X:\Technical\CONTDOC\Manuals\Current\90068-3-CDIT400GT.DOC

5

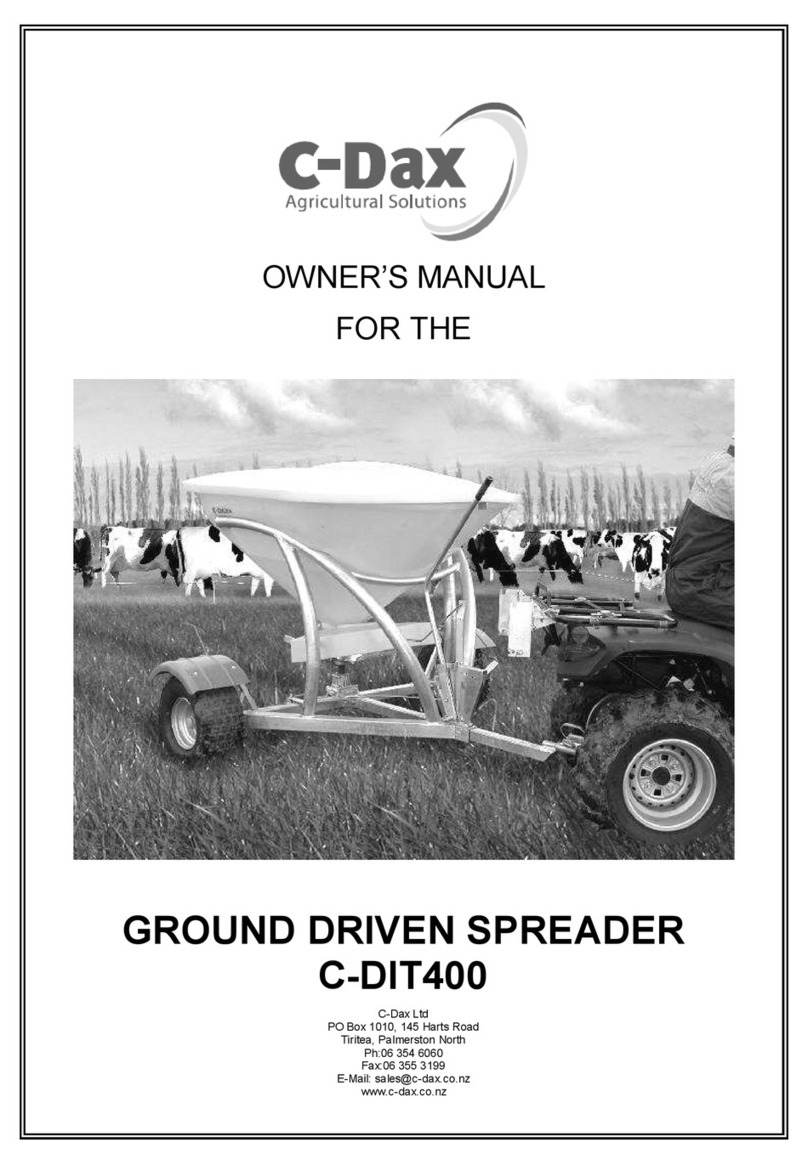

INTRODUCTION

Congratulations. You have just purchased an advanced spreader from C-DAX Systems. C-DAX Systems is

committed to providing you the farmer with quality applicating systems.

DESCRIPTION

The C-DAX C-DIT400GT is a ground-driven spreader designed for application of pelleted fertilisers. It can

also be used for application of other products such as grass seed and magnesium oxide. The uniquely

designed 400-litre translucent non-corrosive polyethylene hopper is specially profiled for good product flow

and ease of filling. The convenient polyethylene cover is easy to remove install and store if not required. A

high-quality stainless steel agitator and shutter ensures even flow of product to the spinner. A unique spinner

design ensures wide even spread of products over 180 degrees (Urea). The heavy-duty galvanised frame is

fitted with knobbly turf tyres as standard equipment. The drive train uses high quality steel and a double

sealed self-aligning bearing and heavy-duty gearbox for maximum durability. While seated the operator has

access to the control handle. This handle allows disengagement and engagement of the clutch and setting of

product feed rate all in one motion. Also standard are mudguards swivel tow-hitch and a fully shrouded

polyethylene front deflector to further protect the operator from product being thrown off the spinner.

Specification

(Specifications subject to change without notice)

Dry Weight 120 Kg

Dimensions W1900mm H1400mm L1850mm

Capacity 400 litre (320Kg Urea)

Drive Ground driven (single wheel)

Wheels 18x950x8 knobbly turf tyres

Tyre pressure 15PSI (100Kpa)

Clutch Lever operated mechanical clutch

Control Adjustable stainless steel slide with index handle

Agitator Mechanical arm stainless steel

Spinner Galvanised steel with three-position adjustable vanes

Hopper Non-corrosive polyethylene ergonomically designed for ease of filling and

inspection

Hopper cover Polyethylene plastic

Frame Galvanised steel

Gearbox Heavy duty with double sealed bearings

Gearbox oil 400ml SAE30

Axle Bearings Sealed ball races

Clutch bearing Heavy-duty phosphor-bronze bush

Axle grease General Purpose

Application Rate 140Kg per hectare @ 10 kph (nominal Urea)

Spread width 18M (nominal Urea @ 15 Kph)

Towing speed 15 Kph (Maximum recommended)

NZ AUST UK FRANCE

Order Information

Standard CDIT400GT P/N 84704 84704 84704 84704

Option Digital Speedometer P/N 32301

Option 50mm Tow Hitch Kit P/N 43803

WARRANTY

C-DAX Systems LTD warrants to the original purchaser that the equipment is sold free from defects in

materials and workmanship for a period of 12 months from date of retail sale (6 Months from date of retail

sale for all equipment sold in the U.K.).

Accordingly C-DAX Systems undertakes to repair the equipment or at our option replace without cost to the

original purchaser either for materials parts or labour any part which within the specified warranty period

from time of delivery is found to be defective. PROVIDED that the equipment has been used for normal

purposes in accordance with the instructions and has not been subject to neglect misuse or accident and

has not been repaired serviced or dismantled by any person other than a service agent or person authorised

by C-DAX Systems.