TriboServ FlexxPump1 Product information sheet

Original User Manual

FlexxPump1 Battery

Revision: 0

FlexxPump1 B

User Manual

02

EN-

I. Revision history & imprint

I.I Revision history

The present user manual is the original user manual.

This user manual is only valid for

Product:

Product designation: FlexxPump1 Battery (FP1 B)

Product revision: ---

User manual:

date of creation: 01.2020

revision of the user manual: 0

This document is protected by copyright.

All rights for layout, content, texts and corporate design are reserved by TriboServ

GmbH & Co. KG, © 2019.

All rights, including those of photomechanical reproduction, duplication and distribution

by means of special processes (e.g. data processing, data carriers and data networks),

even in part and/or in extracts, are reserved by TriboServ GmbH & Co. KG.

The content and technical specications are subject to change without notice.

I.II Imprint of the manufacturer, distribution and service

Adress:

TriboServ GmbH & Co. KG

Gelthari-Ring 3

D-97505 Geldersheim

tel: +49 - (0)9721 - 473 966-0

fax: +49 - (0)9721 - 473 966-9

E-Mail: info@triboserv.de

Internet: www.triboserv.de

Personally liable company: TriboServ Verwaltungs GmbH

Registered ofce of the company: Geldersheim

Commercial Register of Schweinfurt Local Court

HRA 8848

TriboServ Verwaltungs GmbH

HRB 5449

USt.-ID: DE 263 251 758

Managing director: Dr.-Ing. Michael Weigand

Authorized signatory: Gerhard Halbig

Revision: 0

FlexxPump1 B

User Manual

03

EN-

I. Revision history & imprint 02

I.I Revision history 02

I.II Imprint of the manufacturer, distribution and service 02

I.III Table of contents 03

1. General information about this manual 05

1.1 Signal words 05

1.2 Warning symbols 06

1.3 Structure of the safety instructions 06

1.4 Symbols for information 06

2. Safety 07

2.1 EC/EU Directive 07

2.2 Hazards 07

2.3 Staff 07

2.4 Reasonably predictable misuse 07

2.5 Usage for the intended purpose 08

2.6 Warranty and Liabilty 08

2.7 General safety instructions 09

3. Description of function 10

3.1 General information 10

3.2 Nameplate and designation 11

3.3 Scope of delivery 11

3.4 Technical data 12

4. Transport and storage 13

4.1 Packaging 13

4.2 Transport 13

4.3 Storage 13

5. Mounting 14

5.1 Preparations 14

5.2 Assembly 14

5.3 Commissioning 17

6. Operation and settings 18

6.1 General information 18

I.III Table of contents

Chapter Content Page

Revision: 0

FlexxPump1 B

User Manual

04

EN-

6.2 Factory settings 19

6.2.1 Default settings operating mode Hour-Mode -h- 19

6.2.2 Default setting operating mode Empty-Time-Mode Et 20

6.3 Menu and LCD messages 21

6.3.1 LCD 24

6.3.2 Actions with the activation and programming key 27

6.3.3 Switching on and off 29

6.3.4 INF-Menu operating mode Hour-Mode -h- 30

6.3.5 INF-Menu operating mode Empty-Time-Mode Et 31

6.3.6 SET-Menu 32

6.3.7 RUN-Menu 34

6.3.8 PRO-Menu operating mode Hour-Mode -h- 35

6.3.9 PRO-Menu operating mode Empty-Time-Mode Et 38

6.3.10 FIL-Menu 40

6.4 Error codes 41

7. Maintenance and disposal 42

7.1 Maintenance schedule 42

7.1.1 Visual check 43

7.1.2 Cleaning 43

7.1.3 Recommissioning after maintenance 43

7.2 Cartridge and battery change 44

7.3 Disposal 47

8. Released accessories 48

8.1 Lubricants 50

8.2 Tube lengths 50

9. Appendix 51

9.1 Dimension sheet and installation dimensions 51

9.2 EC/EU Declaration of conformity 52

9.3 Spare parts 53

Chapter Content Page

Revision: 0

FlexxPump1 B

User Manual

05

EN-

1. General information about this manual

This user manual contains all necessary information to use FlexxPump1 in the battery

version, hereinafter referred to as FP1 B, safely and as intended. In the event that

supplementary sheets are attached to these instructions, the information and data con-

tained in the supplementary sheets are valid and replace the corresponding information

in this user manual. Any contradictory information contained in this user manual thus

becomes invalid.

If you have any questions regarding special applications, please contact TriboServ

GmbH & Co. KG (chapter I.II).

The actual and factual operator must ensure and guarantee that these instructions,

including any supplementary sheets, have been read and understood by all persons

responsible for the installation, operation or maintenance of the FP1 B. Therefore,

keep these instructions in a suitable place, ideally in an easily accessible place, in the

surrounding area of the FP1 B.

Inform your colleagues who work in the local area of the machine about safety instruc-

tions so that nobody gets hurt.

This manual was written in German, all other language versions are translations of this

manual.

1.1 Signal words

The following signal words are used in this manual to draw your attention to possible

dangers, prohibitions and other important information:

DANGER This signal word points you to an immediate and threatening risk of

serious injury or death.

WARNING This signal word indicates a potentially imminent danger which can

result in serious injury or even death.

CAUTION This signal word indicates a potentially imminent danger that can

result in minor to severe injuries.

NOTICE This signal word indicates a potentially imminent danger which can

result in damage to property.

INFORMATION

This signal word refers to practical application tips or particularly

important information when using the FP1 B.

Revision: 0

FlexxPump1 B

User Manual

06

EN-

General warning

sign

Electricity hazard Flammable

material

1.2 Warning symbols

The following warning symbols are used in this user manual to alert you to hazards,

prohibitions and important information:

1.3 Structure of the safety instructions

The safety instructions in this user manual are structured according to the following

system:

CAUTION

The text explains the consequences of disregarding the refe-

rence.

§The text shows what to do as an instruction.

1.4 Symbols for information

The following information symbols are used in the text and instructions in this manual:

Requests you to take action

ÜShows the consequences of an action

Additional information about the action

Revision: 0

FlexxPump1 B

User Manual

07

EN-

2. Safety

All persons working with the FP1 B must follow these operating instructions, in particu-

lar the safety instructions and the rules and regulations applicable at the place of use.

Generally applicable legal regulations and other rules as well as the relevant rules and

regulations for accident prevention (e.g. Personal Protective Equipment (PPE)) and

environmental protection must be observed.

2.1 EC/EU Directive

Within the scope of the EC/EU Directive, (re)commissioning of a machine on which the

FP1 B has been installed and/or tted is prohibited until it has been clearly established

that the machine complies with the provisions of the applicable Directive.

An EC/EU declaration of conformity for the FP1 B can be found in the appendix (chap-

ter 9.2).

2.2 Hazards

In order to avoid danger to the user or damage to the machine on which the FP1 B

is used, the FP1 B may only be used for its intended purpose (chapter 2.5) and in a

technically safe condition.

Always inform yourself about the general safety instructions (chapter 2.7) before star-

ting to work.

2.3 Staff

Only qualied staff who has read and understood this manual may work with the FP1 B.

Local and/or company regulations apply accordingly.

2.4 Reasonably predictable misuse

Any use of the FP1 B which exceeds the maximum permissible technical data is gene-

rally considered to be improper and therefore prohibited.

Revision: 0

FlexxPump1 B

User Manual

08

EN-

2.5 Usage for the intended purpose

The following points must be observed for the intended purpose of using the FP1 B:

+ The FP1 B is exclusively approved for industrial use.

+ The FP1 B may be used exclusively in accordance with the technical data

(chapter 3.4).

+ Unauthorized structural alterations to the FP1 B are not permitted.

+ Read the user manual and act accordingly.

+ During operation of the FP1 B, a visual inspection of the FP1 B as well as of the

lubrication point must be carried out regularly. Any anomalies must be eliminated

immediately and the cause rectied.

+ Relling the cartridge is not permitted.

+ The FP1 B may not be opened or disassembled.

+ Only lubricants approved by the manufacturer may be used.

+ Relevant regulations and rules on work safety, accident prevention and environmen-

tal protection must be observed.

+ Work and activities with and on the FP1 B are only permitted with appropriate authori-

sation (chapter 2.3).

All other uses than the aforementioned intended usage or the disregard of one of the

above points shall be deemed improper usage. In this case no liability and/or warranty

is assumed.

2.6 Warranty and Liabilty

If the following items are disregarded, all warranty and liability claims for personal injury

and/or damage to property are excluded:

+ Non-observance of the instructions for transport and storage;

+ misuse;

+ Improper or unperformed maintenance or repair work;

+ Improper assembly / disassembly or improper operation;

+ Operation of the FP1 B with defective protective devices and devices;

+ Operation of the FP1 B without lubricant;

+ Operation of the FP1 B with non-approved lubricant;

+ Operation of heavily contaminated FP1 B;

+ Modications or alterations which may be carried out without the written permission of

TriboServ GmbH & Co. KG have taken place;

+ Opening and/or partial or complete disassembly of the FP1 B.

Revision: 0

FlexxPump1 B

User Manual

09

EN-

2.7 General safety instructions

The following safety instructions are given for the FP1 B:

DANGER

Damaged or incorrect electrical connections or unauthorized

live components lead to serious injuries or even death.

§ Have all electrical connection work carried out by qualied

personnel only.

§Replace damaged cables or plugs immediately.

NOTICE

Loose or overloaded screw connections can cause damage to

the FP1 B.

§Mount and check all screw connections with the permissible

torques specied for this purpose. Use a calibrated torque

wrench.

WARNING

Lubricants are ammable.

§ In case of re, do not use a water jet to extinguish the re.

§ In case of re, use only suitable extinguishing agents such as

powder, foam and carbon dioxide.

§Observe the relevant safety instructions of the lubricant manu-

facturer on the safety data sheet of the lubricant used.

CAUTION

Lubricants can cause skin irritations.

§Avoid direct skin contact.

NOTICE

Lubricants can contaminate soil and water.

§Use and dispose lubricants properly.

Revision: 0

FlexxPump1 B

User Manual

10

EN-

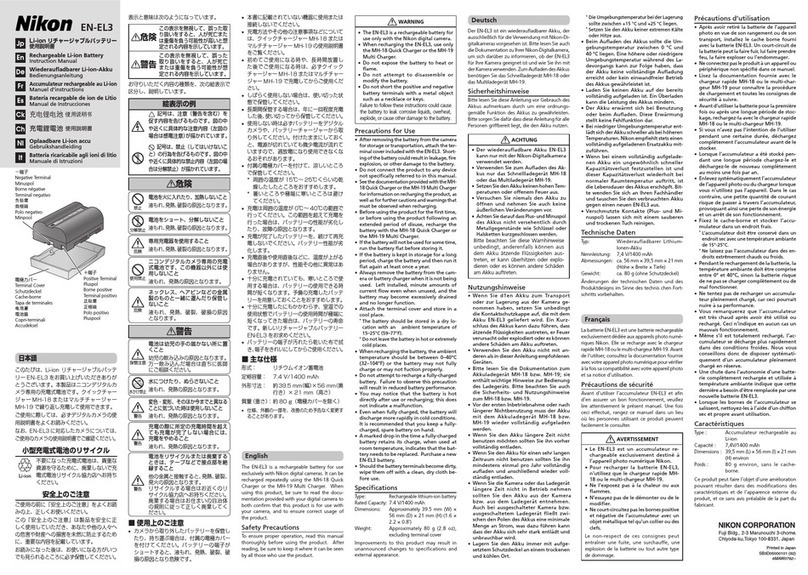

3. Description of function

3.1 General information

Nr. Description

0 FlexxPump1 B (FP1 B)

1 LCD

2 Operation pad (for actions with the activation and programming key)

3 Activation and programming key

4 Lubricant outlet / M16 male thread for bottom mounting

5 M5 female thread for bottom mounting

6 Battery compartment

7 Serial number of the FP1 B

8 M5 female thread for rear mounting

9 Cartridge sensor

10 Lubricant inlet with thread for cartridge

11 Nameplate with designation and CE mark

10

9

8

7

6

Fig. 1: Overview FP1 B

2

1

4

5

3

0

The FP1 B is designed as an extremely compact double piston pump for autonomous

operation with grease or oil as lubricant. The two pistons run force-controlled and

counter-rotating. They are united into one outlet. The outlet is secured by an integra-

ted non-return valve. Approx. 0.16 cm³ of lubricant is pumped during each dispensing

operation; multiple dispensers can be set one after the other.

The LCD on the front panel displays the various operating states; further information

(empty cartridge, error) can be read.

The present FlexxPump1 as battery version has no electrical interface. The supplied

activation and programming key can be used to adjust the operating mode and the

quantity of lubricant pumped per time to supply the lubrication point with the ideal quan-

tity of lubricant.

11

Revision: 0

FlexxPump1 B

User Manual

11

EN-

3.2 Nameplate and designation

The nameplate of the FP1 B is visibly attached to the side of the pump itself. There the

CE mark and the serial number of the FP1 B are visible. Refer to chapter 3, Fig. 1 for

the location of the nameplate and serial number.

3.3 Scope of delivery

The FP1 B is available in several different versions. They differ in the number of acces-

sories supplied.

All versions of the FP1 B are prelled with a neutral, food-grade (H1) lubricant (approx.

3 cm³), which can be mixed with the lubricants approved by TriboServ GmbH & Co. KG,

to simplify the initial commissioning. The manufacturer's designation is Total Ceran FG.

Further data and documentation on the lubricant Total Ceran FG are available on re-

quest from TriboServ GmbH & Co. KG.

Revision: 0

FlexxPump1 B

User Manual

12

EN-

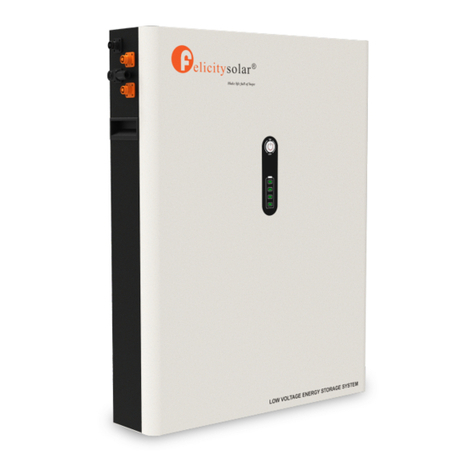

3.4 Technical data

Housing

Dimensions without cartridge width x height x

depth

83 x 82 x 85 mm

Dimensions with catridge 83 x 149 x 85

Weight (without cartridge) appx. 350 g

Mounting options backside: female thread M5 (2x)

bottom: female thread M5 (1x)

bottom: male thread M16 (1x)

max. torque mounting 3 Nm

Mounting position any, upright (preffered)

Material housing PA 6.6 GF30 / POM

Material outlet stainless steel

Operating temperature -15 ... +60* °C

Lubricant and hydraulic

Volume cartridge 125 ml

Lubricant characteristics grease until NLGI class 2

Number of outlets 1

Hydraulic connection directly or via PA-tube

Number of lubrication points up to 8 in conjunction with aluminum progressi-

ve distributor**

max. pressure 35 bar

Grease delivery per stroke 0.16 (-5%) cm³

Electrics

Display LCD

Operating voltage 4.5 V

Protection - A

Protection class IP 54

* Only valid when using the lithium battery. When the alkaline battery is used, the permissible

operating temperature for the FP1 B is +15°C ... +60°C is limited. Please note, however, that in

individual cases the operating temperature may depend on other factors (e.g. lubricant).

** The stated value depends on the specic application and may vary considerably in individual

cases depending on the lubricant used and other conditions.

Revision: 0

FlexxPump1 B

User Manual

13

EN-

4. Transport and storage

4.1 Packaging

The FP1 B is delivered in an outer packaging (cardboard box) and - depending on the

scope of delivery with a lubricant cartridge and other accessories - in the same packa-

ge. To protect them from moisture and dirt, they are also packed in PE lms. As a pre-

ventive protective measure against the escape of the prelled lubricant from the FP1 B,

appropriate protective caps are tted on the lubricant supply and at the lubricant outlet.

Dispose the packaging materials at the designated disposal points in compliance with

the relevant national and company regulations.

After receiving the FP1 B, check the delivery note for completeness and correctness.

Any missing parts or damage must be reported immediately to the forwarding agent,

the insurance company or TriboServ GmbH & Co. KG in writing.

4.2 Transport

NOTICE

Hard shocks, e.g. due to falling or setting down too hard, can

damage the FP1 B.

§Do not throw the FP1 B.

§When using lifting equipment, only use hoists and load

handling attachments in perfect condition and with sufcient

load capacity.

§The permissible lifting weight of the lifting device must not be

exceeded.

Store the FP1 B in its original packaging in a vertical position in a dry, frost-free en-

vironment at an ambient temperature of +5°C to +30°C. The maximum storage time in

unopened condition is 2 years.

The so-called "First-In-First-Out-Principle" (FiFo) is recommended for storage logistics.

4.3 Storage

Revision: 0

FlexxPump1 B

User Manual

14

EN-

5. Mounting

5.1 Preparations

Before starting to work, inform yourself in detail about the FP1 B using this user

manual; in particular about the general safety instructions (section 2.7). Prepare the

installation site carefully.

NOTICE

Pressurised air can damage the seals of the FP1 B and can

transport dirt and foreign matter into the FP1 B or the lubri-

cant.

§Do not use pressurised air.

§Make sure that there is no coarse dirt in the mounting area.

2. Remove the protective cap from top of

the FP1 B.

Remove the yellow protective cap from

the top of the lubricant inlet of the FP1 B.

Make sure that no dirt, water or foreign

bodies enters the lubricant inlet.

5.2 Assembly

1. Condition as delivered

The FP1 B is delivered in a cardboard box.

Depending on the version ordered, further

accessories such as battery, lubricant car-

tridge or additional tube connection parts are

included.

Revision: 0

FlexxPump1 B

User Manual

15

EN-

3. Remove the protective cap from the bot-

tom of the FP1 B.

Unscrew the yellow protective cap coun-

terclockwise from the bottom of the lubricant

outlet of the FP1 B.

4. Inserting the battery

Extract the battery cable from the battery

compartment.

Connect the battery to the battery cable

using the plug.

Store the battery and the battery cable in

the battery compartment.

Make sure that the battery cable or plug

does not protrude from the battery compart-

ment.

Revision: 0

FlexxPump1 B

User Manual

16

EN-

5. Unscrewing the cartridge cap.

Turn the cap on the lubricant cartridge

counterclockwise and pull it off.

Pay attention to cleanliness when

carrying out the work. It is imperative that

dirt and foreign bodies do not enter the

cartridge.

6. Mounting the lubricant cartridge

Place the full lubricant cartridge on the

FP1 B.

Turn the lubricant cartridge clockwise onto

the FP1 B.

The end position is reached after two

full rotations when the label of the lubricant

cartridge is aligned with the front label of the

FP1 B.

LCD

Revision: 0

FlexxPump1 B

User Manual

17

EN-

5.3 Commissioning

Mount the FP1 B carefully according to the steps described in chapter 5.2.

Depending on the scope of delivery, you must also carry out the following additional

measures for the rst-time commissioning:

1. Mechanical fastening

Fix the FP1 B mechanically through the M5 female threads or through the M16 male

thread of the FP1 B lubricant outlet. Pay particular attention to the maximum tightening

torques permissible for the M5 female threads!

2. Check the assembly

Make sure that the FP1 B is properly and completely assembled. In particular, the bat-

tery must be inserted and a lubricant cartridge must be tted.

3. Power on

If you want to put the FP1 B into operation, switch on the FP1 B. Only if you switch on

the FP1 B, it delivers lubricant to the lubrication point according to the settings. The

detailed description for powering on can be found in chapter 6.3.3.

4. Execute FIL function

Execute the FIL function. The detailed description can be found in chapter 6.3.10. FP1

B performs a certain number of strokes and transports the lubricant from the cartridge

to the outlet.

5. Hydraulic connection

Connect the consumer hydraulically to the FP1 B. If you connect tubes to the FP1 B,

make sure that the tubes and connectors are installed tightly, cleanly and correctly.

Ideally, use tubes prefilled with the appropriate lubricant!

6. Check the settings on FP1 B

Check the factory settings of FP1 B with the required values for the lubrication point

and adjust them if necessary. The factory settings are recorded in chapter 6.2; changes

at the FP1 B must be made in the SET-Menu, chapter. 6.3.6, and in the PRO-Menu,

chapter 6.3.8 to 6.3.9.

Revision: 0

FlexxPump1 B

User Manual

18

EN-

6. Operation and settings

6.1 General information

What you should know about operating and setting the FP1 B:

FP1 B is designed as a single point lubricator for one lubrication point. However, de-

pending on the specific application, FP1 B can also supply a limited number of lubricati-

on points reliably and cleanly with lubricant. Accessories from the manufacturer can be

connected to the FP1 B. If necessary, changes must be made to the FP1 B settings to

ensure safe and reliable operation.

The FP1 B is a cycle-controlled lubricant dispenser which operates autonomously and

time-based via the integrated microelectronics. The FP1 B cyclically delivers a dened

quantity of lubricant from the cartridge to the outlet. Two operating modes can be

selected. The Hour-Mode -h- allows setting the number of cycles (c) within a dispen-

sing time (h) in hours. The cycles (c) are evenly distributed over the dispensing time.

Dispensing times (h) between 1...99 hour(s) and cycles (c) between 1...10 can be set.

The Empty-Time-Mode Et allows the emptying time of the cartridge to be set in

months. Emptying times between 1...24 month(s) can be set.

The disposable interchangeable cartridge with 125ml lubricant guarantees a control-

led and constant quality of the lubricant and is lled without air bubble inclusions. The

FP1 B allows a high supply security of the lubrication point and prevents failures. The

FP1 B in its present version is designed for the lubricant grease and oil.

The FP1 B cannot be used in the present version without a lubricant cartridge and

suitable battery. Both can - depending on the version ordered - already be included in

the scope of delivery and may already be connected and installed in the FP1 B.

For operation under normal operating conditions, FP1 B can be operated with an

alkaline battery, for increased requirements with the more powerful lithium battery.

The respective conditiones of the FP1 B can be seen in the LCD, which additionally

enables the optical recognition of the condition by means of coloured LEDs.

If you have any questions about your application and the correct settings for FP1 B,

please contact the manufacturer (chapter I.II).

Revision: 0

FlexxPump1 B

User Manual

19

EN-

6.2 Factory settings

FP1 B is always delivered ex works with the following settings:

operating mode Hour-Mode -h-

Mode OFF FP1 B is switched off

The factory settings foresee using the FP1 B in the Hour-Mode -h-. If you want to

operate the FP1 B in Empty-Time-Mode Et, you have to make changes in the SET-

Menu of the FP1 B to set the Empty-Time-Mode Et (chapter 6.3.6).

Dispensing time h = 6 The dispensing time is 6 hours.

Number of cycles c = 1 The number of cycles is one (1) stroke

during the dispensing time.

The default settings in the Hour-Mode result in an emptying time (service life) of 195

days (= 6.4 months) for a full 125 ml lubricant cartridge, provided that the FP1 B is per-

manently switched on and no special dispensations have been made. Within approx. 6

hours, the FP1 B will deliver one donation per stroke (0.16 cm³).

Verify that the default settings are appropriate for your application and that the lubri-

cation point is supplied with the correct amount of lubricant per time unit.

If this is the case, you can operate the FP1 B with the default settings in the Hour-Mode

-h-.

If this is not the case, change the values for the dispensing time t and number of cycles

c accordingly; see chapter 6.3.8 for an explanation of how to make these changes.

To use FP1 B, it must first be properly mounted and installed and then switched on.

Installation is very simple and described in detail in chapter 5.2; switching on is descri-

bed in chapter 6.3.3.

If you order a special version of FP1 B from the factory, the information contained in

the supplement is authoritative for you!

6.2.1 Default settings operating mode Hour-Mode -h-

Revision: 0

FlexxPump1 B

User Manual

20

EN-

Emptying time Et = 6 The emptying time of one (1) cartridge is 6 months.

The default settings in the Empty-Time-Mode result in an emptying time (service life)

of 6 months for a full 125 ml lubricant cartridge, provided that the FP1 B is permanently

switched on and no special dispensations have been made. Within approx. 5.6 hours,

the FP1 B will deliver one donation per stroke (0.16 cm³).

Verify that the default settings are appropriate for your application and that the lubri-

cation point is supplied with the correct amount of lubricant per time unit.

If this is the case, you can operate the FP1 B with the default settings in the Emp-

ty-Time-Mode Et.

If this is not the case, change the values for the emptying time t accordingly; see chap-

ter 6.3.9 for an explanation of how to make these changes.

To use FP1 B, it must first be properly mounted and installed and then switched on.

Installation is very simple and described in detail in chapter 5.2; switching on is descri-

bed in chapter 6.3.3.

If you order a special version of FP1 B from the factory, the information contained in

the supplement is authoritative for you!

6.2.2 Default setting operating mode Empty-Time-Mode Et

Table of contents