Highland Tank R-HT Series User manual

www.highlandtank.com • 1

User’s Manual

Installation

Operation

Maintenance

Carefully read and follow the instructions in this manual.

WASTEWATER TREATMENT SYSTEMS

RECTANGULAR

OIL/WATER

SEPARATORS Aboveground

HT, HTC, UL-SU2215

Single-wall & Double-wall

Series G, J, S & TF

Unmatched Quality & Service Proudly made

in America

2 • www.highlandtank.com

Warning and Disclaimer

This manual is intended for use only by persons knowledgeable

and experienced in aboveground oil/water separator installation,

operation and maintenance. This manual provides general guidance,

and conditions at your site may render inapplicable some or all of

the guidance. If you are uncertain, or require clarication or further

instruction, please contact Highland Tank prior to commencing any

installation, operation or maintenance procedure. You are solely

responsible for compliance with all federal, state and local laws,

regulations and ordinances applicable to your installation and

operation. Highland Tank disclaims all liability related to any misuse

of the oil/water separator or failure to follow all guidance and

instruction provided by Highland Tank.

www.highlandtank.com • 3

Installation 8

Piping - Inlet, Outlet & Vent 15

Start-up 23

Operation 25

Maintenance 27

Troubleshooting Guide 36

OWS Reference Drawing 38

Appendix - A - Sample Inspection and Maintenance Log

Thank you for purchasing a Highland Tank Oil/Water Separator -

the leading high-performance separator in the industry.

The purpose of this manual is to provide detailed information

on the installation, venting, startup, operation, maintenance

and trouble-shooting of Highland Tank’s Oil/Water Separator.

These instructions should be used in conjunction with any

and all other applicable installation instructions, e.g.:

• Petroleum Equipment Institute Installation of Aboveground

Liquid Storage Systems, PEI/RP200.

• Any and all applicable federal, state and local codes. Always

check with Authority Having Jurisdiction.

Note: This manual is based on standard OWS congurations.

Other custom congurations are available. Verify the supplied

conguration prior to installation and testing.

Abbreviations used:

OWS – Oil/Water Separator

AHJ – Authority Having Jurisdiction

PSIG – Pounds per square inch gauge

OSHA – Occupational Safety and Health Administration

Contents

Introduction

4 • www.highlandtank.com

Important points to consider prior to installation, operation and maintenance

of the OWS:

Carefully read and follow instructions in this manual. Local codes and ordinances may apply.

Check with local AHJ prior to installation of OWS.

• Ensure adequate site space - many of our products are delivered on a 75 foot long

tractor-trailer. Allow space for unloading, positioning and temporary storage if applicable.

• Ensure the crane has adequate lifting capacity and clearance - have operator check site for

clearances (overhead, turning, etc.). Spreader bars may be required for larger OWSs.

• Ensure that installation staff have proper knowledge of proper procedures and inherent dangers

associated with OWS installation for the storage of ammable and combustible liquids. Reliance

on skilled, professional installation staff, can help avoid system failures and accidents.

• Special permits may be required for weight, size, etc. by local code or ordinance.

• Barricade the OWS installation area until job is complete.

• Conrm inlet and outlet piping elevations - check/recheck approval drawing and site plan

when OWS arrives.

• If an OWS hold-down system is required, make sure predetermined system components are

at the site prior to OWS installation. Check anchor bolt locations if applicable.

• The amount of debris, such as sand, gravel, dirt, leaves, wood, rags, etc., permitted to enter

the OWS must be minimized for maximum effectiveness. Installation of an appropriately sized

Collection Catch Basin or other similar device upstream of the OWS is recommended.

• For OWS with integral sludge hoppers, it is recommended that a shut-off valve be installed

at the drain nozzle for periodic sludge removal.

• Detergents and solvents must not enter the OWS. The OWS will not remove chemical

emulsions or dissolved hydrocarbons, and their presence retards the recovery of oils that

would otherwise be separated.

• Never enter the OWS or any of its enclosed spaces without proper conned space entry

training and approved equipment. See OSHA, Regulations for Permit-Required Conned

Spaces 29 C.F.R. § 1910.146.

• The OWS must be kept from freezing at all times. If necessary, a thermostatically controlled

steam or electric heating device may be installed.

www.highlandtank.com • 5

Important points to consider continued:

• IMPORTANT: DO NOT modify OWS structure in any way. DO NOT weld on OWS.

• This is a stationary OWS. DO NOT use for transport of any product over roads and highways.

• Wastewater containing high concentrations of dissolved solids (such as untreated sanitary

sewage) must be excluded due to its emulsifying tendency. Wastewater, which exhibits high

Biological Oxygen Demand, Chemical Oxygen Demand, and Total Suspended Solids may

require additional treatment beyond that of the OWS.

• The OWS will not remove chemical or physical emulsions, dissolved hydrocarbons, solvents

or Volatile Organic Compounds. Installation of an appropriately sized Advanced Hydrocarbon

Filtration System (brochure HT-2502) is recommended for treatment of wastewater contaminated

with these pollutants.

• Waste oils, such as automobile and truck crank case oil, should not be intentionally

drained into the OWS. Filling the OWS with waste oils adversely affects OWS performance.

Waste oil should be dumped into a waste holding tank for proper disposal.

• The OWS needs to be maintained to remain as free of accumulated oil and sediment as

possible. Suction removal of waste, as needed, is the best and recommended method

of maintenance.

• The location of your OWS should be in an area with sufcient truck access for waste removal.

• An absence of gravity ow to the OWS will necessitate wastewater pumping. Pumping

should be restricted to the clean water, efuent end of the OWS where possible. If pumping

cannot be avoided at the inuent end, it may mix the oil and water, increasing the emulsied

and dissolved oil content and may cause separation failure. If a pump is installed upstream of

the OWS, it must be a positive displacement pump (e.g. progressive cavity, diaphragm, sliding

shoe), set at minimum ow rate/RPM and installed as far upstream as possible to minimize

oil/water mixing.

• Piping should be designed to minimize turbulence and promote laminar ow.

• Complete the OWS Installation Checklist and Start-up Report (Form # HT-9060). A copy of

the completed form should be retained by the OWS owner and/or installation contractor.

• OWS must be lled with clean water before introducing any wastewater. Filling should only

be done after OWS has been leveled and anchored in nal installation location.

6 • www.highlandtank.com

Highland Tank’s OWS is a wastewater treatment tank used to

intercept and collect free-oil, raw petroleum hydrocarbons, grease

and oily-coated solids from a wastewater stream.

They are typically required in all facilities that conduct washing,

servicing, repairing, maintenance or storage of motor vehicles,

car washes, commercial vehicle garages, repair facilities, service

stations and similar sites where oil or ammable liquids may be

introduced into a sewer system.

Designed to accept gravity ow, the OWS volume, retention time

and use of coalescing elements permit these contaminants to

separate from the water due to their differences in specic gravity.

The OWS contains multiple chambers where oils separate

and oat to the surface, while sand and grit settle to the bottom.

Free-oating oils and oatable oily-coated solids accumulate in the

OWS until they are pumped out. The clearer water beneath the

separated wastes ows downward and then is transferred to the

clearwell chamber through the PVC riser pipes. The clearest water

exits the OWS via the downcomer pipe where it is discharged from

the nal OWS.

OWS sizing and construction conforms to most plumbing

codes and the efuent discharge meets or exceeds many municipal

industrial sewer pretreatment regulations. Nonetheless, you must

conrm all code and regulatory requirements with your AHJ prior

to and during installation of the OWS. To view an animated

simulation of the OWS operation, go to www.highlandtank.com

Standard OWS

Description

www.highlandtank.com • 7

Aboveground installation

avoids costly excavation

Electronic oil level sensor

can signal remote alarm

panel of high oil condition

Removable, top panels

for easy access and

maintenance

High-performance

wastewater treatment

at varying ow rates

and conditions

Optional Sludge Hopper

with drain for sludge removal

Coalescers engineered

to API-421, accelerate

the separation process

Coalescers are

removable

from the top

Integral Efuent Clearwell

to easily adapt from

gravity to pumped discharge Rugged all-steel construction

for superior structural strength

Also available with a UL-SU2215 Label

Model R-HTC Rectangular Aboveground

Oil/Water Separator with Optional Sludge Hopper

and Level Sensor

8 • www.highlandtank.com

OWSs must not be dropped, dragged or handled with sharp

objects. Lifting equipment must be of adequate size to lift and

lower the OWS without dragging, dropping or damaging the

OWS or its coating.

The OWS must be mechanically unloaded. Use extreme care when

unloading as weight distribution of OWS may be uneven.

DO NOT MOVE OWS UNLESS EMPTY

OWS Care in Handling

OWS Unloading

WARNING:

Under no circumstance

should chains or slings

be used around

the OWS shell.

Always use four lifting

lugs to lift OWS.

Fig. 1

Installation

Use spreader bar

when necessary

Max. 30º

HighlandTank

HTM-0001

www.highlandtank.com

®

Installation & Maintenance Instructions are available at www.highlandtank.com

HighlandTank

HTM-0001

www.highlandtank.com

®

Installation & Maintenance Instructions are available at www.highlandtank.com

Max. 30º

www.highlandtank.com • 9

Lifting and moving the OWS must only to be done using the lifting

lugs welded to the OWS. OWS should be carefully lifted, moved

and lowered using cables, chains or straps of adequate size. When

lifting lugs are used, the angle between the lifting cable and

vertical shall be no more than 30 degrees. See Fig.1. Use a spreader

bar where necessary. Maneuver OWS with guidelines attached to

each end of the OWS. If OWS must be relocated on a job site during

installation, they must be lifted using provided lifting lugs.

Upon delivery, visually inspect the OWS for exterior damage that

may have occurred during shipping or job site handling. Any

damage that could result in leakage or corrosion must be repaired

in a manner approved by Highland Tank. Please refer to coating

repair instructions below. Damaged coatings must be repaired with

the repair kit that was delivered with the OWS. Additional coating

touch-up is available from Highland Tank.

Visually inspect the OWS for damage. Pay particular attention to

areas where coating may have been gouged or abraded. Mark all

areas which appear damaged for repair. Clean damaged OWS

coating areas of rust, contaminants or disbonded coating prior

to application of touch-up coating.

Areas of coating damage shall be roughened up with coarse grit

sandpaper or grinder (see Society of Protective Coatings (SSPC)

SP-2 “Hand Tool Cleaning” or SP-3 “Power Tool Cleaning” for

additional guidance) to remove all glossiness from the surface

surrounding the repair area approximately 6 inches around the

damaged area. Re-coat the area with touch-up coating provided.

See Fig. 2. Allow repaired coating areas to cure completely.

Lifting and Moving

Pre-Installation

Inspection & Testing

Coating Repair

Fig. 2

10 • www.highlandtank.com

Carefully remove access covers so as not to damage the gaskets.

Inspect the interior of the OWS from above (without entry) to ensure

that all bafes, coalescer plates and cartridges and internal piping

are secure and have not been damaged during transport. Do not

allow anyone to enter the OWS unless it has been properly prepared

for entry and the person entering the OWS has been properly trained

for conned-space entry, if required, per OSHA, Regulations for

Permit Required Conned Spaces 29 C.F.R. § 1910.146.

DO NOT ENTER the OWS without following proper conned

space entry procedures.

An appropriate air or hydrostatic test may need to be performed

prior to placing OWS into service, as outlined below. Check with

AHJ to determine appropriate test and approval. Take all necessary

safety precautions during all testing.

DO NOT leave OWS unattended.

DO NOT apply a vacuum to a single-wall OWS or to the primary

tank of a double-wall OWS.

DO NOT connect the air pressure line from the compressor to

the interstitial monitoring port of a double-wall OWS.

After air testing, release air pressure from the OWS before

dismantling testing equipment. Do not relieve pressure until

OWS is secured in its nal resting position.

Internal Inspection

WARNING:

Pre-installation Tightness

Testing Procedures

IMPORTANT:

www.highlandtank.com • 11

Remove factory installed temporary plugs & thread protectors.

Apply compatible, non-hardening pipe sealant to threads and install/

reinstall liquid-tight steel or cast-iron plugs at all unused openings

taking care not to cross-thread or over-tighten plugs. All gaskets, lids

and blind-anges must be in place prior to performing air test.

Perform air test for a single-wall OWS as illustrated in Fig. 3 below.

Temporarily plug, cap or seal off remaining OWS openings to hold

pressure. Open valve A and pressurize the OWS to a maximum of

2.5 PSIG. Seal the OWS by closing valve A and disconnect the

external air supply. Apply a soap solution to all welded seams

and ttings. Inspect to assure that no leaks exist.

Air Supply

Valve A

Overpressure Relief Device - Set at 3 PSIG

Gauge

Fig. 3

Single-Wall OWS

Air Test

Double-Wall OWS

Air Test

Double-wall OWSs require different air pressure testing procedures.

DO NOT connect a high-pressure air supply line directly to the

interstitial monitoring port.

If the AHJ requires on-site testing of the OWS, proceed with the air

test as follows and as illustrated in Fig. 4 below.

12 • www.highlandtank.com

Fig. 4

Valve C

Gauge

2

Gauge 1

Air Supply

Valve B

Valve A

Overpressure Relief Device - Set at 3 PSIG

Flexible

Connection

Pre-installation Tightness

Testing Procedures

continued

Temporarily plug, cap or seal off remaining OWS openings to hold

pressure. Close valve B and pressurize the OWS inner tank to a

maximum of 2.5 PSIG. Seal the inner tank by closing valve A and

disconnect the external air supply. Monitor the pressure for a

period of 1 hour.

While air tests are generally inconclusive without soaping and the

careful inspection for bubbles, this step is recommended to detect

a very large leak in the inner tank and prepare for the next step.

Pressurize the interstice with air from the inner tank by closing

valve C, then opening valve B. Allow pressure to equalize.

Soap the exterior of the OWS and inspect for bubbles while

continuing to monitor the gauges to detect any pressure drop.

Release the pressure from the interstice rst by opening valve C,

then open valves A and B to release all test pressure and vent

both spaces.

Refer to PEI/RP200 and labels on the OWS for testing guidelines.

www.highlandtank.com • 13

An on-site hydrostatic test of the OWS may be required by the

AHJ before installation to ensure no damage has occurred during

shipping and handling.

After the separator has been leveled and secured to foundation,

ll the OWS with clean, fresh water (See Filling the OWS on page

16.) until water is discharged from the outlet. Allow the OWS to

stabilize to a no-ow, static condition. If required by AHJ, attach

blind anges or plugs to inlet/outlet, then ll OWS completely with

clean fresh water.

Accurately measure and record the uid level from the top of the

OWS to the static uid level. After one hour, verify that the

uid level has not dropped. A uid level change would indicate that

there may be a leak in the primary tank. If a leak is detected, contact

Highland Tank before proceeding.

Optional Hydrostatic Test

for OWS if Required

by AHJ

14 • www.highlandtank.com

The foundation to support the OWS must be designed by a

licensed professional engineer, familiar with the site conditions

and regulations. The foundation must consist of a well-drained,

stable, concrete, asphalt or bedding material surface, to prevent

movement or uneven settling of the OWS.

All aboveground OWS are equipped with a grounding connection.

Aboveground OWS installations must be in accordance with local

applicable electrical and re code standards which may include but

not be limited to: National Fire Protection Association publication

NFPA 30, and any local adopted re codes. Contact the local AHJ

for details on all applicable codes and restrictions such as spacing

from existing or new buildings, property lines, public ways, etc.

The OWS must be installed in a level and plumb position.

Check elevations at each end of the OWS with a transit and adjust

as necessary to 1/2 inch in 20 feet. Check elevations across the

width of the separator tank and adjust to 1/4 inch in 10 feet.

High water tables or partially ooded installation sites may exert

signicant buoyant forces on the OWS. Buoyant forces are partially

resisted by the weight of the OWS. Additional buoyant restraint,

when required, is obtained by using properly designed hold-down

system in conjunction with any concrete hold-down pads.

The use of steel cable and/or round bar as buoyant restraints

is prohibited.

Fig. 5 illustrates an installation with the OWS tted with support rails

anchored to a hold-down pad. Anchor bolts are positioned in the

concrete pad to match holes in the support anges. The OWS is

secured with washers and lock nuts. Other hold-down methods are

available. Contact Highland Tank.

Foundation Preparation

Placement of the OWS

CAUTION:

Anchoring

Fig. 5

HighlandTank

HTM-0001

www.highlandtank.com

®

Installation & Maintenance Instructions are available at www.highlandtank.com

www.highlandtank.com • 15

For Series G, J, S and TF OWS, it is recommended that the

hydrostatic test be performed on each separate chamber

to ensure there are no leaks between chambers. Close inlet

valve and seal off all transfer pipe(s) between chambers with

water-tight device. Fill oil/water separation chamber with clean,

fresh water and allow to stabilize. Check for leaks between

chambers. Contact Highland Tank if a leak is detected.

Ballasting may be necessary for additional downward force

on the OWS during the nal stages of installation. Consult AHJ.

If required, ll OWS with clean water. After ballasting is complete,

check elevations for proper tolerances.

Inlet piping installation should be straight and true with as few turns

as possible to limit turbulence. Refer to Petroleum Equipment

Institute PEI/RP200 for additional information.

Attach inlet/outlet piping (contractor supplied) to inlet/outlet pipes

on the OWS. Inlet and outlet inverts were established during

manufacturing. Do not modify without rst consulting Highland Tank.

The OWS inlet piping typically must be sloped from 1/8 inch to 1/4

inch per foot to maintain gravity ow. A greater slope, or a free fall

of wastewater into the OWS will cause turbulence, which adversely

affects OWS performance. Piping must also be designed to limit

ow into the OWS to the ow rate specied. Use of a ow control

device may be required.

IMPORTANT:

Ballasting

Piping - Inlet, Outlet

& Vent

16 • www.highlandtank.com

OWS outlet piping must be designed to ow at a rate equal to or

greater than the inlet piping to avoid any potential backup.

The OWS should be tted with properly sized inlet and outlet

shut-off valves (contractor supplied) for emergency shut-down

and service purposes.

Attach any other contractor supplied piping to the OWS. Take

special care to prevent damage to any gaskets or pipe threads.

OWS is designed for operation at atmospheric pressure ONLY.

OWS inlet and outlet MUST be vented to atmosphere separately

from the oil/water separation chamber to assure proper operation.

See Fig. 6.

Note: Inlet pipe does NOT need to be vented when inuent is being

pumped into the separator. Likewise if the efuent is being pumped,

the outlet pipe does not need to be vented as on Series J OWS.

Piping continued

IMPORTANT:

OWS Venting Guidelines

Fig. 6

Inlet

Outlet

Oil/Water Separation

Chamber Vent

Te

rminate vent piping

as required by AHJ

Oil/Water Separator

The inlet and outlet vents must each have their own separate,

dedicated vent line for the following reasons:

• OWS inlet is vented to prevent hazardous gases from building

up in inlet pipe draining the catch basin or trench drain (which

may be in a building).

• OWS outlet is vented to prevent siphoning during full ow into

a ooded storm sewer or ooded pit.

• OWS primary chamber is vented to prevent hazardous gases

from building up inside.

Venting the inlet, OWS and outlet independently prevents raw oil

or oily wastewater from bypassing and exiting the OWS in the

event of a surge or vapor condensation.

www.highlandtank.com • 17

Vent piping requirements may vary by code. Check with AHJ.

Terminate all vent piping per local code and AHJ.

Note: OWS owners may need to provide ame arrestors where

required by governing codes for safety. Check with AHJ.

If an oil skimmer is to be installed, piping between the OWS and the

waste oil tank should be sloped between 1/8 inch and 1/4 inch per

foot to maintain gravity ow in most conditions.

For OWS with oil level sensors, pump-out pipes and leak detection

sensors, install using compatible non-hardening sealant, taking care

not to cross thread or damage the nonmetallic bushings.

For electrical wiring details, please refer to the sensor and control

panel installation instructions.

An additional air test may be required after OWS is secured. Air

pressure for air testing after installation must not exceed 2.5 PSIG

and must be measured at the top of the OWS. Refer to appropriate

air test procedure on pages 9 and 10.

During the installation process, steel can become exposed at the

lifting lug due to the handling of the OWS. These areas, along with

all other exposed steel surfaces, must be covered using the coating

kit supplied by the manufacturer.

Apply supplied coating touch-up to all exposed steel surfaces of

the OWS and allow to cure completely.

Cure time will vary depending on temperature and conditions.

Contact Highland Tank if additional touch-up coating is needed.

Optional OWS electronics may have been provided for your project.

Optional OWS Electronics may include:

- Interface and/or level sensor

- Leak sensor (for interstitial monitoring of double-wall OWS)

- Control panels

Optional OWS electronics must be installed after OWS has

been installed and before start-up procedures are initiated.

For OWS electronics installation details, please refer to the

specic device’s installation instructions.

Piping continued

OWS with Gravity Oil

Skimmers and/or

Monitoring Equipment

Final Air Test

Sealing of Lifting Lugs

and Pipe Connections

Optional OWS

Electronics

18 • www.highlandtank.com

Oil Level /Leak Alarms

(Optional)

For easy, efcient operation and maintenance, the OWS may be

equipped with an Oil/Water Interface and Level Sensor and/or Leak

Detection Sensor to activate warning alarms at high oil levels or

in the event of a leak.

Oil accumulates in the OWS until a predetermined level is reached,

at which time the oil level sensor activates an alarm signaling that

the OWS is full of oil. The level sensor is a magnetic oat switch type

for oil/water interface detection.

The interstitial space of a double-wall OWS can be monitored for a

leak of either water or hydrocarbons by liquid-only or product

specic sensors.

Highland Tank offers a wide range of control panels and sensors to

monitor the operation of your OWS. All panels include audible/

visual signals to alert the operator of system changes and system

test buttons.

Highland Tank’s typical standard panels are listed here for

quick reference.

Single-channel panel. Performs High-Oil Level sensing OR for

Liquid Only Leak Detection with non-specic alarm.

Two-channel panel. Performs High-Oil Level AND High-High-Oil

Level sensing OR High-Oil Level sensing AND for Liquid Only Leak

Detection with non-specic alarms.

Two-channel panel. Performs High-Oil Level AND High-High-Oil

Level sensing with specic alarms.

Three-channel panel. Performs High-Oil Level, High-High Oil Level

sensing AND Liquid Only Leak Detection with specic alarms for

oil levels only.

Four-channel panel. Performs High-Oil Level, High-High Oil Level

sensing AND Leak Detection for Fuel or Water with specic alarms

for each.

HTAP-1

HTAP-2

HT-A2

HT-A2-LD

HT-A2-LDFW

www.highlandtank.com • 19

TEST

SILENCEALARM #1

HTAP-1 - 1-Channel

High-Oil or Leak Detection

TEST

SILENCEALARM #1 ALARM #2

HTAP-2 - 2-Channel

High-Oil and Leak Detection

or High-Oil and High-High-Oil

If your OWS has a control panel and sensors installed, locate the

diagram for your panel from the ve selections and then refer to

the button/light function listing for operation and required action.

Please consult the job specic project information should you need

detailed information regarding a specic alarm/control panel.

Contact Highland Tank if you still need assistance.

HTA2LD

LEAK TEST ALARM TEST

NORMAL ALARM HORN

ALARM SILENCE

LEAKHIGH OIL HIGH-HIGH OIL

HT-A2-LD - 3-Channel

High-Oil, High-High-Oil

and Leak Detection Specic

Non-discriminating

NORMAL

HTA2

HIGH OIL

ALARM TEST ALARM SILENCE

HIGH-HIGH OIL

ALARM HORN

HT-A2 - 2-Channel

High-Oil and High-High-Oil Specic

Oil Level

Controls

(Optional)

continued

20 • www.highlandtank.com

Oil Level

Controls

(Optional)

continued

HTA2LDFW

ALARM TEST ALARM SILENCE

NORMAL ALARM HORN HIGH-HIGH OIL

FUEL LEAK WATER LEAK HIGH OIL

FUEL LEAK TEST WATER LEAK TEST

HT-A2-LDFW - 4-Channel

High-Oil, High-High-Oil

and discriminating

Fuel/WaterLeak Detection

Below is a listing of Highland Tank’s control panel features. Refer

to the previous diagrams to help understand the function of your

particular panel.

Description / Function

Indicates that system is active in normal operating (non-alarm)

mode.

Temporarily closes the control panel circuits to provide a

system test.

Works in conjunction with yellow alarm lights. Emits audible

(90-95 decibel) sound alerting operator that system has entered

an alarm mode.

Silences the audible alarm temporarily for operator to perform

service. (Does not cancel alarm mode.)

Alerts operator of High-Oil level. Oil has reached a predetermined

level and must be pumped out soon.

RESPONSE: Stop OWS operation. Pump out oil. Rell OWS with

water to reset sensors. Resume OWS operation.

OR

Leak Detection – See Leak Detection System procedure.

Panel Light or Button

NORMAL LIGHT

(White)

TEST

ALARM HORN

SILENCE

ALARM #1

This manual suits for next models

1

Table of contents

Other Highland Tank Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Applied Membranes

Applied Membranes AAA-125 MANUAL FOR INSTALLATION, OPERATION AND MAINTENANCE

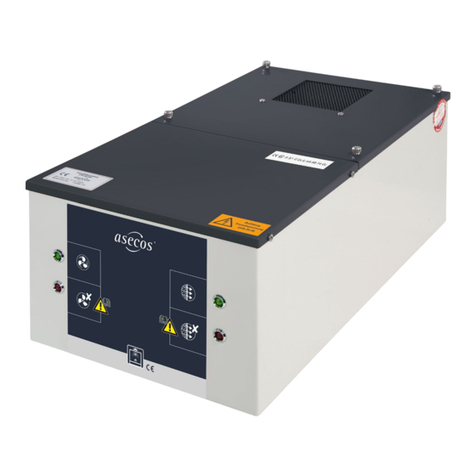

asecos

asecos UFA.20.30 user manual

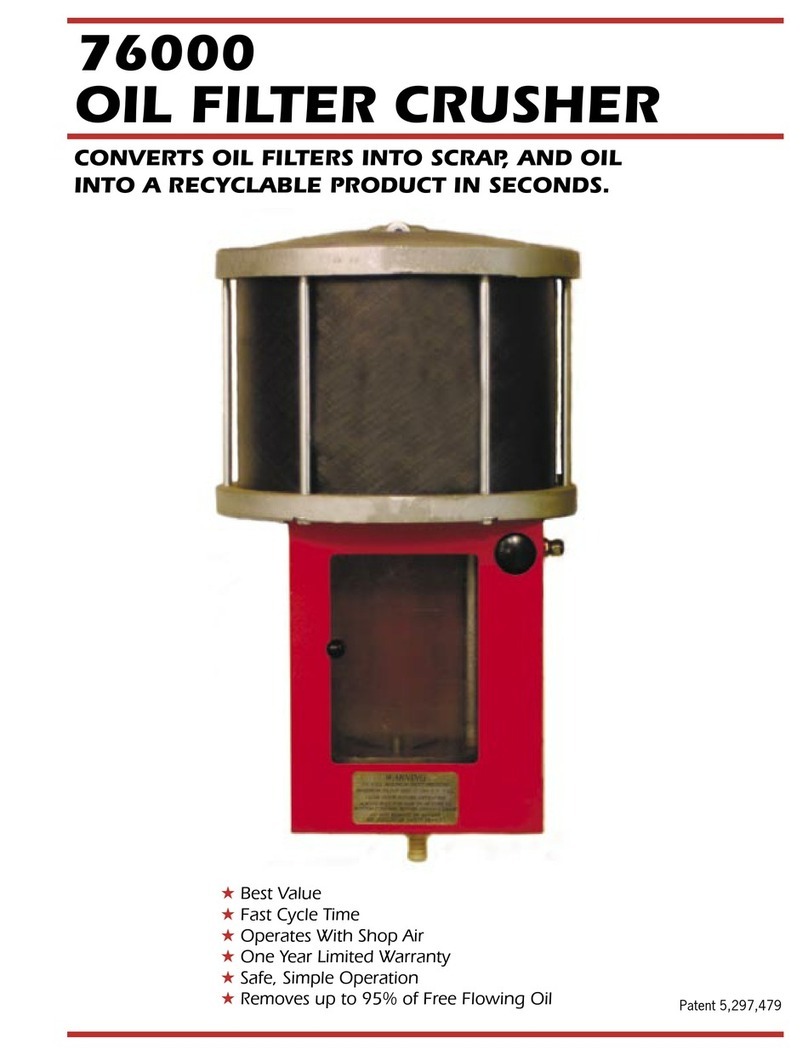

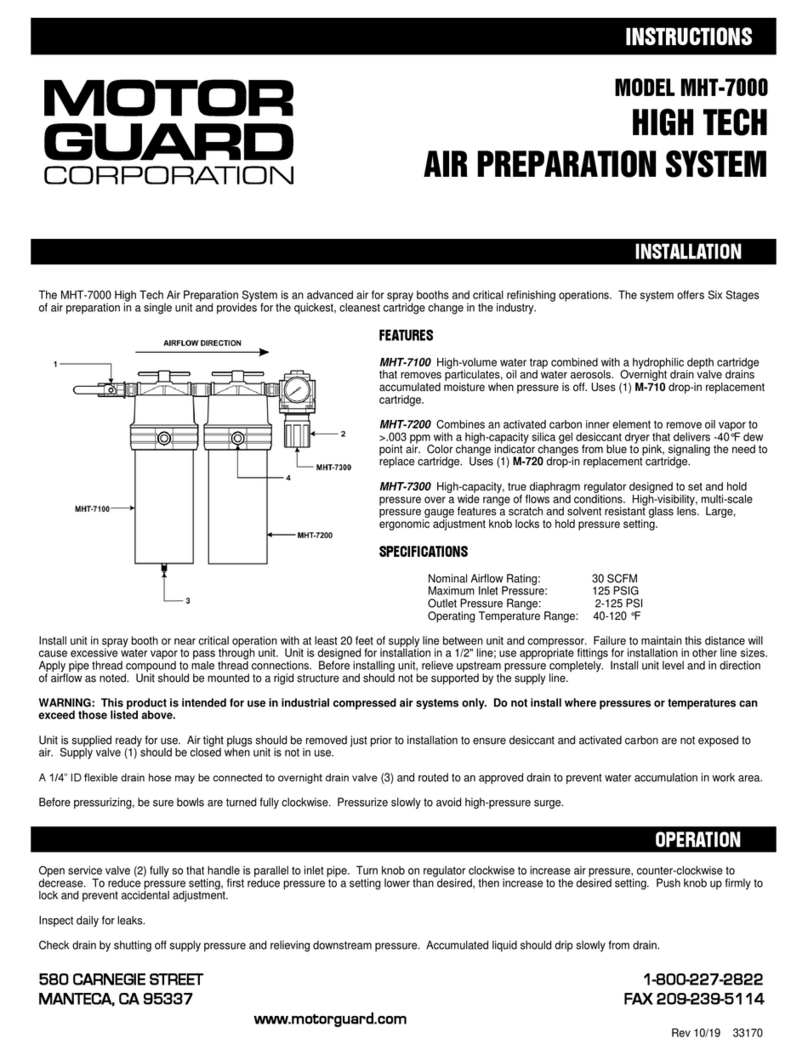

Motor Guard

Motor Guard MHT-7000 instructions

purway Crystal Group

purway Crystal Group PUR Quick 6 UF installation manual

A.O. Smith

A.O. Smith aosbath MAX4 instruction manual

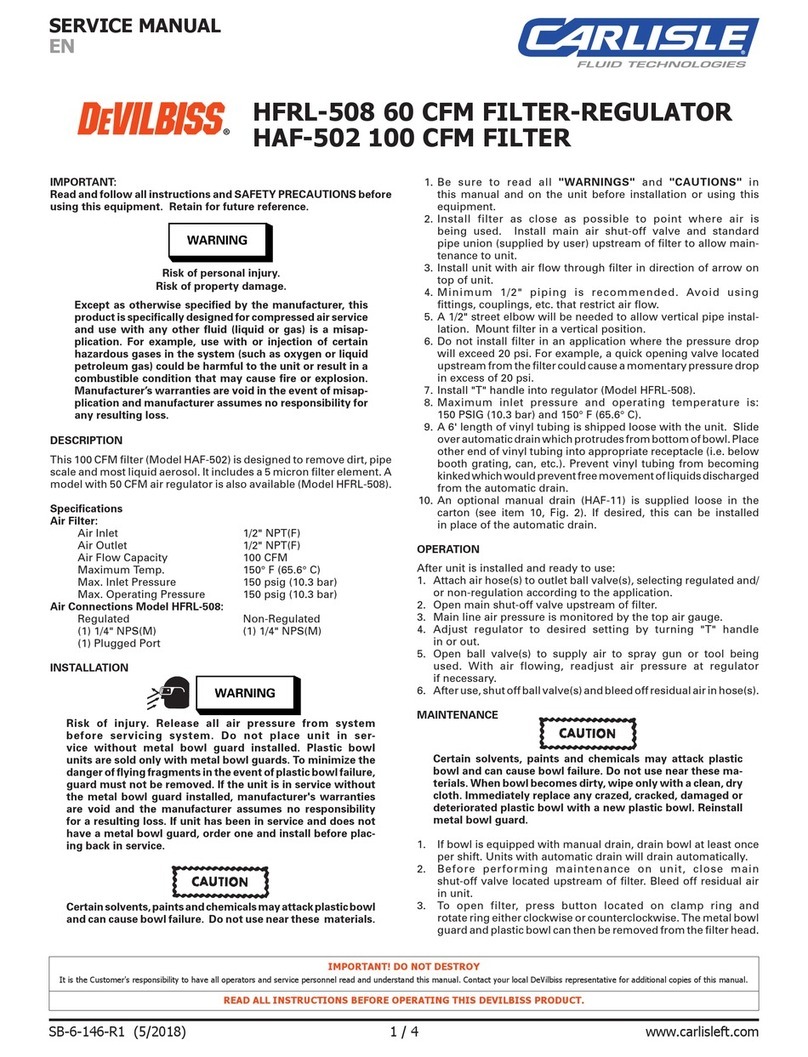

DeVilbiss

DeVilbiss HFRL-508 Service manual