FERREX MM4115A User manual

PRODUCED IN CHINA FOR:

GB IE

Great care has gone into the manufacture of this product and it should

therefore provide you with years of good service when used properly. In

the event of product failure within its intended use over the course of the

first 3 years after date of purchase, we will remedy the problem as quickly

as possible once it has been brought to our attention. In the unlikely event

of such an occurrence, or if you require any information about the product,

please contact us via our helpline support services, details of which are to be

found both in this manual and on the product itself.

ALDI STORES LTD. PO BOX 26, ATHERSTONE

WARWICKSHIRE, CV9 2SH

ALDI STORES (IRELAND) LTD.

PO BOX 726, NAAS, CO. KILDARE

Visit us at www.aldi.com

AFTER SALES SUPPORT 805501

GB IE

MODEL:

MM4115A 07/2021

+44(0) 1904727501 +353(0) 19022605

3

YEAR

WARRANTY

User Manual

BELT AND DISC SANDER

Original User Manual

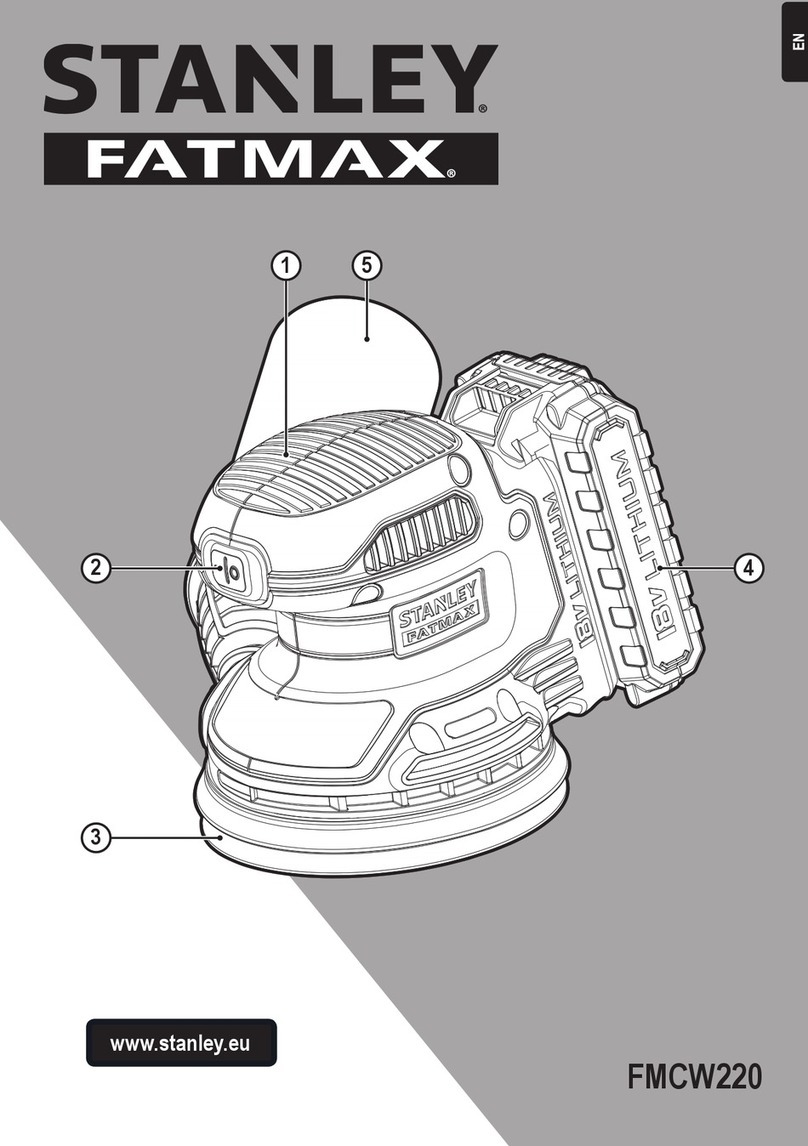

Overview

2

1

2345

67 8 9

10 11 12 13

14 15 16

18 19

22

23

24

25

26

17

27

28

29

A

21 20

Overview

3

Scope of delivery/device components

1

Belt and Disc Sander

2

45° Mitre gauge

3

Worktable rod

4

Rubber foot (x4)

5

Cord wrap (x2)

6

Big flat washer M5 (x12)

7

Screw M5x16 (x4)

8

Base plate

9

Nut M5 (x4)

10

Screw M5x12 (x4)

11

Disc guard

12

Screw M4 x 14

13

Flat washer M4 (x2)

14

Worktable assembly

15

Spanner 10x13 mm

16

Hex key 3, 4, 6 mm (3 pcs)

Operating manual and warranty card

(not depicted)

Device components

17

Sanding disc

18

Work support

19

Sanding belt

20

Carrying-handle

21

Lower belt cover

22

ON /OFF switch

23

Disc Dust outlet

24

Table lock knob

25

Bevel gauge

26

Worktable

27

Belt Dust outlet

28

Belt tension lever

29

Tracking knob

Required tools (not included)

30

Phillips screwdriver

PH1

30

31

Spanner size 8 mm

31

8

Scope of delivery/device components

4

Table of content

Overview..................................................................................................................2

Scope of delivery/device components...................................................................4

General information................................................................................................6

Reading and storing the operating manual..................................................................6

Intended use...................................................................................................................... 6

Explanation of symbols..................................................................................................... 7

Safety.......................................................................................................................8

General safety notes for power tools.............................................................................. 8

Check the device and scope of delivery................................................................14

Assembly instruction............................................................................................. 15

Attaching rubber feet to base plate...............................................................................15

Mounting the base plate................................................................................................. 16

Attaching the cord wrap..................................................................................................16

Attaching the disc guard................................................................................................. 17

Attaching worktable to sanding disc.............................................................................17

Attaching worktable to belt sander...............................................................................18

Before first use...................................................................................................... 20

Operation...............................................................................................................20

Turning the device on and off.........................................................................................21

Chamfering........................................................................................................................21

Mitre sanding....................................................................................................................22

Sanding flat surfaces....................................................................................................... 23

Sanding curved surfaces................................................................................................ 24

Cleaning................................................................................................................. 24

Maintenance.......................................................................................................... 25

Replacing the sanding belt............................................................................................ 25

Adjusting belt tracking....................................................................................................26

Testing....................................................................................................................27

Storage...................................................................................................................27

Transport............................................................................................................... 28

Load securing for transport............................................................................................28

Troubleshooting.................................................................................................... 28

Technical data........................................................................................................29

Noise/vibration information...........................................................................................29

Declaration of conformity......................................................................................31

Disposal..................................................................................................................32

Table of content

5

General information

Reading and storing the operating manual

This operating manual is part of the belt and disc sander (hereinafter also

called "device"). It contains important information on how to set up and

use the device.

Before using the device, read the operating manual carefully, in particular

the safety instructions. Failure to follow this operating manual may lead to severe

injuries or product damage.

This user manual is based on the standards and regulations that are valid within the

European Union. Outside the EU, please also note the country-specific directives and

laws.

Keep this operating manual for future reference. If you pass this device on to a third

party, you must also supply this operating manual.

Intended use

The device is designed for sanding wood of all types, as well as materials that are

similar to wood. It is only suitable for workpieces small enough to fully rest on the

respective worktable. Working on larger workpieces requires additional supports not

included with the device.

The device is suitable for use in non-condensing and non-explosive atmospheres.

This device is intended for private use only and is not suitable for commercial use.

Use the device only as described in this operating manual. Any other use is improper

and may lead to product damage or even personal injury. This device is not a toy.

The manufacturer or retailer assume no liability for damage caused by improper or

incorrect use.

Residual risks

Despite proper use, hidden residual risks cannot be completely excluded.

Depending on the type of device, the following risks may occur:

- Health risks which may result from vibration emissions if the device is used for a

long period of time or is not properly used or maintained.

- Injuries and material damage, which are caused by the moving blade or

breaking tool heads.

- Health risks may result from working with toxic or hazardous materials (eg.

asbestos) or if appropriate personal protection, due to hazardous material use, is

not applied.

General information

6

Explanation of symbols

The following symbols and signal words are used in this user manual, on the device

or on the packaging.

This symbol provides you with useful additional information on

handling and use.

Declaration of conformity (see chapter “Declaration of conformity”):

Products marked with this symbol meet all the applicable Community

regulations of the European Economic Area.

Wear hearing protection.

Wear protective goggles.

Wear a dust mask.

General information

7

Safety

The following signal words are used in this operating manual.

WARNING! This signal symbol/word denotes a

hazard with an average risk level that

could lead to death or severe injury if

it is not avoided.

CAUTION! This signal symbol/word denotes a

hazard with a low risk level that could

lead to mild or moderate injury if it is

not avoided.

NOTE! This signal word provides a warning

about potential material damage.

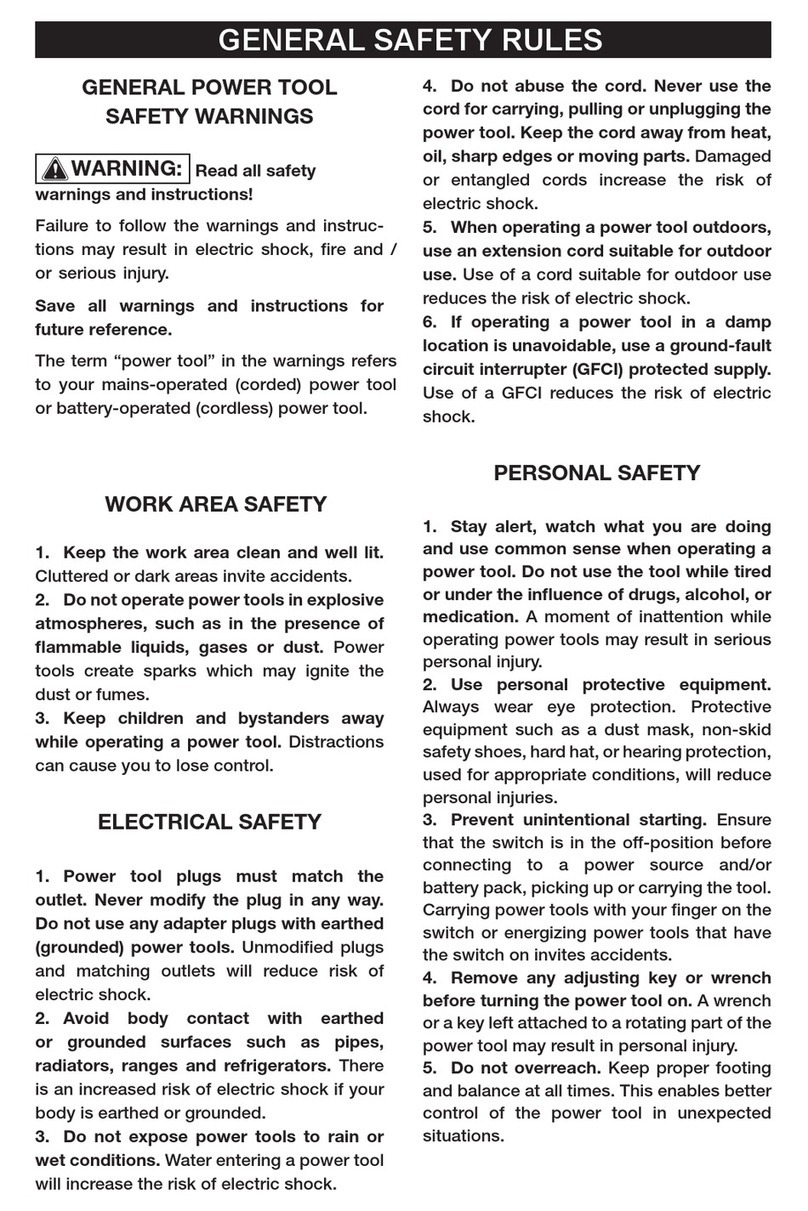

General safety notes for power tools

WARNING!

Read all safety notes, instructions, illustrations and technical

data provided with this power tool. Failure to follow the

instructions below may result in electric shock, fire and/or

serious injury.

Keep all safety notes and instructions for future reference.

The term "power tool" used in the safety notes refers to both

mains-operated power tools (with power cord) and battery-

powered power tools (without power cord).

Workplace safety

-Keep your work area tidy and well lit.

Clutter or unlit work

areas can lead to accidents.

-Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

Safety

8

dust.

Power tools create sparks which may ignite the dust or

fumes.

-Keep children and bystanders away while operating a

power tool.

Distractions can cause you to lose control.

Electrical safety

-Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools.

Unmodified plugs and

matching outlets will reduce risk of electric shock.

-Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators.

There is

an increased risk of electric shock if your body is earthed or

grounded.

-Do not expose power tools to rain or wet conditions.

Water

entering a power tool will increase the risk of electric shock.

-Do not misuse the power cord, such as to carry or hang

the power tool or to pull the plug out of the socket. Keep

the power cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled power cords increase

the risk of electric shock.

-When operating a power tool outdoors, use an extension

cord suitable for outdoor use.

Use of a cord suitable for

outdoor use reduces the risk of electric shock.

-If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply.

Use of an RCD reduces the risk of electric

shock.

Personal safety

-Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

Safety

9

tool while you are tired or under the influence of drugs,

alcohol or medication.

A moment of inattention while

operating power tools may result in serious personal injury.

-Use personal protective equipment. Always wear eye

protection.

Protective equipment such as a dust mask, non-

skid safety shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal injuries.

-Prevent unintentional starting. Ensure the switch is in the

off-position before connecting to power source and/or

battery pack, picking up or carrying the tool.

Carrying

power tools with your finger on the switch or energising

power tools that have the switch on invites accidents.

-Remove any adjusting key or wrench before turning the

power tool on.

A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

-Do not overreach. Keep proper footing and balance at all

times.

This enables better control of the power tool in

unexpected situations.

-Dress properly. Do not wear loose clothing or jewellery.

Keep your hair and clothing away from moving parts.

Loose clothes, jewellery or long hair can be caught in moving

parts.

-If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used.

Use of dust collection can

reduce dust-related hazards.

-Do not let familiarity gained from frequent use of tools

allow you to become complacent and ignore tool safety

principles.

A careless action can cause severe injury within a

fraction of a second.

Safety

10

Using and handling the power tool

-Do not overload the power tool. Use the appropriate

power tool for your work.

The right power tool allows you to

work better and safer in the specified power range.

-Do not use any power tool that has a defective switch.

Power tools that can no longer be switched on or off are

dangerous and must be repaired.

-Disconnect the plug from the socket and/or remove any

removable batteries before making adjustments to the

device, changing any insert tool parts, or putting the

power tool away.

This precaution helps prevent

unintentional starting of the power tool.

-Keep power tools out of the reach of children when not in

use. Whoever is not familiar with the power tool or who

has not read these instructions should not be allowed to

use it.

Power tools are dangerous if used by inexperienced

persons.

-Power tools and insert tools must be subject to careful

maintenance. Check whether moving parts function

properly without jamming, and whether parts are broken

or damaged to such an extent that they impair the

functions of the power tool. Have damaged parts repaired

before using the power tool.

Many accidents happen due to

poorly maintained power tools.

-Keep cutting tools sharp and clean.

Carefully maintained

cutting tools with sharp blades tend to jam less and are easier

to guide.

-Use power tools, insert tools, insert tool parts, etc.

according to these instructions. While doing so, take into

account the working conditions and the activity to be

Safety

11

performed.

The use of power tools for applications other

than those intended can lead to dangerous situations.

-Keep handles and grip surfaces dry, clean and free of oil

and grease.

Slippery handles and grip surfaces hinder safe

operation and control of the power tool in unforeseen

situations.

Service

-Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will

ensure that the safety of the power tool is maintained.

-If the device’s mains power cable is damaged, it must be

replaced by the manufacturer or their customer service or a

similarly qualified person, to avoid any hazard.

- If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons

in order to avoid a hazard.

Additional safety notes for stationary sanding machines

-Wear a suitable dust mask and use an extraction device in

enclosed spaces. Wood dust (from oak, beech etc.) is harmful

to health. The machine must not be used to sand materials

containing asbestos.

-Observers must keep well clear of the workspace.

-Make sure that the floor around the machine is level,

clean and free of loose particles such as chips and cutting

scrap.

-Make sure that the sanding machine cannot be switched

on by children.

-Never use the sanding machine for any purpose other

than its intended purpose. For instance, the sanding

machine must never be used for wet sanding.

Safety

12

-Make sure that the sanding machine is stably positioned

on firm ground. Do this by mounting the sanding machine

firmly on a suitable work surface.

-Check all screws regularly to make sure they are tight.

-Avoid uncomfortable working positions. Ensure secure

footing and keep your balance at all times. This will give you

greater control over the sanding machine in unexpected

situations.

-Please be aware that the sanding disc and the sanding

belt are both always running when the sanding machine

is in operation. Make sure that, for instance, you do not

injure yourself on the moving sanding disc while using the

sanding belt.

-Noise levels: the use of hearing protection is

recommended when operating motor-powered

machinery.

-To prevent suddenly being caught up in the sanding disc

or sanding belt:

• Do not wear gloves.

• Take off any jewellery or loose items of clothing.

• If you have long hair, wear a hairnet.

• If you are wearing long sleeves, roll them up past your

elbows.

-Wear gloves when replacing the sanding disc or sanding

belt, or when handling rough materials.

-In order to prevent accidents caused by unintentional

starting of the sanding machine, always pull the mains

plug out of the socket while the sanding machine is not in

use, before carrying out adjustment and maintenance, and

when changing accessories, e.g. sanding discs.

Safety

13

-Never leave the sanding machine unattended. Always

switch off the device and only leave it once the tool has

completely come to a standstill.

• Please be aware that the sanding disc and sanding belt

will continue to run for a short while when the device is

switched off.

-In order to prevent electric shocks when inserting the

plug in the socket, do not touch the metal contacts of the

plug.

-Do not use the cable to pull the plug out of the socket.

Protect the cable from heat, oil and sharp edges.

-Only use accessories that are listed in the operating

manual.

-Avoid awkward hand positions that could cause one or

both hands to come into contact with the sanding disc or

sanding belt if you slip suddenly.

-If the sanding disc or sanding belt get stuck, or if the

device is jammed with the material being sanded, switch

off the sanding machine immediately, unplug the mains

plug and remove the blockage. Before switching the device

back on, check the sanding disc and sanding belt to ensure

that they can turn freely and are free of damage. Replace the

sanding disc or sanding belt if they are damaged.

Check the device and scope of delivery

WARNING!

Danger of suffocation!

Children may become tangled up in the packaging film when

playing with it and suffocate.

- Do not let children play with the packaging film.

Safety

14

NOTE!

Risk of damage!

If opening the packaging with a sharp knife or other pointed

objects, careless handling can damage the device.

- Therefore, be very careful when opening.

1. With both hands, lift the device out of the packaging.

2. Check that the delivery is complete (see chapter “Scope of delivery/device

components”).

3. Inspect the device and individual parts for damage. Do not operate a damaged

device; instead, contact the manufacturer via the service center listed on the

warranty card.

Assembly instruction

Attaching rubber feet to base plate

1

7

4

6 8

31

8

31

16

-Screw the rubber feet

4

to the base plate

8

as shown in the illustration.

Use the 4 mm hex key

16

supplied and an 8 mm spanner.

Check the device and scope of delivery

15

Mounting the base plate

2

86

10

- Screw the base plate

4

to the belt and disc sander

1

as shown in the

illustration.

Use the 4 mm hex key

16

supplied.

Attaching the cord wrap

3

30

5

1. Unscrew the two screws with flat washers anticlockwise at the positions shown.

2. Screw on the two cord wraps

5

using the two screws and flat washers as

shown in the illustration.

Assembly instruction

16

Attaching the disc guard

4

30

0°5°10°

15°

20°

25°

30°

35°

40°

45°

11

13

12

- Firmly screw on the disc guard

11

as shown in the illustration.

Attaching worktable to sanding disc

5

3

1. Use the 13 mm spanner

15

to loosen the hexagon screw slightly by turning it

anticlockwise.

2. Guide the worktable rod

3

into the opening until it reaches the limit stop as

shown in the illustration.

Assembly instruction

17

6

0°

5°

10°

15°

20°

25°

30°

35°

3. Tighten the hexagon screw on the device by turning it clockwise.

4. Align the worktable

26

so that it is no more than 1.6 mm away from the sanding

disc

17

and tighten the hexagon screw as shown in the illustration.

7

14

30

5. You can fine-tune the spacing between the worktable and the sanding disc by

loosening the two screws on the underside of the worktable as shown in the

illustration.

6. Gently move the worktable forwards or backwards until the spacing is correct.

7. Tighten both screws by turning them clockwise.

Attaching worktable to belt sander

The worktable

26

can be attached to the belt sander in order to enable

vertical working. First, the work support

18

must first be removed.

Assembly instruction

18

818

30

27

1. Unscrew the hexagon screw and the flat washer on the work support using the

10 mm spanner

15

.

2. Unscrew both of the screws on the belt dust outlet

27

.

3. Remove the work support.

9

4. Use the 6 mm hex key

16

to loosen the fixing screw as shown in the illustration.

5. Lift up the belt sander, as shown in the illustration, and bring it into the vertical

position.

6. Tighten the fixing screw by turning it clockwise.

Assembly instruction

19

10

0°5°10°

15°

20°

25°

30°

35°

40°

45°

14

3

7. Use the 13 mm spanner

15

to loosen the hexagon screw slightly by turning it

anticlockwise.

8. Guide the worktable rod

3

into the opening until it reaches the limit stop as

shown in the illustration.

9. Align the worktable (see section "Attaching worktable to sanding disc") and

tighten the screws.

Before first use

Operation

CAUTION!

Risk of injury!

A damaged device or damaged accessories can lead to injuries.

- Check the device and the accessories (see section "Testing").

CAUTION!

Risk of injury!

The tool bit heats up during operation.

- Do not touch the tool bit until it has cooled down again.

Assembly instruction

20

This manual suits for next models

1

Table of contents

Other FERREX Sander manuals

Popular Sander manuals by other brands

Mighty Seven

Mighty Seven DOS-501 manual

Chicago Pneumatic

Chicago Pneumatic CP35 Series Operator's manual

Alpha tools

Alpha tools BT 450 operating instructions

ULTIMATE SPEED

ULTIMATE SPEED UPM 120 A1 Translation of the original instructions

VERTO

VERTO 51G750 instruction manual

Ingersoll-Rand

Ingersoll-Rand G3 Series Product information