Fermator VF7 User manual

ENG

User manual.

Automatic horizontal sliding car door.

Component: VF7 Electronic Module. V7.01.02.

MAN-MU00000V7ENGTC-12.2017

2

VF7

5

6

7

L1’

GND

L2’

26

23 12 V COM

66

67

1

2

3

L2

GND

L1

BAT

ON

29

28

ON 1

OFF2

VF4+ OUTPUT

SALIDA VF4+ SUPPLY

ALIMENTACIÓN

230 V. AC

DO NOT OPEN

THE COVER

NO ABRIR LA TAPA

ALIMENTADOR DE

EMERGENCIA

EMERGENCY

SUPPLIER

CONTROL VF4+

STANDBY

ESTADO

FLOOR / PISO

LANDING FLOOR

RELLANO PISO

FUSE 20A (yellow / amarillo)

BATTERY

BATERIA

ON OFF

INPUTS

ENTRADAS

12

Optional

12...60 V DC 100...230 V AC

12...60 V DC 100...230 V AC

5m :Ref.CFT-FC00.C0000

3m :Ref.CFT-FCDM.C0000

12 V 2 Ah

230 V

230 V

5

6

7

13

19

20

18

17

21

23

22

25

24

26

N

PE

L

U

V

W

PE

M

55

56

57

58

59

47

45

43

41

39

37

35

33

31

46

42

44

40

36

38

34

30

32

12

9

10

11

8

OK STATUS

EMISOR

EMITTER

RECEPTOR

RECEIVER

CERRAR LENTO

SLOW CLOSE

OUT +12 V

REABRIR

RE-OPEN

CONTACTO DE BYPASS

BYPASS CONTACT

SEÑAL DE PISO

FLOOR LEVEL

ABIERTA

OPEN

CERRADA

CLOSED

FOTOCÉLULA

PHOTOCELL

OBSTRUCCIÓN

OBSTRUCTION

BARRERA

FOTOELÉCTRICA

LIGHT CURTAIN

BARRERA

FOTOELÉCTRICA

LIGHT CURTAIN

TEMPERATURA

TEMPERATURE

ABRIR

OPEN

0 V

COM

OUT +12 V

CERRAR

CLOSE

EN 12016: 2013 INMUNIDAD NIVEL INDUSTRIAL

EN 12016: 2013 IMMUNITY INDUSTRIAL LEVEL

NO ABRIR LA TAPA

DO NOT OPEN THE COVER

QCI-VF7ACI0SE

ALIM. SUPPLY

100...230 V AC

MOTOR

ENCODER

ONOFF

ENTRADAS PRIORITARIAS / PRIORITY INPUTS

ENTRADAS / INPUTS

SALIDAS / OUTPUTS

PUERTO COM

COM PORT

FOTOCÉLULA

PHOTOCELL

CONNECTION

3

VF7

INPUTS / OUTPUTS

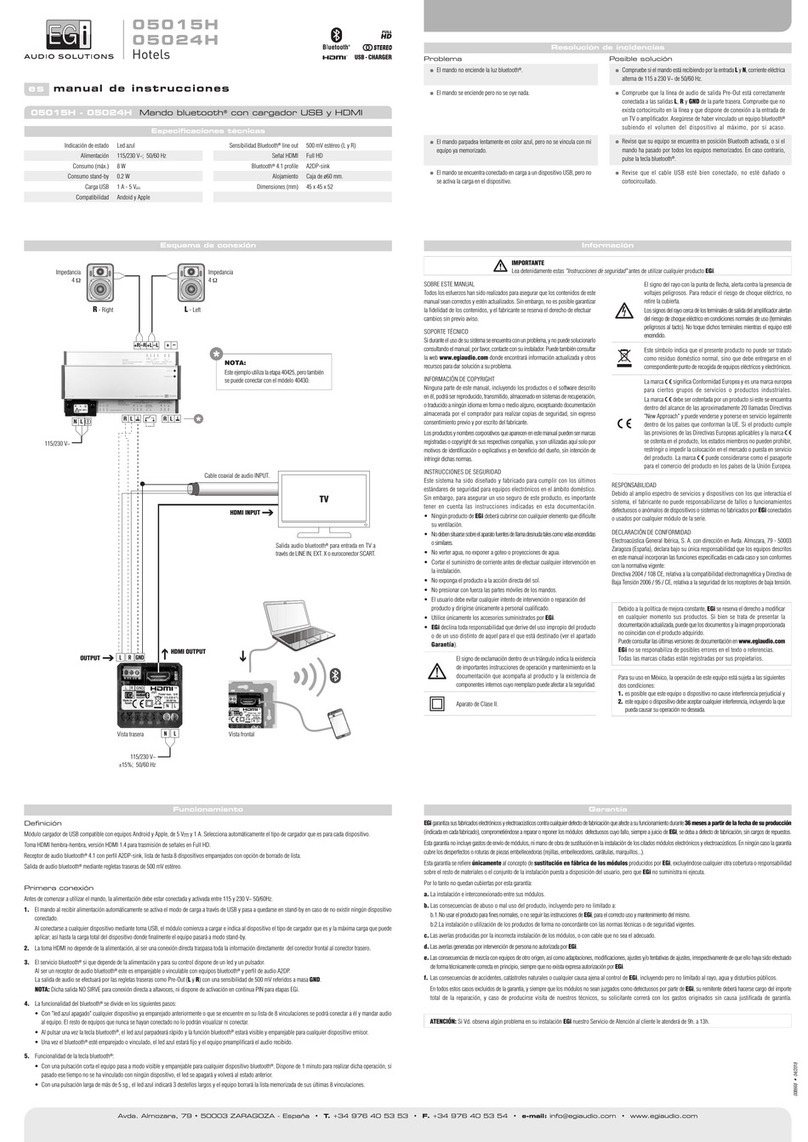

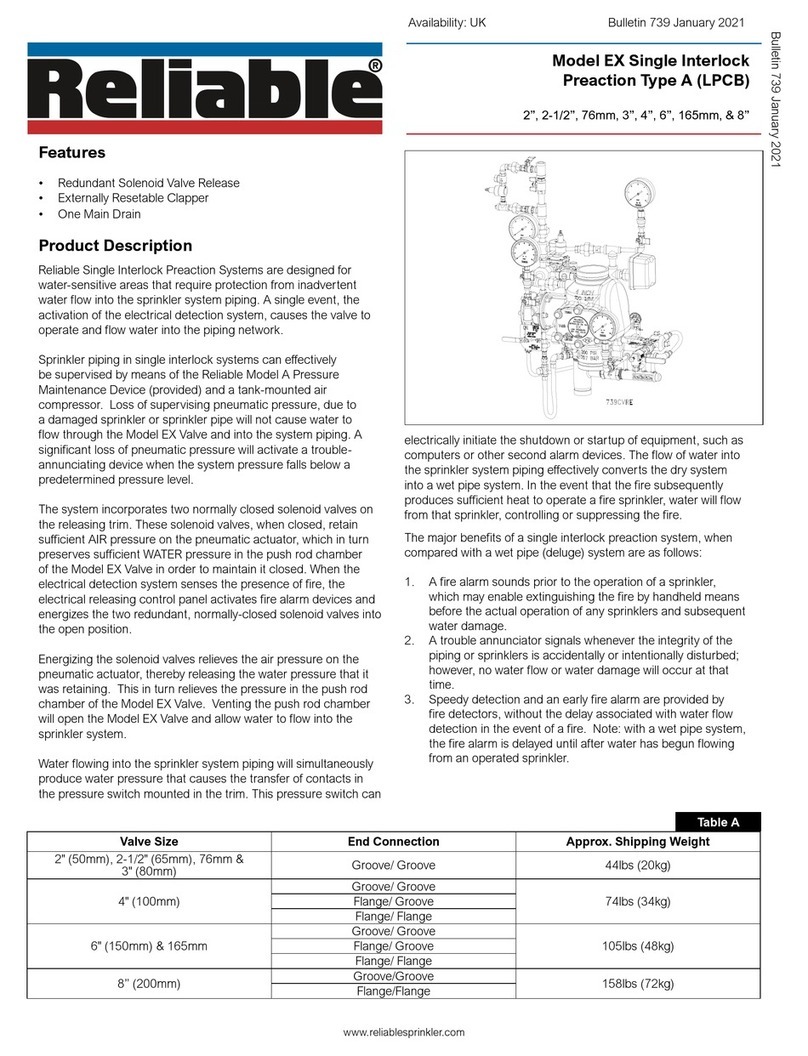

4 - 7 POWER SUPPLY.

The circuit has been designed to operate with a main supply of 230 V AC (+10%,-15%, 50

or 60 Hz).

The VF7 incorporates a soft-start system to control the bulk capacitors charge and prevent

short circuits.

Note: It is important that the Door Operator Module has a good earth connection.

INPUTS

The circuit can work with external voltage inputs or internal voltage input (voltage free contact).

8CLOSE SIGNAL.

This signal is used for ordering to close the door. With an external voltage input the tension

to apply could be from 12 V DC to 60 V DC or 100 V AC to 230 V AC between this input and

common (10). With an internal voltage input the tension applied is 12 V DC between this input

and Out +12 V (9).

912 VOLT.

Isolated 12 Volts output available to control the door through a voltage free contact.

Features are:

a) This supply must only be used for this purpose.

b) This contact must be isolated from any other power supply.

10 COMMON

Is the reference used for the opening and closing signal.

11 0 VOLTS.

Is the opposite pole to 12 V, in the case of using internal voltage it should be connected

to common input.

4

VF7

12 OPEN SIGNAL.

Is a signal that orders the door to open. With an external voltage input the tension to

apply could be from 12 V DC to 60 V DC or 100 V AC to 230 V AC between this input and

common (10). With an internal voltage input the tension applied is 12 V DC between this

input and Out +12 V (9).

13 COM PORT.

The serial port is used to connect with external devices, interfaces and

future expansion devices. Operating speed 1.200 Baud per second,

current loop.

17 - 20 PHOTOCELL.

The control has the option to incorporate the Fermator photocell. It is composed by a

emitter and receptor infrared.

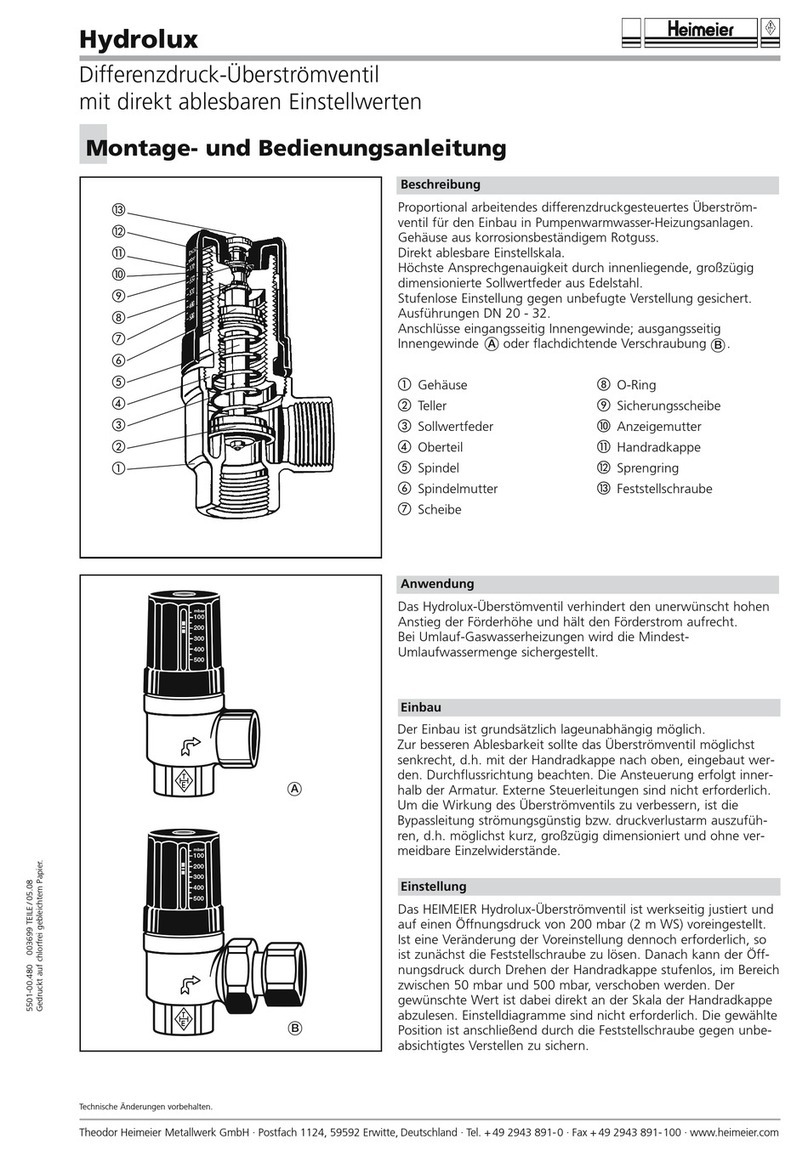

21 - 26 PRIORITY INPUTS.

21 REOPEN.

This signal is used for installing the cabin door switch, an external barrier or other devices.

In order to active this signal, connect the re-open input (21) with the +12 V (23). Use voltage

free contacts. The reopening signal has priority over the closing signal.

22 LIGHT CURTAIN.

This input is used to detect a failure from the light curtain installed.

23 OUT +12 V.

Isolated 12 Volts output available to activate the priority inputs via a voltage free contact.

Features are:

a) This supply must only be used for this purpose.

b) This contact must be isolated from any other power supply.

13

PUERTO COM

COM PORT

INPUTS / OUTPUTS

5

VF7

24 BYPASS CONTACT.

This signal is used to connect an external security switch to detect door closed position.

25 SLOW CLOSING.

This signal is used for ordering to close the door slowly. The slow signal has priority over

the control signals and the photocell. It's created for working with re ghting systems.

26 FLOOR LEVEL.

This input is used to connect the external emergency supplier that allows the opening

manoeuvre in the case of power failure. Fermator emergency supplier uses a battery of

12 V, able to give power during 15 seconds for a passengers rescue.

30 - 47 OUTPUT RELAYS AND LED INDICATORS.

Output relays have been provided to give continuous information to the main lift controller

concerning the status of the doors.

• Open.

LED indicator and relay activated when the doors are fully open.

• Closed.

LED indicator and relay activated when the doors are fully closed and locked.

•Photocell.

LED indicator and relay activated when the photocell or the reopening input is

operated.

• Obstruction.

LED indicator and relay activated when an

obstacle is detected that stops the doors

from closing. The signal will reset when

the doors reach the opened or closed

position.

• Light curtain.

LED indicator and relay activated when a

failure occurs on the light curtain.

• Température.

LED indicator and relay activated when

the VF temperature or motor temperature

exceeds the safety limit. When this output

is activated the manoeuvre must give the

order to the cabin to go to the next oor,

open the door to let out the passengers and stop applying tension to the motor.

• Status.

Blinking green LED indicating proper working conditions. If

an alarm occurs the LED lights red.

OK STATUS

INPUTS / OUTPUTS

6

VF7

55 ENCODEUR.

An integral quadrature pulse encoder is connected to this input.

The purpose of the encoder, which is situated inside the motor, is

to inform the control of the exact position and speed of doors.

The software V7.00.02 is not compatibility with Fermator

asynchronous motor.

56 - 59 MOTOR.

Output to the 3 phase motor varying the voltage and frequency to

control speed and torque.

60 ON / OFF SWITCH

Disconnects the unit from the 230 V AC mains supply.

Three main objectives can be achieved with the VF7 graphic interface:

1. To detect possible alarms or errors in the unit (Alarms Menu).

2. To see the parameters value and active signals (Monitor Menu).

3. To modify the internal program parameters and options (Programming Menu).

Once the unit is connected it will show the software version Fermator V7.01.02 .

Push the button to a access to the VF7 menus.

There are four main menus with different submenus: Alarms Menu, Monitor Menu, Programming

Menu and Settings Menu.

P u s h t h e button to select the menu.

Push the button to enter into the VF7 menus.

Push the button to return to the software version screen.

INPUTS / OUTPUTS

GRAPHIC INTERFACE

or

7

VF7

ALARMS MENU.

The Alarms Menu shows the last ve alarms activated in the unit.

Push the or button to see the different alarms.

While an Alarm is activate the VF7 graphic interface shows the alarm activated in that moment.

After an alarm has been disabled the VF7 performs a start-up.

GRAPHIC INTERFACE

Alarm Description Possible problem Actions VF7 recovery

Short-C The power module has been

short-circuited.

If 3 short-circuits take place

in one minute, the alarm will

be permanent activated.

- The motor could be short-

circuited.

- VF7 malfunction

- Replace the motor.

- Replace the VF7.

Push the OK button.

Current High current consumption. - Hard obstacle in clearance. - Check the mechanical

part.

Push the OK button.

Low Volt The power supply voltage is

under 15 V AC.

- The external power supply

could be damaged.

- Check the external power

supply.

Push the OK button or

increase the power supply

voltage more than 15 V AC.

Memory The memory is failing. - The VF could have some

internal problems.

- Replace the VF7. Push the OK button.

Friction The door has a high friction. - The mechanical part could

not be correct installed.

- Check the mechanical

part.

Push the OK button.

Belt The belt is broken. - The belt could be

damaged.

- The pullet could be

damaged.

- Check the mechanical

part.

Push the OK button.

Encoder The unit does not receive a

signal from the encoder.

- The encoder wire could be

damaged.

- The encoder could be

damaged.

- Replace the encoder

wire.

- Replace the motor.

Push the OK button.

8

VF7

Alarm Description Possible problem Actions VF7 recovery

Close

Obstruction

An obstruction has been

performed in salve mode

and the lift controller does

not reopened.

- The lift controller could has

some problems.

- Check the lift controller.

- Check the signal wires.

- Push the OK button.

- The alarm is disabled

after 15 seconds.

Open Obstruction A blockage has been

happened in the opening

movement.

- The mechanical part could

not be correct installed.

- Check the mechanical

part.

- Push the OK button.

- The alarm is disabled

after 5 seconds.

Calib. The VF7 can not complete

the Motor Calibration

process

- The motor encoder signals

are not arriving correctly to

the VF7.

- Replace the encoder wire. - Push the OK button.

Motor Temper. The motor coil has reached

125ºC.

The VF7 remains in normal

operation.

- The door could have a high

friction.

- The door could be blocked

during the opening / closing

movement.

- The motor could be

damaged.

- Check the mechanical

part.

- Replace the motor.

- The alarm is disabled

when the motor reach

105ºC.

VF7 Temper. The VF7 has reached 90ºC.

The VF7 remains in normal

operation.

- The door could have a high

friction.

- The VF7 metal cover

could not be making good

contact.

- Check the mechanical

part.

- Tighten the screws of the

metal cover.

- Check that the VF is

installed on a metal

surface.

- The alarm is disabled

when the VF7 reach

70ºC.

Motor Temp. Crit The motor coil has reached

140ºC.

The VF7 stops the normal

operation.

- The door could have a high

friction.

- The door could be blocked

during the opening / closing

movement.

- The motor could be

damaged.

- Check the mechanical

part.

- Replace the motor.

- The alarm is disabled

when the temperature of

the motor down enough

after 5 minutes.

VF7 Temper. Crit The VF7 has reached

105ºC.

The VF7 stops the normal

operation.

- The door could have a high

friction.

- The VF7 CAN metal cover

could not be making good

contact.

- Check the mechanical

part.

- Tighten the screws of the

metal cover.

- Check that the VF is

installed on a metal

surface.

- The alarm is disabled

when the temperature of

the VF7 down enough.

Referencing The VF7 can not recognize

the clear opening.

- The learning is not done. - Do a learning - Push the OK button

Motor The unit does not receive a

signal from the Motor.

- The Motor wire could be

damaged.

- The Motor could be

damaged.

- Replace the motor wire.

- Replace the motor.

- Push the OK button.

- The alarm is disabled

after 5 seconds.

GRAPHIC INTERFACE

9

VF7

The Monitor Menu displays the VF7 parameters in real time.

Push the button to select the submenu.

Push the button to return to the VF7 menus.

MONITOR MENU

Push the button to see the different parameters.

Monitor Parameters

Parameter Description Units

Supply Voltage Voltage supply in AC (V). V (RMS)

VF7 Temperature Temperature in the power module area (ºC). ºC

Supply Type AC or DC supply. -

or

or

10

VF7

MONITOR MENU

Monitor Motor

Parameter Description Units

Speed Motor speed (m/s). mm/s

Voltage Tension that the circuit applies to the motor (V). V (RMS)

RMS Current Output current (A). A

Motor Type Motor connected to the circuit. -

Temperature Temperature in the PM motor (Temperature measurement option has to be

enabled).

ºC

Monitor Inputs

Parameter Description Units

Open Status of the open signal. -

Close Status of the close signal. -

Re-open Status of the re-open signal. -

Floor Status of the oor level signal. -

Slow Close Status of the slow close signal. -

Bypass Status of the Close Position signal. -

Curtain error Status of the curtain error. -

Monitor Outputs

Parameter Description Units

Open Door Status of the door open signal. -

Closed Door Status of the door closed signal. -

Re-open Status of the Re-open signal. -

Obstruction Status of the obstruction signal. -

Curtain Error Status of the light curtain signal. -

Temperature Error Status of the temperature signal. -

Monitor Door

Parameter Description Units

Position Position of the door in m, indicating the zero point with the door closed and the clear

opening + Clutch length with the door open.

m

Status Status of the door (Door closed, Door opened, Closing door, ...). -

CDL Door with Car Door Lock (automatic detection during autoadjustment). -

Friction Friction value detected during the autoadjustment. Frictionless door when this

parameter is 0.

Scaled from 0 to 150

Bypass Length The distance from closed door position to open bypass contact detected during the

learning process.

m

11

VF7

MONITOR MENU

Monitor Counters

Parameter Description Units

Hours Number of working hours. -

Total Cycles Number of cycles done by the door. -

Powerups Number of connections to the mains supply or blackouts suffered. -

Learning Cycles Number of learning cycles made. -

Reopenings Number of re-open cycles. -

Short-Circuits Number of times that the short-Circuits alarm has been activated. -

OverCurrents Number of times that the Over Currents alarm has been activated. -

UnderVoltages Number of times that the Under Voltages alarm has been activated. -

Security Device Faults Number of times the light curtain has fault or blocked more than 2 minutes -

VF7 Overtemperature Number of times that the VF7 overtemperature alarm has been activated. -

Motor Overtemperature Number of times that the Motor overtemperature alarm has been activated. -

VF7 Crit. Overtemp. Number of times that the VF7 critical overtemperature alarm has been activated. -

Motor Crit. Overtemp. Number of times that the Motor critical overtemperature alarm has been

activated.

-

Op. Obstructions Number of obstructions in the opening movement. -

Cl. Obstructions Number of blockages in the closing movement. -

Manoeuvre Failures Number of times that the Manoeuvre Failures has been activated. -

Monitor Information

Parameter Description Units

Software Version Circuit software version. -

Hardware Version Circuit hardware version. -

Hardware Subversion Circuit hardware subversion. -

Serial Number Identication serial number for each unit. -

Supplier Supplier identication code. -

Test Date Date of manufacture. -

Software subversion Circuit software subversion. -

PROGRAMMING MENU

The Programming Menu displays the VF7 internal parameters an options.

Push the or button to select the sub-menu.

12

VF7

PROGRAMMING MENU

Push the button to see the different parameters of each submenu.

To modify a parameter or an option to do the following steps:

1. Select de parameter / option to be modify and push the button to enter in modify

mode.

2. The parameter value or option status will appear blinking, push the or

button to increase / decrease the parameter value or enable/disable the option.

3. Push the button to save the modication.

or

13

VF7

PROGRAMMING MENU

Program Options

Options basic

Door Model T1 Automatic horizontal sliding door 1 panel side opening.

T2 Automatic horizontal sliding door 2 panel side opening.

T3 Automatic horizontal sliding door 3 panel side opening.

T4 Automatic horizontal sliding door 4 panel side opening.

C2 Automatic horizontal sliding door 2 panel centre opening.

C4 Automatic horizontal sliding door 4 panel centre opening.

C6 Automatic horizontal sliding door 6 panel centre opening.

C8 Automatic horizontal sliding door 8 panel centre opening.

Control Master The unit will execute the instructions directly. Example: photocell activation will cause the doors to

re-open immediately without control of the lift controller.

Slave There is no automatic reopen movements. The doors will only react to instruction given by the

main lift controller. Example: with the Reopen activated the unit will send a signal to the main lift

controller via the Reopen output (36, 37, 38). Then, the main lift controller must remove the close

signal and active the open signal.

Landing Door Automatic Operators with Clutch (automatic landing door). In this case a special movement is made for

locking and unlocking the Clutch.

Semiautomatic Operators without Clutch (Semiautomatic landing door).

Rotation

Sense

Clockwise (CW) During the opening movement the motor will rotate clockwise.

Counterclockwise

(CCW)

During the opening movement the motor will rotate counterclockwise.

Inputs 1 Input

The unit will be controlled by a single input. Any voltage between 12 V DC to 60 V DC or 100 V AC to 230 V AC applied

between terminals 8 & 10 will close the doors. Without input active the door remains opened. Open input is not used.

2 Inputs

The unit will be controlled by two independent inputs. Any voltage between 12 V DC to 60 V DC or 100 V AC to 230 V AC

applied between terminals 8 & 10 will cause the doors to close. And between terminals 10 & 12 will cause the doors to

open. In the absence of a signal, the doors will remain static. If both inputs are applied then the open signal has priority.

14

VF7

PROGRAMMING MENU

Program Options

Options interact

Priority Input Open In case that open signal and close signal are activated at the same time the door must open.

Close In case that open signal and close signal are activated at the same time the door must close.

Stop In case that open signal and close signal are activated at the same time the door must stop.

No Test priority If enabled, the Test manoeuvre does not have priority over the input signals.

Keyboard shortcuts If enabled, keyboard shortcuts are allowed in the home screen:

• Autoadjustment: Push the button during 2 seconds.

• Test: Push the button during 2 seconds.

• Rotates the screen display: Push the and button during 2 seconds.

• Move the door to open: Push button during 2 seconds.

• Move the door to close: Push button during 2 seconds.

HK Fireght If enabled, the rst opening operation after a power up it is totally slave.

Slow close signal Action Slow close is performed when the Slow close input is activated.

Command Slow close / open is performed when the Slow close input and Close / Open input are

activated.

Unlock on standby If enabled, with the clutch / CDL fully closed, the VF7 opens only the clutch / CDL if the closing signal is

removed or after a delay time (Eco Delay). Once the clutch is open, the VF7 remains in standby. (This option

is not compatible with Eco Mode No).

Close Anticipated The Closed output is activated when the door is closed but doesn't need the Clutch close. This signal is

activated when the door arrives to the distance of the “Clutch Length”.

Signal Close by Bypass When it is active, the closed signal output takes the value of the bypass input.

Function Bypass When it is active, after a power blackout the VF7 will only need to reach closed door position once (detection

of Bypass contact transition closed to open) to apply the normal speed prole.

IMPORTANT: The bypass contact must be installed before doing the door learning process. If the bypass

contact is removed or changes its position, a door learning process has to be repeated.

Curtain error only

closed

When it is active, the curtain error output will be only activated when the door is closing.

DPM System If enabled, the obstruction output frame is sent to indicate when the door is in the rst third of the Open Length.

If an obstruction happens, the photocell output frame will be sent.

15

VF7

PROGRAMMING MENU

Program Options

Options inputs logics

NC Close If enabled, Close signal is activated without voltage (Normally closed contact).

NC Open If enabled, Open signal is activated without voltage (Normally closed contact).

NC Slow Close If enabled, Slow close signal is activated without voltage (Normally closed contact).

NC Reopen If enabled, Reopen signal is activated without voltage (Normally closed contact).

NC Curtain If enabled, Light Curtain is activated without voltage (Normally closed contact).

NC Floor level If enabled, Floor level is activated without voltage (Normally closed contact).

NC Close position If enabled, Close position is activated without voltage (Normally closed contact).

Program Options

Options functions

Eco Mode No The VF always applies the Close Maintenance Torque.

Control The VF stops applying the Close Maintenance Torque if the closing signal is removed.

Close delay The VF stops applying the Close Maintenance Torque after a programmable time delay

(Eco delay) since the door is closed.

Control delay The VF stops applying the Close Maintenance Torque if the closing signal is removed

and the programmable time delay has nished (Eco delay).

CDL Electronic If enabled, After a power failure the VF opens the Car Door Lock if the cabin is on the oor level.

Security Device None None security device installed.

Curtain Light Curtain installed. The blocked signal must be connected to Re-open input and the

failure signal must be connected to Light Curtain input.

Barrier timer If enabled, an intelligent timer is used in case of photocell or curtain permanent obstruction. The protection

is disabled after 2 minutes permanently blocked. If a physical obstruction happens during the next closing

movement, the VF reopens and wait 4 minutes before closing again. If another physical obstruction happens

during the next closing, the VF reopens and wait 10 minutes before closing again. Finally, if another physical

obstruction happens during the next closing, the VF reopens and remains always open. The photocell or

curtain is enabled again when there is not any physical obstruction during the closing movement.

Temperature

measurement

If enabled, the VF7 measure the motor temperature.

Temperature

Protection

Drive When the overheating alarm is active the circuit does not allow the door closing.

Elevator When the overheating alarm is active the elevator does not allow the door closing.

Energy limit The circuit limits the maximum velocity in order not to exceed a kinetic energy of 10 joules.

Obstruction Backstep If enabled and an obstruction occurs in the opening or closing movement, the VF7 makes a backward

movement and wait a delay time (Backstep delay).

E.P.S. Slave If enabled, the Emergency Power Supplier will not open the door if the closing signal is activated.

E.P.S. Open Clutch If enabled, the Emergency Power Supplier will only open the car door clutch.

16

VF7

PROGRAMMING MENU

Programming Parameters (Speed Proles)

Open prole

Close prole

Program Parameters

Parameters generals

Parameter Description Units Min Max

Door mass Mass of the door. (kg) 1 500

Clutch mass Mass of the Clutch. (Kg) 0.0 50

Gear ratio Gear ratio when a reduction pulley is used. - 1.00 10.00

Program Calibration

Calibration The Motor Calibration process has to be done to detect the electrical characteristics of the motor

installed. The calibration only has to be done one time. Before doing the motor calibration place the door

in a middle position.

If the motor installed is removed, another calibration has to be done with the new motor.

To perform an optimal calibration of the motor installed the process has to be done without charge. Never

perform calibration with the car door and landing door.

Program Parameters

Parameters speeds

Parameter Description Units Min Max

Open Initial Speed The initial speed at opening. (m/s) 0.025 0.100

Close Initial Speed The initial speed at closing. (m/s) 0.025 0.100

Open Proximity Speed The approximation speed at opening. (m/s) 0.025 0.100

Close Proximity Speed The approximation speed at closing. (m/s) 0.025 0.100

Open Clutch Speed Clutch speed at opening. (m/s) 0.025 0.100

Close Clutch Speed Clutch speed at closing. (m/s) 0.025 0.100

Open Limit Speed Speed limit at opening. (m/s) 0.100 1.000

Close Limit Speed Speed limit at closing. (m/s) 0.100 0.600

Open Acceleration The opening acceleration. (m/s2) 0.050 0.700

Close Acceleration The closing acceleration. (m/s2) 0.050 0.700

Open Deceleration The opening deceleration. (m/s2) 0.050 0.700

Close Deceleration The closing deceleration. (m/s2) 0.050 0.500

17

VF7

PROGRAMMING MENU

Program Parameters

Parameters torques

Parameter Description Units Min Max

Max open torque Maximum torque in the opening movement. (Value 0 is disabled the limit

torque).

(N·m) 1 4.0

Max close torque Maximum torque in the closing movement. (Value 0 is disabled the limit

torque).

(N·m) 0.5 3.0

Hold torque Torque applied to maintain the door stopped in any position of the clear

opening.

(N·m) 0.5 1.5

Program Parameters

Parameters times

Parameter Description Units Min Max

Eco Delay Programmable time delay (Eco mode option). (s) 1 60

Backstep delay Programmable time delay (Obstruction Backstep option). (s) 0 60

Time standby Hold Programmable time during the hold voltage is applied. (s) 0 1.800

Program Parameters

Parameters lengths

Parameter Description Units Min Max

Open Length Door clear opening + Clutch length. (m) 0.100 5.000

Open Initial Length The space at the initial opening movement. (m) 0.001 0.100

Close Initial Length The space at the initial closing movement. (m) 0.001 0.100

Open Proximity Length The space at the nal opening movement. (m) 0.001 0.040

Close Proximity Length The space at the nal closing movement. (m) 0.001 0.040

Clutch Length The required space to open / close the Clutch. (m) 0.000 0.100

Additional Clutch

Movement

Additional clutch movement to personalize the opening distance in

emergency mode.

(m) 0 0.2

Pinion Perimeter Perimeter of the motor pinion. (m) 0.001 1.000

Backstep length Length of the backwards movement (Obstruction Backstep option). (m) 0.010 0.150

Program Control

Test Makes a door open or close cycle to verify proper operation.

Door Learning Makes a Door Learning process to set up the door.

Before doing a Door Learning a Motor Calibrations has to be done.

The door will do a close movement and then will do two complete movements to detect the clear opening. From

the information obtained the microprocessor will calculate the acceleration and deceleration ramps to give the

optimum control of the doors. Once the autoadjustment has been completed the parameters are stored in non

volatile EEPROM. The autoadjustment process sets all parameters to the factory value if these are not protected.

Autoadjustment process:

1. The door will close completely in slow speed until the end to detect the 0 position.

2. The door will open slowly counting the clear opening until it reach the open mechanical stop.

3. The door will close after a short delay. From the information obtained the microprocessor will calculate the

acceleration and deceleration ramps and to give the optimum control of the doors.

18

VF7

SETTINGS MENU

Settings Menu

The Settings Menu is used to change the VF conguration.

Push the or button to see the different options.

To modify an option to do the following steps:

1. Select de option to be modify and push the button to enter in

modify mode.

2. The option status will appear blinking, pus the or button to enable / disable it.

3. Push the button to save the modication.

Settings Menu

Language The unit can be programmed in the following languages:

• English.

• Spanish.

• German.

• French.

• Italian.

Display Rotates the screen display (Straight / Invert).

Factory Settings Sets all parameters to the factory value.

Password Entering the correct password the advanced menu will be unlocked.

INSTALLATION PROCESS

The whole installation process has to been done when a new circuit is installed on a door.

If the circuit is already installed only do steps 9 and 10.

• Connections.

• Connect the motor wire and encoder wire (#55, #56, #57, #58, #59).

• If it has been installed, connect the Fermator photocell (#17, #18, #19, #20).

• Disconnect all other inputs and outputs.

• Connect the 230 V AC mains supply to the controller (#5, #6, #7).

• Switch on the VF door controller button I / O in the front of the box.

• Program in ”2 INPUTS” and “MASTER”, this options are located in the Programming Options

menu in the VF7 Graphic Interface.

• Active the Motor Calibration, to detect the electrical characteristics of the motor installed,

place the door in a middle position.To perform an optimal calibration of the motor installed the

process has to be done without charge.

Never perform calibration with the car door and landing door.

19

VF7

INSTALLATION PROCESS

• Program the door type, this options are located in the Programming Options menu in the VF7

Graphic Interface.

• Door model (T1, T2, T3, T4, C2, C4, C6 or C8).

• Landing door type (Semiautomatic or Automatic).

• Rotation sense (Clockwise or Counterclockwise).

• Place the door in a middle position in order to see the starting movement.

• Active the Door Learning option to start the learning cycle.

This option is located in the Programming Options menu in the VF7 Graphic Interface.

The correct steps that the door has to make are:

1. The door will close completely in slow speed until the end to detect the 0 position.

2. The door will open slowly counting the pulses from the encoder built into drive motor until

it reach the open mechanical stop. Will detect the nal position.

3. The door will close after a short delay. From the information obtained the microprocessor

will calculate the acceleration and deceleration ramps and the braking torque required to

give the optimum control of the doors.

• Door Test.

• Active the Test option to open the door and verify the proper operation. Active again the

test option to close the door.

• Program the VF7 control behaviour, this options are located in the Programming Options

menu in the VF7 Graphic Interface.

• 1 Input or 2 Inputs.

• Master or Slave.

• Connect the cables coming from the lift controller.

• Connect the inputs cables (Pins 8 to 12).

• Connect the priority inputs cables (Pins 21 to 26).

• Connect the relays outputs cables that inform the lift controller (Pins 30 to 47).

POWER FAILURES

The VF7 incorporates two new security systems related to power failures:

• Anti-banging system.

When a power failure occurs while the door is opening, closing or fully open, the new anti-banging

system brakes the PM motor to perform a slow closing and avoid the door hits at closing.

20

VF7

POWER FAILURES

• Electronic Car Door Lock.

When a power failure occurs while the door is fully closed, the VF7 detects the voltage drop and

opens the Car Door Lock if the cabin is on the oor level.

The Electronic Car Door Lock system could be enable or disabled by software.

Note: After the power supply has been restored and the open signal is activated, the doors will open

slowly for the rst operation in order to recognize the clear opening.

In this section the modications are listed for customer knowledge in order to comply with the new lift

standard EN 81-20/50.

KINETIC ENERGY.

The average closing speed has to be limited to 10 J. To limit it is necessary to know the moving mass,

the door opening and the panels number. This parameters are programmed by default except for the

spare part. In this case the parameters have to be introduced by the VF7 programming menu. In order

to comply the standard is necessary to congure some options and parameters:

LIGHT CURTAIN.

• The light curtain is mandatory and it can be

connected to the lift controller or to the VF7

in the pin 22.

LIFT STANDARD EN 81-20/50

Menu Option Conguration to comply EN81-20/50

Programming options

Door model. Select door model.

Photoc. / Curtain timer. Enable.

Eco Mode. Select modes Control, Close delay or Control delay.

Security Device. Curtain.

Close Anticipated (recommended). Enable.

Unlock on standby. Enable.

Temperature measurement. Enable.

Energy limit. Enable.

Menu Option Conguration to comply EN81-20/50

Programming parameters

Max. open torque. Limit only in case of a glass door. If glass door the value must to be

up to 1,2.

Max. close torque. Up to 1,2.

Door mass. Masses of the door and landing door. To know check Annex 1 and

Annex 2.

21

23

22

25

24

26

CERRAR LENTO

SLOW CLOSE

OUT +12 V

REABRIR

RE-OPEN

CONTACTO DE BYPASS

BYPASS CONTACT

SEÑAL DE PISO

FLOOR LEVEL

BARRERA

FOTOELÉCTRICA

LIGHT CURTAIN

ABRIR

OPEN

ENTRADAS PRIORITARIAS / PRIORITY INPUTS

Table of contents

Other Fermator Control Unit manuals

Popular Control Unit manuals by other brands

Reliable

Reliable EX Series manual

Mircom

Mircom MIX-M500MAP Installation and maintenance instructions

Dembla

Dembla 8100F21 Series instruction manual

Panasonic

Panasonic GP-US932CSAE operating instructions

Mec

Mec Excelerator ME990S-2DFM Installation and operating manual

Texas Instruments

Texas Instruments INA190EVM user guide