Fermator ECC 230 V User manual

MAN-MUEC00000ENGTC-05.2016

ENG

Assembly manual.

Automatic horizontal sliding car door.

Component: ECC 230 V Electronic Module.

AUTOMATIC DOORS FOR LIFTS

AUTOMATIC DOORS FOR LIFTS

2

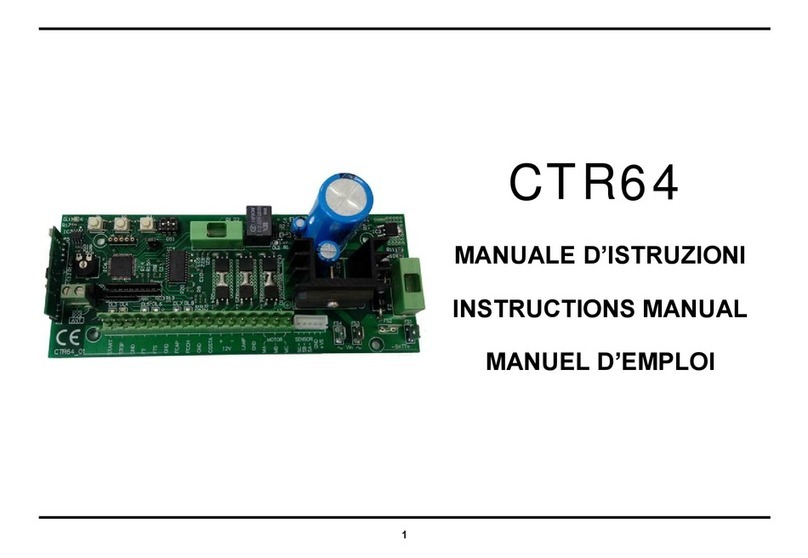

ECC 230 V

CONNECTIONS

Motor 24 V DC

3

230 V

24...230 V

24...230 V

1-IN

J209

2-IN

12 V 2,2 Ah

Azul/Blue

Reopening Contact

Rojo/Red

Azul/Blue

Encoder

Final close course contact

Microrruptor

final carrera cerrar

Microrruptor

reapertura contacto

cerrado

Marrón/Brown

Azul/Blue

Marrón/Brown

11

12

8

9

10

L5

N7

PE6

18

19

20

384041 39

1 2 34

1 2 3 4

37

36

35

34

33

29

30

27

28

31

32

22

23

21

25

26

24

0V

14

13

+

12 V

15

16

17

QCI.EC00.C00EE

BATERÍA

BATTERY

FUS 20A SP

FUS 4A SP

SEÑAL

DE PISO

FLOOR

LEVEL

...OK STATUS

NO ABRIR

LA TAPA

DO NOT OPEN

THE COVER

FUERZA

SAFETY

OPEN SPEED

VELOCIDAD

ABRIR

VELOCIDAD

CERRAR

CLOSE SPEED

PULSAR PARA

VERIFICAR

PUSH TO CHECK

THE DOOR

SPECIAL

ESPECIAL

STANDARD

ESTÁNDAR

MOTOR

ENCODER

FINAL CARRERA

LIMIT SWITCH

WORKING

FUNCIONAMIENTO

DOOR MODEL

MODELO PUERTA

HEAVY

PESADA

STANDARD

ESTÁNDAR

FLOOR LEVEL

SEÑAL DE PISO

2 INPUTS / 1 INPUT WITHOUT BATTERY

2 ENTRADAS / 1 ENTRADA SIN BATERÍA

1 INPUT WITH BATTERY

1 ENTRADA CON BATERÍA

ENTRADAS

INPUTS

OUT 24 V

CERRAR

CLOSE

ABRIR

OPEN

0 V

COM

ALIMENT.

SUPPLY

ABIERTA / OPEN

MOTOR & ENCODER

F.C. ABRIR

OPEN L.S.

F.C. CERRAR

CLOSE L.S.

SIN ENCODER

WITHOUT

ENCODER

CON ENCODER

WITH

ENCODER

CONTACTO

SERIE

SERIAL

SWITCH

CONTACTO

SEGURIDAD

SAFETY

SWITCH

REABRIR 2

REOPEN 2

REABRIR 1

REOPEN 1

F.C.CERRAR

CLOSE L.S.

ABIERTA / CERRADA // OPEN / CLOSED

AUTOMATIC DOORS FOR LIFTS

3

ECC 230 V

The unit has to be programmed using the DIP switches on the front of the unit. If any

change is made to any of the above switch selections, the unit must be switched OFF

and ON again to read the new programming.

The switches functions are:

1 Working.

ON: Encoder.

The door movement control will be done using the motor encoder or the motor encoder

and a close limit switch.

OFF: Limit switch.

The door movement control will be done using an open limit switch and a close limit

switch.

2 Motor.

ON: Special Motor.

Different control is applied to perform the door movement with a special motor.

OFF: Standard Motor.

Standard control is applied to perform the door movement.

3 Door model.

ON: Heavy door.

The motor supplies a 30% extra torque to be able to move heavy doors.

OFF: Standard door.

Standard control is applied to perform the door movement.

4 Floor level.

Inputs 12 V battery

ON 2 Inputs

1 Input

OFF

Note: With DIP-switch No. 4 OFF is necessary to install a oor level contact in each oor.

J209 1 & 2 INGRESSI.

1 InPUT (1-IN ).

The door control unit will be controlled by a single input. Any voltage between 24 V DC to

60 V DC or 100 V AC to 230 V AC applied between terminals 10 & 12 will close the doors.

Without input active the door remains opened. Open input is not used.

2 Inputs (2-IN ).

The door control unit will be controlled by two independent inputs. Any voltage between

24 V DC to 60 V DC or 100 V AC to 230 V AC applied between terminals 10 & 12 will

cause the doors to close. And between terminals 8 & 10 will cause the doors to open. In

the absence of a signal, the doors will remain static. If both inputs are applied then the

open signal has priority.

1

O

N

234

O

F

F

PROGRAMMING

AUTOMATIC DOORS FOR LIFTS

4

ECC 230 V

5 / 6 / 7 POWER INPUTS 230 VOLTS SINGLE PHASE AC.

The circuit has been designed to operate on a mains supply of 230 V AC (+10%,-15%, 50

or 60 Hz).

CONTROLS INPUTS

The circuit can work with external voltage inputs or by means a volt free contact input.

8 Open signal.

This signal orders the door to open. The tension to apply could be from 24 V DC to 60

V DC or 100 V AC to 230 V AC, with an external supply between this input and common

(10).

9 0 V.

Opposite pole to 12 V, in the case of using internal VOLTAGE, it should be connected to

the common input.

10 Common.

This input is the reference used for the open and close inputs.

11 12 V.

Isolated 12 V output available to control the door via a voltage free contact. Features are:

a) This supply must only be used for this purpose.

b) This contact must be isolated from any other power supply.

12 Close signal.

This signal is used for ordering to close the door.

13 / 14 Floor level.

This input activates the open movement in emergency rescue mode in case of power

failure, through a 12 V battery to rescue the passengers from the lift. The door only will

open if this signal is bridged (Normally Open).

PROGRAMING

INPUTS

Open

Close

Voltage

OPEN

Voltage

CLOSE

Open

Close

OPEN

CLOSE

EXTERNAL VOLTAGE INPUT VOLT FREE CONTACT INPUT

8

9

10

11

12

8

9

10

11

12

24...230 V

24...230 V

Open

Close

Without Voltage

OPEN

With Voltage

CLOSE

Open

Close

Voltage

OPEN

Voltage

CLOSE

1 INPUT 2 INPUTS

Com

12 V

0 V

8

9

10

11

12

Com

12 V

0 V

8

9

10

11

12

24...230 V

24...230 V

24...230 V

24...230 V

AUTOMATIC DOORS FOR LIFTS

5

ECC 230 V

INPUTS

15 / 16 / 17 Battery.

This input is for connecting a 12 V battery 2,2 Ah to act as external emergency power

supply and allows the opening movement of the door in case of power failure.

Output relay

Output relay have been provided to give continuous information to the main lift controller

concerning the status of the doors.

18 / 19 / 20 Open.

Relay activated when the doors are fully open.

LED INDICATORS:

Ok status.

Red LED indicates proper working conditions.

Depending on how the ECC - 230 V is powered, red LED lights up in different ways:

12 V battery230 V power supplyRed LED

Lighting

Blinking

Single ash

– LED lighting: constantly on.

– LED blinking: iso-phase on and off with a frequency of approximately 5 Hz: on for

approximately 100 ms followed by off for approximately 100 ms.

– LED single ash: one short ash (approximately 100 ms) followed by a long off phase

(approximately 2.250 ms).

21 / 22 / 23 Serial switch.

Connection serial exit-entrance. It must be connected in series with the external lock series.

24 / 25 / 26 Safety switch.

Direct connection between the entrance and the exit without any inuence in the electrical

circuit function.

27 / 28 / 29 / 30

Reopen.

This connections are in serial and when it’s activated the door reopens. It is very useful for

the photocell, the cabin push-button or any other device that initiates the reopening process

when the door starts to close. It does not activate when the door is closed. As it is a serial

connection it is necessary to over-bridge the free one.

20

18

19 OPEN

Indicator states and flash rates

Blinking

Lighting

Single

flash

100

100 2250

ms

ms ms

ms

100

on

on

on

off

off

off

AUTOMATIC DOORS FOR LIFTS

6

ECC 230 V

31 / 32 Limit switch with encoder.

Limit switch connection if used with encoder. With DIP-switch No. 1 ON is necessary to

install a close limit switch.

33 / 34 / 35 / 36

Limit switch without encoder.

Limit switch connection if used without encoder. With DIP-switch No. 1 OFF is necessary

to install an open and close limit switch.

37 Motor and encoder.

Output to the 24 DC motor to control speed and torque. The ECC - 230 V motor controller is

formed by a power stage with a feedback speed control circuit with voltage compensation

and current limiting protections (Imax).

38 Test pushbutton.

Operation of the Test pushbutton will cause a door open or close cycle.

39 Safety.

La velocità di apertura della porta può essere regolata da 100 mm/s no a 300 mm/s.

40 Close speed.

The door closing speed can be independently adjusted from 100 mm/s up to 300 mm/s.

41 Open speed.

The door opening speed can be independently adjusted from 100 mm/s up to 300 mm/s.

42 On / Off switch.

Disconnects the unit from the 230 V AC mains supply.

POWER SUPPLY

• DC voltage range 230 V +10%, -15%. AC/DC.

• Minimum power 83 mA 2,8 W.

• Average power (240 cycles/hour) 0,17 A 14,7 W.

• Maximum power 0,27 A 33,7 W.

PWM REGULATION

• PWM frequency 15KHz.

• Voltage range 0...24 V DC III.

• Maximum output current 2 A.

• Positional control: Quadrature encoder.

MOTOR

• Brushed DC motor

• Voltage supply 24 V.

• Power 7 W.

• Enclosure class IP 20.

• Nominal speed 17 rpm.

REFERENCE DATA

INPUTS

Tecnolama, S.A.

Ctra. Constantí Km 3

43206 REUS (Spain)

Tecnolama, S.A., 2016

Josep Vilà Gomis

Amministrator

AUTOMATIC DOORS FOR LIFTS

7

ECC 230 V

INPUTS

• Impedance 8K2 Ω.

• Voltage 24...230 V AC / DC.

OUTPUTS

• Contacts Switched.

• R. contact 50 mW.

• Swich time 5 ms.

• Output current Máximum: 5 A.

• Voltage 240 V

PERFORMANCE

• Open Speed 100...300 mm/s.

• Close speed 100...300 mm/s.

• Safety force 40...150 N adjustable.

REFERENCE DATA

DECLARATION OF CONFORMITY

Herewith declares that the products mentioned below conform with the following E.U.

council directives:

Norm EN 81-1/2

DIRECTIVE 2006/42/EC (Machinery directive), DIRECTIVE 2014/30/UE

(Electromagnetic compatibility), of the European Parliament and of the Council.

ECC 230 V Electronic Module

(10/31700971_M1)

Tecnolama, S.A.

●

Ctra. Constantí, Km 3

●

43206 REUS (Spain)

●

Tel.: +34 977 774 065

Fax: +34 977 771 615

●

www.fermator.com

●

e-mail: info.es@fermator.com

ATENTION: Any type of modication not reexed in this manual, before testing it should be notied

to our Technical Department.

TECNOLAMA accepts no responsability in the event of any damage produced in the equipment

described in this manual and associated installation if the instructions given have not been followed.

TECNOLAMA reserves the rights to modify the products specications of this technical brochure

without any previous advise.

Table of contents

Other Fermator Control Unit manuals