Filtration Learning System

4© Festo Didactic 696684

8.6 Stirrer ____________________________________________________________________________ 28

8.7 Pump_____________________________________________________________________________ 29

8.8 3-way ball valve unit ________________________________________________________________ 29

8.9 Gate valve and butterfly valve_________________________________________________________ 30

8.10 Level monitoring __________________________________________________________________ 31

8.10.1 Capacitive proximity sensors _____________________________________________________ 31

8.10.2 Float switch, lateral installation ___________________________________________________ 32

8.11 Compressed air supply _____________________________________________________________ 32

8.12 Electrical connection technology _____________________________________________________ 33

8.12.1 Connection board ______________________________________________________________ 33

8.12.2 Mounting frame _______________________________________________________________ 34

8.12.3 19″frame_____________________________________________________________________ 35

8.13 PLC EduTrainer Universal S7-1512C ___________________________________________________ 36

8.14 Control console with operator unit TP700 Comfort _______________________________________ 37

8.15 EasyPort and FluidLab-PA closed-loop V5 ______________________________________________ 37

8.16 USB device server _________________________________________________________________ 38

8.17 Trolley 700 _______________________________________________________________________ 38

9 Function______________________________________________________________________________ 39

9.1 Function as individual station _________________________________________________________ 39

9.2 Operation as a downstream station ____________________________________________________ 39

10 Sequence description__________________________________________________________________ 40

10.1 Sequence description, filter process __________________________________________________ 40

10.2 Start-up prerequisites ______________________________________________________________ 40

10.2.1 individual station ______________________________________________________________ 40

10.2.2 Station with downstream station__________________________________________________ 40

10.2.3 Rinsing process________________________________________________________________ 40

10.3 Initial position ____________________________________________________________________ 40

10.4 Sequence ________________________________________________________________________ 40

10.4.1 Automatic mode without downstream station _______________________________________ 40

10.4.2 Automatic mode with downstream station __________________________________________ 41

10.4.3 Automatic operation, rinsing process ______________________________________________ 41

10.4.4 Manual mode _________________________________________________________________ 42

11 Commissioning _______________________________________________________________________ 43

11.1 Workstation ______________________________________________________________________ 44

11.2 Filling and emptying________________________________________________________________ 44

11.3 Power supply _____________________________________________________________________ 45

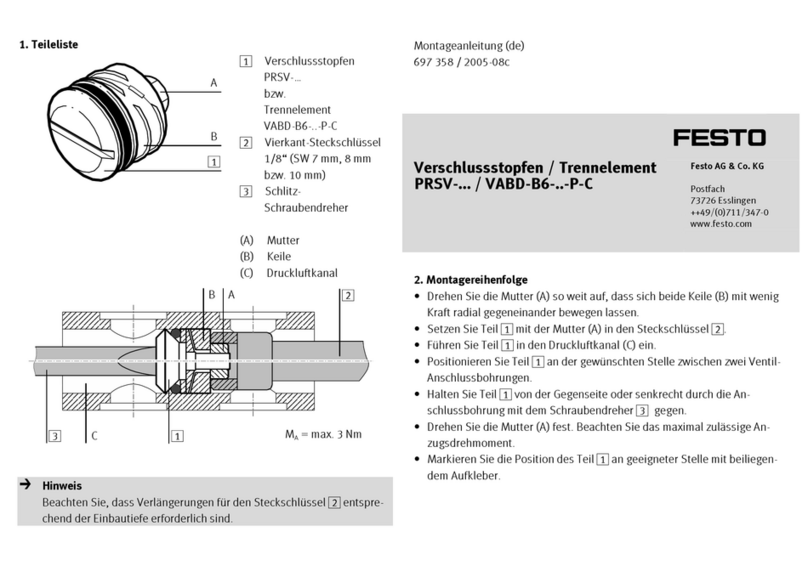

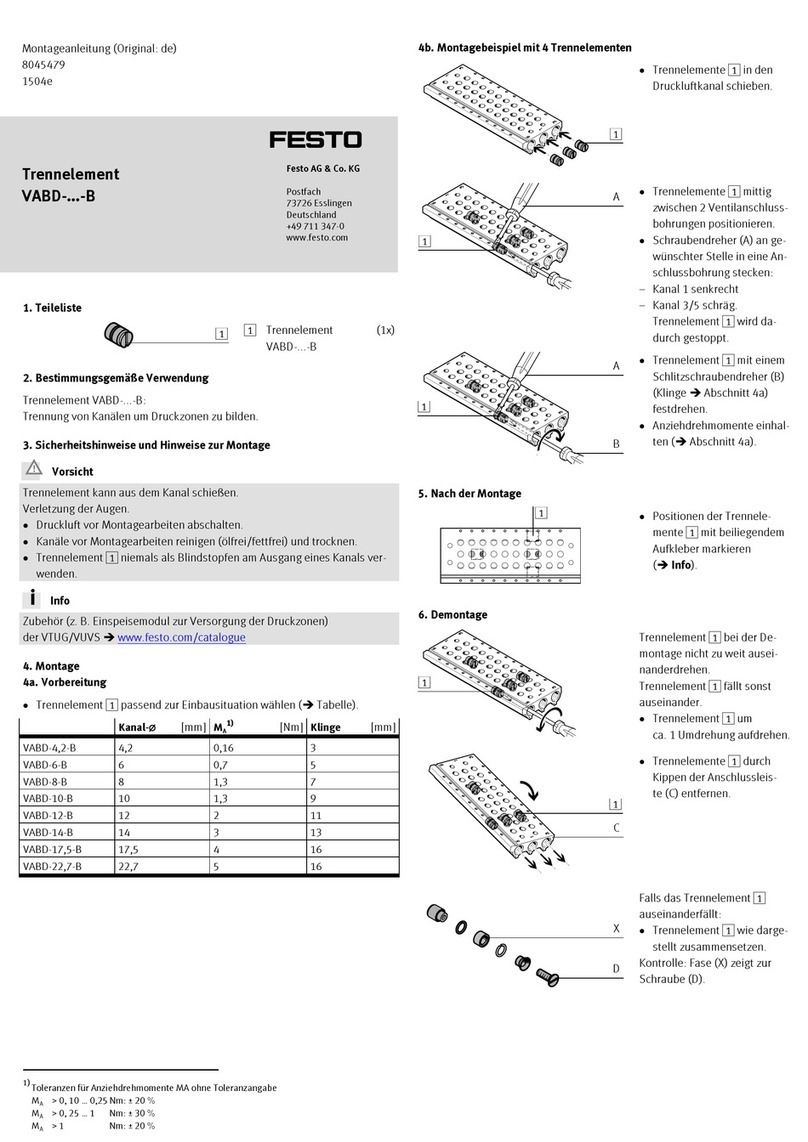

11.4 Compressed air supply _____________________________________________________________ 45