Ferm Industrial CDM1141P User manual

WWW.FERM.COM

SL

PL

LT

LV

RO

BG

EL

AR

EN

DE

NL

FR

ES

IT

SV

FI

DA

HU

CS

SK

Original instructions 04

Übersetzung der Originalbetriebsanleitung 09

Vertaling van de oorspronkelijke gebruiksaanwijzing 16

Traduction de la notice originale 22

Traducción del manual original 28

Traduzione delle istruzioni originali 34

Översättning av bruksanvisning i original 40

Alkuperäisten ohjeiden käännös 46

Oversættelse af den originale brugsanvisning 51

Eredeti használati utasítás fordítása 57

Překlad püvodního návodu k používání 63

Preklad pôvodného návodu na použitie 69

Prevod izvirnih navodil 75

Tłumaczenie instrukcji oryginalnej 80

Originalios instrukcijos vertimas 86

Instrukciju tulkojums no oriģinālvalodas 92

Traducere a instrucţiunilor originale 97

Оригинални инструкции 103

Μετάφραση του πρωτοτύπου των οδηγιών χρήσης 110

116

CDM1141P

CDM1141P

2

Fig. A

14

7 12

2

10

1

13

3

4

11

9

3

Fig. C

Fig. B

3

2

2

5

6

1

2

4

EN

Cordless Li-Ion Drill 20V

CDM1141P

Thank you for buying this Ferm product. By doing

so you now have an excellent product, delivered

by one of Europe’s leading suppliers. All products

delivered to you by Ferm are manufactured

according to the highest standards of

performance and safety. As part of our philosophy

we also provide an excellent customer service,

backed by our comprehensive warranty. We hope

you will enjoy using this product for many years

to come.

1. SAFETY INSTRUCTIONS

Read the enclosed safety warnings,

the additional safety warnings and the

instructions. Failure to follow the safety

warnings and the instructions may result in

electric shock, fire and/or serious injury. Save the

safety warnings and the instructions for future

reference.

The following symbols are used in the user

manual or on the product:

Read the user manual.

Denotes risk of personal injury, loss of life

or damage to the tool in case of non-

observance of the instructions in this

manual.

Risk of electric shock

Variable electronic speed

Rotation, left/right

Do not use in rain

Indoor use only

Class II machine - Double insulation - You

don’t need any earthed plug.

Max temperature 400C

Do not throw the battery into fire

Do not throw the battery into water

Do not dispose of the product in

unsuitable containers.

Separate collection for Li-ion battery.

T2.0A

Time-lag miniature fuse-link

The product is in accordance with the

applicable safety standards in the

European directives.

Additional safety warnings for drills

and screw drivers

Drill safety warnings

a) Wear ear protectors when impact drilling.

Exposure to noise can cause hearing loss.

b) Hold the power tool by insulated gripping

surfaces, when performing an operation

where the cutting accessory may contact

hidden wiring. Cutting accessory contacting

a “live” wire may make exposed metal parts

of the power tool “live” and could give the

operator an electric shock.

c)

Brace the tool properly before use. This tool

produces a high output torque and without

properly bracing the tool during operation, loss

of control may occur resulting in personal injury.

Safety instructions when using long drill bits

a) Never operate at higher speed than the

maximum speed rating of the drill bit.

At higher speeds, the bit is likely to bend if

allowed to rotate freely without contacting the

workpiece, resulting in personal injury.

b) Always start drilling at low speed and with

the bit tip in contact with the workpiece.

At higher speeds, the bit is likely to bend if

allowed to rotate freely without contacting the

workpiece, resulting in personal injury.

5

EN

c) Apply pressure only in direct line with the bit

and do not apply excessive pressure. Bits

can bend causing breakage or loss of control,

resulting in personal injury.

Safety warnings for battery

a) Do not open the battery. Danger of

shortcircuiting.

b) Protect the battery against heat, e. g.,

against continuous intense sunlight, fire,

water, and moisture. Danger of explosion.

c) In case of damage and improper use of the

battery, vapours may be emitted. Ventilate

the area and seek medical help in case

of complaints. The vapours can irritate the

respiratory system.

d)

Use the battery only in conjunction with your

Ferm Industrial product. This measure alone

protects the battery against dangerous overload.

e) The battery can be damaged by pointed

objects such as nails or screwdrivers or by

force applied externally. An internal short

circuit can occur and the battery can burn,

smoke, explode or overheat.

Safety warnings for charger

Intended use

Charge only CDA1132P and CDA1133P type

rechargeable Battery packs with the charger.

Only use the following batteries of the Ferm

Industrial FI20V battery platform. Using any other

batteries could cause serious injury or damage

the tool.

CDA1132P 20V, 2Ah Lithium-Ion

CDA1133P 20V, 4Ah Lithium-Ion

The following charger of the can be used to

charge these batteries.

CDA1131P Quick charger

The batteries of the Ferm Industrial FI20V battery

platform are interchangeable with all the Ferm

Industrial FI20V battery platform tools.

Residual risks

Even when the power tool is used as

prescribed it is not possible to eliminate all

residual risk factors. The following hazards

may arise in connection with the power tool’s

construction and design:

a) Health defects resulting from vibration

emission if the power tool is being used

over longer period of time or not adequately

managed and properly maintained.

b) Injuries and damage to property to due to

broken accessories that are suddenly dashed.

Warning! This power tool produces an

electromagnetic field during operation.

This field may under some circumstances

interfere with active or passive medical

implants. To reduce the risk of serious or

fatal injury, we recommend persons with

medical implants to consult their physician

and the medical implant manufacturer

before operating this power tool.

Power cord replacement

If the supply cord is damaged, it must be replaced

by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

2. MACHINE INFORMATION

Intended use

This cordless drill is intended for driving in and

loosening screws as well as for drilling in wood,

metal and plastic.

Technical specifications

Machine CDM1141P

Voltage 20V

Chuck capacity 1.5-13mm

No load speed

Position 1:

Position 2:

0-450/min

0-1700/min

Max torque 50 Nm

Torque settings 21 + drill mode

Weight (without battery pack) 1.24 kg

Sound pressure level LpA 92 dB(A), K=3dB(A)

Sound power level LwA 103 dB(A), K=3dB(A)

Vibration 2.93 m/s2 K=1.5 m/s2

6

EN

Charger CDA1131P

Charger input 100-240VAC 50-60Hz,

50W

Charger output 20V 2A

Charging time 2Ah battery 60 minutes

Charging time 4Ah battery 120 minutes

Recommended batteries CDA1132P, CDA1133P

Weight 0.36 kg

Battery CDA1132P

Battery Type Lithium-Ion

Voltage 20V

Capacity 2.0 Ah

Recommended charger CDA1131P

Weight 0.38 kg

Vibration level

The vibration emission level stated in this instruction

manual has been measured in accordance with

a standardized test given in EN 62841; it may be

used to compare one tool with another and as a

preliminary assessment of exposure to vibration

when using the tool for the applications mentioned.

• Using the tool for different applications, or with

different or poorly maintained accessories, may

significantly increase the exposure level.

• The times when the tool is switched off or when

it is running but not actually doing the job, may

significantly reduce the exposure level.

Protect yourself against the effects of vibration by

maintaining the tool and its accessories, keeping

your hands warm, and organizing your work patterns.

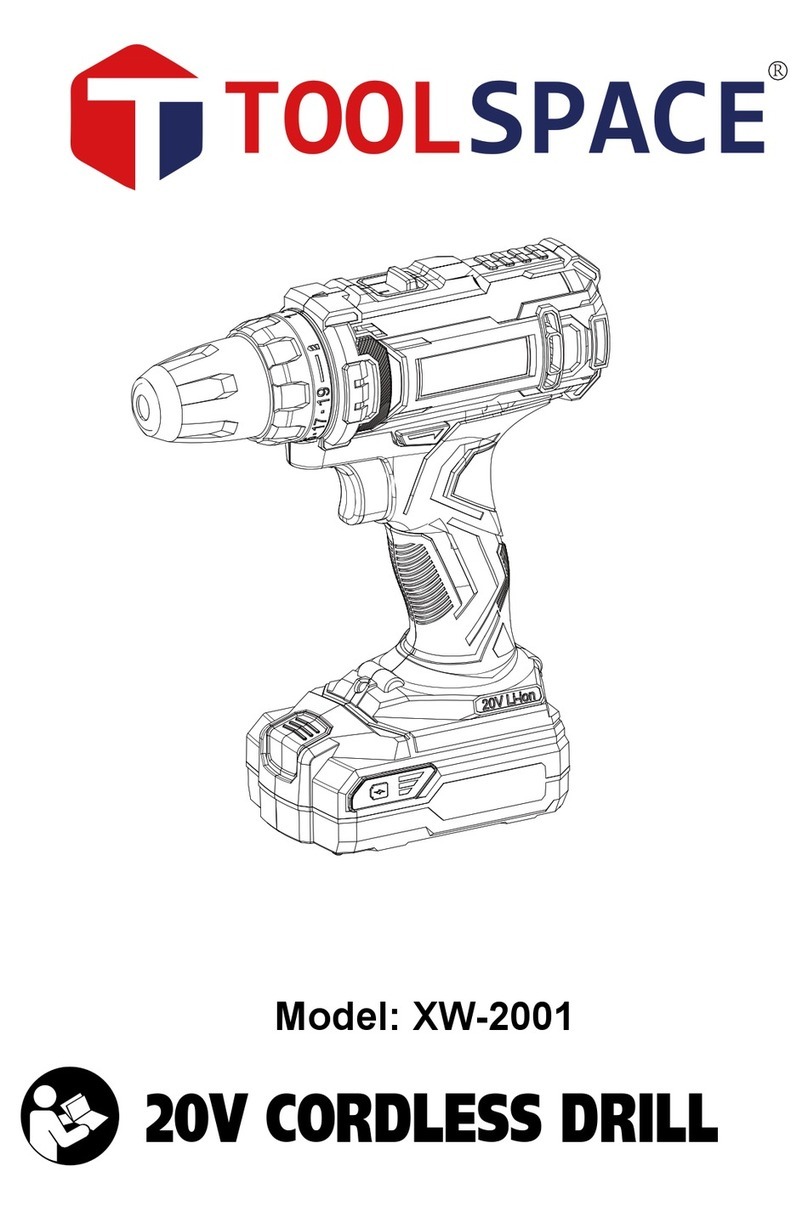

Description

The numbers in the text refer to the diagrams on

pages 2- 3

Fig. A

1. Machine

2. Battery

3. Battery unlock button

4. Battery charge indication

5. Charger

6. Charger LED indicators

7. Chuck

9. Gear selection switch

10. Direction switch

11. On / off switch

12. Torque adjustment ring

13. Work light

14. Belt hook

3. OPERATING

The battery must be charged before first

use.

Removing the battery from the machine

Fig. B

• Hold the machine (1) firmly with one hand

• Push down the battery unlock button (3)

located on the rear side of the battery (2) with

the other hand.

• Keep pushing this button (3) down and slide

the battery backwards out of the machine, like

shown in Fig. B.

Inserting the battery into the machine

Fig. B

Ensure that the exterior of the battery is

clean and dry before connecting to the

charger or machine.

• Hold the machine (1) firmly with one hand

• Insert the battery (2) into the base of the

machine as shown in Fig. B.

• Push the battery further forward until it clicks

into place.

Checking the battery charging status

Fig. C

The included battery is delivered in partly

charged condition.

• To check the battery charge status, push the

button (4) on battery shortly.

• The battery has 3 lights indicating the charge

level, the more lights that burn, the more

charge the battery has left.

Charging the battery (with the charger)

Fig. C

• Take the battery (2) from the machine

• Turn the battery (2) to upside down position and

slide it onto the charger (5) as shown in Fig. C.

•

Push the battery until it is fully pushed into the

slot.

7

EN

•

Plug the charger plug into an electrical outlet

and wait for a while. The LED indicators on

the charger (6) will lighten up and show the

charger status.

LED indicators (6)

Fig.C

The charger has 2 LED indicators (6) which

indicate the status of the charging process:

Red LED

status:

Green LED

status: Charger status

Off Off No power

On Off

Standby mode:

-No battery is inserted or,

-Battery inserted but charging has

finished more then 2 hours ago

Blinking Blinking Defective battery

On Blinking Battery charging in progress

On On Battery charging finished, battery

fully charged

Blinking Off

Battery is too hot, charging

progress is on hold. Charging will

start automatically after the battery

has cooled down.

• Fully charging the battery may take up to 60

minutes.

• After the battery is fully charged remove the

charger plug from the outlet and remove the

battery from the charger.

• The battery can be stored or directly installed

on the machine.

Lithium-Ion cells can be stored for a long

period without losing much of their

charge. When the machine is not being

used over a longer period of time it is best

to store the battery in charged condition.

Fitting and removing drills or screwdriver bits

Fig. A

Always remove the battery before

mounting an accessory.

The drill chuck (7) is suitable for drills and

screwdriver bits with round shaft as well as

hexagonal shaft.

• Hold the machine firmly with one hand

•

Open the drill chuck (7) by rotating the chuck

sleeve with your other hand in clockwise direction

until it is opened far enough for the bit to slide in.

• Insert the shaft of the drill or screwdriver bit

• Tighten the drill chuck again by firmly rotating

the chuck sleeve counterclockwise.

• Check if the bit is centered well by shortly

activating the machine´s on/off switch.

Adjusting the gears

Fig. A

Never switch gears when the motor is

running, this will damage your machine.

Never put switch in the middle between

both positions, this will damage your

machine.

The machine has 2 drill speeds, which can be

adjusted by sliding the gear switch (9) forward or

backwards. The number on the gear switch (9)

shows which position is chosen.

• Position 1: For slow drilling, large drilling

diameter or screw driving. The machine has

high power at a low speed.

• Position 2: For fast drilling or small drilling

diameter.

Adjusting the direction of rotation

Fig. A

• Set the direction switch (10) to position “” in

order to drive screws or to use it for drilling.

• Set the direction switch (10) to position “” in

order to remove screws

Switching the machine on and off

Fig. A

The on/off switch (11) is used for activating the

machine and adjusting rotation speed.

• Pressing the on/off switch (11) will activate

the machine, the further the switch is being

pushed, the faster the drill will turn.

• Releasing the on/off switch (11) will stop the

machine.

•

Move the direction reversing switch (10) to the

middle position to lock the movement of the on/

off switch. It cannot be activated in this position.

Only lay down the machine when it has

stopped running completely. Do not

place it on a dusty surface as particles of

dust could get into the mechanism.

8

EN

Adjusting the torque

Fig. A

The machine has different torque settings and

a special drill mode to set the power being

transmitted to the chuck.

By rotating the torque adjustment ring (12),

screws can be driven to a predetermined depth,

which is ideal for repetitive work. The higher the

number, the more torque will be transmitted.

• Select a low setting for small screws or soft

work material.

• Select a high setting for large screws, hard

work materials and when removing screws.

• You should preferably choose a setting as

low as possible when driving screws. Select

a higher setting if the motor slips before the

screw is fully tightened.

• For drilling, turn the torque adjustment ring

(12) to the setting for drilling by fully turning it

counterclockwise.

Ensure that the direction switch (10) is

always set to during drilling.

The machine is equipped with electronic

overload protection function. When the

machine gets overloaded it will shut

down automatically. When this happens,

please wait for at least 5 seconds to let

the overload protection reset itself.

Work light (13)

Fig. A

The machine is equipped with a work light to

illuminate the work location.

• It automatically switches on when the on/off

switch is being pressed.

• It automatically switches off when the on/off

switch is released again.

Belt hook (14)

Fig. A

The machine is equipped with a belt hook for

hanging the machine to your belt during use.

Always switch the direction switch (10) to

middle position to avoid accidental

startup of the machine.

• When delivered, the belt hook (14) is

assembled to the left side of the machine.

• It can easily be removed by removing the

screw on the hook and taking it off.

• It can be assembled on the right side of the

machine when this is preferred.

User tips

When driving screws into wood, metal and other

materials:

• Before using the appliance check if the drill or

screw bit is properly fitted and centered inside

the drill chuck.

• Screw bits are available in several shapes and

dimensions. When unsure, always try if the bit

fits on the screw head without any free play

before using the machine.

• Make sure the machine is not running when

it contacts the screw. A rotating bit may slip.

This could result in damage to the work piece.

When drilling into wood, metal and other materials:

• With small diameter drills use a high drill speed.

For large diameter drills use a low drill speed.

• For hard materials, select a low drill speed, for

soft materials select a high drill speed.

• Fix the work piece properly, preferably by

using a clamp or vice.

• During drilling draw back the drill out of the

hole frequently so swarf or drill dust will be

removed.

When drilling in metal:

• Use a metal drill (HSS). For the best results you

should cool the bit with oil.

• Metal (HSS) drills can also be used drilling into

plastic.

4. MAINTENANCE

Before cleaning and maintenance, always

switch off the machine and remove the

battery pack from the machine.

Clean the machine casings regularly with a soft

cloth, preferably after each use. Make sure that

the ventilation openings are free of dust and

dirt. Remove very persistent dirt using a soft

cloth moistened with soapsuds. Do not use any

solvents such as gasoline, alcohol, ammonia,

Table of contents

Other Ferm Industrial Power Screwdriver manuals