Fenwal 35-62 Series User manual

SERIES 35-62

24 VAC Microprocessor Based Dual Point

Direct Spark Ignition Control

FEATURES

24 VAC microprocessor based DSI control

System diagnostic LED

Multiple tries

Custom prepurge and interpurge timings

Remote flame sensing

Full time flame sensing

Flame sense test pins

Software conforms to UL 1998 requirements

DESCRIPTION

The Series 35-62 is a 24 VAC Microprocessor Based Dual Point

Direct Spark Ignition Control continually and safely monitors,

analyzes and controls the proper operation of two gas burners.

Value added features such as LED diagnostics, automatic one hour

reset, and flame current test pins highlight the controls benefits.

®

35.62.03

Input Power Control:20-28 VAC 50/60 Hz

(Class 2 Transformer)

Input Current Drain 300 mA @ 24 VAC and

gas valve relay energized

(control only)

Gas Valve Rating 1.5A @ 24 VAC

(Inrush 3,0A maximum)

Operating Temperature -40°F to +160°F

-40°C to +71°C

Flame Sensitivity >1.0uA minimum

Flame Failure 0.8 seconds

Response Time

Types of Gases Natural, LP, or manufactured

Spark Rate Line frequency

(50/60 sparks/sec)

Enclosure Gray (Noryl N-190) fire

retardant plastic integral

standoffs optional

Moisture Resistance Conformal coated to operate

to 95% R.H. Care must be

taken to protect module from

direct exposure to water

Tries for Ignition One or three try versions

available

Trial for Ignition Periods 4.0,7.0,10.0,15.0 or 21.0

seconds available

Prepurge & Interpurge None,15, or 30 seconds

depending on model.

APPLICATIONS

Gas furnaces

Boilers

Water heaters

Commercial cooking

Other similar appliances

SPECIFICATIONS

Series 35-62, 24 VAC Dual Point DSI Control Page 1

www.fenwalcontrols.com 1-800-FENWAL-1

Agency Certifications

Design certified to ANSI Z21.20-1993 and

CAN/CSA C22.2 No. 199-M89

MOUNTING AND WIRING

CAUTIONS:

1. Ceramic insulators should nor be in or close to the flame.

2. Electrode assemblies should not be adjusted or disassem bled.

Electrodes should have a gap spacing of 0.125± 0.031 in

(3.12± 0.81 mm). If this spacing is not correct, the assembly must

be replaced. Electrodes are NOT field adjustable.

3. Exceeding the temperature limits can cause nuisance lockouts and

premature electrode failure.

4. Electrodes must be placed where they could not be exposed to the

appliance user in normal operation.

SEQUENCE OF OPERATION / FLAME

RECOVERY / SAFETY LOCKOUT

Power Up/Stand-By

• Upon applying power (24 VAC) to 24V terminal, the control will

reset, perform a self check routine, initiate full time flame sensing,

flash the diagnostic LED for up to four seconds, and enter the

thermostat scan state.

Heat Mode

• When a call for heat is received from the thermostat supplying 24

volts to TH/W, a pre-purge delay begins, then the gas valve is

energized and the sparks commence at both burners for the trial

for ignition period.

• When flame is detected during the trial for ignition, sparks are

shutoff immediately and the gas valve remains energized. The

thermostat and burner flame are constantly monitored to assure

the system continues to operate properly. When the thermostat

is satisfied and the demand for heat ends, the main valve is

de-energized immediately.

Failure to Light - Lockout

SINGLE TRIAL MODEL

Should either burner fail to light, or flame is not detected during the

trial for ignition period, the control will go into lockout and the valve

will be turned of immediately.

MULTI TRIAL MODEL

Should either burner fail to light, or flame is not detected during

the first trial for ignition period, the gas valve is de-energized

and the control goes through an interpurge delay before another

ignition attempt. The control will attempt two additional ignition

trials before going into lockout and the valve relay will be de-

energized immediately.

Recovery from lockout requires a manual reset by either resetting

the thermostat or removing 24 volts for a period of 5 seconds.

FLAME FAILURE- RE-IGNITION

If the established flame signal is lost from either burner while the

burners are operating, the control will respond within 0.8 seconds.

The HV spark will be energized for a trial for ignition period in an

attempt to relight the burners. If either burner does not light the

control will de-energize the gas valve. Multi-try models will make

two more attempts to relight the burners. If either burner does not

relight the control will go into lockout as noted above in “Failure

to light”. If flame is re-established, normal operation resumes.

Flame Fault

If at any time the main valve fails to close completely and main

tains a flame, the full time flame sense circuit will detect it and

flash an error code of 2.

CAUTION:

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation.

A functional checkout of a replacement control is recommended.

WARNING:

Operation outside specifications could result in failure of the

Fenwal product and other equipment with injury to people

and product.

TERMINAL DESIGNATIONS

TH/W THERMOSTAT INPUT

GND SYSTEM GROUND

V1 VALVE POWER

V2 VALVE GROUND

NC ALARM

S1 REMOTE FLAME SENSOR

S2 REMOTE FLAME SENSOR

FC1 FLAME CURRENT TEST PIN

FC2 FLAME CURRENT TEST PIN

24V 24 VAC INPUT (FULL TIME)

WARNING:

The Series 35-62 uses voltages of shock hazard potential. Wiring

and initial operation must be done by a qualified service technician.

The Series 35-62 is not position sensitive and can be mounted

vertically or horizontally. The control may be mounted on any

surface with #6 sheet metal screws.

All wiring must be done in accordance with both local and

national electrical code. The control must be secured in a area

that will experience a minimum of vibration and remain below the

maximum operating temperature of 160°F.

All connections should be made with UL approved 105°C rated

18 gauge, stranded,.054 thick insulated wire. Refer to wiring

diagram when connecting the Series 35-62 to other components

in the system.

PROPER ELECTRODE LOCATION

Proper location of the electrode assembly is important for

optimum system performance. It is recommended that electrode

assembly be mounted temporarily using clamps or other suitable

means so that the system can be checked before permanently

mounting the assembly. The electrode assembly should be

located so that the tips are inside the flame envelope and about

1/2 inch (1 cm) above the base of the flame. See Figure 3.

Page 2 Series 35-62, 24 VAC Dual Point DSI Control www.fenwalcontrols.com 1-800-FENWAL-1

ERROR MODE LED INDICATION

Internal Control Failure Steady on

Flame with No Call for Heat 2 flashes

Ignition Lockout 3 flashes

FAULT CONDITIONS

The LED will flash on for 1/4 seconds, then off for 1/4 second

during a fault condition, the pause between fault codes is

3 seconds.

TROUBLESHOOTING GUIDE

SYMPTOMS RECOMMENDED ACTIONS

1.Dead A. Miswired

B. Transformer bad

C. Fuse/Circuit breaker bad

D. Bad control (check LED for steady on)

2. Thermostat on- no spark A. Miswired

B. Bad t’stat no voltage@ terminal W

3. Valve on, no spark A. Shorted electrode

B. Open HV cable

C. Miswired

D. Bad control

4. Spark on, no valve A. Valve coil open

B. Open valve wire

C. Bad control (check voltage

between V1 & V2)

5. Flame okay during TFI, A. Bad electrode

no flame sense (after TFI) B. Bad S1 or HV wire

C. Poor ground at burner

D. Poor flame (check flame current)

6. Flame with no call for heat A. Stuck valve (check LED for 2 flashes)

FLAME CURRENT CHECK

Flame current is the current which passes through the flame from

the sensor to ground. The minimum flame current necessary to keep

the system from lockout is .7 microamps. To measure flame current,

connect an analog DC microammeter to the FC - FC+ terminals.

Meter should read .7 uA or higher. If the meter reads below “0” on

scale, meter leads are reversed. Disconnect power and reconnect

meter leads for proper polarity.

HIGH VOLTAGE CABLE

Fenwal Part Number 05-129608-624 Suppression Cable

(or equivalent) must be used for proper operation of control.

IGNITOR LOCATION

Figure 3

WIRING DIAGRAM

Series 35-62, 24 VAC Dual Point DSI Control Page 3

www.fenwalcontrols.com 1-800-FENWAL-1

The Series 35-62 series direct spark ignition controller

is a custom manufactured control. Consult factory with

operational requirements.

Variable Options:

Pre-purge time

Single or multiple tries for ignition

Trial for ignition time

Inter-purge time

The Series 35-62 is only available

with remote flame sensing

CONTROL CONFIGURATION

SERIES 35-625 X X X - X X X Description

DIMENSIONS

FENWAL

400 MAIN STREET, ASHLAND, MA 01721

TEL: (508) 881-2000 FAX: (508) 881-6729

www.fenwalcontrols.com

© 2003 Fenwal Printed in U.S.A. TAG

These instructions do not purport to cover all the details or variations in the equipment

described, nor do they provide for every possible contingency to be met in connection with

installation, operation and maintenance. All specifications subject to change without notice.

Should further information be desired or should particular problems arise which are not covered

sufficiently for the purchaser’s purposes, the matter should be referred to KIDDE-FENWAL,

Inc., Ashland, Massachusetts.

P/N 35.62.03 10/30/03

®

Page 4 Series 35-62, 24 VAC Dual Point DSI Control www.fenwalcontrols.com 1-800-FENWAL-1

Non-Standard Configurations

9 = Non Standard Configuration

A 9 in this location of the part number

(i.e. 35-62 5 -113) identifies this

configuration as a non-standard design.

The part number does not follow the part

numbering system. The 9XX is a sequential

part number assigned by Fenwal. Consult

factory for operating characteristics of this

control.

901

Other Fenwal Computer Hardware manuals

Popular Computer Hardware manuals by other brands

Infortrend

Infortrend SentinelRAID 170 Installation and hardware reference manual

Texas Instruments

Texas Instruments TUSB1004EVM user guide

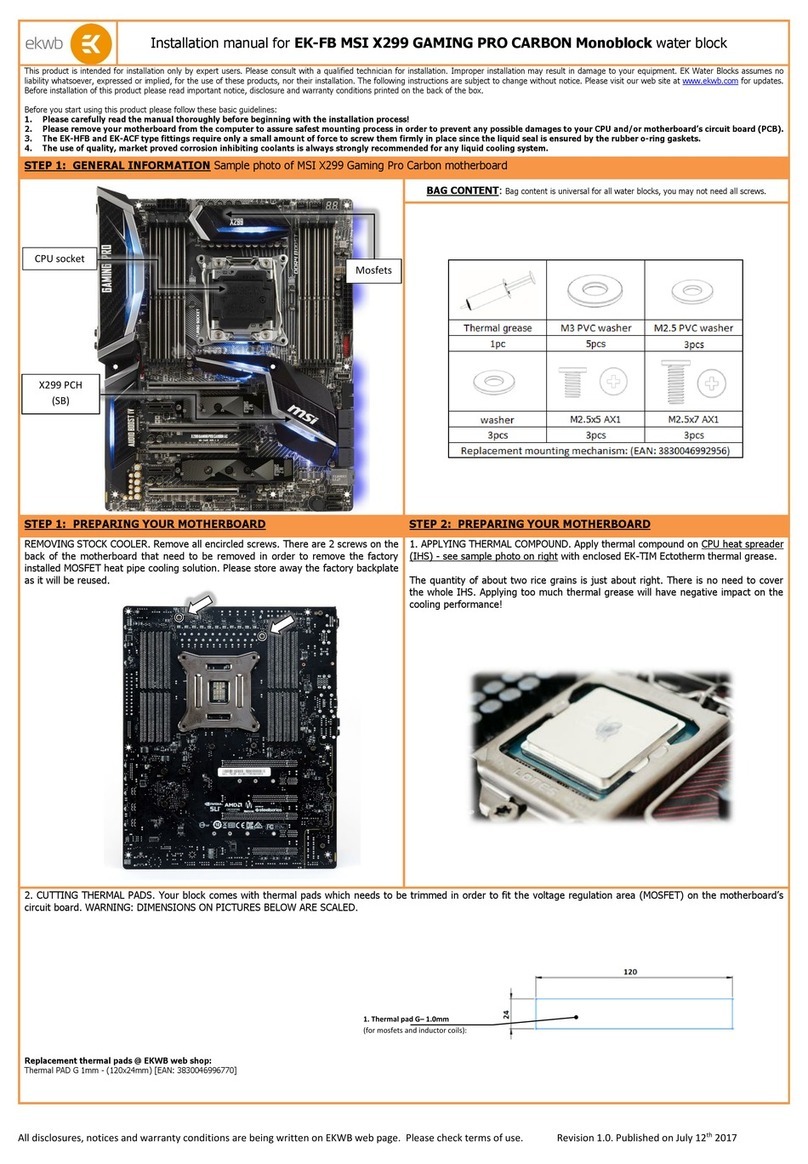

ekwb

ekwb EK-FB MSI X299 GAMING PRO CARBON Monoblock installation manual

Seagate

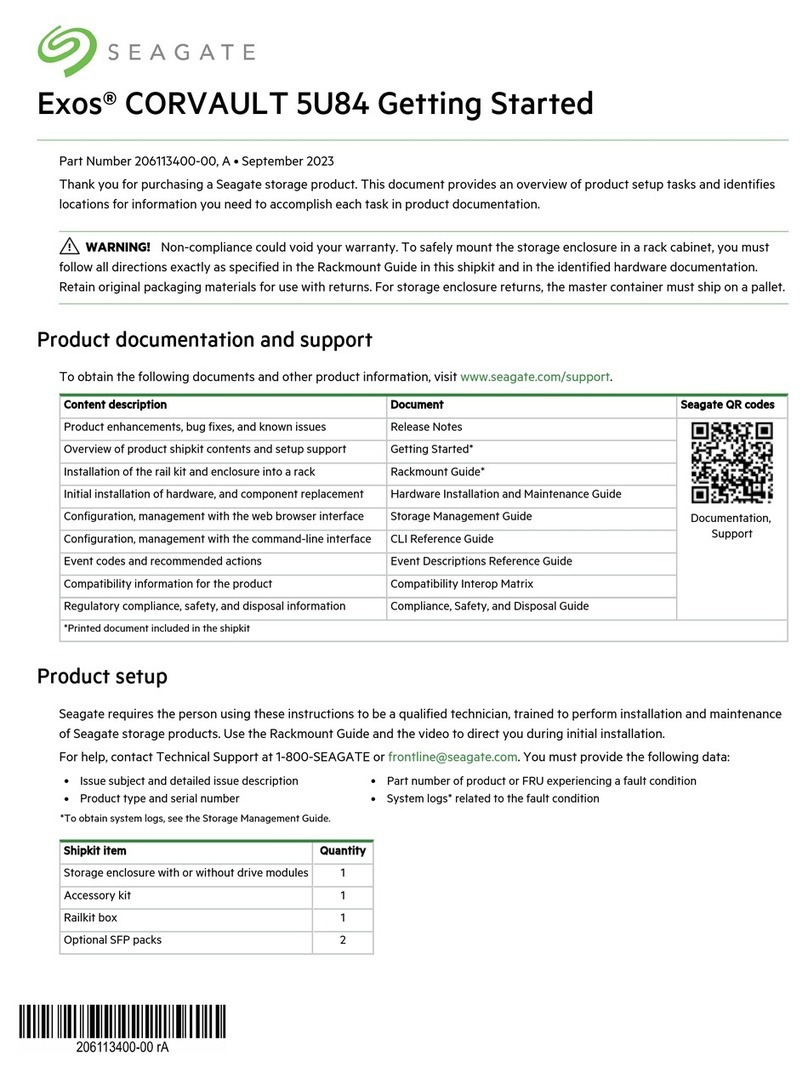

Seagate Exos 5U84 Series Getting started

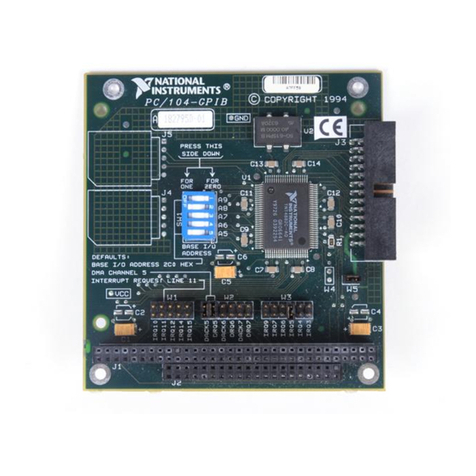

National Instruments

National Instruments PC/104-GPIB Getting started

Avaya

Avaya X330F2 installation guide