Warning..................................................

For electrical isolation of operating voltage:

• Use only power units which guarantee reliable

electrical isolation of the operating voltage as per

IEC/DIN EN 60204-1. Observe also the general

requirements for PELV power circuits as per IEC/DIN

EN 60204-1.

Switch power packs are permitted, providing they

guarantee reliable isolation in accordance with

EN 60950/VDE 0805.

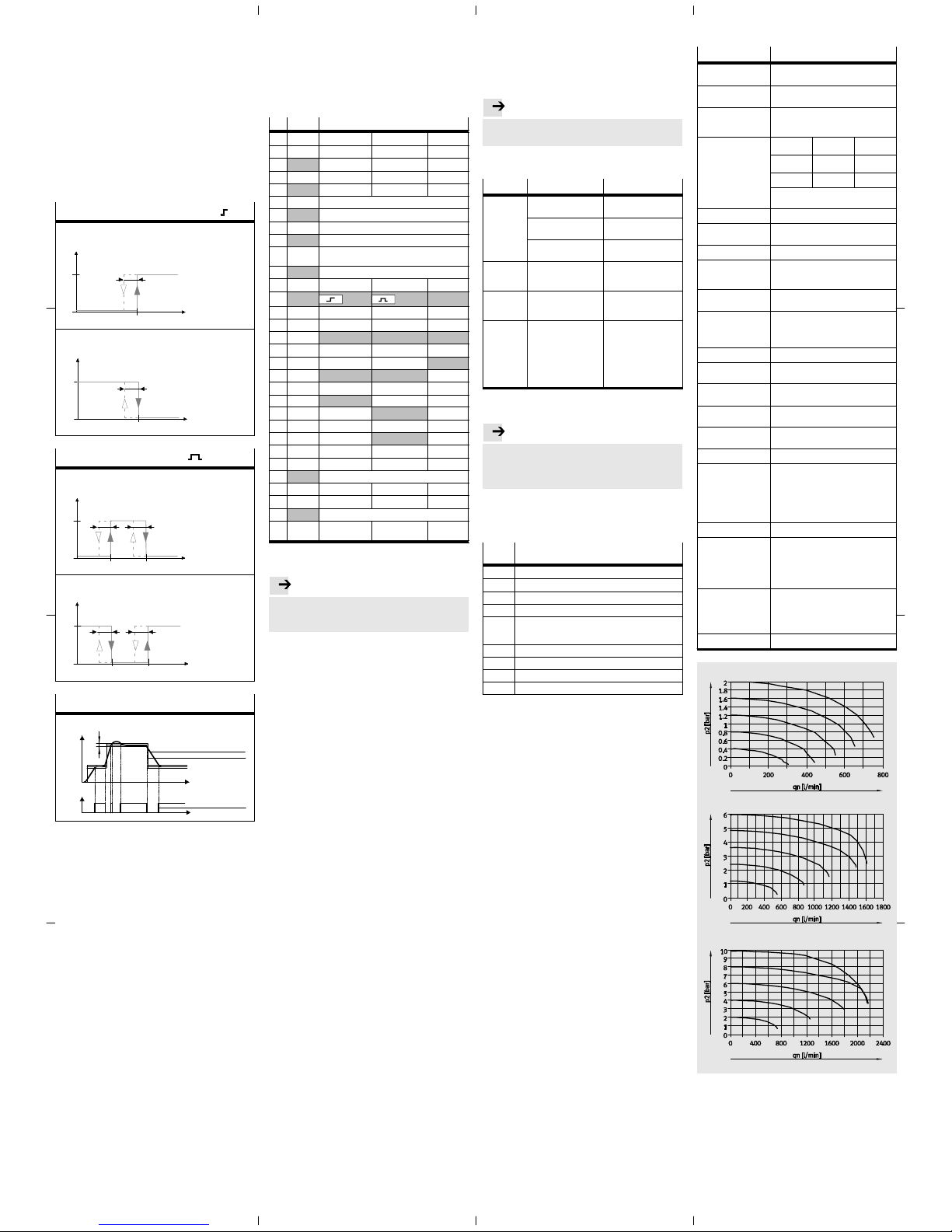

1Supply port (1)

2Electrical connection

3Status LED (green)

4Earth terminal, external (front and back side)

5Operating key upwards (UP)

6LED display

7Operating key downwards (DOWN)

8Edit key

9Pressure output (2)

aJ Venting (3)

aA Front fastening hole

aB Side fastening hole

1

2

35

6

4

7

8

9

aJ

aA

aB

1

aB

2

6

65

7

9

aJ

aA

4

4

Type: ...E1T

Type: ...E1

8

3

Fig. 1

Proportional pressure regulating valve en

..................

Note.......................................................

• Installation and commissioning may only be

performed in accordance with the operating

instructions and by qualified personnel.

1 Application and function

The VPPE-... is designed to control pressure proportion-

ately to a specified setpoint value.

Replacement of manually adjustable pressure regulators

by remotely, electrically adjustable regulators, to have

different machine parameters available quickly and auto-

matically, for example.

Supply port

Setpoint value

Setpoint value

Pressure

output

Venting

Pin 5

2 Variants of the VPPE-...

Type code of the VPPE-...

VPPE-3- 1-1/8-6-010-E1T

123

Item Features Meaning

1Pressure regulation range:

2

6

10

0.02 … 2.0 bar

0.06 … 6.0 bar

0.1 … 10.0 bar

2Setpoint specification:

010

420

0 … 10 V (voltage)

4 … 20 mA (current)

3Control unit: E1

Type o f mounting: T

7-segment LED display

Supply manifold mounting

3 Conditions of use

General conditions for the correct and safe use of the

product, which must be observed at all times:

• Observe the specified limits (e.g. for pressures,

temperatures and electric voltage).

• Makesurethereisasupplyofcorrectlyprepared

compressed air in accordance with the specifications on

the medium Technical specifications.

• Please observe the prevailing ambient conditions.

• Please comply with national and local safety laws and

regulations.

• Remove all transport packing, such as protective wax,

foils, caps, cardboard boxes (with exception of the

covers in the pneumatic connections).

The individual materials can be stored in containers for

recycling purposes.

• Slowly pressurize the complete system.

This will prevent uncontrolled movements from

occurring.

• Note the warnings and instructions

–ontheproduct

– in these operating instructions.

• Use the product in its original state without undertaking

any modifications.

4 Fitting

4.1 Mechanical

• Handle the VPPE-... with care so that the electrical

connection is not damaged.

Such damage reduces the operational reliability.

• Make sure there is sufficient space for the cable

connection and tube couplings. This avoids breakage of

the connecting cable.

• Put the VPPE-... as close as possible to the consuming

device. This leads to improved control precision annd

shorter response times.

• Push two screws (M4) into the side mounting holes aB

or the front mounting holes aA (see Fig. 1),

max. torque: 2 Nm.

• Fasten the VPPE-... in the intended location.

4.2 Pneumatic

• Remove the covers on the compressed air connections.

• Attach the pneumatic tubing to the following connec-

tions (see Fig. 1):

– Supply port (1) 1

– Pressure output (2) 9

• Install a silencer at venting (3) (item aJ )orremovethe

exhaust with ducted tubing.

Note.......................................................

The position of the pneumatic connections depends on

the variant ordered.

4.3 Electrical

Note.......................................................

Make sure that the cable is laid as follows:

– not squashed

–notbent

–notstretched.

• Use accessories from Festo (see “Accessories”):

– plug socket with cable

or

– socket cable, ready-to-use.

This ensures that the specified protection class IP65

and EMC are achieved.

Note......................................................

To ensure EMC safety, the device must be earthed as

follows:

• Use the earth terminal (see Fig. 1).

• Use the following earthing accessories (included in

delivery):

– Self-cutting screw

– Flat plug

–Contactdisc

• Connect the circuitry of the VPPE-... as show in the

circuit diagram. Preferably use cable from Festo.

12

5

4

PIN no. Colour 1) VPPE

1brown +24 VDC

2white Analogue input – setpoint value / – w

3blue GND

4black Analogue input + setpoint value / + w

(0 … 10 V or 4 … 20 mA)

5grey Switch output (24 V) or

analogue output (0 … 10 V or 4 … 20 mA)

+ actual value / XOUT

1) Colour is only valid for accessory cable from Festo

5 Commissioning

Note......................................................

• The VPPE-... interprets setpoint signals less than

0.1 V as 0 V and setpoint signals less than 4.16 mA

as 4 mA. In this case, the output pressure is set to

0 bar through activation of the ventilation valve.

Asaresult,aclearvalveconditionisassuredat

w=0.

• Safety position:

In case of setpoint cable break of the voltage variant,

the output pressure is set to 0 bar. In case of setpoint

cable break of the current variant, or in case of loss

of power supply, the output pressure remains uncon-

trolled. Leakage produces a change in pressure in the

long term.

• Connect the VPPE-... with a setpoint signal.

The VPPE has a so-called “differential input”. The

setpoint signal is applied to the contact Pin 2 and Pin 4,

whereby the lower potential must be connected to

contact Pin 2 and the higher potential to contact Pin 4.

Contact Pin 2 (– setpoint) can be connected to contact

Pin 3 (GND).

• Apply current to the VPPE-... with direct current

(Supply voltage UV=24VDC±10%).

• Pressurise the VPPE-... with a supply pressure (p1) at

least 1 bar higher than the maximum desired output

pressure. A proportional output pressure (p2) is set

automatically.

The following output pressure range is then assigned to

the setpoint signal range 0 … 10 V or 4 … 20 mA:

Setpoint

Output pressure range of the variant

e2bar 6bar 10 bar

0…10Vor

4…20mA

0.02 … 2 bar 0.06 … 6 bar 0.1 … 10 bar

5.1 Recommended parameter sets

The valves in all pressure variants are set at the factory

with Preset 2.

Preset

Preset

recommendation 1 2 3

Consuming device volumes <0.5l ~0.5l >0.5l

5.2 VPPE display and meaning

Notes on the following table:

Preset, control behaviour:

You can select the desired factory parameter set in the

menu on the VPPE (Pr1, Pr2, Pr3).

Dis-

play

Meaning Description

[An] Analogue Output: Analogue

[bAr] bar Pressure unit

[Eco] ECO mode Display switch-off (adjustable)

[Frc] Force Manual setpoint input

[HY] Hysteresis Spread, switch difference

[in] Setpoint value When key is pressed (1 sec.), [in]

appears. When the key is released,

the setpoint value is displayed.

[Loc] Lock Input blocked with Pin code

[n.Hi] Switch normally

closed

Contact (normally closed)

[n.Lo] Switch normally

open

Contact (normally open)

[OFS] Offset Zeropointlift(outputpressure

withoutsetpointvalue)

[out] Actual value When key is pressed (1 sec.), [out]

appears. When the key is released,

the actual value is displayed.

[PA] Kilo pascal Pressure unit (in KPa !)

[Pin] Pin code Enter value for locking (1 … 999)

[Pr1] Preset 1 (see section 5.1)

[Pr2] Preset 2 (see section 5.1)

[Pr3] Preset 3 (see section 5.1)

[PSi] psi Pressure unit

[rES] Reset

(factory setting)

Switch on device with pressed

++ Edit keys. Observe the

instruction in chapter 10.

[rnG] Range Pressure range adjustment

[Snr] Display series

number

Switch on device with pressed

+ Edit keys: Series number is

displayed to 6 places, first [xxx.] than

[xxx], alternating approx. 2 sec.

[SOF] Display software

version

Switch on device with pressed

+ Edit keys: Software version

appears

[SP] Switching point (see section 5.3)

[SP.H] Switching point high Top switching point (see section 5.3)

[SP.L] Switching point low Bottom switching point

(see section 5.3)

[SP.O.] Set point ok Setpoint value reached

(see section 5.3)

[unL] Unlock Lock removed

Threshold value

comparator

(see section 5.3)

Window comparator (see section 5.3)

[._..] ECO mode activated After x seconds (adjustable), a line

moves through the display [._..]

VPPE-3-1-1/8-...-E1

(LED-Display)

Operating instructions

Original: de

Festo AG & Co. KG

Postfach

D-73726 Esslingen

Phone:

+49/711/347-0

www.festo.de

0909a 749 698