FERREX BDG 915 User manual

User Manual

Original Instructions

BELT&DISC SANDER

AFTER SALES SUPPORT 703625

00800 4003 4003

MODEL:

BDG915 07/2020

3

YEAR

WARRANTY

PRODUCED IN CHINA FOR:

ALDI STORES LTD. PO BOX 26, ATHERSTONE

WARWICKSHIRE, CV9 2SH.

ALDI STORES (IRELAND) LTD.

PO BOX 726, NAAS, CO. KILDARE.

Visit us at www.aldi.com

Great care has gone into the manufacture of this product and it should

therefore provide you with years of good service when used properly.

In the event of product failure within its intended use over the course of the

first 3 years after date of purchase, we will remedy the problem as quickly

as possible once it has been brought to our attention. In the unlikely event

of such an occurrence, or if you require any information about the product,

please contact us via our helpline support services, details of which are to be

found both in this manual and on the product itself.

GB IE

GB IE

Contents

Dok./Rev.-Nr. 703625_20200123

Overview ..................................................................................4

Package contents/part list......................................................6

Explanation of symbols ...........................................................9

Introduction ........................................................................... 10

Layout ......................................................................................11

Scope of delivery.....................................................................11

Intended use ...........................................................................12

General safety instructions for power tools..........................12

Before starting the equipment............................................. 16

Attachment and operation.................................................... 16

Working instructions ............................................................. 19

Cleaning and maintenance....................................................20

Technical data ........................................................................ 21

Storage and transport........................................................... 22

Electrical connection.............................................................. 22

Disposal and recycling...........................................................23

Troubleshooting.....................................................................24

Declaration of Conformity .....................................................26

12

12

7

314

5

13

11

9

10

8

6

4

1

14

1

4

17

7

5

18

6 7

10

8

5

10

15

16

2

1

14

3

19

5 64

96

20

11

17

Package contents/part list

1Belt&Disc sander

2Locking screw for grinding/sanding table

3Grinding belt (pre-assembled)

4Stop rail

5Grinding/sanding disk

6Cross stop

7Grinding/sanding table

8Warranty card

9Instruction manual

7

0

15

45

max. 1,6 mm

3

14

7

15

6

14

13

16

(7)

(W)

17

(W)

(R)

18

(W)

19

1

14

20

12

15

16

13

8

9

Explanation of symbols

Explanation of symbols

m ATTENTION!These operating instruction provide places concerning your

safety which are marked with this indication

m CAUTION!Failure to follow these instructions may cause light to medi-

um risk of injury

m WARNING!Failure to follow these instructions may cause danger to life

or danger of serious injuries

Warning! In case of non-compliance danger to life,

risk of injury or damage to the tool possible!

Read the operating instructions to reduce the risk

of injury.

Wear safety goggles.

Wear ear-muffs.

Wear a breathing mask.

Important! Risk of injury! Never reach into the run-

ning sanding belt / disc.

Warning! Before installation, cleaning, alterations,

maintenance, storage and transport switch off the

device and disconnect it from the power supply.

10

Introduction

I. Introduction

Congratulations on choosing to buy a FERREX®product.

All products brought to you by FERREX®are manufactured to the highest standards of per-

formance and safety, and as part of our philosophy of customer service and satisfaction, are

backed by our comprehensive 3 Year Warranty.

We hope you will enjoy using your purchase for many years to come.

Note:

According to the applicable product liability law the manufacturer of this device is not liable

for damages which arise on or in connection with this device in case of:

• improper handling,

• non-compliance with the instructions for use,

• repairs by third party, non-authorised skilled workers,

• installation and replacement of non-original spare parts,

• improper use,

• failures of the electrical system due to the non-compliance with the electrical specifications

and regulations.

Recommendations:

Read the entire text of the operating instructions prior to the assembly and operation of the

device.

These operating instructions are intended to make it easier for you to get familiar with your

device and utilise its intended possibilities of use.

The operating instructions contain important notes on how to work safely, proper-

ly and economically with your machine and how to avoid dangers, save repair costs,

reduce downtime, and increase the reliability and working life of the machine.

In addition to the safety regulations contained herein, you must in any case com-

ply with the applicable regulations of your country with respect to the operation of the

machine.

Put the operating instructions in a clear plastic folder to protect them from dirt and humidity,

and store them near the machine. The instructions must be read and carefully observed by

each operator prior to starting the work. Only persons who have been trained in the use of

the machine and have been informed on the related dangers and risks are allowed to use the

machine. The required minimum age must be met.

In addition to the safety notes contained in the present operating instructions and the special

regulationsofyour country,the generally recognised technical rules forthe operationofiden-

tically constructed machines must be observed.

11

Layout/Scope of delivery

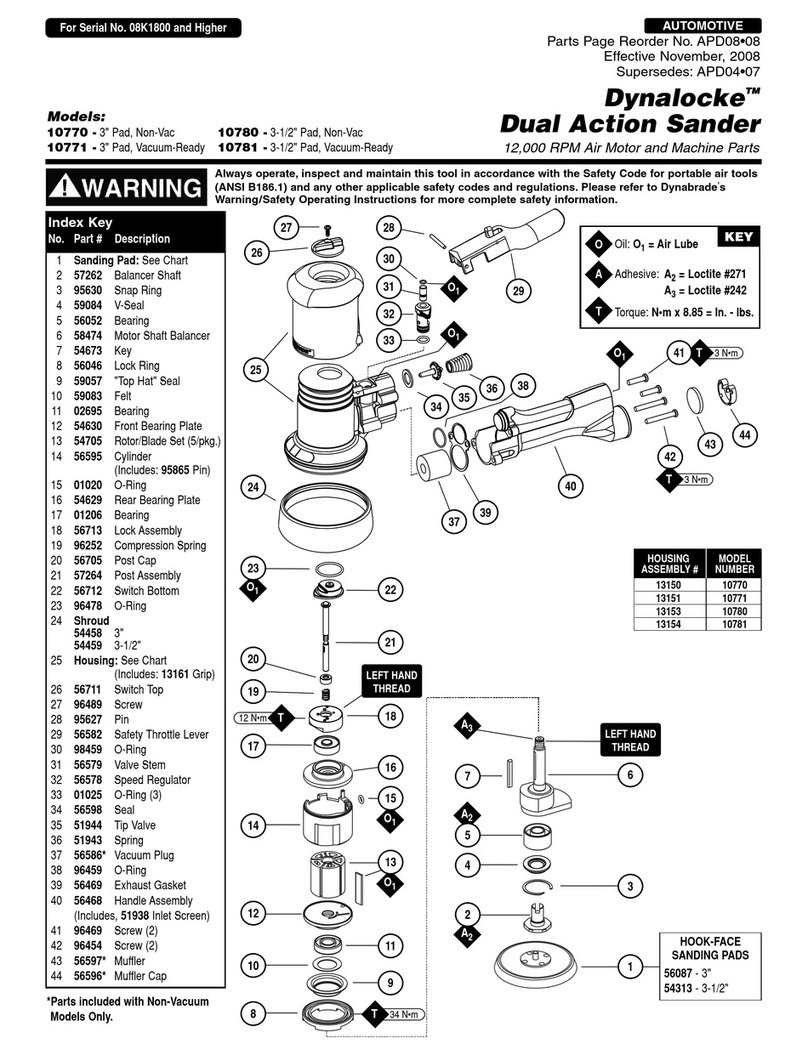

II. Layout (Fig. 1, 2, 5, 6, 7 , 11)

1 Locking screw for grinding/sanding table

2 Angle scale

3 Suction connection

4 Base plate

5 Allen screw

6 Grinding belt

7 Stop rail

8 Knurled screw for grinding/sanding belt adjustment

9 Support leg

10 Grinding/sanding belt tensioner

11 Grinding/sanding disk

12 On/Off switch

13 Cross stop

14 Grinding/sanding table

15 Lower wheel guard

16 Screw

17 Allen screw

18 Screw

19 Grinding/Sanding belt guard

20 Hole

III. Scope of delivery

• Open the packaging and remove the device carefully.

• Remove the packaging material as well as the packaging and transport bracing (if availa-

ble).

• Check that the delivery is complete.

• Check the device and accessory parts for transport damage.

• If possible, store the packaging until the warranty period has expired.

mATTENTION! The device and packaging materials are not toys!

Children must not be allowed to play with plastic bags, film and small parts! There is a

risk of swallowing and suffocation!

Belt&Disc sander Grinding/sanding disk

Locking screw for grinding/sanding table Cross stop

Grinding belt (pre-assembled) Grinding/sanding table

Stop rail Warranty card

Instruction manual

12

Intended use/ General safety instructions for power tools

IV. Intended use

The belt and disc sander is used for sanding all types of wood, depending on the size of the

machine.

The machine meets the currently valid EU machine directive.

• The manufacturer’s safety, operation and maintenance instructions as well as the technical

data given in the calibrations and dimensions must be adhered to.

• Relevant accident prevention regulations and other generally recognized safety and tech-

nical rules must also be adhered to.

• The machine may only be used, maintained or repaired by trained persons who are familiar

with the machine and have been informed about the dangers. Unauthorized modifications

of the machine exclude a liability of the manufacturer for damages resulting from the mod-

ifications.

• The machine is intended for use only with original spare parts and original tools from the

producer.

• Any other use is considered to be not intended. The manufacturer excludes any liability for

resulting damages, the risk is exclusively borne by the user.

Please note that our equipment has not been designed for use in commercial, trade or indus-

trial applications. Our warranty will be voided if the equipment is used in commercial, trade

or industrial businesses or for equivalent purposes.

V. General safety instructions for power tools

mWARNING! Read all safety warnings, instructions, illustrations and specifications pro-

vided with this power tool. Failure to follow all instructions listed below may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) Work area safety

a.Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b.Do not operate power tools in explosive atmospheres, such as in the presence of flam-

mable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while operating a power tool. Distractions cancau-

se you to lose control.

2) Electrical safety

a.Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

13

General safety instructions for power tools

b.Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is eart-

hed or grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d.Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e.When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f. If operating a power tool in a damp location is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces the risk of electric shock.

3) Personal safety

a.Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol

or medication. A moment of inattention while operating power tools may result in serious

personal injury.

b.Use personal protective equipment. Always wear eye protection. Protective equipment

such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for appro-

priate conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure the switch is in the off-position before connec-

ting to power source and/or battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or energising power tools that have the switch

on invites accidents.

d.Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

e.Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or jewellery. Keep your hair and clothing away

from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g.If devices are provided for the connection of dust extraction and collection facili-

ties, ensure these are connected and properly used. Use of dust collection can reduce

dust-related hazards.

h.Do not let familiarity gained from frequent use of tools allow you to become compla-

cent and ignore tool safety principles. A careless action can cause severe injury within a

fraction of a second.

14

General safety instructions for power tools

4) Power tool use and care

a.Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

b.Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or remove the battery pack, if detacha-

ble, from the power tool before making any adjustments, changing accessories, or sto-

ring power tools. Such preventive safety measures reduce the risk of starting the power tool

accidentally.

d.Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e.Maintain power tools and accessories. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the power tool’s ope-

ration. If damaged, have the power tool repaired before use. Many accidents are cau-

sed by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g.Use the power tool, accessories and tool bits etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the power

tool for operations different from those intended could result in a hazardous situation.

h.Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery han-

dles and grasping surfaces do not allow for safe handling and control of the tool in unexpected

situations.

5) Service

a.Have your power tool serviced by a qualified repair person using only identical replace-

ment parts. This will ensure that the safety of the power tool is maintained.

mWARNING! This electric tool generates an electromagnetic field during operation. This field

can impair active or passive medical implants under certain conditions. In order to prevent

the risk of serious or deadly injuries, we recommend that persons with medical implants con-

sult with their physician and the manufacturer of the medical implant prior to operating the

electric tool.

Additional safety rules for the belt and disc sanding machine

mWARNING! Do not use your machine until it is completely assembled and installed according to

the instructions.

• Attention: This machine has only been designed for sanding wood or similar materials. The

sanding of other materials can cause fire, injuries, or damage the product.

• Always wear safety goggles.

• This machine may only be operated indoors.

• Important: Mount and use the machine on a horizontal surface. A non-horizontal surface

can damage the motor.

15

General safety instructions for power tools

• If the machine tends to tilt or walk (especially when sanding long and heavy panels), it must

be fastened to a solid surface of sufficient carrying force.

• Make sure the sanding belt runs in the correct direction – see arrows at the back of the belt.

• Make sure the sanding belt is running correctly so that it cannot come off the drive pulleys.

• Make sure the sanding belt is not twisted or loose.

• Firmly hold the workpiece when sanding.

• Always use the fence when using the sanding machine in horizontal position.

• Always hold the workpiece firmly to the table when using the sanding disc.

• Always hold the workpiece to the side of the sanding disc running downwards, in order to

maintain the workpiece pressed to the table. By using the upward-running side of the sand-

ing disc, the workpiece could be ejected and cause injury to persons.

• Always keep a minimum distance of about 1.5 mm or less between the table or fence and

the sanding belt or disc.

• Do not wear gloves. Do not hold the workpiece with a cloth during sanding.

• Use sanding belt or disc of the correct grit corresponding with the wood.

• Never sand workpieces too small to be held safely.

• Avoidawkward handpositionswherea sudden slipcould causeyour handto touch thesanding belt

or disc.

• When sanding a large piece of material, provide an additional support at table height.

• Never sand an unsupported workpiece. Secure the workpiece with the table or the fence. Excep-

tions are the sanding of curved workpieces on the outside of the sanding disc.

• Alwaysclear the table,fence orsanding belt ofscraps orother objects, before turning the machine

on.

• Do not perform any layout assembly or set-up work on the table while the sanding machine

is in operation.

• Switch the machine off and pull the power plug from the socket when fitting or removing ac-

cessories.

• Never leave the working area of the sanding machine while the tool is running, or as long as

it has not come to an absolute standstill.

Remaining hazards

The machine has been built using modern technology and in accordance with recognized

safety rules.

Some hazards, however, may still remain.

• The sanding belt / disc poses a danger of injury to fingers and hands by improper feeding

or placement of tools.

• Danger of injury from thrown tools due to improper holding or feeding.

• The use of incorrect or damaged mains cables can lead to electrical injuries.

• Although having regarded all considerable rules there may still remain not obvious remain-

ing hazrds.

• Minimize remaining hazards by following the instructions in ”Safety Rules”, ”Use only as au-

thorized” and in the entire operating manual.

16

Before starting the equipment/Attachment and operation

VI.Before starting the equipment

Before you connect the equipment to the mains supply make sure that the data on the rating

plate are identical to the mains data.

mWARNING! Always ensure the machine is switched off and disconnected from the power

supply before making adjustments to the equipment.

• All covers and safety devices have to be properly fitted before the equipment is switched on.

• It must be possible for the sanding belt and disk to run freely.

• When working with wood that has been processed before, watch out for foreign bodies

such as nails or screws, etc.

• Before you actuate the On/Off switch, make sure that the abrasive paper is correctly fitted

and that the equipment‘s moving parts run smoothly.

VII. Attachment and operation

Before starting the equipment

Before you connect the equipment to the mains supply make sure that the data on the rating

plate are identical to the mains data.

mWARNING!:

Always pull the power plug before making adjustments to the equipment.

• All covers and safety devices have to be properly fitted before the equipment is switched on.

• It must be possible for the grinding/sanding belt and disk to run freely.

• When working with wood that has been processed before, watch out for foreign bodies

such as nails or screws, etc.

• Before you actuate the On/Off switch, make sure that the abrasive paper is correctly fitted

and that the equipment‘s moving parts run smoothly.

Assembling the machine (Fig. 1 - 5)

• Mount the lower wheel guard (15) with the screws (16). (Fig. 2)

• Mount the grinding/sanding table (14) and secure with the screw (1). (Fig. 3+4) The grind-

ing/ sanding table (14) can be infinitely adjusted from 0° to 45° with the miter scale (2) and

the thumb screw (1).

• The adjustable cross stop (13) ensures safe guidance of the workpiece. Important. The

grinding/sanding disk (11) must be able to run freely, but the distance between the grind-

ing/sanding table (14) and the grinding/sanding disk (11) is not allowed to exceed 1.6 mm.

• Put on the stop rail (7) and secure with the allen screw (17). (Fig. 5) Important. The grinding/

sanding belt (6) must be able to run freely.

17

Attachment and operation

Changing the grinding/sanding belt (6) (Fig. 6 - 9)

• Pull out the power plug

• Remove the screws (18).

• Remove the grinding/sanding belt guard (19).

• Turn the grinding/sanding tensioner (10) to the right in order to reduce the tension on the

grinding/sanding belt (6).

• Remove the grinding/sanding belt (6) to the rear.

• Mount and the new grinding/sanding belt in reverse order. Important. Note the running

direction: On the housing and on the inside of the grinding/ sanding belt!

Adjusting the grinding/sanding belt (6)

• Pull out the power plug

• Push the grinding/sanding belt (6) by hand slowly in the running direction.

• The grinding/sanding belt (6) must run centrally on the grinding/sanding surface. If not,

you can use the knurled screw (8) to make adjustments.

Moving the grinding/sanding position of the grinding/sanding belt (6) (Fig. 10-12)

• Loosen the Allen screw (5)

• Move the grinding/sanding belt (6) upwards into the desired position.

• Tighten the Allen screw (5) again to fix this position.

• In this position you can use the grinding/ sanding table to support the workpiece. To do this,

first loosen the two allen screws (17) and then remove the stop rail (7). The grinding table

can now be pushed into the hole in the holder tube (20) and fixed with the screw (1)

Replacing the abrasive paper on the grinding/sanding disk (11)

Dismantle the bottom wheel guard (15) by removing the 2 screws (16). Pull the sanding/ grind-

ing paper off the sanding/grinding disk (11) and attach the new sanding/grinding paper

(quick-fit fastening system).

Mounting belt/disc sander to work bench

If your belt/disc sander is to be used in a permanent location, it is recommended you secure it

to a workbench or other stable surface.

• Mark holes on workbench where belt/disc sander is to be mounted using holes in the base

as a template for hole pattern.

• Drill holes through workbench.

• Place belt/disc sander on workbench aligning holes in the base with holes drilled in the

workbench.

• Insert bolts (not included) and tighten securely with lock washers and hex nuts (not

included). Note: All bolts should be inserted from the top. Install the lock washers and hex

nuts from the underside of the workbench.

18

Attachment and operation

Using the belt/disc sander as portable tool

If your belt/disc sander is to be used as a portable tool, it is recommended you fasten it per-

manently to a mounting board that can easily be clamped to a workbench or other stable

surface.

The mounting board should be of sufficient size to avoid tipping while belt/disc sander is in

use. Any good grade plywood or chipboard with a 3/4 in. (19 mm) thickness is recommended.

• Mark holes on board where belt/disc sander is to be mounted using holes in the base as a

template for hole pattern.

• Follow last three steps in section Mounting Belt/Disc Sander to Workbench.

If lag bolts are used, make sure they are long enough to go through holes in belt/disc sander

base and material the belt/ disc sander is being mounted to. If machine bolts are used, make

sure bolts are long enough to go through holes in belt/disc sander, the material being mounted

to, and the lock washers and hex nuts.

On/O switch (12)

• The grinder/sander can be switched on by pressing the green button „1“.

• To switch o the grinder/sander you must press the red button „0“.

Warning: Do not reach across the sanding disc to turn the belt/disc sander ON or OFF.

Contact with the sanding disc can result in serious personal injury.

Grinding/sanding

• Always hold the workpiece rmly during grinding/ sanding.

• Do not exert excessive pressure.

• To prevent the abrasive paper from becoming worn on one side, the workpiece should

be moved to and from on the grindinög/sanding belt or grinding/sanding plate as you

grind/sand.

• Important! Pieces of wood should always be sanded with the grain to prevent them

splitting. Important. If the grinding wheel or the grinding/sanding belt becomes jammed

during operation, please remove the workpiece until the tool reaches its top speed

again.

19

Working instructions

VIII. Working instructions

Bevel sanding, Fig. 14

The worktable can be tilted from 0° to 45° for bevel sanding. To tilt the worktable:

• Loosen the fixing screw (1).

• Set worktable to desired angle. Note: Position the worktable not further than 1/16 in. (1.6

mm) from the sanding surface.

• Retighten the fixing screw (1) again.

Sanding small end surfaces using the miter gauge, Fig. 15

A miter gauge (13) is included with your tool for increased accuracy. Use of a miter gauge is

recommended for sanding small end surfaces on the sanding disc.

Note: Always move the workpiece across the sanding disc from the left side towards the right

side.

Horizontal and vertical sanding, Fig 10-12+16

Your belt/disc sander can sand both vertically and horizontally. Depending on the workpiece,

the work support can be used with either the horizontal or vertical sanding operation.

• Loosen the Allen screw (5)

• Move the grinding/sanding belt (6) upwards into the desired position.

• Tighten the Allen screw (5) again to fix this position.

• In this position you can use the grinding/ sanding table to support the workpiece. To do this, first

loosen the two Allen screws (17) and then remove the stop rail (7). The grinding table can now be

pushed into the hole in the holder tube (20) and fixed with the screw (1)

Note: Sand long workpieces with the sanding belt in the vertical position by moving the work

evenly across the sanding belt.

Surface sanding on the sanding belt, Fig. 17

• Hold the workpiece firmly, keeping fingers away from the sanding belt.

• Keep the end pressed firmly against the work support (7) moving work evenly across the

sanding belt. Note: Use extra caution when sanding very thin pieces and when sanding

extra long pieces, remove the work support (7). Apply only enough pressure to allow the

sanding belt to remove the material.

Sanding curved pieces, see Fig. 18

Warning: Never attempt to sand the end pieces of a workpiece on the idler drum. Applying

the end of the workpiece on the idler drum could cause the workpiece to fly up. Failure to

heed this warning could result in serious personal injury.

Always sand inside curves on the idler drum as shown in Figure 18.

• Hold the workpiece firmly, keeping fingers away from the sanding belt.

• Keep the curve pressed firmly against the idler drum moving work evenly across the sand-

ing belt.

Note: Use extra caution when sanding very thin pieces and apply only enough pressure to

allow the sanding belt to remove the material.

20

Working instructions/Cleaning and maintenance

Sanding outside curves on sanding disc Fig. 19

Always sand outside curves using the sanding disc and moving the workpiece (W) from the

left side of center as shown in Figure 19

• Hold the workpiece firmly, keeping fingers away from the sanding disc.

• Keep the curve pressed firmly against the sanding disc moving work evenly on the left side

of the sanding disc.

Warning: Applying the workpiece to the right side of the sanding disc could cause the work-

piece kickback. Failure to heed this warning could result in serious personal injury.

IX. Cleaning and maintenance

mWARNING!Prior to any adjustment, maintenance or service work switch off the machine

and disconnect the mains power plug!

Cleaning

• Keep all safety devices, air vents and the motor housing free of dirt and dust as far as possible. Wipe

the equipment with a clean cloth or blow it with compressed air at low pressure.

• Werecommendthatyouclean thedeviceimmediately each timeyouhavefinishedusing it.

• Clean the equipment regularly with a moist cloth and some soft soap. Do not use cleaning

agents or solvents; these could attack the plastic parts of the equipment. Ensure that no

water can seep into the device.

Maintenance

After using your belt/disc sander, clean it completely and lubricate all sliding and moving parts.

Applyalight coat ofautomotivetype pastewax totheworktable tohelpkeepthesurfaces clean.

Motor housing

Frequently blow out any dust that may accumulate inside the motor housing.

Changing drive belt.

Note: Excessive tightness on the drive belt may cause increased noise and overload the motor.

Excessive looseness on the drive belt may cause the drive belt to fail prematurely and make a

severe chattering noise.

mATTENTION!The drive belt should only be changed by a specialist.

Service information

Please note that the following parts of this product are subject to normal or natural wear and

that the following parts are therefore also required for use as consumables.

Wear parts*: Carbon brushes, v-belt, grinding medium

* Not necessarily included in the scope of delivery!

21

Technical data

X. Technical data

Dimensions l x w x h mm 470 x 370 x 330(640 highest position)

Ø disc mm 150

Belt dimensions mm 100 x 915

Belt speed m/min 450

Belt tilt 0° - 90°

Table tilt 0 - 450

Weight kg 16.5

Motor V/Hz 230-240/50

Input S1 W 370

Idle speed n0 rpm 2980

The work piece must have a minimum height of 10 mm and a minimum width of 10 mm.

Noise

Total noise values determined in accordance with EN 62841-1

Sound pressure level load / no load LpA 76.8 / 76.2 dB(A)

Uncertainty KpA 3 dB

Sound power level load / no load LWA 89.4 / 88.7 dB(A)

Uncertainty KWA 3 dB

Wear ear protection.

The impact of noise can cause damage to hearing.

Limit the noise to a minimum!

• Only use appliances which are in perfect working order.

• Service and clean the appliance regularly.

• Adapt your working style to suit the appliance.

• Do not overload the appliance.

• Have the appliance serviced whenever necessary.

• Switch the appliance off when it is not in use.

• Wear protective gloves.

m WARNING: The noise emission values can vary from the specified values during the actual

use of the electric tool, depending on the type and the manner in which the electric tool is

used, and in particular the type of workpiece being processed.

Implement measures to protect against noise nuisance. In doing so, take into account the

complete working process, including the times when the electric tool is working without load

or switched off.

Suitable measures include regular maintenance and care of the electric tool and the insertion

tools, regular breaks as well as proper planning of the working process.

22

Storage and transport/Electrical connection

XI. Storage and transport

Store the equipment and accessories out of children’s reach in a dark and dry place at above

freezing temperature. The ideal storage temperature is between

5 and 30 °C. Store the electric tool in its original packaging.

mATTENTION! The appliance must unconditionally be secured against falling or turning

down during transport.

The machine must only be lifted and transported on its frame or the frame plate.

mCAUTION! Two person handling required. Weight is 16.5 kg.

XII. Electrical connection

The electrical motor installed is connected and ready for operation. The connection complies

with the applicable European standards. The customer‘s mains connection as well as the ex-

tension cable used must also comply with these regulations.

mATTENTION! The power supply cord of this machine has an equipment-grounding con-

ductor and a grounding plug. The plug must be plugged into an appropriate outlet which

is properly installed and grounded in accordance with all local codes and ordinances.

mWARNING! Check the voltage! The voltage must comply with the information on the

rating label!

The customer‘s mains connection as well as the extension cable used must also comply

with these regulations.

Damaged electrical connection cable

The insulation on electrical connection cables is often damaged.

This may have the following causes:

• Passage points, where connection cables are passed through windows or doors.

• Kinks where the connection cable has been improperly fastened or routed.

• Places where the connection cables have been cut due to being driven over.

• Insulation damage due to being ripped out of the wall outlet.

• Cracks due to the insulation ageing.

Such damagedelectrical connectioncablesmustnot beusedandarelife-threateningduetothe

insulation damage.Check the electrical connection cables for damage regularly. Make sure that

the power is switched off before inspecting the cable. Electrical connection cables must comply

with the applicable European standards and must be correctly marked. Only use connection

cables with the marking ''H05VV-F''.Replacement cables can only be fitted by an approved and

certified electritian. If you are in any doubt please contact the help line at the foot of this page.

23

Electrical connection/Disposal and recycling

AC motor

• The mains voltage must be 230 - 240 V~

• Extension cables up to 25 m long must have a cross-section of 1.5 mm2.

Connections and repairs of electrical equipment may only be carried out by an electrician.

Please provide the following information in the event of any enquiries:

• Type of current for the motor

• Machine data - type plate

• Machine data - type plate

XIII. Disposal and recycling

The equipment is supplied in packaging to prevent it from being damaged in transit. The raw

materials in this packaging can be reused or recycled. The equipment and its accessories are

made of various types of material, such as metal and plastic. Defective components must be

disposed of as special waste. Ask your dealer or your local council.

Old devices must not be disposed of with household waste!

This symbol indicates that this product must not be disposed of together with domes-

tic waste in compliance with the Directive (2012/19/EU) pertaining to waste electrical

and electronic equipment (WEEE). This product must be disposed of at a designated

collection point. This can occur, for example, by handing it in at an authorised collect-

ing point for the recycling of waste electrical and electronic equipment. Improper handling

of waste equipment may have negative consequences for the environment and human health

due to potentially hazardous substances that are often contained in electrical and electron-

ic equipment. By properly disposing of this product, you are also contributing to the effective

use of natural resources. You can obtain information on collection points for waste equipment

from your municipal administration, public waste disposal authority, an authorised body for

the disposal of waste electrical and electronic equipment or your waste disposal company.

24

Troubleshooting

XIV. Troubleshooting

Problem Possible Cause Action

Motor doesn’t

start

a) ON/OFF switch damaged.

b) power cord damaged.

c) switch relay damaged.

d) Fuse blown.

e) Motor burnt.

a-d) Replace all damaged parts

before you use your machine

again.

e) Contact your local service centre.

Every attempt to carry out a re-

pair, can be dangerous if it is not

done by skilled personnel.

Machine gets

slower during

work.

Too much pressure put on the

workpiece.

Reduce the pressure on the work-

piece.

Sanding belt

comes off the

drive pulleys.

Belt does not run straight. Reset the track.

The wood gets

burnt during

sanding.

a) Sanding disc or belt covered with

grease.

b) Excessive pressure on workpiece.

a) Replace disc or belt.

b) Reduce pressure on workpiece.

Table of contents

Other FERREX Sander manuals