New Leader AGCO NL4258G4 User manual

AGCO NL4258G4 / NL4330G4 EDGE

M˞˕˝A˙˙˕˒ˎ˛

Operator’s Manual

UNIT SERIAL NUMBER ___________________________

MULTAPPLIER SERIAL NUMBER______________________

MANUAL NUMBER: 312521-AA-C

EFFECTIVE 02/2019

1330 76TH AVE SW

CEDAR RAPIDS, IA 52404-7052

PHONE (800) 363-1771 | FAX (319) 286-3350

www.newleader.com

Copyright 2019 Highway Equipment Company, Inc.

Now doing business as New Leader Manufacturing

- 2 -

www.New-Leader.com

(800) 363-1771

312521-AA-C

NL4258/4330G4 EDGE

Header

Table of Contents

Interactive Features ...............................................................................................................................4

Warranty .................................................................................................................................................6

Preface....................................................................................................................................................7

Safety ......................................................................................................................................................8

Important Safety Information ......................................................................................................8

Safety Alert Symbols ....................................................................................................................8

General Safety Rules .............................................................................................................................9

Safety Decals........................................................................................................................................19

Informational Decals ........................................................................................................................... 23

Installation............................................................................................................................................ 25

Hydraulic Requirements.............................................................................................................25

Lifting the Spreader ...................................................................................................................25

Installing Body ............................................................................................................................ 26

Hydraulic Hose Installation........................................................................................................ 26

Hydraulic Hose Installation Guide .................................................................................. 27

Electrical Connections ...............................................................................................................28

ISOBUS Connections ....................................................................................................... 28

Insert Installation..................................................................................................................................29

Spreader Preparation................................................................................................................. 29

Feedgate Adjustment................................................................................................................30

Insert Installation ........................................................................................................................31

Hydraulics.................................................................................................................................... 34

Hydraulic Installation.................................................................................................................. 34

Hillside Divider & Conveyor Cover - MultApplier ...................................................................35

Electrical Connections ...............................................................................................................36

Insert Removal/Endgate Installation......................................................................................... 36

General Description ............................................................................................................................37

Introduction.......................................................................................................................................... 38

Dimensions & Capacities .................................................................................................................... 41

Initial Start-Up ......................................................................................................................................44

General Operating Procedures .......................................................................................................... 45

Lubrication & Maintenance................................................................................................................. 47

Preventative Maintenance Pays!...............................................................................................47

Hydraulic System........................................................................................................................ 47

Service Schedule .............................................................................................................. 47

Hydraulic Hose ...........................................................................................................................48

Conveyor Chain..........................................................................................................................48

Conveyor Belt Maintenance......................................................................................................50

Bin Sensor ...................................................................................................................................50

Spinner Fins ................................................................................................................................51

Spinner Deflectors......................................................................................................................51

Material & Hillside Flow Dividers ..............................................................................................51

Conveyor Gearcase.................................................................................................................... 52

Lubrication of Bearings.............................................................................................................. 52

Fasteners..................................................................................................................................... 52

Clean Up .....................................................................................................................................52

Lubricant & Oil Specifications ............................................................................................................53

Hydraulic System........................................................................................................................ 53

Gearcase Lubricant .................................................................................................................... 53

Grease Gun Lubricant................................................................................................................53

Chain Oiler Mixture.................................................................................................................... 53

Lubrication & Maintenance Chart ...................................................................................................... 54

Troubleshooting................................................................................................................................... 56

Spreader Module LED Light Alerts........................................................................................... 58

- 3 -

NL4258/4330G4 EDGE

www.New-Leader.com

(800) 363-1771

312521-AA-C

Header

Standard Torques................................................................................................................................. 59

Pre- and Post-Season Checklist..........................................................................................................60

Controller Operations ......................................................................................................................... 71

Introduction ................................................................................................................................71

How the ISOBUS Works................................................................................................... 71

Terminologies ................................................................................................................... 71

Cab to Enclosure Diagram ........................................................................................................ 72

Modules to Function Diagram ..................................................................................................73

Requirements..............................................................................................................................74

Navigation................................................................................................................................... 75

Navigation Control Buttons.......................................................................................................76

Machine Configuration ..............................................................................................................77

Initial Configuration/Factory Setup ..........................................................................................77

Enable Installed Bins..................................................................................................................78

Bin Settings................................................................................................................................. 78

GPS Offsets................................................................................................................................. 80

System Setup Summary .............................................................................................................80

Configuring Auxiliary Switches..................................................................................................80

Settings .......................................................................................................................................81

Enable/Disable Bins ................................................................................................................... 81

Valve Calibration Adjustment...................................................................................................81

Alarm Settings ............................................................................................................................83

Reconfigure System ...................................................................................................................84

Switch Assignment ..................................................................................................................... 85

Material Profile Management.................................................................................................... 86

Creating a New Profile...............................................................................................................87

Component Calibration............................................................................................................. 92

Spinner Disc Calibration ............................................................................................................92

Spinner Assembly Calibration...................................................................................................93

Feedgate Calibration.................................................................................................................94

Conveyor Calibration ................................................................................................................. 97

Operations/Features................................................................................................................ 100

Feedgate Optimizer.................................................................................................................103

Boundary Spreading ................................................................................................................104

Remote Spreading ...................................................................................................................105

Diagnostics ...............................................................................................................................106

Hydraulics.................................................................................................................................. 109

Cylinder Bleeding..................................................................................................................... 110

Bin Flush....................................................................................................................................111

Body Module ............................................................................................................................113

Bin Cover Control.....................................................................................................................113

Chain Oiler................................................................................................................................ 114

Bin Sequencing ........................................................................................................................116

General Alarms.........................................................................................................................118

General Product Control Alarms............................................................................................. 119

Spinner Alarms .........................................................................................................................120

Fan Frame Alarms .................................................................................................................... 121

Feed Gate Alarms .................................................................................................................... 122

Hydraulic Alarms ...................................................................................................................... 123

Bin Sequencing Alarms............................................................................................................ 123

Chain Oiler Alarms ................................................................................................................... 123

Default Settings........................................................................................................................124

Calibration ................................................................................................................................125

Table of Contents

- 4 -

www.New-Leader.com

(800) 363-1771

312521-AA-C

NL4258/4330G4 EDGE

Header

Table of Contents

Alarms .......................................................................................................................................125

Spread Pattern ................................................................................................................................... 127

Crushing Strength ....................................................................................................................127

SGN ...........................................................................................................................................127

Catch Test ................................................................................................................................. 127

Product Setup Guidelines........................................................................................................128

Crush Test........................................................................................................................ 129

SGN Scale Test .........................................................................................................................130

Catch Test ................................................................................................................................. 132

Spread Pattern Test Kit ............................................................................................................ 133

Spinners ....................................................................................................................................134

Spreader Preparation............................................................................................................... 134

Test Procedure..........................................................................................................................135

Test Results ..................................................................................................................... 137

Determining Driving Centers ........................................................................................ 138

Troubleshooting .......................................................................................................................139

Verifying Driving Centers ............................................................................................... 140

- 5 -

NL4258/4330G4 EDGE

www.New-Leader.com

(800) 363-1771

312521-AA-C

Header

Interactive Features

NOTE:

This manual incorporates several interactive features to provide supplemental information

and ease of navigation. The information below is to aid in the identification and use of these

features.

Hyperlinks

Hyperlinks provide direct access to a specific destination when clicked. The entire Table of Contents

of this manual is hyperlinked to provide quick access to all sections of this manual when viewing the

electronic version.

Hyperlinks within the content are denoted by blue, bold underlined text. Electronic format viewers can

click these links for direct access to New Leader online features. Internet access is required.

Quick Reference (QR) Codes

Quick reference codes provide direct access to a specific destination when activated. An example is

provided below. In the printed version of this manual, viewers may scan the codes with a supporting

mobile device for direct access to New Leader online features. Mobile data is required.

The electronic version of this manual provides the option to scan codes on-screen, or to click the code

like a button. Internet access/mobile data is required.

Click or Scan - NewLeader.com

Insert Current New Leader Warranty

Warranty

- 7 -

NL4258/4330G4 EDGE

www.New-Leader.com

(800) 363-1771

312521-AA-C

Header

Preface

PLEASE ! ALWAYS THINK SAFETY FIRST !!

The purpose of this manual is to familiarize the person (or persons) using this unit with the information

necessary to properly install, operate, and maintain this system. The safety instructions indicated by the

safety alert symbol in the following pages supersede the general safety rules. These instructions cannot

replace the following: the fundamental knowledge that must be possessed by the installer or operator,

the knowledge of a qualified person, or the clear thinking necessary to install and operate this equipment.

Since the life of any machine depends largely upon the care it is given, we require that this manual be read

thoroughly and referred to frequently. If for any reason you do not understand the instructions, please call

your authorized dealer or our Product Sales and Support Department at 1-888-363-8006.

It has been our experience that by following these installation instructions, and by observing the operation

of the spreader, you will have sufficient understanding of the machine enabling you to troubleshoot and

correct all normal problems that you may encounter. Again, we urge you to call your authorized dealer

or our Product Sales and Support Department if you find the unit is not operating properly, or if you are

having trouble with repairs, installation, or removal of this unit.

We urge you to protect your investment by using genuine HECO parts and our authorized dealers for all

work other than routine care and adjustments.

Highway Equipment Company reserves the right to make alterations or modifications to this equipment at

any time. The manufacturer shall not be obligated to make such changes to machines already in the field.

This Safety Section should be read thoroughly and referred to frequently.

ACCIDENTS HURT !!!

ACCIDENTS COST !!!

ACCIDENTS CAN BE AVOIDED !!!

- 8 -

www.New-Leader.com

(800) 363-1771

312521-AA-C

NL4258/4330G4 EDGE

Header

Safety

Important Safety Information

Figure 1.1 - The need for safety cannot be stressed strongly enough in

this manual. At Highway Equipment Company, we urge you to make

safety your top priority when operating any equipment. We firmly

advise that anyone allowed to operate this machine carefully read,

learn and understand all messages and information in this manual

and on machine’s safety decals before operating machine, as well as

familiarize themselves with the location and function of all machine

controls.

The following guidelines are intended to cover general usage and to

assist you in avoiding accidents. There will be times when you will

run into situations that are not covered in this section. At those times

the best standard to use is common sense. If, at any time, you have

a question concerning these guidelines, please call your authorized

dealer or our Product Sales & Support Department at (800) 363-1771.

Figure 1.1

Safety Alert Symbols

TAKE NOTE! THIS SAFETY ALERT SYMBOL FOUND THROUGHOUT THIS MANUAL IS

USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING YOUR PERSONAL

SAFETY AND THAT OF OTHERS. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN INJURY OR DEATH.

In this manual and on the safety signs placed on the unit, the words “DANGER,” “WARNING,” “CAUTION,”

and “NOTICE” are used to indicate the following:

Indicates an imminently hazardous situation that, if not avoided, WILL

result in death or serious injury. This signal word is to be limited to the

most extreme situations and typically for machine components that, for

functional purposes, cannot be guarded.

DANGER

Indicates a potentially hazardous situation that, if not avoided, COULD

result in death or serious injury, and includes hazards that are exposed

when guards are removed. It may also be used to alert against unsafe

practices.

WARNING

Indicates a potentially hazardous situation that, if not avoided, MAY result

in minor or moderate injury. It may also be used to alert against unsafe

practices.

CAUTION

NOTICE!

Is used for informational purposes in areas which may involve damage or

deterioration to equipment but generally would not involve the potential

for personal injury.

- 9 -

NL4258/4330G4 EDGE

www.New-Leader.com

(800) 363-1771

312521-AA-C

Header

Operations

PREPARE FOR EMERGENCIES

Figure 1.2 - Be prepared if a fire starts. Keep a fully charged fire

extinguisher and first aid kit in accessible place on the vehicle at all

times.

Fire extinguisher must be Type ABC or Type BC.

Keep emergency numbers for doctors, ambulance service, hospital

and fire department available at all times.

Figure 1.2

General Safety Rules

INSPECT HARDWARE BEFORE USE

Figure 1.3 - Inspect all bolts, screws, fasteners, keys, chain drives,

body mounts and other attachments periodically. Immediately

replace any missing or damaged parts immediately with proper

specification parts.

Inspect spinner fins, spinner frame mounting and spinner fin hardware

daily. Look for missing or loose fasteners, wear and cracks. Replace

immediately if needed. Use only new SAE grade 5 or grade 8 screws

and self-locking nuts.

Tighten all bolts, nuts and screws to specified torques. Refer to

“Standard Torques” in Maintenance section of this manual.

Figure 1.3

HANDLE FLAMMABLE MATERIALS SAFELY

Figure 1.4 - Handle fuel and hydraulic oil with care. They are highly

flammable.

Always stop the engine before refueling machine or filling hydraulic

reservoir.

Never smoke while adding fuel or oil to machine. Add fluids in a safe

place away from open flame and sparks.

Do not allow overflow. Clean up spilled fuel and oil immediately. Figure 1.4

Always have a multipurpose dry chemical fire extinguisher filled and available during machine

operation and when adding fuel. Know how to use it.

- 10 -

www.New-Leader.com

(800) 363-1771

312521-AA-C

NL4258/4330G4 EDGE

Header

PROTECT AGAINST NOISE

Figure 1.7 - Long periods of exposure to high decibles or loud noise

can cause hearing impairment or loss.

Wear proper hearing protection during periods of exposure to high

decibels or loud noise.

Wear a proper hearing protective device such as earmuffs or earplugs

to protect against high decibels and / or uncomfortable loud noises.

Figure 1.7

HANDLE HAZARDOUS MATERIALS SAFELY

Figure 1.5 - Materials to spread can be dangerous.

Improper selection, application, use or handling may be a hazard to

persons, animals, plants, crops or other property.

A Safety Data Sheet (SDS) provides specific details on chemical

products: physical and health hazards, safety procedures and

emergency response techniques.

Check the SDS before starting any job using a hazardous material.

Follow all instructions and precautions given by the material

manufacturer.

Figure 1.5

WORK IN WELL-VENTILATED AREAS

Never run machine engine inside a building

unless adequate ventilation is provided to safely

and properly remove exhaust fumes.

Figure 1.6 - Always work in a properly ventilated area.

Engine exhaust fumes can cause sickness or death. If it is necessary

to run an engine in an enclosed area, use proper equipment to safely

remove exhaust fumes from the working area.

Open building doors and get fresh air into the working area whenever

possible.

Figure 1.6

Operations

General Safety Rules

- 11 -

NL4258/4330G4 EDGE

www.New-Leader.com

(800) 363-1771

312521-AA-C

Header

AVOID MOVING PART HAZARDS

Figure 1.8 - Entanglement in rotating drive lines or moving parts will

cause serious injury or death.

Stay clear of all moving parts, such as shafts, couplings and universal

joints.

Make sure all personnel are clear of machine before starting.

Figure 1.8

Figure 1.9 - Do not operate machine without all guards and shields

closed and secured. Disconnect and lock out power source before

removing guards.

Disconnect and lock out power source before adjusting or servicing.

Keep hands, feet, hair and clothing away from moving parts.

Figure 1.9

Figure 1.11 - Stay out of the spreader.

If it is necessary to enter the spreader, return to the shop, empty

body, turn off all power, engage brakes, shut down engine and

remove keys before entering.

Tag all controls to prohibit operation. Tags should only be placed,

and later removed, by the person working in the body.

Figure 1.11

Figure 1.10 - Keep away from spinners while they are turning.

Rocks, scrap metal and other material can be thrown from the

spinners violently. Stay away from discharge area.

Stop machine before servicing or adjusting. Wear eye protection.

Make sure discharge area is clear before spreading.

Figure 1.10

Operations

General Safety Rules

- 12 -

www.New-Leader.com

(800) 363-1771

312521-AA-C

NL4258/4330G4 EDGE

Header

Operations

General Safety Rules

DO NOT CLIMB OR STAND ON MACHINE

Figure 1.12 - Never allow any personnel to ride in or on the machine.

Use only inspection ladder or portable ladder to view the unit. Use

caution when getting on and off the ladder, especially in wet, icy,

snowy or muddy conditions. Clean mud, snow and ice from steps and

footwear.

Always maintain three-point contact with steps, ladders and

handholds. Face the machine when mounting and dismounting

inspection ladder. Do not jump off the machine. Figure 1.12

OPERATE MACHINE SAFELY

Always walk around and visually inspect the machine before using. Check immediate vicinity of machine

for people and obstructions. Ensure adequate visibility.

Avoid distractions such as reading, eating or operating personal electronics that take your attention

away from operating the machine. Never operate the machine under the influence of alcohol, drugs or

while otherwise impaired.

Always come to a complete stop before reversing. Be sure that all personnel are clear of machine path.

Turn around and look directly for best visibility. Ensure all rear view mirrors are properly installed and

adjusted. Use a signal person when backing if view is obstructed or when in close quarters.

Always disengage hydraulics before shutting down engine. DO NOT start engine with hydraulics

engaged.

- 13 -

NL4258/4330G4 EDGE

www.New-Leader.com

(800) 363-1771

312521-AA-C

Header

Transportation & Handling

General Safety Rules

TRAVELING & TRANSPORTING ON PUBLIC ROADS

Always walk around and visually inspect the machine before traveling on public roads. Check for

damage and/or faulty components that can fail and create a hazard or unsafe condition. Make sure

all machine systems operate properly, including but not limited to: headlights, tail and brake lights,

hazard warning lights, turn indicators, parking brake, horn and rear view mirrors. Repair or replace any

component that is not in proper working order.

Never drive machine at a speed that causes it to bounce or cause loss of control.

Obey all traffic safety laws and regulations. Operate the machine with hazard warning lights on, unless

prohibited by law. It is the operator’s responsibility to activate and use road lights properly while

traveling on public roads.

Cover all loads that may spill or blow away. Environmental damage may result. Do not spread dusty

materials where dust may create pollution, visibility issues or interfere with traffic on public roads.

When transporting equipment or machine on a trailer, ensure it is properly secured. Be sure that SMV

signs on equipment or machine are covered while in transport on a trailer.

Be aware of overhead structures and power lines. Make sure machine can safely pass under. Refer to

“Dimensions & Capacities” pages in the Operations section of this manual.

NAVIGATING ROUGH & UNEVEN TERRAIN

Figure 2.1 - Turn slowly and be careful when traveling on rough

surfaces and side slopes. Avoid holes, ditches and obstructions that

may cause machine to roll over, especially with a loaded spreader.

Never drive near the edge of a gully or steep embankment.

Load may shift, causing vehicle to tip.

Figure 2.1

- 14 -

www.New-Leader.com

(800) 363-1771

312521-AA-C

NL4258/4330G4 EDGE

Header

Maintenance

General Safety Rules

READ AND UNDERSTAND MAINTENANCE PROCEDURES

Figure 3.1 - Read the maintenance and safety instructions and

understand them before performing any maintenance procedure.

Never perform any maintenance procedure or repair if the instructions

and safety procedures are not fully understood. Only trained and

qualified personnel should perform any maintenance procedure or

repair.

Never modify any equipment or add attachements not approved by

Highway Equipment Company.

Figure 3.1

DO NOT SERVICE OR ADJUST MACHINE WHILE IN MOTION

Figure 3.2 - Never lubricate, service or adjust the machine or any of its

components while they are moving.

Never wear loose clothing or jewelry when working near machine

tools or moving parts.

Remove rings and other jewelry to prevent electrical shorts and other

personal injury when in contact with machine tools or moving parts.

Close and secure all guards removed for service. Check all screws,

bolts, nuts and fasteners for proper torques before operating

machine.

Figure 3.2

WEAR PROPER PROTECTIVE EQUIPMENT

Figure 3.3 - Wear close-fitting clothing and proper safety equipment

for the job.

Always wear eye protection when working on or around the machine.

Wear a suitable hearing protection device such as earmuffs or

earplugs to protect against high decibels or loud noises.

Prolonged exposure to high decibels or loud noise can cause hearing

impairment or loss of hearing. Figure 3.3

Wear protective gloves to protect hands from cuts, abrasions and minor burns.

- 15 -

NL4258/4330G4 EDGE

www.New-Leader.com

(800) 363-1771

312521-AA-C

Header

Maintenance

General Safety Rules

HANDLE FLAMMABLE SOLVENTS SAFELY

Figure 3.4 - Never use diesel fuel, kerosene, gasoline or any

flammable solvents for cleaning.

Perform work using flammable fluids and solvents in a safe place away

from open flame and sparks. Do not smoke.

Do not weld, grind or flame cut on any tank containing oil, fuel, fumes

or any other flammable material, or any container that contents or

previous contents are unknown. Move all flammable materials and

containers away from work area. Figure 3.4

Clean up spilled fuel and oil immediately.

Always have a multipurpose dry chemical fire extinguisher filled and available. Know how to use it.

USE PROPER TOOLS FOR THE JOB

Figure 3.6 - Use of improper tools (such as a screwdriver instead of a

pry bar, pliers instead of a wrench, a wrench instead of a hammer) can

cause serious injuries or machine damage.

Use power tools only to loosen threaded parts and fasteners. Using

power tools to tighten may cause over-tightening and component

damage.

Use only service parts meeting New Leader specifications.

Figure 3.6

USE PROPER LIFTING EQUIPMENT

Figure 3.5 - Use only lifting devices that meet or exceed OSHA

standard 1910.184 or ASME B30.20-2013.

Never lift equipment over people.

Never lift a loaded unit. Never lift unit with any loose objects or

persons in the body. Loads may shift or fall if improperly supported,

causing death, serious injury or machine damage.

Before unfastening heavy parts or assemblies, support with adequate

hoist or other device to prevent falling, tipping, swinging or any other

movement that may cause injury or damage.

Figure 3.5

- 16 -

www.New-Leader.com

(800) 363-1771

312521-AA-C

NL4258/4330G4 EDGE

Header

HIGH PRESSURE FLUID HAZARDS

Figure 3.7 - Escaping fluid under pressure can penetrate the skin

causing serious injury.

Always stop machine, allow to cool and relieve pressure before

servicing hydraulic system. Never open hydraulic lines under pressure.

Make sure all connections are tight and all hoses are in good

condition before pressurizing system.

Always use a piece of cardboard or wood to search for leaks instead

of hand. Wear impervious gloves and eye protection when servicing

system.

Seek medical attention immediately if fluid penetrates your skin.

Gangrene may result if wound is left untreated.

Figure 3.7

Maintenance

General Safety Rules

AVOID HEATING NEAR HIGH PRESSURE FLUID LINES

Figure 3.8 - Flammable spray can be generated by heating near

pressurized fluid lines, resulting in burns to yourself and bystanders.

Do not heat by welding, soldering or using a torch near pressurized

fluid lines or other flammable materials.

Pressure lines can suddenly burst when heat goes beyond the

immediate flame area.

Figure 3.8

AVOID TOXIC FUMES & DUST

Figure 3.9 - Hazardous fumes can be generated when paint is heated

from welding, soldering or using a torch.

Remove paint before heating:

• Remove a minimum of 4 in (100mm) from area to be affected by

heating. If paint cannot be removed, wear an approved respirator

while heating or welding.

• Avoid breathing dust from sanding or grinding on paint.

• If a solvent or paint stripper is used, wash stripper away with

soap and water before heating or welding. Remove solvent or

paint stripper containers and other flammable material from area.

Allow fumes to disperse for at least 15 minutes before heating or

welding.

Do not use chlorinated solvents in areas where welding will take

place.

Perform all work in a well-ventilated area that willl carry all toxic fumes

and dust away.

Figure 3.9

- 17 -

NL4258/4330G4 EDGE

www.New-Leader.com

(800) 363-1771

312521-AA-C

Header

Maintenance

General Safety Rules

CLEAN MACHINE OF HAZARDOUS CHEMICALS

During application of hazardous chemicals,

residue can build up on the inside or outside

of the vehicle. Clean vehicle according to use

instructions of hazardous chemical.

Figure 3.10 - When exposed to to hazardous chemicals, clean exterior

and interior of vehicle daily to keep free of the accumulation of visible

dirt and contamination.

1. Clean operator’s station to maintain unobstructed visibility of all

windows and mirrors, and safe operation of all controls. Figure 3.10

NOTICE!

Directing pressurized water at electronic/

electrical components, bearings and

hydraulic seals or other sensitive parts

and components may cause product

malfunctions. Reduce pressure and spray at

45 to 90 degree angles.

2. Wash entire exterior of vehicle.

3. Dispose of any wash water with

hazardous concentrations of

active or non-active ingredients

according to published

regulations or directives.

PROPER TIRE MAINTENANCE

Figure 3.12 - Never weld on a wheel or rim that has a tire on it.

Never attempt to mount or remove a tire unless using the proper

equipment, tire safety cage, instructions, training, and you are

qualified to perform the work safely. Failure to follow the correct

procedures when mounting a tire on a wheel or rim can cause an

explosion and serious injury.

Tire service procedures must be performed by trained and qualified

personnel. Figure 3.12

HANDLE BATTERIES SAFELY

WARNING

Sulfiric acid in battery electrolyte is poisonous. It can

burn skin, eat holes in clothing, and cause blindness if

it contacts eyes.

Figure 3.11 - Lead acid batteries generate flammable and explosive

gases. Keep sparks and flame away from batteries. Do not smoke.

If acid contacts eyes, skin or clothing, flush with water immediately.

Seek immediate medical attention if acid contacts eyes.

Figure 3.11

- 18 -

www.New-Leader.com

(800) 363-1771

312521-AA-C

NL4258/4330G4 EDGE

Header

Storage

General Safety Rules

SUPPORT MACHINE PROPERLY

Figure 4.2 - When machine is removed from vehicle, always store on

adequate supports on a firm level surface. Improper supporting or

storage of spreader may cause machine to fall, resulting in serious

injury or death.

Never use lifting device to free machine from a chassis, storage

stands or frozen ground, or to lift the chassis in any way. Shock

loading is prohibited and sudden accelerations must be avoided.

Lifting in such a manner could result in injury or machine damage.

Figure 4.2

PARK VEHICLE SAFELY

Figure 4.1 - When leaving the vehicle unattended for any reason, be

sure to:

• Shut down PTO.

• Shut off vehicle’s engine, and unit’s engine if applicable.

• Place vehicle transmission in “Neutral” or “Park”.

• Set parking brake firmly.

• Remove ignition key and take it with you.

• Block wheels.

These actions are recommended to avoid unauthorized use, runaway,

vandalism, theft and unexpected operation during startup. Figure 4.1

DISPOSE OF WASTE PROPERLY

Figure 4.3 - Improper disposal of waste can threaten the

environment and ecology. Potentially harmful waste used with

New Leader equipment such as fuel, oil, filters and batteries.

Use leakproof containers when draining fluids. Do not use food

or beverage containers that may mislead someone into drinking

from them. Do not pour waste onto the ground, down a drain, or

into any water source.

Inquire on proper disposal methods from your local environmental

or recycling center, or from your local dealer. Figure 4.3

- 19 -

NL4258/4330G4 EDGE

www.New-Leader.com

(800) 363-1771

312521-AA-C

Header

Safety Decals

SAFETY DECAL MAINTENANCE

Keep safety decals and signs clean and legible at all times.

Replace safety decals and signs that are missing or have become illegible.

Replaced parts that displayed a safety sign should also display the current sign.

Safety decals or signs are available from your dealer’s Parts Department or from Highway Equipment

Company by calling (800) 363-1771.

SAFETY DECAL INSTALLATION

Clean Surface

Wash the installation surface with a synthetic, free-rinsing detergent. Avoid washing the surface with

a soap containing creams or lotion. Allow to dry.

Position Safety Decal

Decide on the exact position before application. Application marks may be made on the top or

side edge of the substrate with a lead pencil, marking pen, or small pieces of masking tape. NOTE:

Do not use chalk line, china marker, or grease pencil. Safety decals will not adhere to these.

Remove the Liner

A small bend at the corner or edge will cause the liner to separate from the decal. Pull the liner

away in a continuous motion at a 180-degree angle. If the liner is scored, bend at score and remove.

Apply Safety Decal

Tack decal in place with thumb pressure in upper corners. Using firm initial squeegee pressure, begin

at the center of the decal and work outward in all directions with overlapping strokes. NOTE:

Keep squeegee blade even—nicked edges will leave application bubbles. Pull up tack points before

squeegeeing over them to avoid wrinkles.

Remove Pre-mask

If safety decal has a pre-mask cover remove it at this time by pulling it away from the decal at a 180

degree angle. NOTE: It is important that the pre-mask covering is removed before the decal is

exposed to sunlight to avoid the pre-mask from permanently adhering to the decal.

Remove Air Pockets

Inspect the decal in the flat areas for bubbles. To eliminate the bubbles, puncture the decal at one

end of the bubble with a pin (never a razor blade) and press out entrapped air with thumb moving

toward the puncture.

Re-Squeegee All Edges

- 20 -

www.New-Leader.com

(800) 363-1771

312521-AA-C

NL4258/4330G4 EDGE

Header

Safety Decals

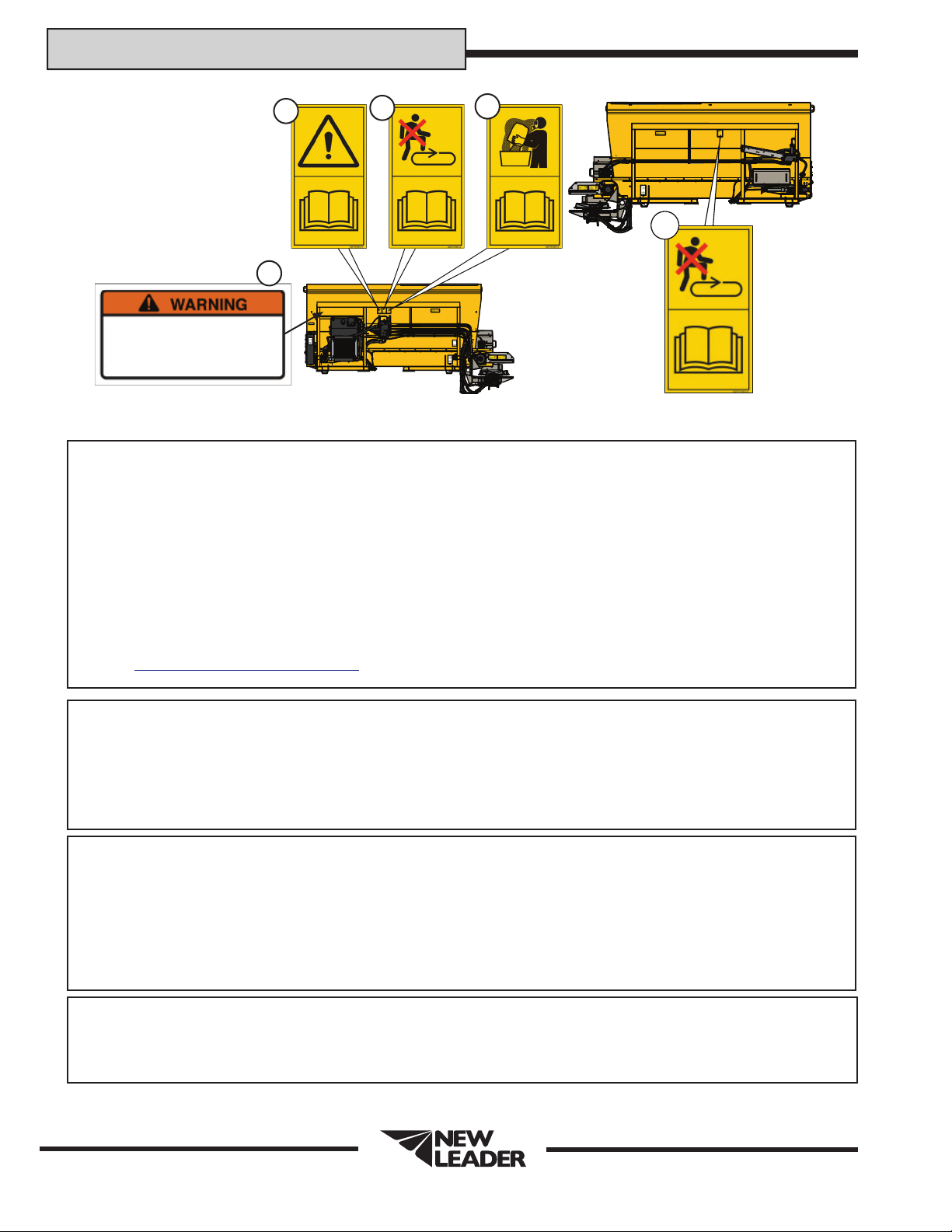

1. CAUTION: TO AVOID INJURY OR MACHINE DAMAGE:

• Do not operate or work on this machine without reading and understanding the operator’s

manual.

• Keep hands, feet, hair and clothing away from moving parts.

• Do not allow riders on machine.

• Avoid unsafe operation or maintenance.

• Disengage power takeoff and shut off engine before removing guards, servicing or unclogging

machine.

• Keep unauthorized people away from machine.

• Keep all guards in place when machine is in use.

• If operator’s manual is missing, contact your local New Leader dealer or print a new copy from

www.highwayequipment.com.309778

2. DANGER: MOVING PART HAZARD

To prevent death or serious injury:

• Stay out of box while conveyor is moving.

• Disconnect and lock out power source before adjusting or

servicing.

• Do not ride on the spreader. 309777

3. CAUTION: HAZARDOUS MATERIALS

To avoid injury or machine damage:

• Materials to be spread can be dangerous.

• Improper selection, application, use or handling may be hazardous to

persons, animals, crops or other property.

• Follow instructions and precautions given by material manufacturer.

309779

3A. WARNING: Prop 65-B

To avoid injury or machine damage:

• Cancer and Reproductive Harm - www.P65Warning.ca.gov

315865-A

Cancer and Reproductive Harm -

www.P65Warning.ca.gov

315865-A

123

3A

22

This manual suits for next models

1

Table of contents

Other New Leader Spreader manuals

New Leader

New Leader L4000G4 User manual

New Leader

New Leader L5034G4 AGCO User manual

New Leader

New Leader NL5000G5 AGCO User manual

New Leader

New Leader Hi-Way SUPER P User manual

New Leader

New Leader L5034G4 AGCO User manual

New Leader

New Leader NL4500G4 User manual

New Leader

New Leader Hi-Way SA-6C User manual

New Leader

New Leader AGCO NL5258G5 User manual

New Leader

New Leader L3020G4 Configuration guide

New Leader

New Leader L5034 G4 User manual