FERREX YT-7251A Product information sheet

PRODUCED IN CHINA FOR:

GB IE

Great care has gone into the manufacture of this product and it should

therefore provide you with years of good service when used properly. In

the event of product failure within its intended use over the course of the

first 3 years after date of purchase, we will remedy the problem as quickly

as possible once it has been brought to our attention. In the unlikely event

of such an occurrence, or if you require any information about the product,

please contact us via our helpline support services, details of which are to be

found both in this manual and on the product itself.

ALDI STORES LTD. PO BOX 26, ATHERSTONE

WARWICKSHIRE, CV9 2SH

ALDI STORES (IRELAND) LTD.

PO BOX 726, NAAS, CO. KILDARE

Visit us at www.aldi.com

AFTER SALES SUPPORT 805353

GB IE

MODEL:

YT-7251A 03/2021

+44(0) 1904727501 +353(0) 19022605

3

YEAR

WARRANTY

User Manual

DRYWALL SANDER

Original User Manual

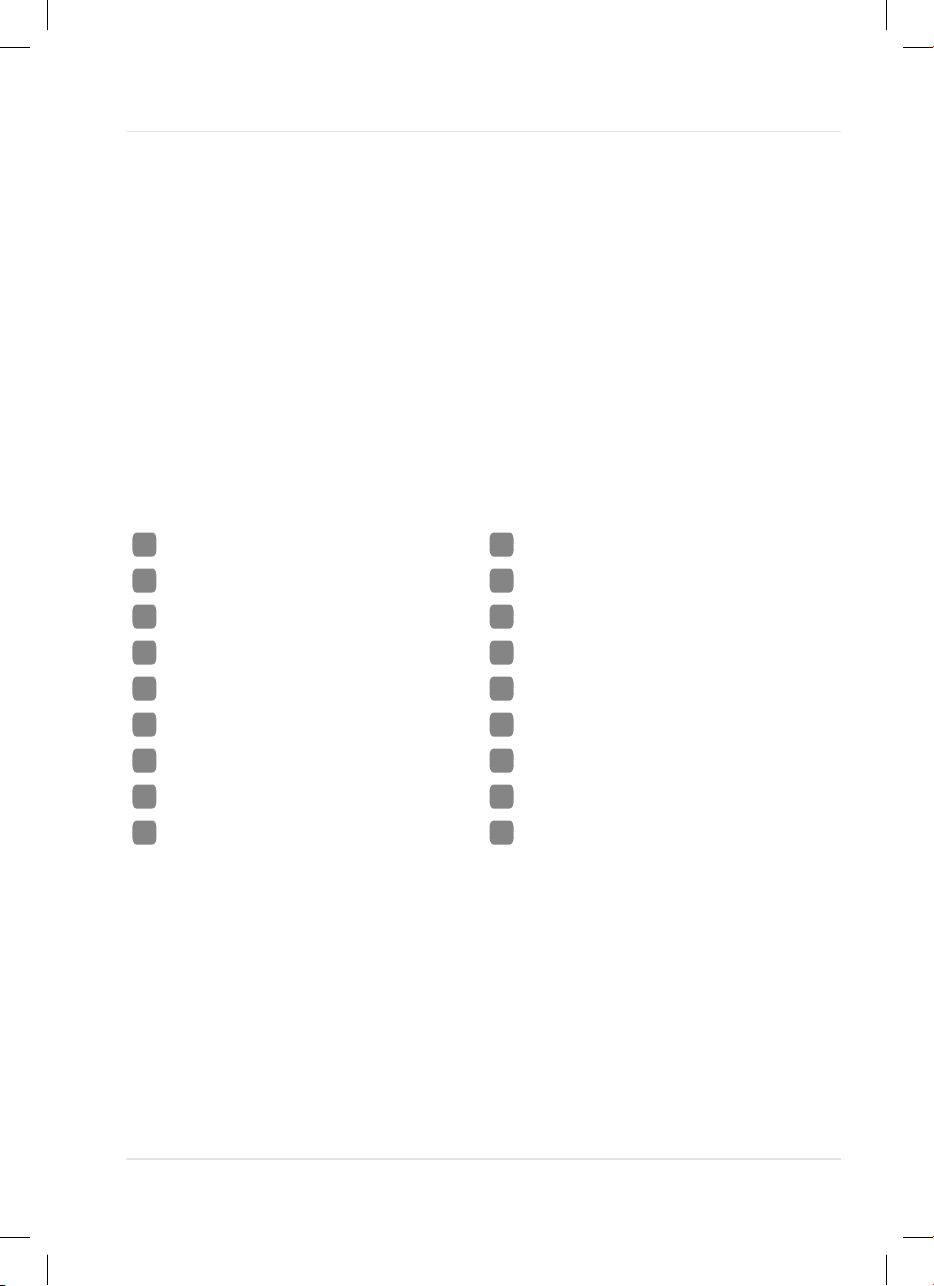

Overview

2

8

9

4

10

7651 2 3

13 16

11

15 17

12

14

Package Content List

1 x Drywall Sander

1 x Support Spring

1 x 4 m Suction hose

2 x Hose adaptor (already connected to the hose)

6 x Sanding Paper

1 x Set of spare coal brushes

1 x Allen key

1 x Instruction Manual

1 x Warranty Certificate

Package contents/device parts

1

Sanding pad

2

Front handle

3

Collapsible handle lock

4

Variable speed dial

5

Lock-on button

6

Main handle

7

Power cord

8

Additional handle

9

Dust extraction hose lock

10

Extension handle

11

Extension handle lock

12

On/off trigger

13

Dust extraction hose

14

Hose adaptor

15

Sanding paper

16

Allen key

17

Support spring

18

Spare coal brushes (not illustrated)

Package Content List

3

Table of content

Overview..................................................................................................................2

Package Content List............................................................................................... 3

Package contents/device parts.............................................................................. 3

Intended Use........................................................................................................... 6

Residual risk............................................................................................................ 6

Unpacking............................................................................................................... 6

Explanation of symbols........................................................................................... 7

Safety Instructions.................................................................................................. 8

General Power Tool Safety Warnings.............................................................................. 9

Safety warnings common for sanding operation........................................................ 11

Kickback and related warnings......................................................................................13

Safety warnings for sanding operations.......................................................................13

Assembly................................................................................................................ 14

Assembling the handle................................................................................................... 14

Fitting the extension handle...........................................................................................14

Selecting the right sanding paper.................................................................................15

Attaching and removing the sanding paper............................................................... 15

Connecting the dust extraction hose............................................................................ 15

Installing the support spring ......................................................................................... 16

Operation............................................................................................................... 16

Switching on/off............................................................................................................... 16

Continuous operation......................................................................................................16

Adjusting the speed of the product............................................................................... 17

Grinding............................................................................................................................. 17

Cleaning, Maintenance and Storage..................................................................... 17

Cleaning............................................................................................................................. 17

Maintenance..................................................................................................................... 18

Storage...............................................................................................................................18

Troubleshooting.................................................................................................... 19

Technical Data........................................................................................................20

Declaration of conformity...................................................................................... 21

Disposal..................................................................................................................22

Disposing of packaging...................................................................................................22

Dispose of old electrical device...................................................................................... 22

Table of content

5

Intended Use

This drywall sander (referred to below only as "product") is designed for sanding

large areas of plasterboard as a preparation before painting or wallpapering. It is

designed for domestic use and is not designed for commercial, trade or industrial

use.

Only use the product as described in this instruction manual. Any other use is

deemed improper and may result in damage to property or even personal injury.

The product is not a children’s toy.

The manufacturer or vendor accepts no liability for damage caused by improper or

incorrect use.

Please read and familiarise yourself with this user manual before using the product.

This instruction manual must be passed on together with the product to the next

person to use it.

The tool must only be used for its prescribed purpose. Any use other than those

mentioned in this instruction manual will be considered a case of misuse. The user,

and not the manufacturer, shall be liable for any damage or injury resulting from

such cases of misuse.

The manufacturer shall not be liable for any unauthorised changes made to the tool,

nor for any damage resulting from such changes.

Residual risk

Even if you use the product properly per the instructions provided and following all

safety notes, there are always residual risks. The following risk may occur:

Residual risks may arise when using the tool which may not be included in the safety

warnings. These risks can arise from misuse, prolonged use etc.

Even with the application of the relevant safety regulations and the implementation

of safety devices, certain residual risks cannot be avoided. These included:

-Injuries caused by touching any rotating/moving parts.

-Injuries caused when changing any parts, blades or accessories.

-Injuries caused by prolonged use of a tool. When using any tool for prolonged

periods ensure you take regular breaks.

-Impairment of hearing.

-Health hazards caused by breathing dust developed when using your tool

(example: working with wood, especially oak, beech and MDF.)

Unpacking

Due to modern mass production techniques, it is unlikely that yourproduct is faulty

or that a part is missing. If you find anything wrong, do not operate the product until

Intended Use

6

the parts have been replaced or the fault has been rectified. Failure to do so could

result in serious personal injury.

Explanation of symbols

The following symbols and signal words are used in this user manual, on the

compressor or on the packaging.

WARNING! This signal symbol/word denotes a hazard with

an average risk level that could lead to death or

severe injury if it is not avoided.

NOTE! This signal word provides a warning about

potential material damage.

This symbol provides you with useful additional information on

handling and use.

Read the operating manual.

Declaration of conformity (see chapter “Declaration of conformity”):

Products marked with this symbol meet all the applicable Community

regulations of the European Economic Area.

Wear eye protection.

Wear ear protection.

Wear a dust mask.

This symbol identifies devices that belong to the protection class II.

Unpacking

7

Safety Instructions

Read the entire owner’s manual carefully and make sure you know how to

switch the appliance off in an emergency, before operating the appliance.

WARNING! Do not connect the product to a power source

until you have read and understood the entire

owner’s manual.

WARNING! When using mains-powered appliances, basic

safety precautions, including the following,

should always be followed to reduce the risk

of fire, electric shock, personal injury and

material damage.

This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

WARNING! Children should be supervised to ensure that

they do not play with the appliance.

Electrical Safety:

The product’s electric motor has been designed for 230-240V only. Always

check that the power supply corresponds to the voltage on the rating plate.

If the supply cord is damaged, it must be replaced by the manufacturer or a

certified electrician in order to avoid a hazard.

Do not misuse the mains lead by carrying the tool by the lead, hanging it from

the lead, or by pulling on the lead to remove the plug. Keep the lead away

from heat, oil, sharp edges or moving tool parts. Damaged or twisted leads

increase the risk of an electric shock.

Using an Extension Lead:

Always use an approved extension lead suitable for the power input of this

tool. Before use, inspect the extension lead for signs of damage, wear and

ageing. Replace the extension lead if damaged or defective. When using an

extension lead on a reel, always unwind the lead completely. Use of an

extension lead not suitable for the power input of the tool or which is damaged

or defective may result in a risk of fire and electric shock.

Safety Instructions

8

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions.

Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious

injury.

Please save this instruction manual. Save all warnings and instructions for

future reference. Please ensure you give this instruction manual to the next

person that uses this product.

The term "power tool" in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

1. Work Area Safety:

a. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b. Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c. Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2. Electrical Safety:

a. Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce the risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase the risk of electric shock.

e. When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal Safety:

Safety Instructions

9

a. Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A moment of inattention

while operating power tools may result in serious personal injury.

b. Use personal protective equipment. Always wear eye protection. Protective

equipment such as a dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure the switch is in the off-position

before connecting to power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites accidents.

d. Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e. Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g. If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust

collection can reduce dust-related hazards.

4. Power Tool Use and Care:

a. Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and must be

repaired.

c. Disconnect the plug from the power source and/or the battery pack from

the power tool before making any adjustments, changing accessories, or

storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power

tool. Power tools are dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

Safety Instructions

10

operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended

could result in a hazardous situation.

5. Service:

a. Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power tool is

maintained.

b. If the supply cord is damaged, it must be replaced by the manufacturer, its

service agent, or a similarly qualified person in order to avoid a hazard.

Safety warnings common for sanding operation

a. This power tool is intended to function as a sander. Read all safety

warnings, instructions, illustrations and specifications provided with this

power tool. Failure to follow all instructions listed below may result in electric

shock, fire and/or serious injury.

b. Operations such as grinding, sanding, wire brushing, polishing or cutting-

off are not recommended to be performed with this power tool. Operations

for which the power tool was not designed may create a hazard and cause

personal injury.

c. Do not use accessories which are not specifically designed and

recommended by the tool manufacturer. Just because the accessory can be

attached to your power tool, it does not assure safe operation.

d. The rated speed of the accessory must be at least equal to the maximum

speed marked on the power tool. Accessories running faster than their rated

speed can break and fly apart.

e. The outside diameter and the thickness of your accessory must be within

the capacity rating of your power tool. Incorrectly sized accessories cannot be

adequately guarded or controlled.

f. The arbour size of wheels, flanges, backing pads or any other accessory

must properly fit the spindle of the power tool. Accessories with arbour holes

that do not match the mounting hardware of the power tool will run out of

balance, vibrate excessively and may causeloss of control.

g. Threaded mounting of accessories must match the grinder spindle thread.

For accessories mounted by flanges, the arbour hole of the accessory must

Safety Instructions

11

fit the locating diameter of the flange. Accessories that do not match the

mounting hardware of the power tool will run out of balance, vibrate excessively

and may cause loss of control.

h. Do not use a damaged accessory. Before each use inspect the accessory

such as abrasive wheels for chips and cracks, backing pad for cracks, tear or

excess wear, wire brush for loose or cracked wires. If power tool or

accessory is dropped, inspect for damage or install an undamaged

accessory. After inspecting and installing an accessory, position yourself

and bystanders away from the plane of the rotating accessory and run the

power tool at maximum no-load speed for one minute. Damaged accessories

will normally break apart during this test time.

i. Wear personal protective equipment. Depending on application, use face

shield, safety goggles or safety glasses. As appropriate, wear dust mask,

hearing protectors, gloves and workshop apron capable of stopping small

abrasive or workpiece fragments. The eye protection must be capable of

stopping flying debris generated by various operations . The dust mask or

respirator must be capable of filtrating particles generated by your operation.

Prolonged exposure to high intensity noise may cause hearing loss.

j. Keep bystanders a safe distance away from work area. Anyone entering

the work area must wear personal protective equipment. Fragments of

workpiece or of a broken accessory may fly away and cause injury beyond

immediate area of operation.

k. Hold the power tool by insulated gripping surfaces only, when performing

an operation where the cutting accessory may contact hidden wiring or its

own cord. Cutting accessory contacting a "live" wire may make exposed metal

parts of the power tool "live" and could give the operator an electric shock.

l. Position the cord clear of the spinning accessory. If you lose control, the cord

may be cut or snagged and your hand or arm may be pulled into the spinning

accessory.

m.Never lay the power tool down until the accessory has come to a complete

stop. The spinning accessory may grab the surface and pull the power tool out

of your control.

n. Do not run the power tool while carrying it at your side. Accidental contact

with the spinning accessory could snag your clothing, pulling the accessory into

your body.

o. Regularly clean the power tool’s air vents. The motor’s fan will draw the dust

inside the housing and excessive accumulation of powdered metal may cause

electrical hazards.

p. Do not operate the power tool near flammable materials. Sparks could ignite

these materials.

Safety Instructions

12

q. Do not use accessories that require liquid coolants. Using water or other

liquid coolants may result in electrocution or shock.

Kickback and related warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad,

brush or any other accessory. Pinching or snagging causes rapid stalling of the

rotating accessory which in turn causes the uncontrolled power tool to be forced in

the direction opposite of the accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge

of the wheel that is entering into the pinch point can dig into the surface of the

material causing the wheel to climb out or kick out. The wheel may either jump

toward or away from the operator, depending on direction of the wheel’s movement

at the point of pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or

conditions and can be avoided by taking proper precautions as given below.

a. Maintain a firm grip on the power tool and position your body and arm to

allow you to resist kickback forces. Always use auxiliary handle, if

provided, for maximum control over kickback or torque reaction during

start-up. The operator can control torque reactions or kickback forces, if proper

precautions are taken.

b. Never place your hand near the rotating accessory. Accessory may kickback

over your hand.

c. Do not position your body in the area where power tool will move if

kickback occurs. Kickback will propel the tool in direction opposite to the

wheel’s movement at the point of snagging.

d. Use special care when working corners, sharp edges etc. Avoid bouncing

and snagging the accessory. Corners, sharp edges or bouncing have a

tendency to snag the rotating accessory and cause loss of control or kickback.

e. Do not attach a saw chain woodcarving blade or toothed saw blade. Such

blades create frequent kickback and loss of control.

Safety warnings for sanding operations

a. Do not use excessively oversized sanding disc paper. Follow manufacturers

recommendations, when selecting sanding paper. Larger sanding paper

extending beyond the sanding pad presents a laceration hazard and may cause

snagging, tearing of the disc or kickback.

Safety Instructions

13

Assembly

WARNING! Always disconnect the plug from the power

source before making any adjustment or

attaching any accessories.

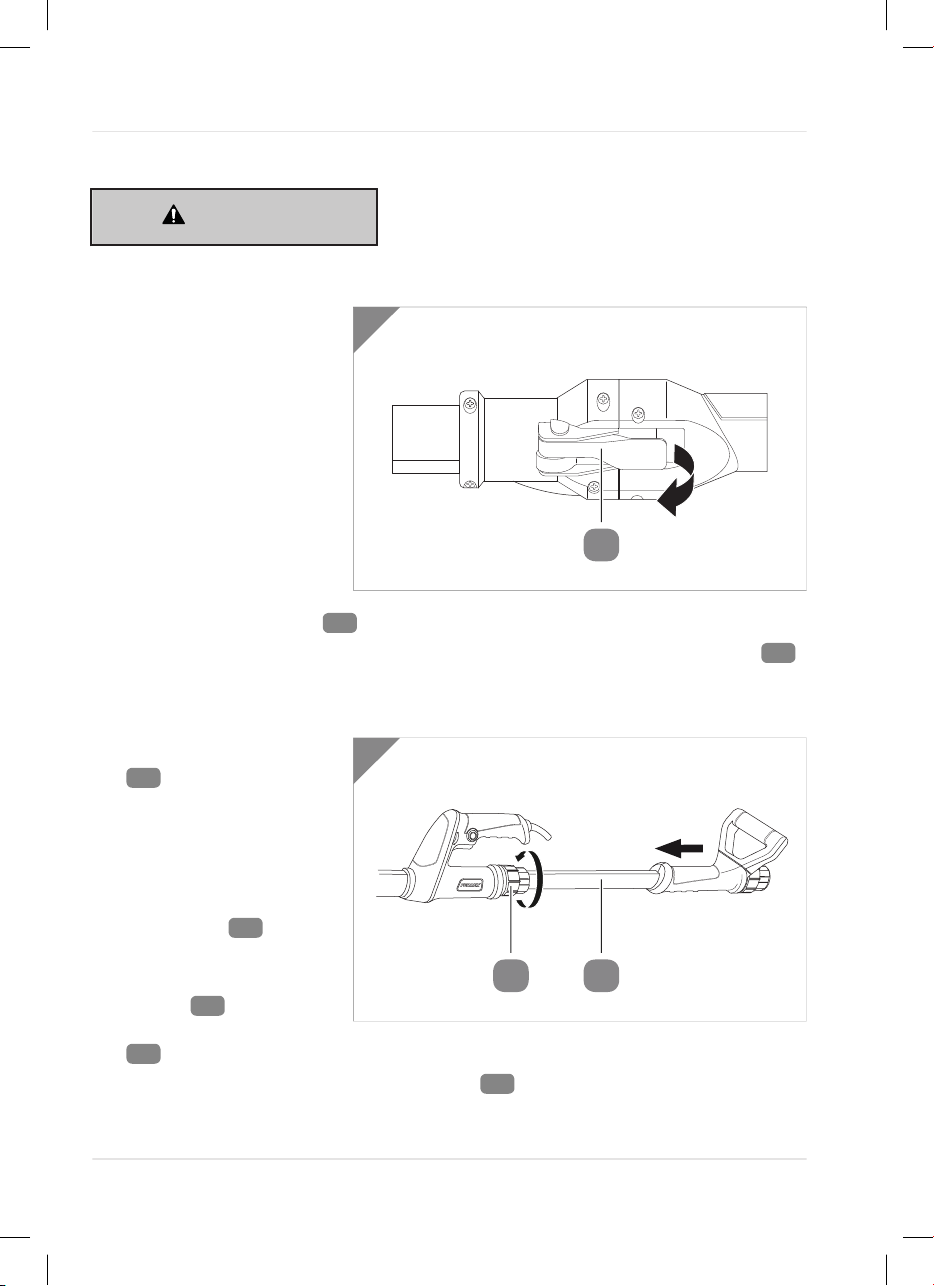

Assembling the handle

1. The product features a

collapsible handle to

enable compact storage.

To operate the product,

this handle will have to

be locked into the

operating position.

2. Unfold the collapsible

handle so that the shaft is

in a continuous straight

line.

3. Secure in place using the

collapsible handle lock

3

.

4. To collapse the handle again for storage, unlock the collapsible handle lock

3

.

5. Then fold the handle for storage.

Fitting the extension handle

1. The rear extension handle

10

can provide

additional support when

sanding surfaces high

above your head or far

away from your body.

2. Loosen the extension

handle lock

11

by

rotating it anti-clockwise.

3. Insert the extension

handle

10

into the

extension handle lock

11

.

4. Adjust the length of the extension handle

10

or rotate it into the desired

position.

3

1

2

11 10

Assembly

14

5. Rotate the extension handle lock

11

clockwise to secure the extension handle

10

.

Note: The product can also be used without the extension handle.

Selecting the right sanding paper

1. The grain size of the sanding paper is specified on the back of the sanding paper.

The smaller the number, the coarser is the grain.

2. Use sand paper with coarse grain for rough grinding and sand paper with fine

grain for finishing grinding.

3. Start the grinding with coarse grain sand paper and complete the grinding

process with fine grain sand paper.

Attaching and removing the sanding paper

1. The sanding pad

1

features a hook & loop

system to allow quick and easy sanding paper

15

changes.

2. Align the sanding paper

15

with the sanding

pad

1

, ensuring the extraction holes on the

sanding pad

1

align with the holes in the

sanding paper

15

.

3. Press the sanding paper

15

firmly onto the

sanding pad

1

.

4. To remove the sanding paper

15

, peel off the

sanding paper

15

, starting from the edge.

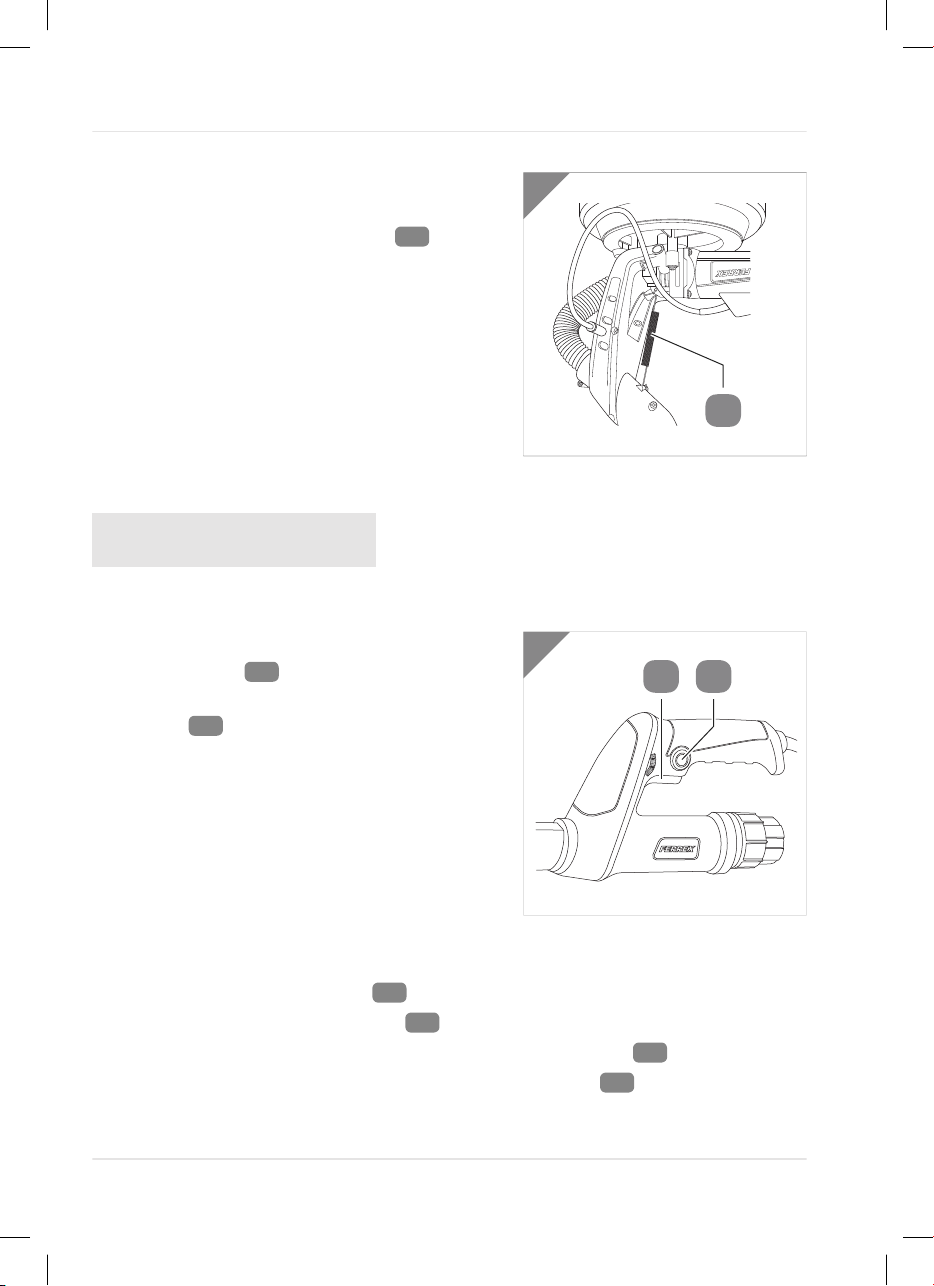

Connecting the dust extraction hose

1. The product comes with a dust extraction

hose

13

that can be fitted to a dust

extraction unit or vacuum cleaner to minimise

the dust in the air and on the working surface.

2. Loosen the dust extraction hose lock

9

on

the extension handle

10

or the extension

handle lock

11

by rotating it anti-clockwise.

3. Insert the extraction hose adaptor

14

into

the extraction hose lock

9

or the extension

handle lock

11

.

4. Rotate the extraction hose lock

9

or the

extension handle lock

11

clockwise to secure

the dust extraction hose

13

.

15 1 A

3

4

914 13

Assembly

15

Installing the support spring

1. It is easier to sand the ceiling when the

sanding pad is held at an angle to the handle

by installing the support spring

17

.

2. To install the support spring, hook one end

into the hole in the motor's housing. Fix the

other end to the respective receptacle on the

handle as shown in Fig. 5.

Operation

NOTE! RECOMMENDATION: The tool should always be

supplied via a residual current device with a

rated residual current of 30 mA or less.

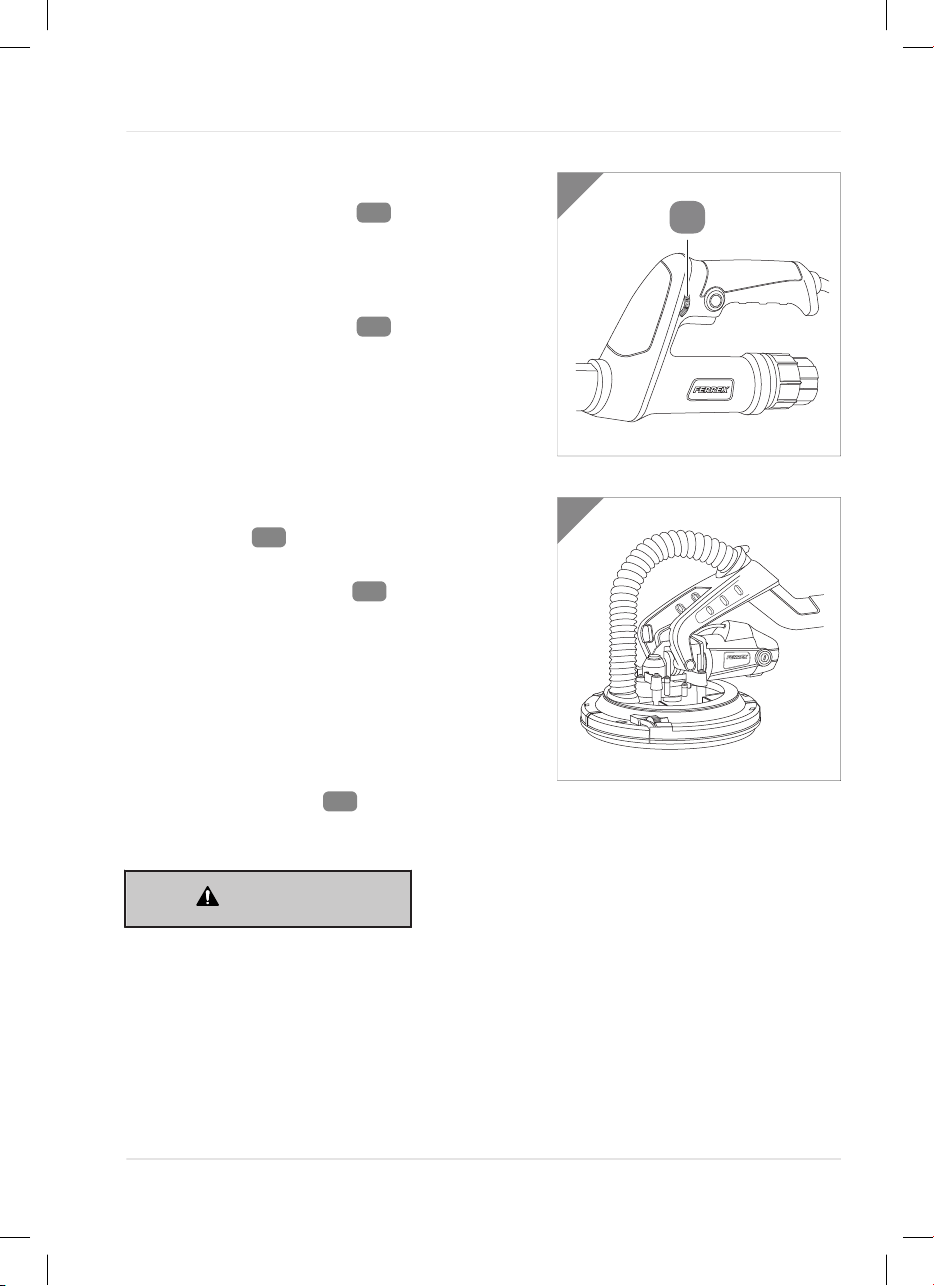

Switching on/off

1. To switch on the product, press and hold the

on/off trigger

12

.

2. To switch off the product, release the on/off

trigger

12

.

Continuous operation

1. The product has a lock-on button for continuous operation without having to

hold down the on/off trigger

12

.

2. Press and hold the on/off trigger

12

to start the product.

3. Press the lock-on button and then release the on/off trigger

12

.

4. To stop the product, press and release the on/off trigger

12

.

5

17

6

512

Assembly

16

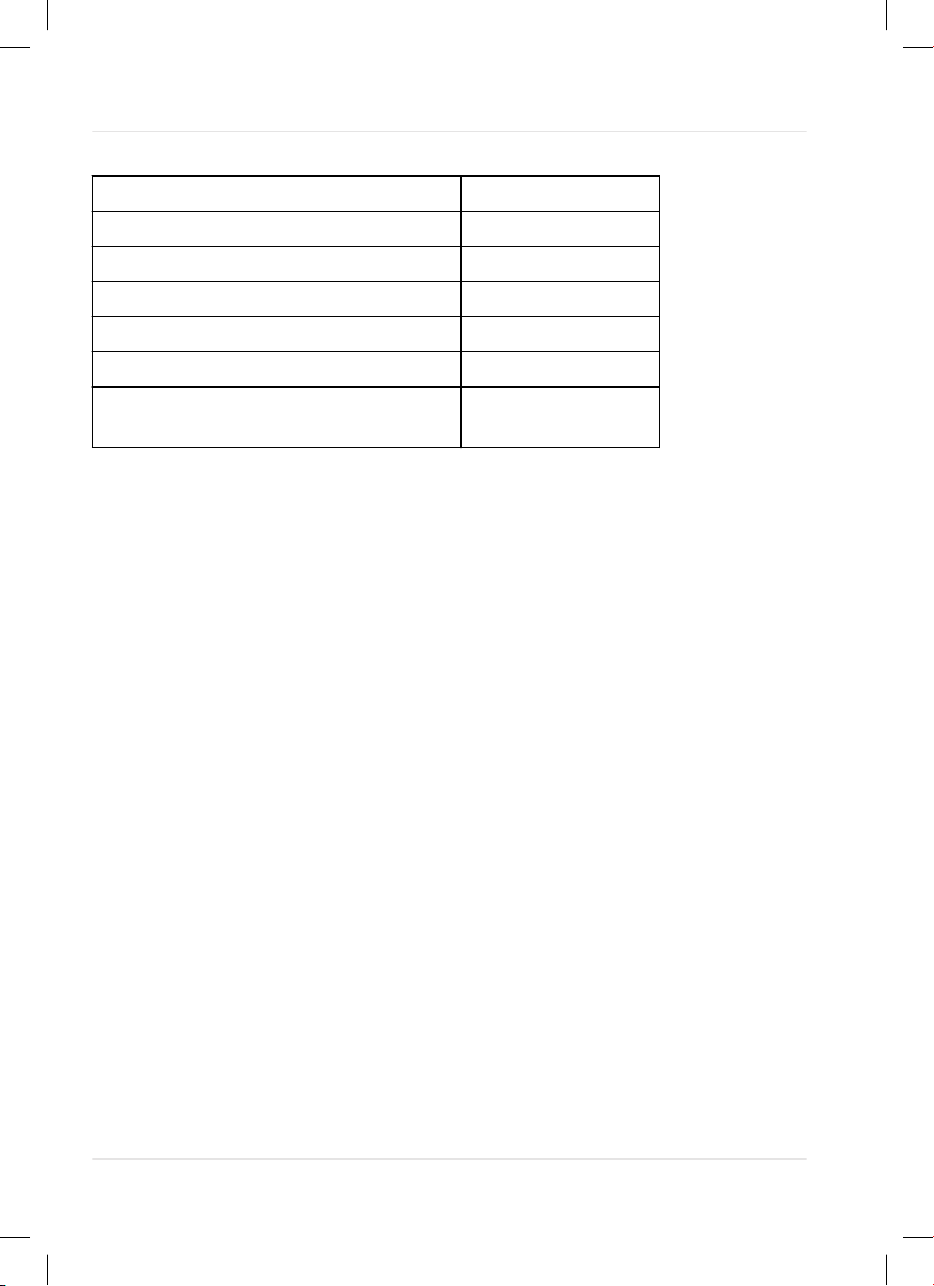

Adjusting the speed of the product

1. To increase the speed of the product, rotate

the variable speed dial

4

clockwise.

- - low speed for rough grinding.

- - high speed for fine grinding.

2. To decrease the speed of the product, rotate

the variable speed dial

4

anticlockwise.

Grinding

1. Select the desired speed using the variable

speed dial

4

and then hold the product

securely.

2. Place the sanding pad

1

flat onto the

working surface and switch on the product.

3. Move the product smoothly with gentle

pressure in circular or transverse movements.

4. Once the job is complete, switch off the

product and wait till the sanding pad is

completely stop before putting it down.

5. For ceiling grinding, fix the sanding pad with

the Support spring

17

as shown in Fig. 5.

Cleaning, Maintenance and Storage

WARNING! Always disconnect the product from the mains

before carrying out any cleaning, maintenance

and storage.

The product shall only be repaired by an

authorised service centre.

Cleaning

1. Keep the ventilation slots free from dust and dirt to prevent overheating.

2. Regularly clean the housing with a soft cloth, preferably after each use. If the dirt

does not come off, use a soft cloth moistened with soapy water

4

7

8

Operation

17

3. Never use solvents such as petrol, alcohol, ammonia water etc. These solvents

may damage the plastic parts.

Maintenance

1. The product has been designed to operate over a long period of time with a

minimum of maintenance. Continuous satisfactory operation depends upon

proper care and regular cleaning.

2. The product shall only be repaired by an authorised service centre.

3. If the replacement of supply cord is necessary, this has to be done by an

authorised service centre in order to avoid a safety hazard.

4. When a carbon brushes wear out, the product will spark and/or stop. Switch off

the product as soon as this happens. Carbon brushes will wear out after many

uses, when the carbon brushes need to be replaced, take the product to an

authorised service centre. Carbon brushes are wearing components and are

covered under warranty. Always replace both carbon brushes at the same time.

Storage

1. Thoroughly clean the product and its accessories before storage.

2. Store the product out of the reach of children in a stable and secure place.

Cleaning, Maintenance and Storage

18

Troubleshooting

Problem Possible Causes Suggested Solutions

Not working No power Insert the plug to the mains

properly.

Plug or supply cord ist

damaged

Check and replace the plug or

supply cord by an authorised

service centre

Internal damage or wear e.g.

motor is damaged

Repair by an authorised service

centre.

Poor sanding result Sand paper worn out Replace the sanding paper

Noisy or rattling Internal damage or wear Repair by an authorised service

centre.

Overheat Ventilation vents blocked Clean the dust from the

ventilation vents

Excessive sparking

visible through air vents

The product ist running for

too long

Turn off the product and let it

cools down

May indicate the carbon

brushes have worn out and

need to be raplaced

Replace the carbon brushes by an

authorised service centre

Troubleshooting

19

Technical Data

Model No. YT-7251A

Rated voltage 230-240 V~, 50 Hz

Rated power 750 W

No load speed 1000-1800 min-1

Sanding disc diameter 225 mm

Product dimension 1750 x 257 x 270 mm

Standard AS/NZS 60745.1 and

AS/NZS 60745.2.3

Technical Data

20

Table of contents

Other FERREX Sander manuals