EXPT

Festo – GDCP-EXPT-KM-KOMP-EN – 1204a – English 3

Table of Contents – EXPT

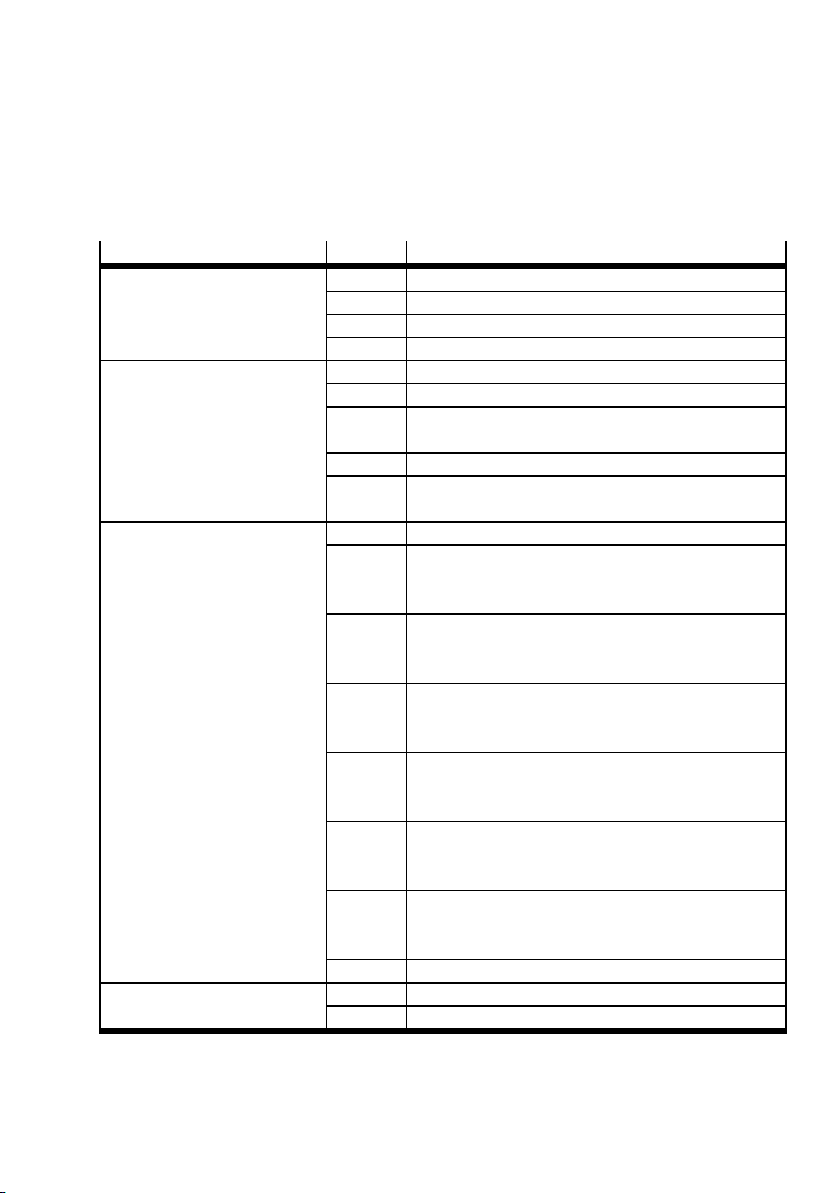

1 Safety and requirements for product use 5......................................

1.1 Safety 5..................................................................

1.1.1 General safety regulations 5..........................................

1.1.2 Intended use 5.....................................................

1.2 Safety conditions 6.........................................................

1.2.1 Technical requirements 6............................................

1.2.2 Qualification of trained personnel 6....................................

1.2.3 Areas of application and approval by authorities 6........................

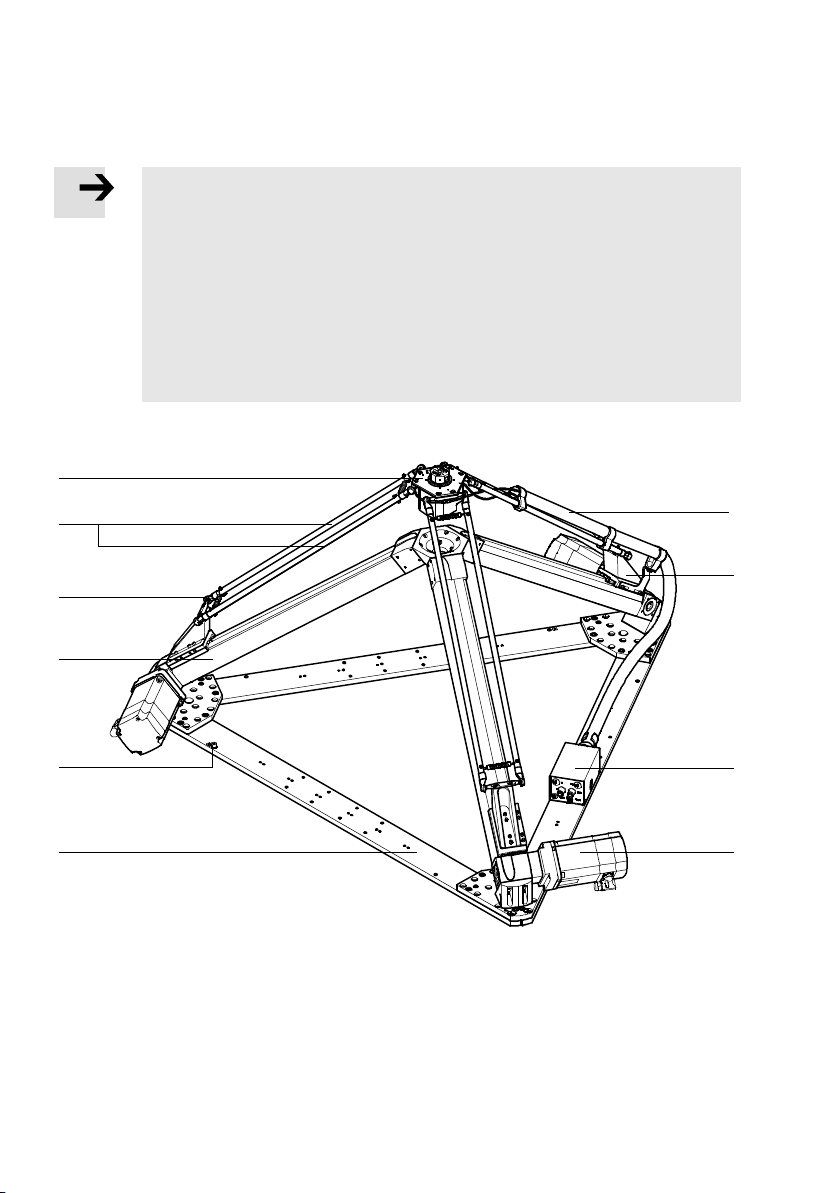

2Overview 7................................................................

2.1 Features 7................................................................

2.2 Function and application 9....................................................

2.3 Overview of interfaces 9.....................................................

2.4 Control elements and connections 10............................................

3 Assembly and installation 11..................................................

3.1 Transport 11................................................................

3.2 Storage conditions 11........................................................

3.3 Unpacking 12...............................................................

3.4 Checking tripod kinematics and scope of delivery 13................................

3.5 Preparations for assembly 14..................................................

3.5.1 Dimensions 14......................................................

3.5.2 Requirements for the assembly site 14..................................

3.6 Assembly on a frame 15.......................................................

3.7 Mounting options 16.........................................................

3.7.1 Direct mounting with screws 16........................................

3.7.2 Mounting with slot nuts 17............................................

3.8 Preparing tripod kinematics for mounting 19......................................

3.9 Mounting of attachments 23...................................................

3.9.1 Attachment for EXPT-...-T0 23..........................................

3.9.2 Attachment for EXPT-...-T1 to T4 23.....................................

3.10 Installation 24..............................................................

3.10.1 Overview 24........................................................

3.10.2 Overview of connections 25...........................................

3.10.3 Connect compressed air 25............................................

3.10.4 Installing motor cables and sensor cable 25..............................

3.10.5 Earthing 27........................................................