Fermator ECC+ 230 V User manual

MAN-MUED00000ENGTC-12.2017

ENG

User manual.

Automatic horizontal sliding car door.

Component: ECC+ 230 V Electronic Module.

2

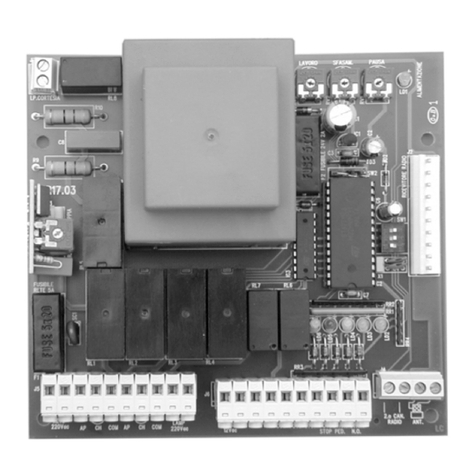

ECC+ 230 V Electronic Module

CONNECTIONS

38

4041

FUS 4A SP

42

43

44

18

19

20

37

+

-

12 V

15

16

17

11

12

8

9

10

L5

N7

PE6

36

35

34

33

35

21

22

23

24

25

26

28

27

30

29

13

14

31

32

0 V

39

1 2

1 2 3 4

34

FUS 20A SP

FUERZA

SAFETY

OPEN SPEED

VELOCIDAD

ABRIR

NO ABRIR

LA TAPA

DO NOT OPEN

THE COVER

VELOCIDAD

CERRAR

CLOSE SPEED

TEST

PULSAR PARA

VERIFICAR

PUSH TO CHECK

THE DOOR

QCI-EP00PC4EE

CERRADA / CLOSED

ABIERTA / OPEN

MOTOR & ENCODER

BATERÍA

BATTERY

ENTRADAS

INPUTS

OUT 24 V

CERRAR

CLOSE

ABRIR

OPEN

0 V

COM

ALIMENT.

SUPPLY

F.C. ABRIR

OPEN L.S.

F.C. CERRAR

CLOSE L.S.

SIN ENCODER

WITHOUT

ENCODER

PUERTO SERIE

SERIAL PORT

CONTACTO

SERIE

SERIAL

SWITCH

CONTACTO

SEGURIDAD

SAFETY

SWITCH

REABRIR 2

REOPEN 2

REABRIR 1

REOPEN 1

SEÑAL DE PISO

FLOOR LEVEL

F.C.CERRAR

CLOSE L.S.

CON ENCODER

WITH

ENCODER

ABIERTA / CERRADA // OPEN / CLOSED

...OK STATUS

SPECIAL

ESPECIAL

STANDARD

ESTÁNDAR

MOTOR

ENCODER

FINAL CARRERA

LIMIT SWITCH

WORKING

FUNCIONAMIENTO

DOOR MODEL

MODELO PUERTA

HEAVY

PESADA

STANDARD

ESTÁNDAR

FLOOR LEVEL

SEÑAL DE PISO

2 INPUTS / 1 INPUT WITHOUT BATTERY

2 ENTRADAS / 1 ENTRADA SIN BATERÍA

1 INPUT WITH BATTERY

1 ENTRADA CON BATERÍA

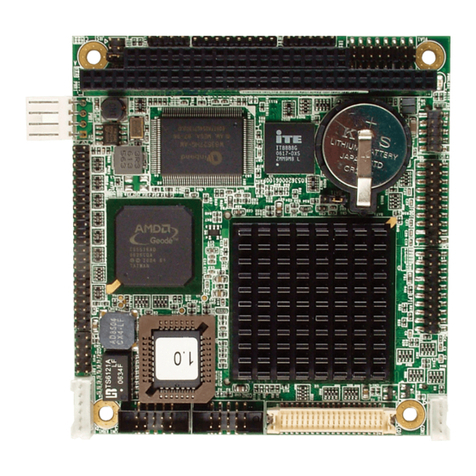

3

12 V 2 Ah

J100

SW401

J202-203

J201

J206 J204

J205

J208

SW2POT402POT401POT400

J207

J212

J401

J209

2-ENT 1-ENT

SW1

F200

Brown

Serial Contact

Close limit switch

Motor 24 V DC

Red

Blue

Encoder

Brown

Blue

Brown

Brown

Jumper 1E/2E

24...230 V

24...230 V

J200

Thermal protection

230 V

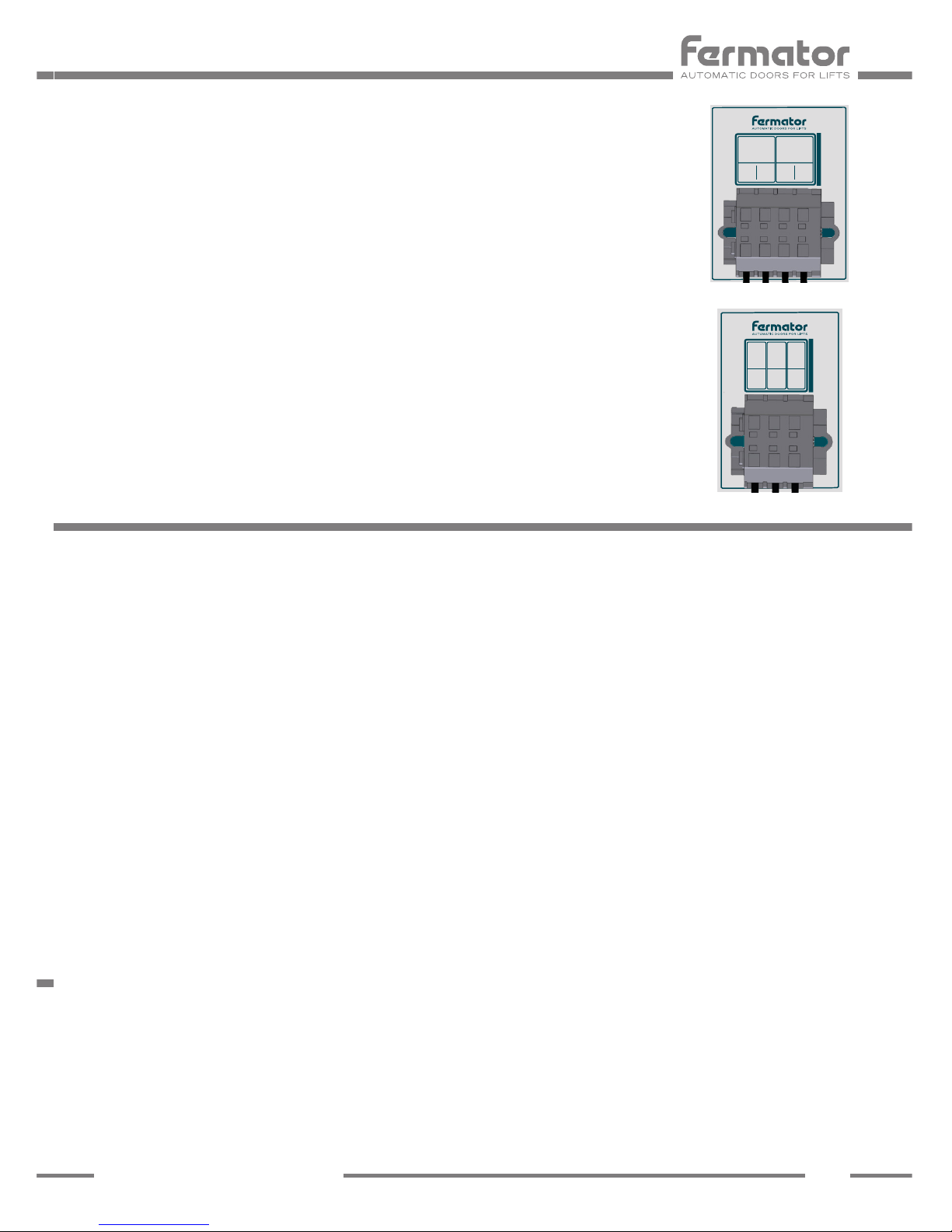

Interior detail of the Electronic module.

The cover must be removed to access.

3

ECC+ 230 V Electronic Module

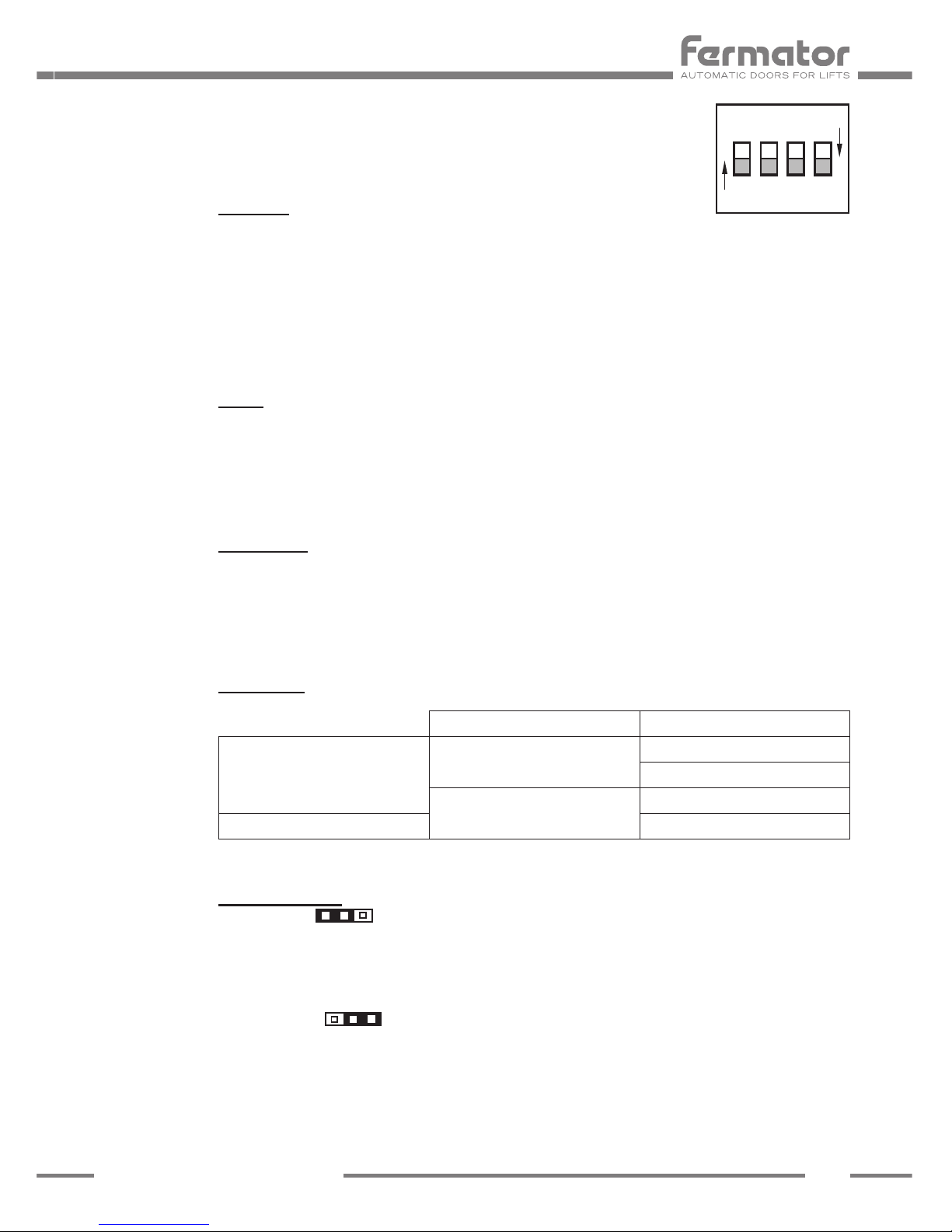

The unit has to be programmed using the DIP switches on the front of the unit. If any

change is made to any of the above switch selections, the unit must be switched OFF

and ON again to read the new programming.

The switches functions are:

1 Working.

ON: Encoder.

The door movement control will be done using the motor encoder or the motor encoder

and a close limit switch.

OFF: Limit switch.

The door movement control will be done using an open limit switch and a close limit

switch.

2 Motor (This option is only used with the motor ELVI 104661 FCE).

ON: Special Motor.

Different control is applied to perform the door movement with a special motor.

OFF: Standard Motor.

Standard control is applied to perform the door movement.

3 Door model (This option is only used with the motor ELVI 104661 FCE).

ON: Heavy door.

The motor supplies a 30% extra torque to be able to move heavy doors.

OFF: Standard door.

Standard control is applied to perform the door movement.

4 Floor level.

Inputs 12 V battery

ON 2 Inputs

1 Input

OFF

Note: With DIP-switch No. 4 OFF is necessary to install a oor level contact in each oor.

J209 1 and 2 INPUTS.

1 Input (1-IN ).

The door control unit will be controlled by a single input. Any voltage between 24 V DC

to 60 V DC or 100 V AC to 230 V AC applied between terminals 10 and 12 will close the

doors. Without input active the door remains opened. Open input is not used.

2 Inputs (2-IN ).

The door control unit will be controlled by two independent inputs. Any voltage between

24 V DC to 60 V DC or 100 V AC to 230 V AC applied between terminals 10 and 12 will

cause the doors to close. And between terminals 8 and 10 will cause the doors to open.

In the absence of a signal, the doors will remain static. If both inputs are applied then the

open signal has priority.

1

O

N

234

O

F

F

PROGRAMMING

4

ECC+ 230 V Electronic Module

5 / 6 / 7 POWER INPUTS 230 VOLTS SINGLE PHASE AC.

The circuit has been designed to operate on a mains supply of 230 V AC (+10%,-15%, 50

or 60 Hz).

CONTROLS INPUTS

The circuit can work with external voltage inputs or by means a volt free contact input.

8 Open signal.

This signal orders the door to open. The voltage required can be from 24 V DC to 60 V DC

or 100 V AC to 230 V AC with an external supply between this input and common (10).

9 0 V.

Opposite pole to Out 24 V (11). In the case of using internal voltage it should be connected

to the common input (10).

10 Common.

This input is the reference used for the open and close inputs.

11 Out 24 V.

Isolated 24 V output available to control the door via a voltage free contact. Features are:

a) This supply must only be used for this purpose.

b) This contact must be isolated from any other power supply.

12 Close signal.

This signal is used for ordering to close the door.

13 / 14 Floor level.

This input activates the open movement in emergency rescue mode in case of power

failure. A 12 V battery is used to rescue the passengers from the lift. The door only will

open if this signal is bridged (Normally Open).

15 / 16 / 17 Battery.

This input is for connecting a 12 V battery 2,2 Ah to act as external emergency power

supply and allows the opening movement of the door in case of power failure.

PROGRAMING

INPUTS

Open

Close

Voltage

OPEN

Voltage

CLOSE

Open

Close

OPEN

CLOSE

EXTERNAL VOLTAGE INPUT VOLT FREE CONTACT INPUT

8

9

10

11

12

8

9

10

11

12

24...230 V

24...230 V

Open

Close

Without Voltage

OPEN

With Voltage

CLOSE

Open

Close

Voltage

OPEN

Voltage

CLOSE

1 INPUT 2 INPUTS

Com

12 V

0 V

8

9

10

11

12

Com

12 V

0 V

8

9

10

11

12

24...230 V

24...230 V

24...230 V

24...230 V

5

ECC+ 230 V Electronic Module

INPUTS

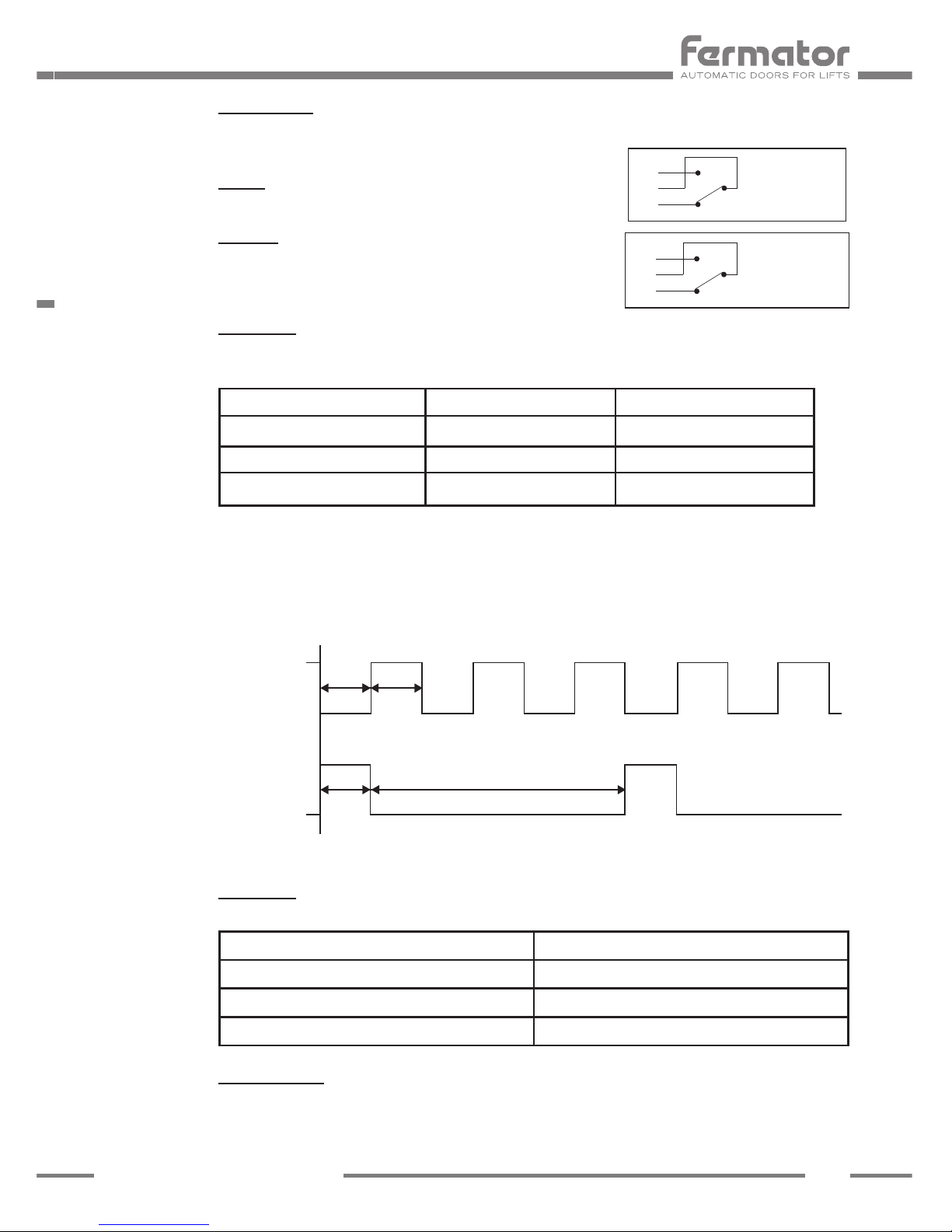

Output relay

An output relay is provided to give continuous information to the main lift controller

concerning the status of the doors.

18 / 19 / 20 Open.

Relay activated when the doors are fully open.

42 / 43 / 44 Closed.

Relay activated when the doors are fully closed.

LED INDICATORS:

Ok status.

Green LED indicates proper working conditions.

Depending on how the ECC + 230 V is powered the green LED lights up in different ways:

12 V battery230 V power supplyOk Status LED

Lit

Blinking

Single ash

– LED lit: constantly on.

– LED blinking: iso-phase on and off with a frequency of approximately 5 Hz: on for

approximately 100 ms followed by off for approximately 100 ms.

– LED single ash: one short ash (approximately 100 ms) followed by a long off phase

(approximately 2.400 ms).

Ok status.

LED indicates the status of the door.

Door StatusOpen / Closed LED colour

Door fully openLighting green

Door fully closedLighting red

Alarm activatedLighting orange

21 / 22 / 23 Serial switch.

Serial switch connection. Direct connection between the entrance and the exit without

any inuence in the electrical circuit function.

20

18

19 OPEN

44

42

43 CLOSED

Indicator states and flash rates

Blinking

Single

flash

100

100 2.400

ms

ms ms

ms

100

on

on

off

off

6

ECC+ 230 V Electronic Module

24 / 25 / 26 Safety switch.

Serial switch connection. Direct connection between the entrance and the exit without

any inuence in the electrical circuit function.

27 / 28 / 29 / 30

Reopen.

These connections are in series and are normally closed. These inputs are used to connect

a light curtain, the cabin push-button or any other device that initiates the reopening

process when the door starts to close. It does not activate when the door is closed. If

these inputs are not used it is necessary to bridge them.

31 / 32 Limit switch with encoder.

With DIP-switch No. 1 switched to ON it is necessary to install a close limit switch. The

open position is given by the motor encoder.

33 / 34 / 35 / 36

Limit switch without encoder.

With DIP-switch No. 1 switched to OFF it is necessary to install both an open and close

limit switch.

37 Motor and encoder.

Output to the 24 V DC motor to control speed and torque. The ECC+ 230 V motor controller

is formed by a power stage with a current limiting protection.

The 24 V DC motor incorporates a thermal protection in order to inform the lift controller

in case of motor overheating. Once the thermal protection is activated, the lift control has

to remove immediately the open/close input to stop the motor and allow it to cool down.

38 Test pushbutton.

Operation of the Test pushbutton will cause a door open or close cycle.

39 Safety.

This potentiometer is used to set the closing force over an obstacle in the clear opening.

40 Close speed.

The door closing speed can be independently adjusted.

41 Open speed.

The door closing speed can be independently adjusted.

42 On / Off switch.

Disconnects the unit from the 230 V AC mains supply.

45 Com port.

The serial port is used to connect with external devices, interfaces and

future expansion devices. Operating speed 1.200 Baud per second,

current loop.

In this section the modications are listed to provide customer awareness in order to comply with the new

lift standard EN 81-20.

LIGHT CURTAIN

· The light curtain is mandatory and has to be connected to the lift controller.

INPUTS

45

PUERTO SERIE

SERIAL PORT

LIFT STANDARD EN 81-20

7

ECC+ 230 V Electronic Module

OVERHEATING PROTECTION

· Two clixon sensors are added in the motor winding to measure the

temperature and protect the motor against overheating. The signals of these

sensors are connected in a 2-conductor terminal strip:

The motor thermal protection 1 is the clixon sensor that indicates the

motor is near to reach the critical temperature. In this case the lift

controller must stop the car at a landing to alow the passengers to leave.

The motor thermal protection 2 is the clixon sensor that indicates the

motor has reached the critical temperature. Then the lift controller has

to remove the ECC + 230 V supply voltage.

The maximum contact rating is 7.0 (2.0) A 250 Vac.

DOOR CONTACT

· A separate monitoring signal is necessary to check that the car door(s)

is/are in the closed position. To comply with this point an additional door

contact is added, and the signal has to be connected to the lift controller.

The maximum contact rating is 2 A 230 Vac.

POWER SUPPLY

• DC voltage range: 230 V +10%, -15%. AC/DC.

• Standby: 100 mA 2 W.

PWM REGULATION

• PWM frequency: 15KHz.

• Voltage range: 0...24 V DC III.

• Maximum output current: 2 A.

• Positional control: Encoder.

MOTOR

• Brushed DC motor:

• Voltage supply: 24 V.

• Power: 7 W.

• Enclosure class: IP 20.

• Nominal speed: 17 rpm.

MOTOR THERMAL PROTECTION

• Opening temperature: 80 ºC.

• Maximum voltage: 250 V AC.

• Maximum current: 2 A.

INPUTS

• Impedance: 33 K Ω.

• Voltage: 24...60 V DC,

100...230 V AC.

OUTPUTS

• Contacts: Switched.

• R. contact: 50 mW.

• Swich time: 5 ms.

• Output current: Máximum: 5 A.

• Voltage: 250 V.

1234

Motor

thermal

protection

2

Motor

thermal

protection

1

ETQ-CAPTMSED0004355

REFERENCE DATA

LIFT STANDARD EN 81-20

1

Supply NC NO

23

ETQ-ED000BENG000000

Tecnolama, S.A.

●

Ctra. Constantí, Km 3

●

43204 REUS (Spain)

●

Tel.: +34 977 774 065

Fax: +34 977 771 615

●

www.fermator.com

●

e-mail: info.es@fermator.com

Tecnolama, S.A.

Ctra. Constantí Km 3

43204 REUS (Spain)

Reus, 11-12-17

David Román

General Manager

ATTENTION: Any proposed modication not shown in this manual should be claried with our

Technical Department before actioning.

TECNOLAMA accepts no responsability for any resultant damage produced in the equipment

described in this manual and associated installation if the instructions given have not been followed.

TECNOLAMA reserves the right to modify the product or specications in this technical brochure

without prior notication.

CE DECLARATION OF CONFORMITY

We hereby declare that the products described in this document

conform with the following E.U. council directive:

Norm EN 81-1/2, EN 81-20/50.

DIRECTIVE 2006/42/EC (Machinery directive), DIRECTIVE 2014/30/EU

(Electromagnetic compatibility), of the European Parliament and of the Council.

ECC+ 230 V Electronic Module

Table of contents

Other Fermator Control Unit manuals

Popular Control Unit manuals by other brands

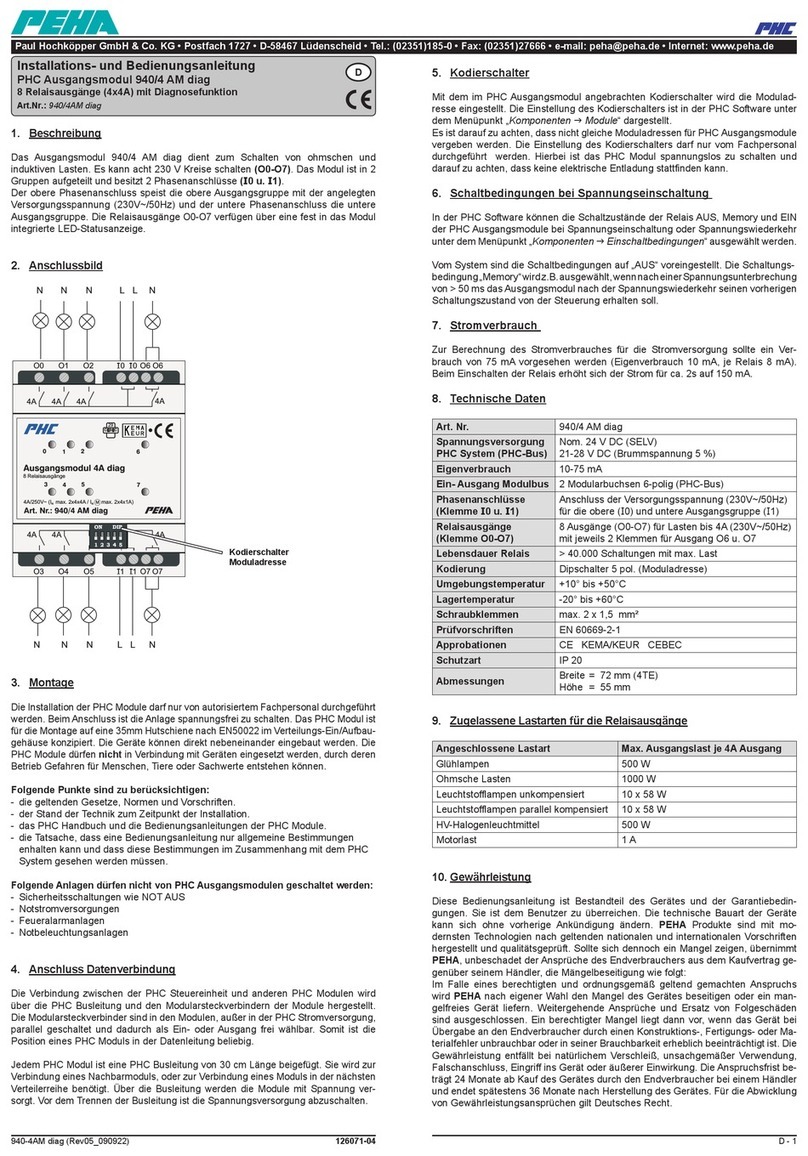

PEHA

PEHA PHC 940/4 AM diag Installation and operating instructions

Cricut

Cricut Jaffas CBM002 user guide

Wilo

Wilo Electronic Control MT6 Installation and operating instructions

Leb Electronics

Leb Electronics CTR17 instruction manual

Epson

Epson RA4803SA Applications manual

SPX

SPX APV DELTA DET3 operating manual

Keystone

Keystone EPI2-MAN-652NA-OM1 user manual

Arbor Technology

Arbor Technology Em104-a5362 Quick installation guide

Siemens

Siemens Simatic S7-1500 manual

ICP DAS USA

ICP DAS USA I-7083 user manual

Brizo

Brizo SENSORI T66T050 Series installation instructions

Grundfos

Grundfos Unilift AP12 Installation and operating instructions