TOOLSPACE XW-2001 User manual

20V CORDLESS DRILL

Model: XW-2001

Dear Customer,

Thank you for your purchase.

Your purchase means the world to us.

If you have any questions, we are here to service you.

lf the product you received is damaged or has quality

problems, please contact us through Email below and

attach product pictures of related problems,we will

reply to you as soon as possible,and provide you with

the best solution.

Email: TOOLSPACE01@outlook.com

Best regards,

Toolspace Customer Service Team

Do not discard electrical appliances with household waste.

CONGRATULATIONS ON YOUR PURCHASE OF OUR PRODUCT. This instruction manual is intended

primarily to familiarise the operator with safety, installation, operation, maintenance, product storage and

troubleshooting and it provides important information. So keep it well so that other users can information in the future

too. Due to the constant development and adaptation to the latest demanding EU standards, technical and optical changes

can be made to the products without prior notice. Photos and drawings in this instruction manual may only be illustrative.

Therefore, no legal claims related to this instruction manual, in particular any slight minor deviations from the information

contained therein, can be applied if the product continues to meet all of the above mentioned standards and

declarations, and works as described. In case of confusion, contact the importer or retailer.

Before the first operation, please read the owner’s manual carefully!

The battery contains toxic substances.

Please dispose of batteries at your local battery disposal depot.

IPX1

T3,15A

Do not store or use the battery in

locations where the temperature may reach or exceed 50°C!

Do not throw the battery into fire.

Do not throw the battery into water.

Do not throw the battery into household waste.

5

14

13

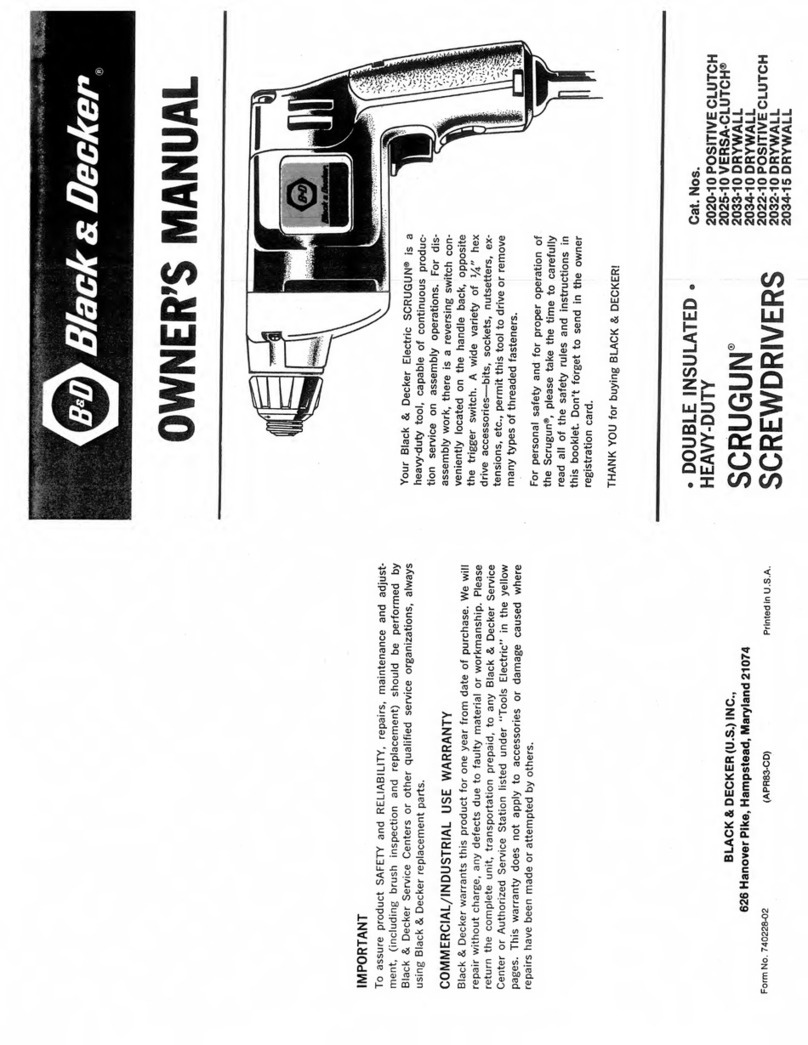

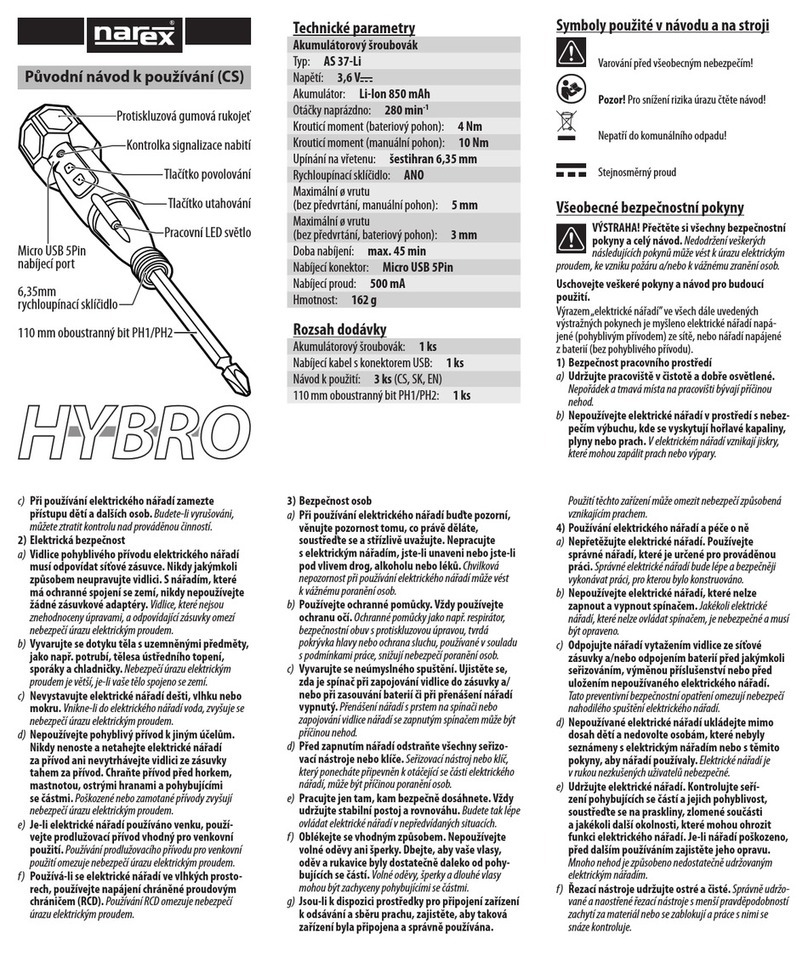

Features

Gear selector

Bit holder (magnc)

Rotonal direon switch/lock

ON/OFF switch/speed control

Bery charge level bon

Bery display LED

Bery pack

Release bn for bery pack

LED work light

Chuck

Torque selon ring

High-speed charger

Red charge control LED

Green charge control LED

Technical details

Cordless drill: XW-2001

Rated voltage: 20 V (DC)

Rated idle speed:

1st gear: n 00–400 rpm

2nd gear: n 0 0–1400 rpm

Chuck clamping

range : max. Ø 10 mm

Max. drill diameter:

Steel: 13 mm

Wood: 30 mm

Ba�ery: XW-200102C

Type: LITHIUM ION

Rated voltage: 20 V (DC)

Capacity: 2.0 Ah

Cells 5

High-speed baery charger: XZ2150-2400KT

INPUT:

Rated voltage: 120V~ , 50 Hz(AC)

Rated power consump

ti

ti

ti

tion: 65 W

OUTPUT:

Rated voltage: 21.5 V (DC)

Rated current: 2.4 A

Charging me: approx. 60 min.

Protec on class: II / (double insula on)

Noise emission value:

Noise measurement value determined in accordance with EN ISO 4817 The A-rated noise level of

the power tool is typically as follows:

Sound pressure level: L pA = 71 dB(A) Uncertainty K: K pA = 5 dB

Sound power level: L WA = 82 dB(A) Uncertainty K: K WA = 5 dB

Vibra�on emission value:

Total vibra�on values (vector total of three direc�ons) determined in accordance with EN 62841:

Drilling in metal: Vibra�on emission value

a h,D : 1.3m/s 2 Uncertainty K = 1.5 m/s2

NOTE

►The vibra�on level specified in these instruc�ons has been measured in accordance with the

standardised measuring procedure specified and can be used to make equipment comparisons.

The specified vibra�on emission value can also be used to make an ini�al exposure es�mate.

WARNING!

►The vibra�on level varies in accordance with the use of the power tool and may be higher than

the value specified in these instruc ons in some cases. Regular use of the electric tool in such a

way may cause the user to underes�mate the vibra�on. Try to keep the vib

r

a�on loads as low as

possible. Measures to reduce the vibra�on load are, e.g. wearing gloves and limi�ng the working

�me. Wherein all states of opera�on must be included (e.g. �mes when the power tool is

switched offand times where the power tool is switched on but running without load).

WARNING! Read all safety warnings designated by the symbol and

all instruons.

General Power Tool Safety Warnings

WARNING! Read all safety warnings, instructions, illustrations and

specifications provided with this power tool. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual current

device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

NOTE The term “residual current device (RCD)”can be replaced by the term “ground fault

circuit interrupter (GFCI)”or “earth leakage circuit breaker (ELCB)”.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair and

clothing away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection can

reduce dust-related hazards.

h) Do not let familiarity gained from frequent use of tools allow you to become

complacent and ignore tool safety principles. A careless action can cause severe injury

within a fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or remove the battery pack, if

detachable, from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools and accessories. Check for misalignment or binding of

moving parts, breakage of parts and any other condition that may affect the power

tool’s operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could result in a

hazardous situation.

h) Keep handles and grasping surfaces dry, clean and free from oil and grease.

Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in

unexpected situations.

5.Battery tool use and care

a) Recharge only with the charger specified by the manufacturer. A charger that is

suitable for one type of battery pack may create a risk of fire when used with another battery

pack.

b) Use power tools only with specifically designated battery packs. Use of any other

battery packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects, like

paper clips, coins, keys, nails, screws or other small metal objects, that can make a

connection from one terminal to another. Shorting the battery terminals together may

cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid contact.

If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from the battery may cause irritation or burns.

e) Do not use a battery pack or tool that is damaged or modified. Damaged or

modified batteries may exhibit unpredictable behaviour resulting in fire, explosion or risk of

injury.

f) Do not expose a battery pack or tool to fire or excessive temperature. Exposure to

fire or temperature above 130 °C may cause explosion.

NOTE The temperature „130 °C”can be replaced by the temperature „265 °F”.

g) Follow all charging instructions and do not charge the battery pack or tool

outside the temperature range specified in the instructions. Charging improperly or at

temperatures outside the specified range may damage the battery and increase the risk of fire.

6.Service

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

b) Never service damaged battery packs. Service of battery packs should only be

performed by the manufacturer or authorized service providers.

Drill Safety Warnings

1) Safety instructions for all operations

a) Wear ear protectors when impact drilling. Exposure to noise can cause hearing loss.

b) Hold the power tool by insulated gripping surfaces, when performing an

operation where the cutting accessory or fasteners may contact hidden wiring or its

own cord. Cutting accessory contacting a “live”wire may make exposed metal parts of the

power tools “live”and could give the operator an electric shock.

2) Safety instructions when using long drill bits

a) Never operate at higher speed than the maximum speed rating of the drill bit. At

higher speeds, the bit is likely to bend if allowed to rotate freely without contacting the

workpiece, resulting in personal injury.

b) Always start drilling at low speed and with the bit tip in contact with the

workpiece. At higher speeds, the bit is likely to bend if allowed to rotate freely without

contacting the workpiece, resulting in personal injury.

c) Apply pressure only in direct line with the bit and do not apply excessive

pressure. Bits can bend causing breakage or loss of control, resulting in personal injury.

For battery tools:

1) Instructions regarding battery charging, information regarding ambient temperature range for

tool and battery use and storage, and the recommended ambient temperature range for the

charging system during charging;

2) For a battery-operated tool intended for use with a detachable battery pack or a

separable battery pack: instructions indicating the appropriate battery packs for use, such as

by a catalog number, series identification or the equivalent;

3) Instructions indicating the appropriate charger for use, such as by a catalog number, series

identification or the equivalent.

4)For battery tools with integral battery: instruction, how the integral battery can be removed

safely from the tool after the tool’s end of life, and information about the type of battery such as

Li-Ion, NiCd and NiMH.

WARNING!

■Hold the power tool by the insulated gripping surfaces when performing an operation where

the screw or attached tool could come into contact with hidden wiring. Contact between the

screw or attached tool and a live wire may cause exposed metal parts of the power tool to

become live and give the operator an electric shock.

Safety guidelines for battery chargers

■This appliance may be used by children aged 8 years and above and by persons with limited

physical, sensory or mental capabilities or lack of experience and knowledge, provided that they

are under supervision or have been told how to use the appliance safely and are aware of the

potential risks. Children must not play with the appliance. Cleaning and user maintenance tasks

may not be carried out by children unless they are supervised.

The charger is suitable for indoor use only.

WARNING!

■To avoid potential risks, damaged mains cables should be replaced by the manufacturer or

the manufacturer’s customer service department or a similarly qualified person.

Before use

Charging the battery pack (see fig. A)

CAUTION!

►Always pull out the plug before you remove the battery pack ⑧from or connect the battery

pack to the charger.

■Never charge the battery pack⑧when the ambient temperature is below 10°C or above

40°C.

Connect the battery pack ⑧to the rapid battery charger ⑬(see Fig. A).

Insert the power plug into the socket. The control LED ⑭lights up red to indicate that the

appliance is charging.

The green control LED ⑮indicates that the charging process is complete and the battery

pack ⑧is ready.

Insert the battery pack ⑧back into the appliance (see Fig. B).

Attaching/disconnecting the battery pack to/from the appliance

Inserting the battery pack:

Push the rotation direction switch ③into the middle position (lock) (see Fig. C). Allow the

battery pack ⑧to click into the handle (see Fig. B).

Removing the battery pack:

Press the release button ⑨and remove the battery pack ⑧(see Fig. D).

Checking the battery charge level

Press the battery charge level button ⑥to check the charge level of the battery (see Fig. E).

The status/remaining charge will be shown on the battery display LED ⑦as follows:

GREEN/RED/ORANGE = maximum charge/performance

RED/ORANGE = medium charge/performance

RED = low charge –charge the battery

Changing tools

Your cordless drill has a fully automatic spindle lock .

When the motor is stopped, the power train locks so that the chuck ⑪can be opened by turning

it . After you have attached the desired tool and tightened it by turning the chuck , you

can continue working (see Fig. F). The spindle lock is automatically released when the motor

starts (ON/OFF switch ④pressed).

Torque selection ring/drill setting

You can set the torque using the torque selection ring ⑫(see Fig. G).

Select a low level for small screws or soft materials.

Select a high level for large screws, hard materials or removing screws.

Select the drill setting for drilling work by adjusting the torque selection ring ⑫to the

position (see Fig. H).

2 speed gearbox

CAUTION!

►Only operate the gear selection switch ①when the appliance is at a standstill. Otherwise the

appliance can be damaged.

In first gear (gear selector switch ①in position: 1) (see Fig. I)

you can reach a speed of approx. 400 rpm and a high torque. This setting is suitable for all

screwing jobs.

In second gear (gear selector switch ①in position: 2) (see Fig. J)

you can reach a speed of approx. 1400 rpm for carrying out drilling work.

Operation

Switching on and off

Switching on:

To start the appliance, press the ON/OFF switch ④and keep it pressed in (see Fig. K).

The LED work light ⑩lights up when the ON/OFF switch ④is depressed lightly or fully. This

allows for illumination of the work area in low lighting.

Switching off:

Release the appliance's ON/OFF switch ④to switch off the appliance.

Adjusting the rotational speed

The ON/OFF switch ④has a variable speed control. Pressing the ON/OFF switch ④lightly yields

a low speed. Increasing pressure increases the speed (see Fig. K).

NOTE

►The integrated motor brake ensures rapid stoppage.

Changing the direction of rotation

Change the direction of rotation by pressing the rotational direction switch ③towards the

left or right (see Fig. L).

Tips and tricks

Tip! This symbol indicates proper behaviour!

Before operation, check whether the screw or drill bit is correctly positioned, i.e. centred in

the

drill chuck.

Screw bits are labelled according to their dimensions and their shape. If you are uncertain,

always check whether the bit fits tightly in the screw head without any free play.

Torque:

Smaller screws/bits can be damaged if you set the torque or rotational speed too high.

Hard screw joints (in metal):

Particularly high torques occur, for example, in metal screw joints made using drive sockets.

Select a low rotational speed.

Soft screw joints (e.g. in soft wood):

Again, use a low rotational speed, to avoid e.g. damaging the surface of the wood upon

contact with the screw head. Use a countersink.

When drilling in wood, metal and other materials, observe the following:

Use a high speed for drill bits with small diameter and a low speed for drill bits with large

diameter.

Select a low speed for hard materials and a high speed for soft materials.

Secure or fasten the workpiece in a clamp or vice (if possible).

Mark the spot where you want to drill using a centre punch or nail. Select a low rotational

speed when starting.

Pull the rotating drill bit from the hole repeatedly to remove dust and chips and clear the

hole.

Drilling in metal:

Use a metal drill (HSS). For optimum results, cool the drill bit with cutting oil. Metal drill bits

can also be used to drill into plastics. Start with a 3 mm diameter drill bit and then increase the

size until the desired hole diameter is achieved.

Drilling in wood:

Use a wood drill with a lathe centre; for deep holes, use an auger bit; for large-diameter

holes, use a Forstner bit. Small screws can be screwed directly into soft wood.

Maintenance and cleaning

WARNING! RISK OF INJURY! Always switch the appliance off and remove

the battery before carrying out any work on the appliance.

The cordless drill is maintenance-free.

■The appliance must always be kept clean, dry and free from oil or grease.

■Never allow liquids to get into the appliance.

■Use a soft, dry cloth to clean the housing. Never use petrol, solvents or cleansers which can

damage plastic.

■If a lithium-ion battery is to be stored for an extended period, the charge level should be

checked regularly. The optimum charge level is between 50% and 80%. The optimum storage

environment is cool and dry.

NOTE

►Replacement parts not listed (such as batteries, switches) can be ordered via our service

hotline.

Table of contents

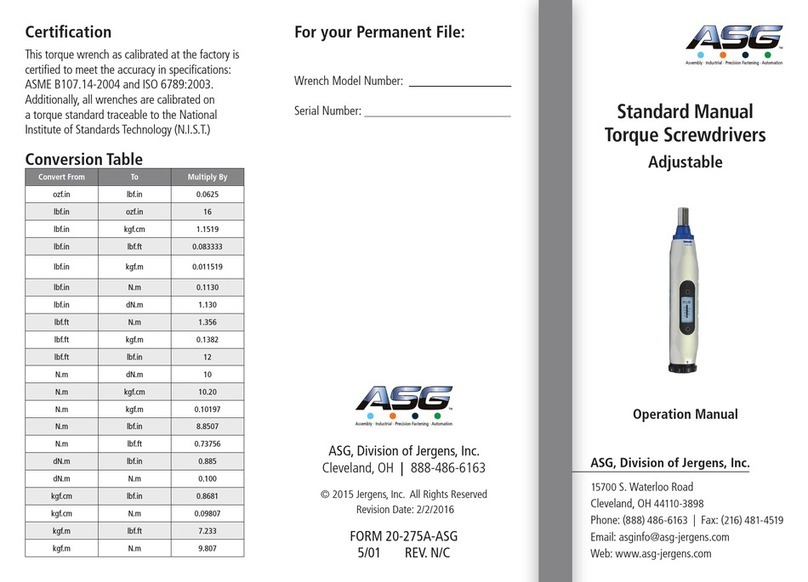

Other TOOLSPACE Power Screwdriver manuals

Popular Power Screwdriver manuals by other brands

Worcraft PROFESSIONAL

Worcraft PROFESSIONAL CD-12LiA instruction manual

Narex

Narex AS 37-Li Original operating manual

AEG

AEG BSS18CB3 Original instructions

Ingersoll-Rand

Ingersoll-Rand 41PA8PSQ4 Product information

Bosch

Bosch GDR 120-LI Professional Original instructions

Blaupunkt

Blaupunkt CD2010 Original instruction manual