FHM FH-25G Application guide

Farmer-Helper 25 & 27G 1 Revision06/2017

Specificationssubjecttochangewithoutnotice.

Rugged Labor Saving Equipment Since 1995

www.Betstco.com

Toll Free: 877-876-7895, E-mail: [email protected]

83371 Melton Rd, Creswell OR 97426

Ground Pull Manure Spreaders FH-25/27G

Save This Manual for Future Reference

OPERATION & PARTS MANUAL

Please read these instructions carefully before using!

You must GREASE ALL FITTINGS BEFORE OPERATING!

Farmer-Helper 25 & 27G 2 Revision06/2017

Contents

Guide to this Manual...........................................................................3

For Your Safety...........................................................................................................................................3

Safety Labels.........................................................................................................................................4

SECTION 2: OPERATION..................................................................7

Understanding Spreader Operation...........................................................................................................7

The Spreader Operating Components................................................................................................7

Connecting the Spreader to the Towing Vehicle...............................................................................7

Guidelines for Loading the Spreader for Operation..........................................................................8

Operating the Spreader......................................................................................................................9

SECTION 3: MAINTENANCE & ADJUSTMENT.........................10

Guidelines for Regular Maintenance.......................................................................................................10

Procedures for Spreader Adjustment................................................................................................15

Adjusting the Rear Pawl....................................................................................................................15

Re-installing the Beater Drive Chain................................................................................................16

APPENDIX A: PARTS REFERENCE............................................17

General Spreader Specifications..............................................................................................................17

Ordering Information...............................................................................................................................18

Spreader Box, Hitch Assembly and Spreader Controls....................................................................18

Axle, Wheel and Safety Shield Assembly..............................................................................................20

Apron Chain Drive Group........................................................................................................................22

Beaters and Drive Assembly....................................................................................................................24

Jack Stand & Dolly Wheel........................................................................................................................26

Manual Endgate......................................................................................................................................24

Parts Request Form...................................................................................................................................24

FARMER HELPER MACHINERY REGISTRATION..........................................26

Farmer-Helper 25 & 27G 3 Revision06/2017

SECTION 1: INTRODUCTION

Guide to this Manual

This m anual contains all the information necessary to safely operate and m aintain the F ar m e r H e l p e r 27+ or 37+

Spreader. Consult the Table o f Contents for a detailed list of topics covered. You'll find this m anual's step-by-

step procedures easy to follow and understand. Should questions arise, please contact Betstco before

starting any o f the procedures in this manual.

NOTE: Procedures provided in this manual apply to both spreader models (Model 27+ and Model

37+) unless specifically noted otherwise.

R egarding the information presented in this m anual:

All safety, operating, and servicing information reflects current production m odels at the tim e

o f publication o f this manual.

References made to left, right, front, and rear are those directions view ed w hen facing the

unit from the rear.

Please read all sections in the manual carefully—including the important safety information found

in this section—before beginning any procedures; doing so ensures your safety and the optimal

performance o f your Farmer Helper Spreader.

For Your Safety...

For your safety, F a r m e r H e l p e r docum entation contains the following types o f safety statem ents (listed

here

in order o f increasing intensity):

N O T E : A clarification o f previous inform ation or additional pertin ent information.

AT T E N T IO N : A safety statem ent indicating th at potential equipm ent dam age m ay occur if

instructions are n ot followed.

C A U T IO N : A safety' statem ent that rem inds o f safety practices or directs attention to unsafe

practices w hich could result in personal injury if prop er precautions are not taken.

WA R N IN G : A strong safety statem ent indicating that a hazard exists w hich can result in

injury or death if prop er precautions are not taken.

D A N G E R ! The utmost levels o f safety must be observed; an extrem e hazard exists which

w ould result in high probability o f death or irreparable serious personal injury if proper

precautions are not taken.

The best operator is a careful operator. By using comm on sense, observing general safety rules, and

Farmer-Helper 25 & 27G 4 Revision06/2017

For Your Safety... (continued)

In addition to observing the specific precautions listed through out the manual, the following genera l

p re c a u tio n s a p p ly an d must be heeded fo r p ro p e r, safe o p eratio n.

WA R N IN G : Keep hands and feet from under the spreader at all times. Ensure that you are

safely distanced from any other persons before operating the spreader.

WA R N IN G : D O N O T attem pt to operate the spreader in areas w ith steep inclines, ditches,

large rocks, stum ps, or holes w hich m ay endanger the operator by upsetting the tractor or cause dam

age to the spreader.

W A R N IN G : To prevent serious personal injury and to prom ote safe spreader operation, keep all

shields in place during operation. Ensure that all mounting hardware is properly tightened.

WA R N IN G : N ev er clean, adjust, or repair the spreader while the tractor is running.

WA R N IN G : Never get off th e tractor while it is in m otion and/or w hile the spreader is in operation.

WA R N ING : N ever w ear loose clothing when operating the spreader as it may becom e caught

in the m oving parts o f the machine.

WA R N IN G : N ever allow children or anyone else to ride on th e spreader.

AT T E NT ION : For proper and safe operation of th e spreader, periodically inspect all parts for

excessive wear. Replace worn components w ith factory-authorize parts.

AT T E NT ION : To prevent the hitch from coming disconnected during operation, use the proper size hitch pin

with a safety cotter at all times.

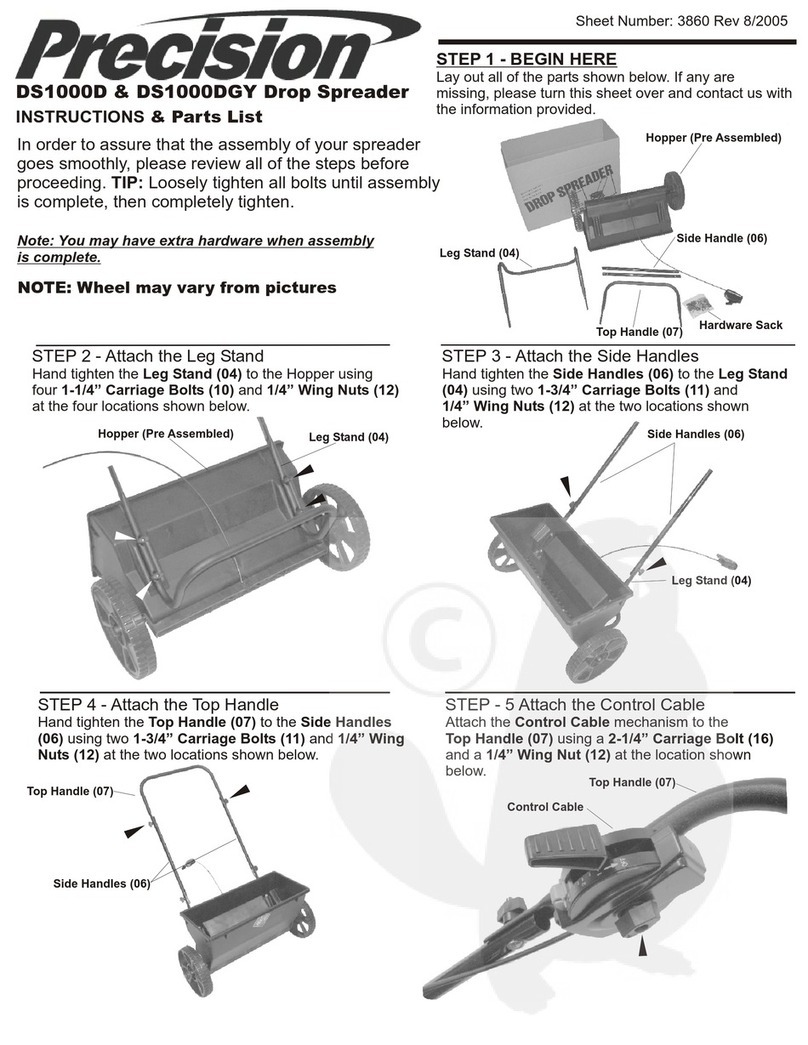

Safety Labels

Follow ing are the locations and descriptions o f all labels on the spreader (labels are identical for both M odels

2 7 + and 37 + );refer to Figure 1A. Please note that some labels denote m odel num ber, m odel description, etc.

while others contain important safety messages.

Each Safety L a b el contains an im portant safety m essage starting w ith a key word as discussed earlier in this

section (e.g. ATT EN TIO N , CA U TIO N , WAR N IN G , D A N G ER ). Fo r you r safety and the safe operation o f

your equipm ent, review all labels and heed all safety messages as printed on the labels.

Be sure to keep the safety labels clean and readable. I f the labels ever becom e damaged or illegible, contact

Betstco for replacements.

Farmer-Helper 25 & 27G 5 Revision06/2017

S p re a d e r S afety L ab e ls

Safety Labels (continued)

Label P a rt# Description

42792 D A N G E R -N O riders

42710 WARNING - Flying Debris

42756 WARNING - Entanglem ent, Do NOT operate without shields

42772 WAR NING - Spreader combination safety label - m oving parts, read manual

42814 ATTEN TION - D o N O T exceed specified speed

42700 F a r m e r He l p e r Logo Label

42815/42816 Spreader Serial N um ber Label

42817/42818 Spreader Model Num ber Label

1-86259

42815-27

42816- 37

42817- 27

42818-37

F ig u re 1A - S p re a d e r Safety L a b el L o catio n s

For your safety, be sure to locate all safety labels and review their content before proceeding with

operating the spreader!

Farmer-Helper 25 & 27G 6 Revision06/2017

Farmer-Helper 25 & 27G 7 Revision06/2017

SECTION 2: OPERATION

Understanding Spreader Operation

Proper and safe operation of the F a r m e r H e l p e r 27G Spreader requires: (1) being fam iliar with the

spreader's

operating com ponents and (2) heeding all safety precautions as stated in this manual.

The Spreader Operating Components

By definition, the left and right sides o f the spreader are determined while sitting on the tractor seat.

The following operating components are included with all M odel 21+131+ spreaders:

The left h a n d sp re a d e r lev er engages thefloor apron chain which moves the manure to the

rear o f the spreader and into the beater.

The r ig h t h a n d s p re a d e r lev er engages the chain that drives the beater and spreads the

manure.

The following are optional operating components included with some Model 21+131+ spreaders (depending on

the specific model configuration ordered):

The j ack st and do lly whee l o pti on allows easy m ovem ent o f the spreader around the stable

or bam ; also adjusts the height o f the spreader to facilitate hook-up to the spreader tow ing vehicle.

The end g ate helps to contain loads between spreading and also shields the operator during

spreading.

Connecting the Spreader to the Towing Vehicle

For operation in the field, the F a r m e r H e l p e r M odel 27G spreaders can be tow ed by a num ber o f vehicles--

garden tractor, A TV , or utility vehicle. Please adhere to the follow ing procedure for connecting the spreader to

your tow ing vehicle. Attaching the spreader to the towing vehicle as instructed is necessary for safe

and proper operation o f the equipment.

1. Back the tow ing vehicle within a few inches o f the spreader hitch.

2. R efer to Figure 2A. D eterm ine the spreader hitch position required to allow the spreader to remain

parallel to the ground w ith relation to the towing vehicle.

N O T E : A s shown in Figure 2A, the adjustable hitch on the front of the spreader m ay be positioned in

A num ber o f ways, by sliding up/down or inverting, to achieve a higher or lower positioning of the

Figure 2A - Adjusting the Hitch Position

Farmer-Helper 25 & 27G 8 Revision06/2017

4. Refer to Figure 2B. A djust the overall height o f the spreader/hitch w ith the dolly wheel/jack so the

height o f the spreader hitch m atches the height o f the tractor drawbar or vehicle hitch point (as

applicable).

N O T E : The Jack is held in its upright position with a spring-loaded pin. To release the jack

to m ove it into its operational position, simply pull the pin outw ard and swing the jack dow n.

Attaching the Spreader to the Towing Vehicle (continued)

F ig u re 2B - U sing the Jack S tand with Dolly Wheel

5.

6.

7.

8.

Back the towing veh icle into the hitch until the holes of th e spreader hitch line up w ith the vehicle hitch

point.

Fasten the spreader hitch to the vehicle drawbar/hitch point with a hitch pin that fits securely (i .e. so that

it will n ot come out during spreader operation) and lock in place with the safety clip.

WA R N IN G : D am age to the spreader or other vehicle, as well as injury to the operator, m ay occur if

A properly-sized hitch pin is not installed as recomm ended. Note that the installation o f the safety clip to

hold the hitch pin in place is also required for safe spreader operation.

Remove the w eight from the Jack /Dolly Wheel by lowering he spreader hitch on the vehicle drawbar/

Hitch point.

T o provide adequate ground clearance for operation, sw ing the j ack up into its resting

position (i.e. pull the spring-loaded pin out to release the jack and swing the jack upw ard, then allow

Th e pin to re-engage to h o ld the jack in its upw ard position.)

Guidelines for Loading the Spreader for Operation

F a r m e r H e l p e r recomm ends that you load the spreader from the front toward the back to

facilitate

Easier unloading.

AT T E N T ION : N E V E R store m anure in the spreader between unloading tim es during critical cold

Weather months w hen a frozen load could result in severe equipm ent damage (i.e. tom floor apron

chain).

DO N O T store w et m anure in the spreader (or keep the spreader outdoors with m anure in it)—

Farmer-Helper 25 & 27G 9 Revision06/2017

Operating the Spreader

Before proceeding with operation ofthe spreader, review all safety statements

as provided in Section 1 of this manual.

WA R N IN G : To prevent serious personal injury, ensure that A LL safety shields are in place on the

spreader before starting operation. N E V ER operate the spreader w ithout ALL safety shields in place.

AT T E NT ION / C A U T IO N : In order to obtain proper, aggressive spreading action, the spreader ground

speed must reach a minimum o f 3.0 miles per hour—the equivalent o f a comfortable walking pace.

(N ote that the w heels drive the beater action.) H ow ever, spreading at speeds over 5.0 m iles per hour (i.e.

Similar to a very brisk walking pace) can cause excessive w ear or dam age to the equipm ent, w hich may void

Your warranty.

1. Ensure that the spreader (and tow ing vehicle) are in a stopped position (i.e. N OT in motion).

2. L if t th e manual end gate. (Optional equipment)

3. Engage the right lever tostart the beater.

4. Engage the left lever to start the action o f the apron floor chain (m oving the m aterial towards the rear

o f the spreader).

5. Begin m oving forward, and ensure that you are reaching the optimal operating speed for spreading

(at least 3.0 m ph, but not m ore than 5.0 m ph ). Rem ember that this optim al speed is sim ilar to a

comfortable walking ace.

6. W hen the spreader is almost empty and there is very little manure pushing against the beater,

disengage the right spreader lever (which controls the beater rotation).

7. A llow the apron chain to run the rem aining m anure out the back o f the spreader.

8. W hen com pletely unloaded, disengage the left spreader lever to stop the action o f t he apron

chain.

9. If your spreader is equipped with a manual end gate, return the end gate to the closed (down) position.

10. Refer to Section 3 in this m anual for maintenance to be performed following operation of the spreader.

IMPORTANT! After afew hours o f initial operation, watch and listen fo r any loose components.

Be aware that it may he necessary to re-tighten hitch hardware and/or wheel bolts: please refer to

Section 3 in this manual fo r the proper torque specifications.

Farmer-Helper 25 & 27G 10 Revision06/2017

SECTION 3: MAINTENANCE &

ADJUSTMENT

Guidelines for Regular Maintenance

WA R N IN G : All shields m ust be replaced after m aintenance or adjustm ent procedures are

performed. Failure to do so could result in serious personal injury or death.

Perform ing regular m aintenance on your F a r m e r H e l p e r Spreader will help ensure optimal performance.

Please follow these guidelines for maintaining your spreader:

Clean the spreader once a w eek and before storing the unit for an extended period o f time.

AT T E N T ION : NE V E R store m anure in the spreader between unloading times during

critical cold w eather months when a frozen load could result in severe equipment damage

(i .e. tom floor apron chain). Storing w et m anure in the spreader (or keeping the spreader

outdoors w ith manure in it) will accelerate rusting o f the steel.

Check the spreader each tim e it is used for loose, bent, broken or m issing parts.

ATT E N T ION : During operation, listen for abnormal sounds which might indicate loose

parts or other equipment damage. Correct any parts problems imm ediately; expanded parts

view s o f all spreader assemblies are provided in the A ppendixes at the back of this manual.

AT T E N T ION : For safe and proper operation o f the spreader, adhere to the follow ing

specifications for tightening the H IT C H H A R D W A R E ; failure to tighten all hitch hardware

securely may result in equipment damage.

H itch H ard w a re* To rq u e Specification

3/8" 25 ft. lbs.

5/16" 15 ft. lbs.

*N ote th a t th ese to rq u e spe cifications ap p ly to th e hitch m emb e rs faste n ed to th e

s p re a d e r box, N O T to the adjustable hitch p rong bracket at the front o f the hitch.

C heck that implem ent tires have adequate air pressure (28 psi). Alw ays use ag-traction

Im plem ent tires on the drive w heels. W heel bolts should be torqued to 60 ft. lbs.

Farmer-Helper 25 & 27G 11 Revision06/2017

Guidelines for Regular Maintenance (continued)

Periodically check the floor apron chain for tension/tightness (refer to Figure 3A).

P ro c e d u re fo r check ing/ adjusting th e floo r a p ro n c h a in :

a) Pull up firmly on the center slat o f the floor apron chain.

N OTE : The force required to adequately pul1up on the apron chain to determine the

tension m easures approxim ately 30 lbs.

b) If y o u can lift it higher than five (5) inches, the chain is too loose.

c) If you can lift it not higher than three (3) inches, the chain is too tight.

d) If the chain needs adjustment, turn the front nut clockwise or counterclockwise until correct

tension/tightness is achieved. (See Figure 3B.) R ep eat for the other side. Make sure

that the chains on each side o f the apron are equally taut

Figure 3B - Adjusting the Floor Apron Chain

Farmer-Helper 25 & 27G 12 Revision06/2017

LUBRICATION

The Model 27G is designed to require little maintenance and lubrication. However, it is still

important to keep all moving parts well lubricated. Following a regular maintenance and lubri-

cation schedule will enhance the operation and increase the life of the spreader significantly.

The following pages show the grease points on the spreader. The operator should establish a

systematic routine to ensure complete and quick lubrication of the spreader.

The spreader should be greased every 50 loads or once a month. Wipe the old grease and any

dirt or dust off the grease fittings before greasing so it doesn’t get forced into the bearing.

There are two grease fittings inside the

front cover on the engaging lever pivot.

One on each side of the spreader.

Figure 6

There is a grease fitting on each wheel

hub.

Figure 7

Farmer-Helper 25 & 27G 13 Revision06/2017

LUBRICATION

There is one grease fitting on each axle

bearing.

Figure 8

There is one grease fitting on each rear

web bearing.

Figure 9

There is one grease fitting on each beater

bearing.

Figure 10

Farmer-Helper 25 & 27G 14 Revision06/2017

LUBRICATION

Lubricate the apron chain with SAE #30

oil or similar lubricant at least twice yearly.

More often if the manure is of high acid

nature or if the spreader is stored outside.

Regular lubrication of the apron chain will

substantially increase its life

Figure 11

Lubricate the beater drive chain with en-

gine oil every 50 loads or once a month.

Figure

Farmer-Helper 25 & 27G 15 Revision06/2017

Procedures for Spreader Adjustment

Problems with spreader operation may indicate that certain adjustments are required to restore proper function.

The follow ing procedures address comm on problems w hich may be encountered in spreaderoperation.

Adjusting the Rear Pawl

If the floor apron chain is not m oving, the m ost com mon cause is im proper brake (rear) pawl adjustment.

N O T E : By engaging both side drives and turning the beater by hand, you w ill be able to observe the brake

pawl engagement in the sprocket teeth.

1. Refer to Figure 3C.

2. Rem ove the shield covering the brake pawl assembly by removing the tw o (2) nuts holding it in place.

3. Loosen th e nut behind the brake pawl using a 9/16" wrench.

4. With the roller positioned at the highest point on the star cam, tap the brake paw l up or down as

necessary to attain a 1/16" to 1/8" clearance between the brake pawl and th e sprocket tooth (see

close-up detail in Figure 3C).

5. After the desired adjustm ent is achieved, re-tighten the rear nut.

6. Replace the safety shield.

Figure 3C - Adjusting the Rear Brake Pawl

Farmer-Helper 25 & 27G 16 Revision06/2017

Re-installing the Beater

Procedures for Spreader Adjustment (continued)

The follow ing procedure explains how to re-install the chain should this ever become necessary. As needed,

refer to the B e a ters a n d D riv e A ssem bly parts detail in A p pen d ix A at the back o f this m anual.

1. Disconnect the spreader from the tractor.

2. Securely block up the right side o f the spreader, and rem ove the right side w heel.

3. Remove the rig ht safety shield by removing the three (3) nuts holding the shield in place.

4. At the front o f the spreader, pull up on the right lever to engage the beater drive com ponents.

5. As shown in Figure 3D, re-install the chain around the small rear sprocket.

6. Re-install the chain over the top idler sprocket.

7. Re-install the chain around the bottom idler sprocket.

8. Push the operating lever down (right side) to disengage the beater drive.

9. Verify th at the chain is positioned properly over and around all sprockets as shown in Figure 3D.

10. Re-install the safety shield with the three (3) nuts to hold it in place.

11. Re-install the wheel and torque the wheel bolts to 60 ft. lbs. Rem ove the safety blocking.

Proper

Engaged

Position

Proper

Disengaged

Position

F ig u re 3D - B e a te r D rive C h a in In stalled in th e P r o p e r Position

Farmer-Helper 25 & 27G 17 Revision06/2017

APPENDIX A: PARTS REFERENCE

The following inform ation is provided for your reference in understanding how the spreader is

assem bled and how spare parts can be identified and ordered properly.

General Spreader Specifications

*NOTE: Thetiresaremountedinreversedirectionof"normal"installation.

Exploded View of 25G Manure Spreader

Farmer-Helper 25G 18

Spare Parts List of 25G Manure Spreader

NO. PART NO. Name & Specifications QTY

1 25G.10.001 Spreader Box Assy 1

2 25G.20.001 Transmission Assy 1

3 25G.30.001 Tire Assy 1

4 25G.40.001 WidespreadShaft Assy 1

5 25G.50.001 Chain Tension Assy 1

6 25G.50.001 Hitch Assy 1

Farmer-Helper 25G 19

Exploded View of Spreader Box

Farmer-Helper 25G 20

This manual suits for next models

1

Table of contents

Popular Spreader manuals by other brands

Fisher

Fisher PRO-CASTER 0806 installation instructions

Millcreek

Millcreek 4300 TURF TIGER Operator's manual

Texas Equipment

Texas Equipment Smart Spreder 200 user manual

Gardena

Gardena Comfort 500 Assembly instructions

SnowEx

SnowEx Sidewalk-Pro SD-95 instruction manual

Dalton

Dalton MOBILITY 800 Operating and parts manual

Scotts

Scotts Turf Builder EdgeGuard MINI quick start guide

Amazone

Amazone ZA-V Series operating manual

LEHNER

LEHNER Vento Operating manual with parts list

Metal-Fach

Metal-Fach N 267 OPERATING INSTRUCTIONS, PARTS CATALOGUE

ICL

ICL LHC 5886 Installation/Removal Guide

XPOtool

XPOtool GT1507 instruction manual