Since the interface between the calibrator

and the module is digital all the accuracy and display resolution is derived from the

module.

43

Figure 6

4. Measuring Current

To measure current use the input terminals in the front of the calibrator. Select the mA

function on one of the displays. Current is measured in mA and percentage of range.

The range on the calibrator is set to 0% at 4 mA and 100% at 20 mA.

For example:

If the current measured is displayed as 75% then the mA value is 16 mA.

Figure 7

Model BPPA

Pressure Module

Adapter

Pressure Module

Device

under

Test

4 to 20mA

P1 P2

30V

24mA

max

44

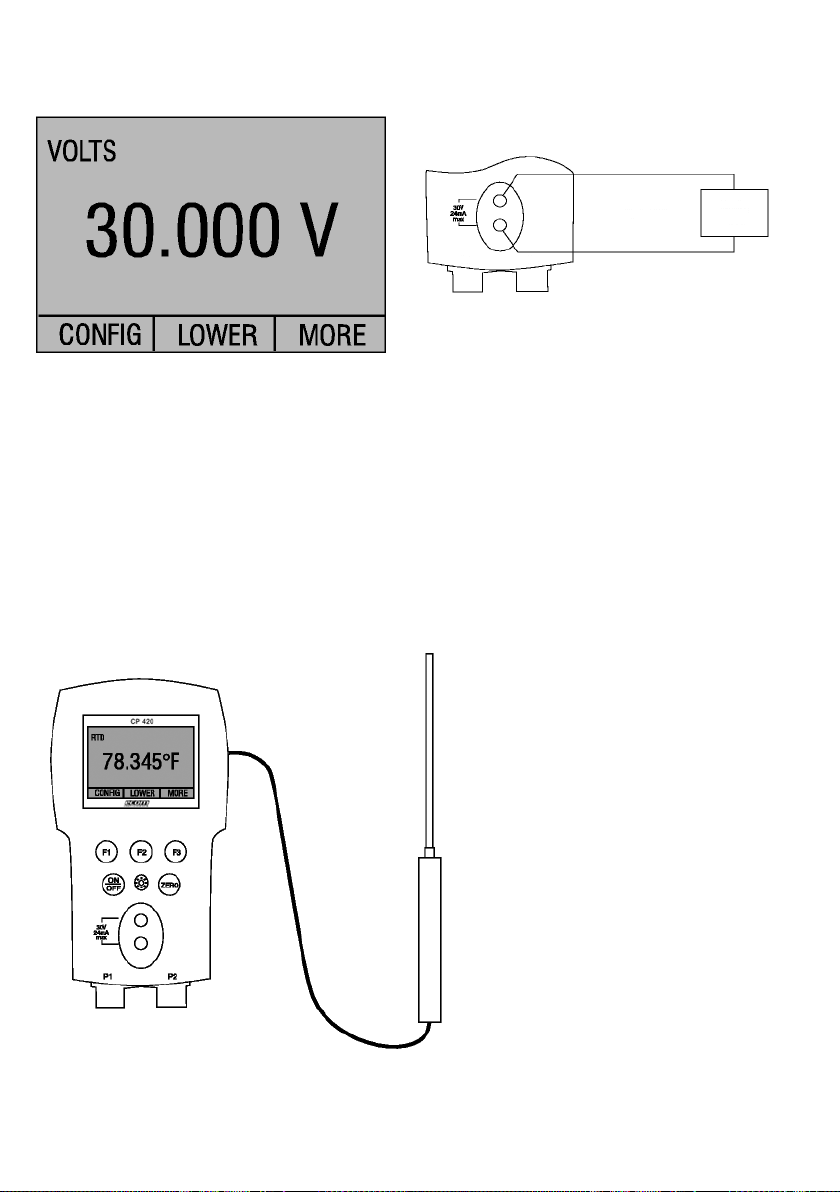

5. Measuring Voltage

To measure voltage use the input terminals in the front of the calibrator. Select the Volts

function on one of the displays. The calibrator can measure up to 30V.

Figure 8

6. Measuring Temperature with and RTD

To measure temperature using an RTD probe you must select the RTD function on one of

the displays. Make sure the proper probe type is selected. There are 4 probe types

supported, P100-385, P100-392, P100-JIS and CUSTOM.

Note: The factory default type is PT100-385 so if the CP 400/420 is being used with the ecom

Model LPT100A probe you do not have to set the probe type. Simply plug the probe into

the CP 400/420 and configure the display to read temperature.

If a custom probe is being used, the entering of R0 and coefficients is handled through

the serial interface (see section 11).

Figure 9

Device

under

Test

Up to

30V

P1 P2

RTD Probe

45

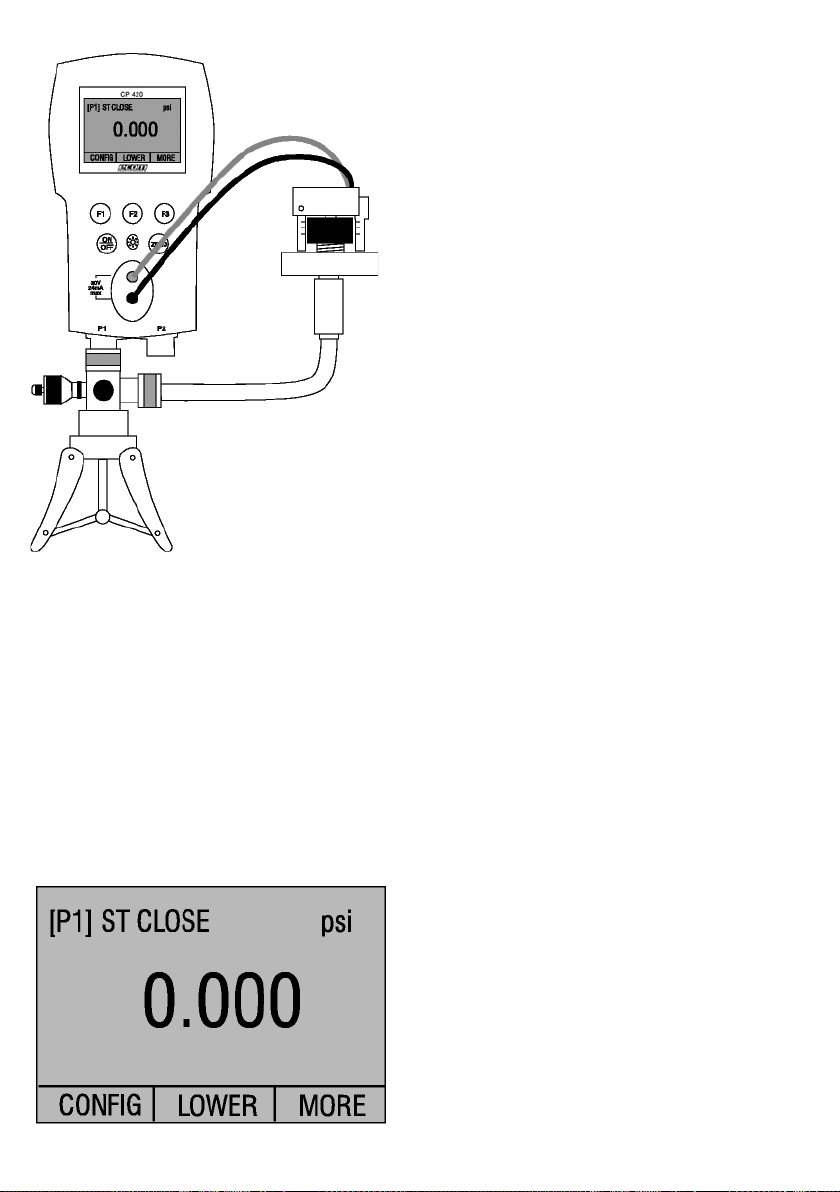

7. Performing a Pressure Switch Test

Figure 10

To perform a switch test, follow these steps:

1. Change the setup to Setup 4 (default switch test).

Setup 4: The upper display is set to [P1] ST, all other displays are off.

Important NOTE:

The pressure Switch Test can be performed with the following functions[P1] ST, [P2] ST, or EXT ST.

2. Connect the calibrator to the switch using the pressure switch terminals. The polarity

of the terminals does not matter. Then connect the pump to the calibrator and the

pressure switch.

3. Make sure the vent on the pump is open. Zero the calibrator if necessary.

Close the vent after zeroing the calibrator.

4. The top of the display will read “CLOSE”.

Pressure switch under test

46

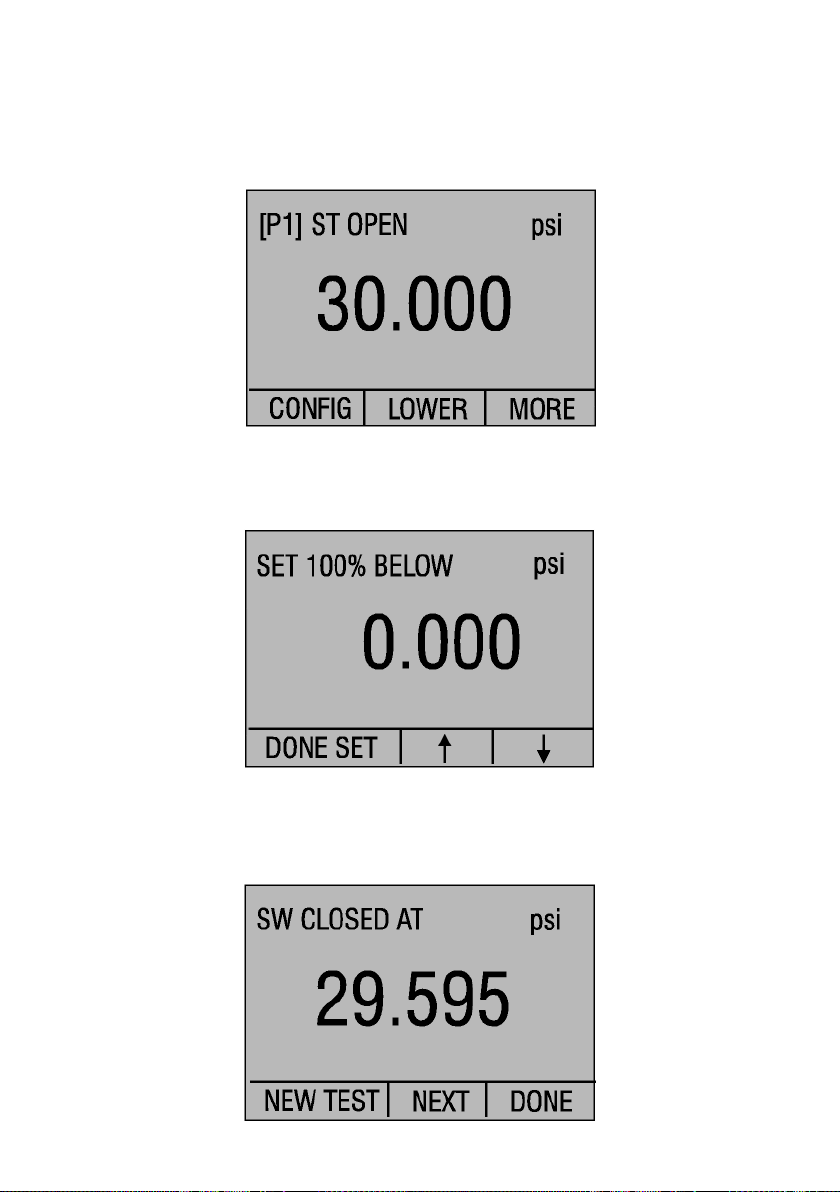

5. Apply pressure with the pump slowly until the switch opens.

Important NOTE: In the switch test mode the display update rate is increased to help

capture changing pressure inputs. Even with this enhanced sample rate pressurizing the

device under test should be done slowly to ensure accurate readings.

6. Once the switch is open, “OPEN” will be displayed, bleed the pump slowly until the

pressure switch closes.

7. At the top of the display it will now read, “SW OPENED AT” and give you the

pressure that the switch opened at.

8. Press the “NEXT” option to view when the switch closed, and the dead band.

47

9. Press the “NEW TEST” option to clear the data and perform another test.

10. Press the “DONE” option to end the test and return to the standard pressure setting.

Example:

[P1] ST will return to [P1].

Important NOTE: The previous example uses a normally closed switch.

The basic procedure is still the same for a normally open switch, the display will just read “OPEN”

instead of “CLOSE”.

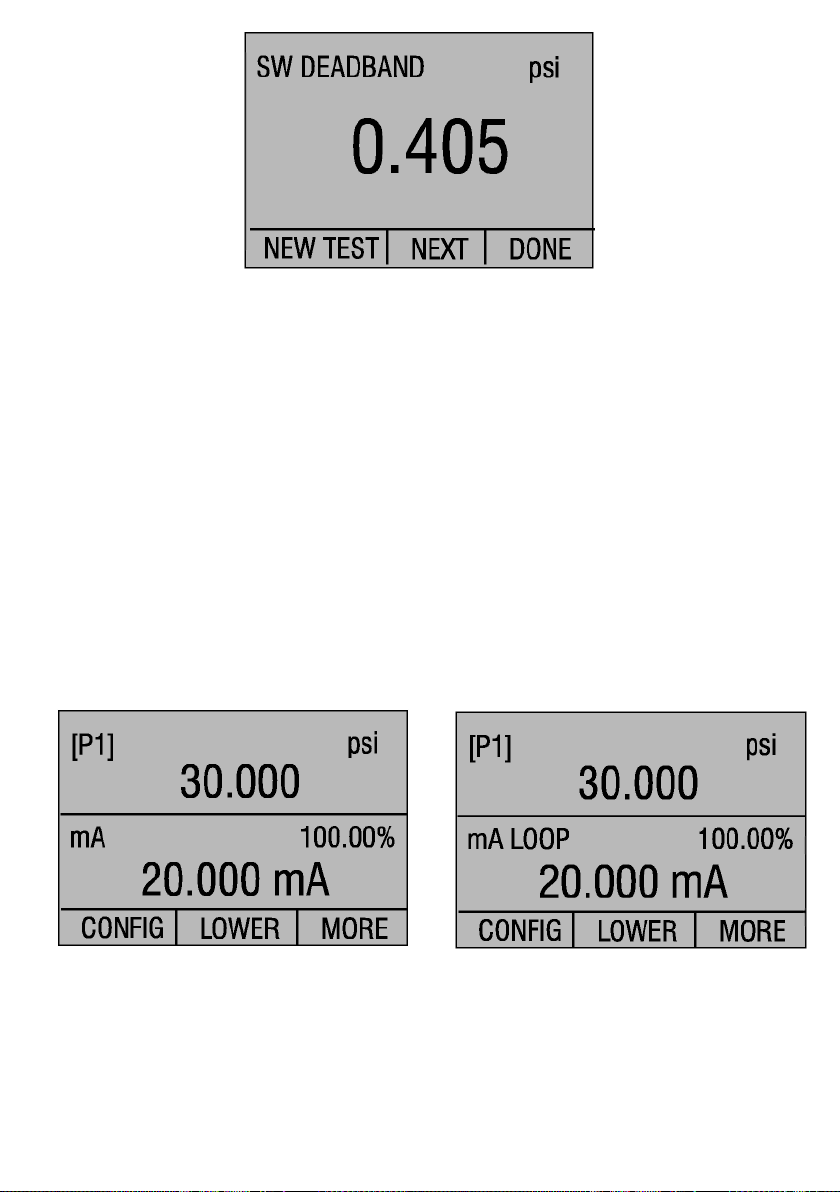

8. Calibrating Transmitters

8.1 Using the mA Input Function

The mA input function allows the user to read back the 4-20 mA output from the device

being calibrated. This can be done in one of two ways.

1) Passively - Where the device under test directly generates 4-20 mA and can be read by

the calibrator.

2) Actively – Where the calibrator supplies 24 VDC loop power to the device under test to

power the device while reading the resulting 4-20 mA signal.

1) 2)

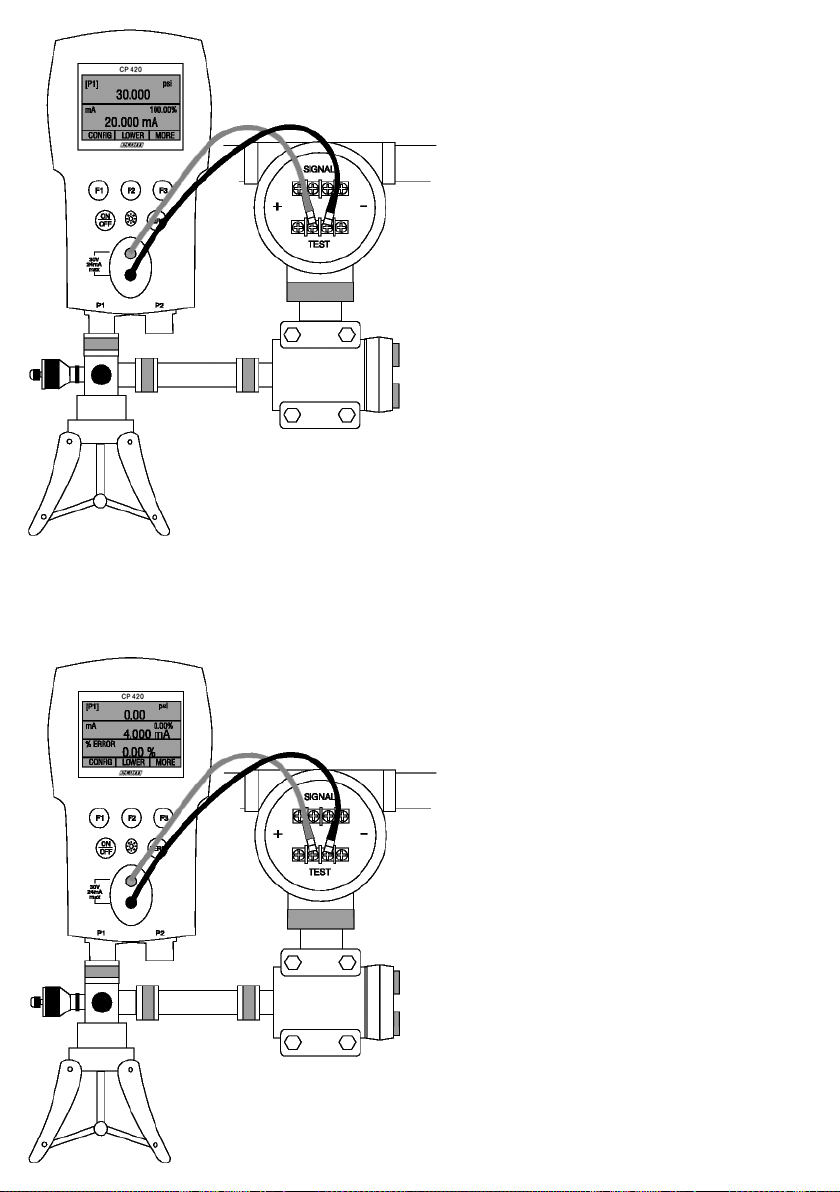

8.2 Calibrating a Pressure-to-Current Transmitter

To calibrate a pressure-to-current transmitter (P/I), perform the following steps:

1. Connect the calibrator and the pump to the transmitter.

2. Apply pressure with the pump.

3. Measure the current output of the transmitter.

4. Ensure the reading is correct. If not, adjust the transmitter as necessary.

48

Figure 11.

8.3 Percent Error Function

The calibrator features a unique function which can calculate pressure vs. milliamp error

as a percentage of the 4 to 20 mA loop span. The percent error mode uses all 3 screens

and has a unique menu structure. It simultaneously displays pressure, mA and percent

error.

Figure 12.

49

Example:

Suppose a pressure transmitter under test is 30 psi (2 Bar) Full Scale and outputs a corresponding 4

to 20 mA signal. The user can program in a 0 to 30 psi pressure span into the calibrator and the

calibrator will calculate and display the deviation or % Error from the expected 4 to 20 mA output.

This eliminates the need for manual calculations and also helps if it becomes difficult to set an exact

pressure with an external pump.

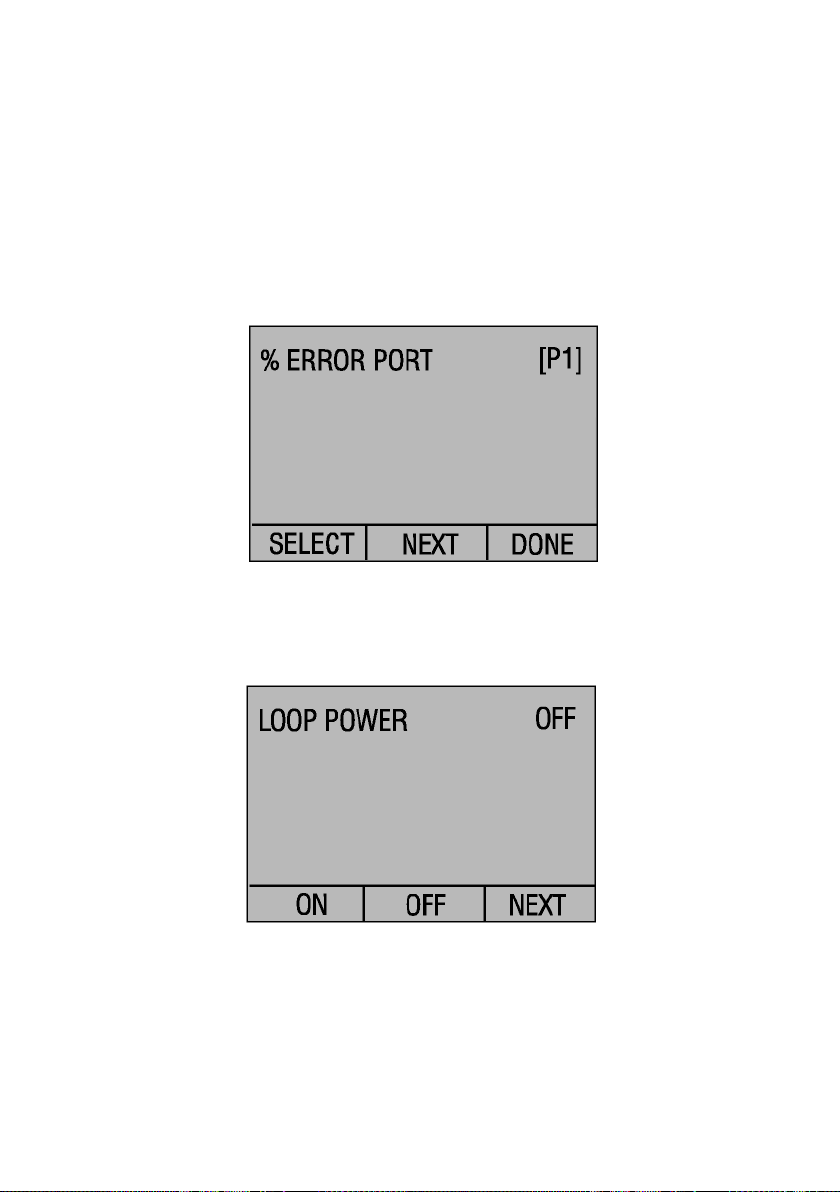

To use the %ERROR function proceed as follows:

1. With the calibrator turned on and operating press the F3 key to activate the MORE

menu option. Now press the F1 key to activate the %ERROR option.

2. Press the F1 key to select the CONFIG option.

3. The first option is setting the Port, use the select option to scroll through the port

choices, when finished select the NEXT option.

4. LOOP POWER can be toggled on/off, select NEXT when done.

5. Use SELECT to toggle through the UNIT options, and select NEXT to move on.

50

6. Use the and arrows to set the 100% point of the desired pressure range, select

DONE SET when finished.

7. Again, use the arrows to set 0% point and select DONE SET when finished and the

%ERROR mode will be ready to use.

Note: The 0% and 100% point will be saved in non-volatile memory until they are

changed again by the user for the internal sensors, and external pressure modules.

When using an external module the 0% and 100% are set to low and full scale of the

module until the user changes it, or if it was previously saved.

51

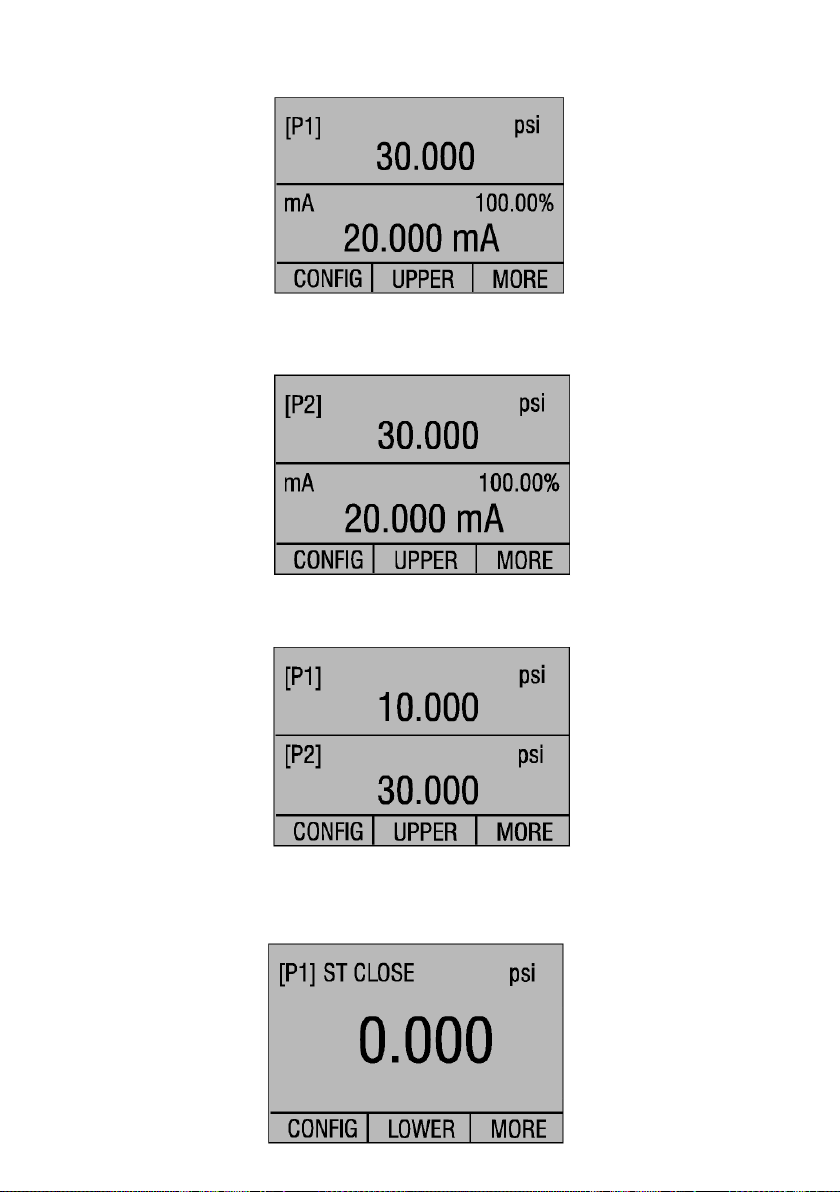

9. Factory Setups

The Calibrator is loaded with five factory setups. These setups are shown below.

Setup 1: The upper display is set to [P1] mode and the middle is set to mA, lower is off.

Setup 2: The upper display is set to [P2] mode and the middle is set to mA, lower is off.

Setup 3: The upper display is set to [P1] mode and the middle is set to [P2], lower is off.

Setup 4: The lower display is set to [P1] switch test, the other displays are off.

This manual suits for next models

1

Table of contents

Other Ecom Test Equipment manuals